Large mode field diameter negative refractive index mono-mode glass fiber

A glass fiber, negative refractive index technology, applied in graded index core/clad fiber, clad fiber, optical waveguide light guide, etc., can solve problems such as difficult high-power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

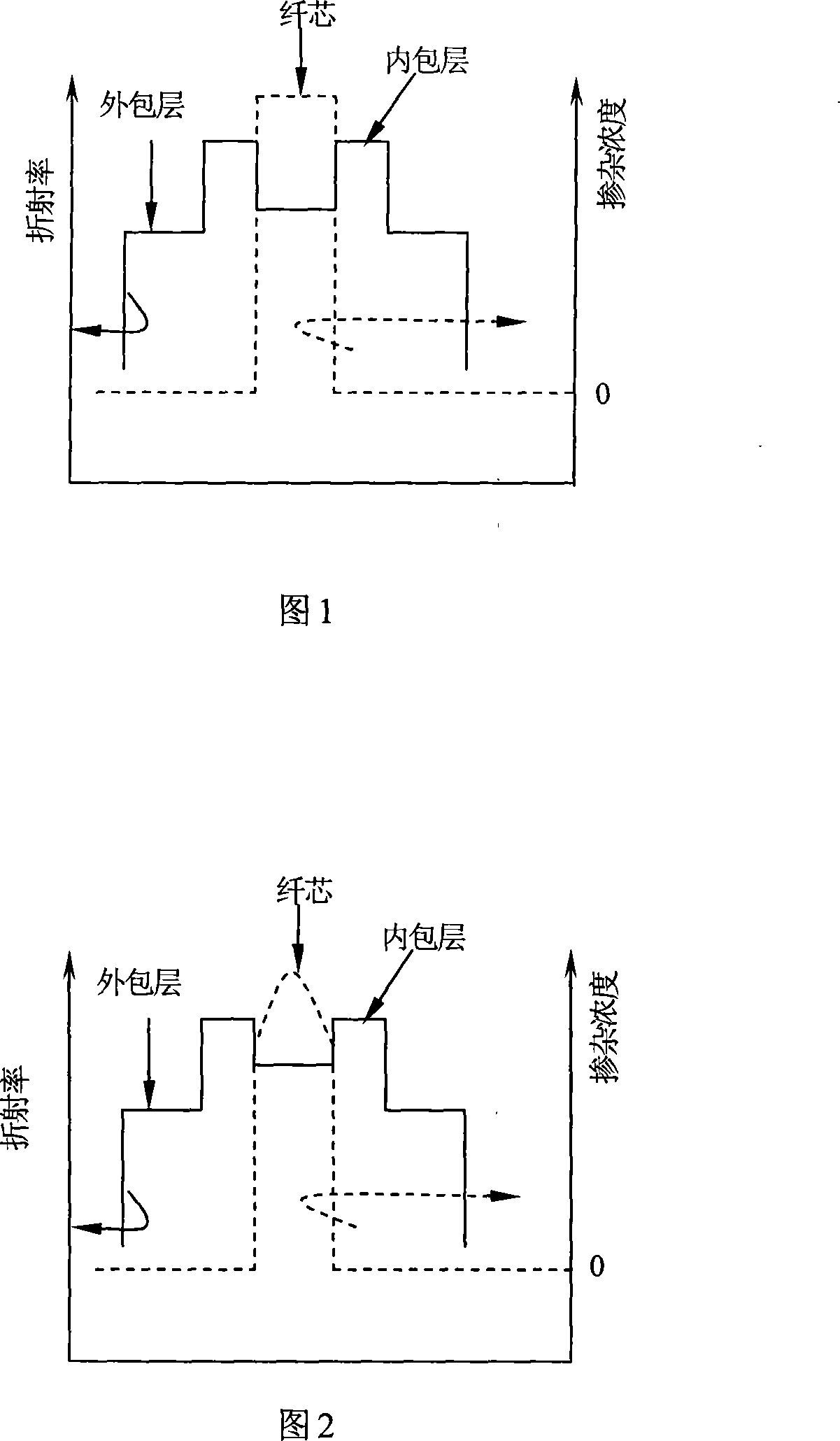

[0014] Embodiment 1: FIG. 1 is a schematic diagram of the cross-sectional refractive index distribution of the large mode field diameter double-clad single-mode optical fiber of the present invention, and the core refractive index of the optical fiber is N 1 , the refractive index distributions of the inner and outer cladding are respectively N 2 and N 3 , and satisfy the relation: N 2 ≥N 1 and N 2 >N 3 , the refractive index changes stepwise at the interface between the core and the inner cladding and the inner cladding and the outer cladding. The fiber core composition is phosphate glass, and its composition is: 70P 2 o 5 -8Al 2 o 3 -15BaO-4La 2 o 3 -3Nd 2 o 3 , where Nd 3+ The concentration is 8.4×10 19 ions / cm 3 . The doping concentration of rare earth ions varies with the direction of the core radius as shown by the dotted line in Fig. 1 . The core and inner and outer cladding materials of the optical fiber can be made of phosphate glass or other types of...

Embodiment 2

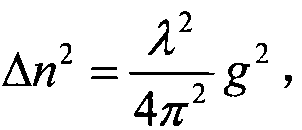

[0016] Embodiment 2: Figure 2 is a schematic diagram of the cross-sectional refractive index distribution of the large mode field diameter double-clad single-mode fiber of the present invention, which is similar to Embodiment 1 and satisfies the relationship N 2 ≥N 1 and N 2 >N 3 . The concentration of doping ions changes gradually along the radial direction, and the concentration is highest at the center of the fiber core, as shown by the dotted line in Fig. 2 . The advantage of this structure is that because the concentration of ions at the interface between the core and the inner cladding is low, the gain coefficient is small and the refractive index change caused by the gain is small. In an optical fiber, the high-order modes are generally distributed at the interface between the fiber core and the cladding, where the effective waveguide structure cannot be formed, further suppressing the generation of high-order modes. In this structure, a single-mode laser output wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com