Lanthanum-based organic acid montmorillonite and water phase one-step preparation technology thereof

A technology of montmorillonite and organic acid, which is applied in the chemical industry, can solve the problems of inability to guarantee the complete entry of organic chemical reagents, weak strong polar interaction, unstable uniformity of composite materials, etc., to achieve uniform product shape and environmentally friendly process Energy saving and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

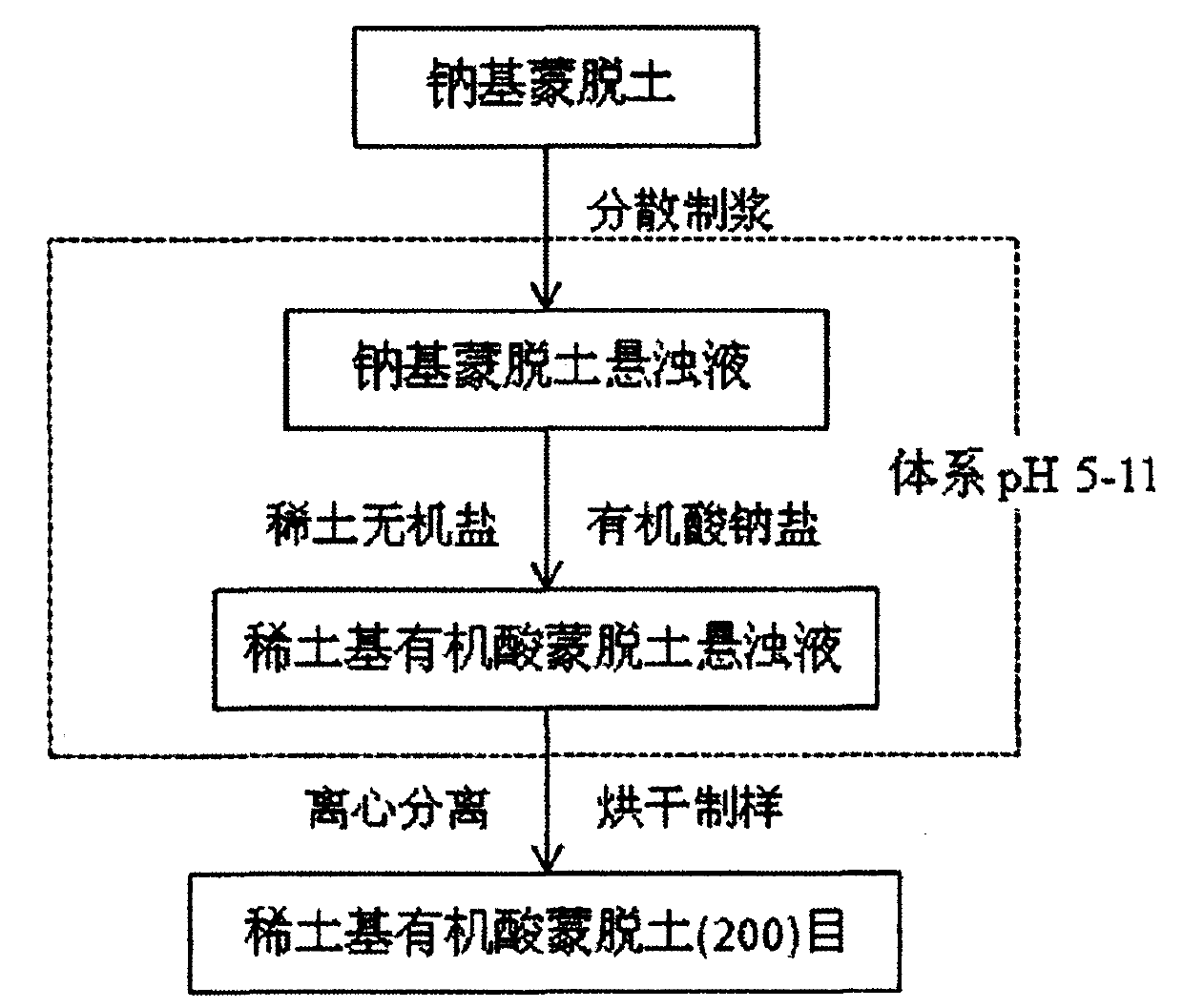

Method used

Image

Examples

Embodiment 1

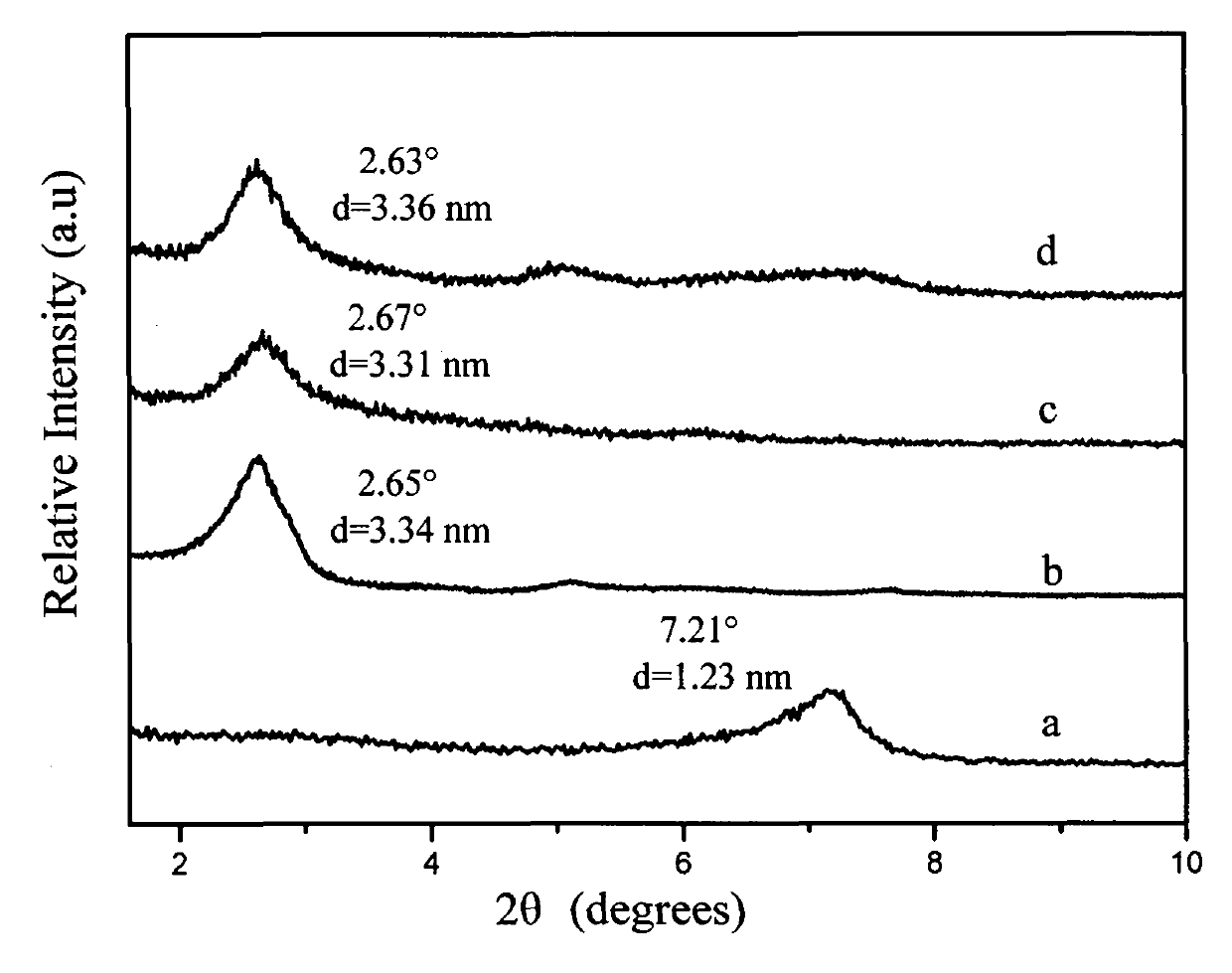

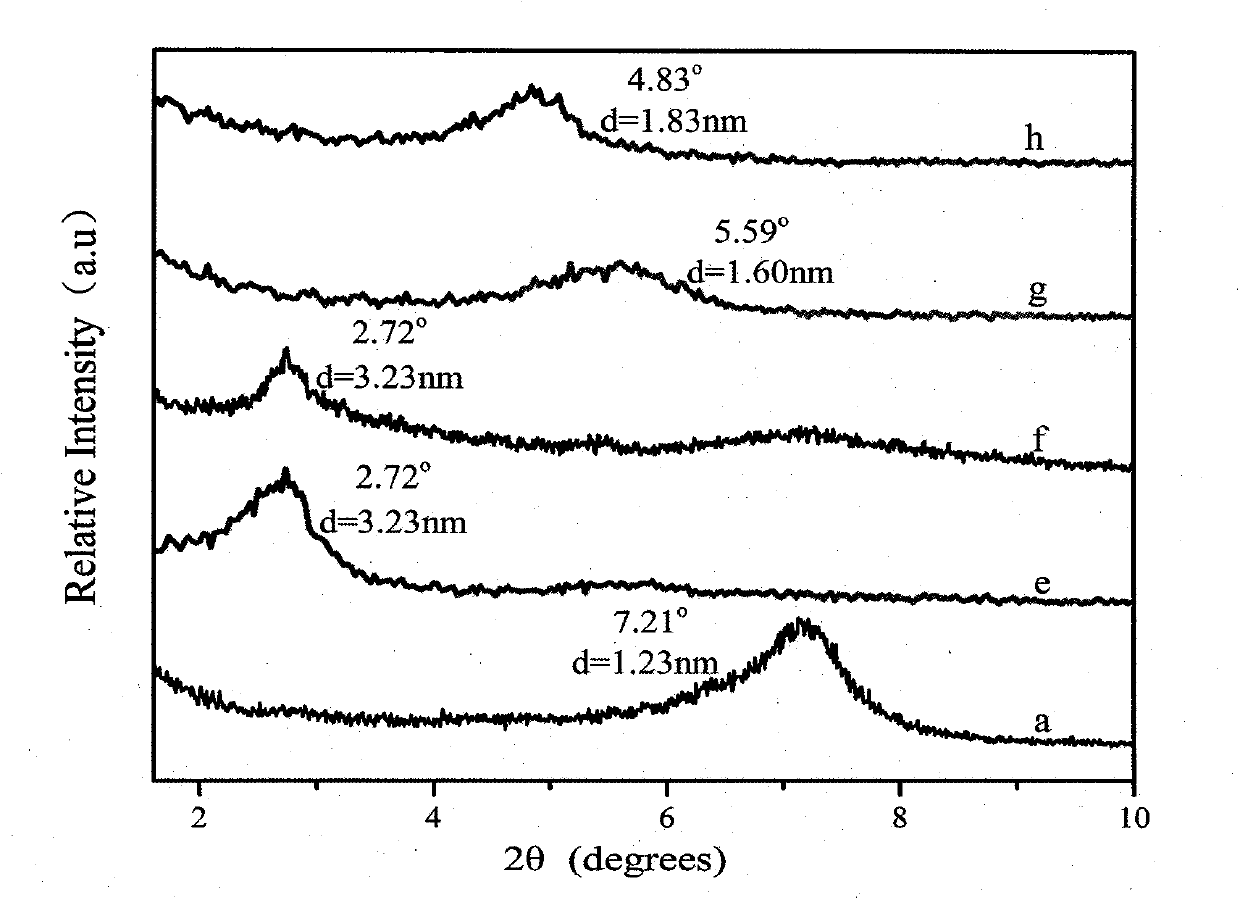

[0029] Preparation of lanthanum-based dodecylsulfonate montmorillonite (SDS-La-MMT): put the cation exchange capacity (CEC) of 145meq / 100g sodium-based montmorillonite into water with an amount 30 times the mass of montmorillonite, Stir and disperse for 1 hour, heat and stir at constant temperature for 2 hours after dispersing evenly, adjust pH to 5, stir at constant temperature for 2 hours, add 2CEC of lanthanum chloride solution, stir at constant temperature for 2 hours, adjust pH to 8, add 2CEC of dodecyl sulfonate Sodium acid aqueous solution, continue to stir and react for 2 hours, and the product is washed, dehydrated, dried, and ground to make a lanthanum dodecyl sulfonic acid montmorillonite product. Through XRD and TGA analysis, its result sees figure 2 -b, Figure 4 -b.

Embodiment 2

[0031] Preparation of lanthanum lauric acid montmorillonite (SDD-La-MMT): Put the cation exchange capacity (CEC) of 145meq / 100g sodium montmorillonite into water with an amount 30 times the mass of montmorillonite, stir and disperse for 1 hour After dispersing evenly, heat and stir at constant temperature for 4 hours, add 2CEC of lanthanum chloride solution, under constant temperature, stir for 2 hours, adjust the pH to 7, add 2CEC of sodium laurate aqueous solution to adjust the pH to 10, continue stirring for 2 hours, the product After washing, dehydration, drying and grinding, the lanthanum-based lauric acid montmorillonite product is made. Through XRD and TGA analysis, its result sees figure 2 -c, Figure 4 -c.

Embodiment 3

[0033] Preparation of lanthanum-based dodecyl phosphate montmorillonite (SMDP-La-MMT): Put the cation exchange capacity (CEC) of 145meq / 100g sodium-based montmorillonite into water with an amount 30 times the mass of montmorillonite, and stir Disperse for 1 hour, heat and stir at constant temperature for 2 hours after dispersing evenly, adjust pH to 5, stir at constant temperature for 2 hours, add 2CEC of lanthanum chloride solution, stir at constant temperature for 2 hours, adjust pH to 8, add 2CEC of dodecyl phosphoric acid mono The sodium ester aqueous solution was stirred and reacted for 2 hours, and the product was washed, dehydrated, dried and ground to produce a lanthanum-based dodecyl phosphate montmorillonite product. Through XRD and TGA analysis, its result sees figure 2 -d, Figure 4 -d.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com