Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47 results about "Ytterbium fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ytterbium Fluoride is a water insoluble Ytterbium source for use in oxygen-sensitive applications, such as metal production. Fluoride compounds have diverse applications in current technologies and science, from oil refining and etching to synthetic organic chemistry and the manufacture of pharmaceuticals.

Nano-class conversion fluorescence material on fluoride matrix and its preparing process

InactiveCN1376759ASmall and uniform particle sizeThe particle size can be adjusted at willNanotechLuminescent compositionsYtterbium fluorideGadolinium oxide

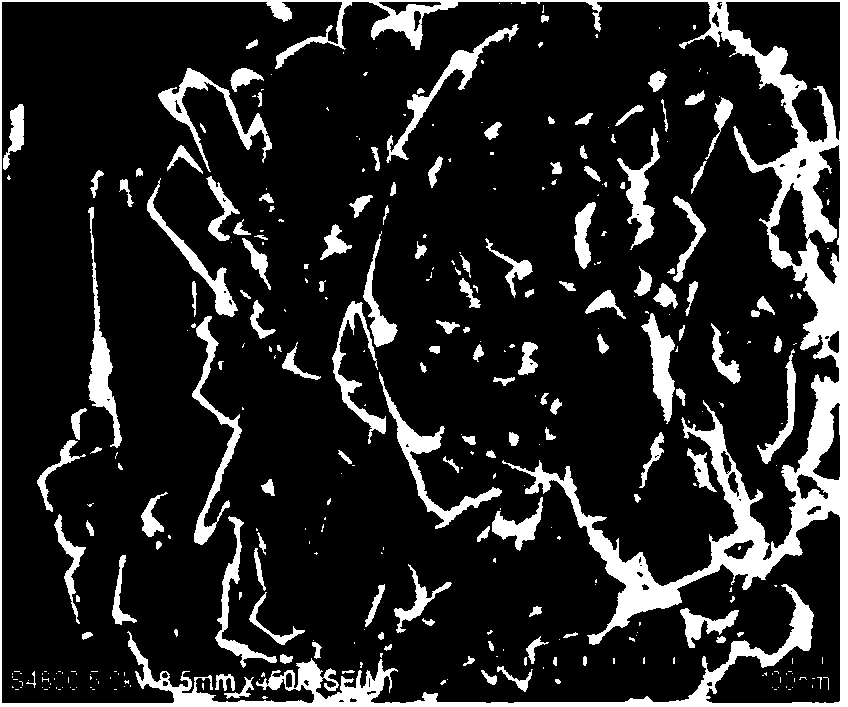

A nano-class conversion fluorescent material used for biomolecular fluorescent marker is prepared through dissolving yttrium (or lanthanum or gadolinium) oxide in acid to obtain solution A, adding aminocarboxylic comple, adding it to the solution of fluoride, centrifugal treating, drying to obtain precursor, and high-temp calcining. Its advantages are 37-166 nm of granularity, low calcining temp and strong fluorescence.

Owner:CAPITALBIO CORP +1

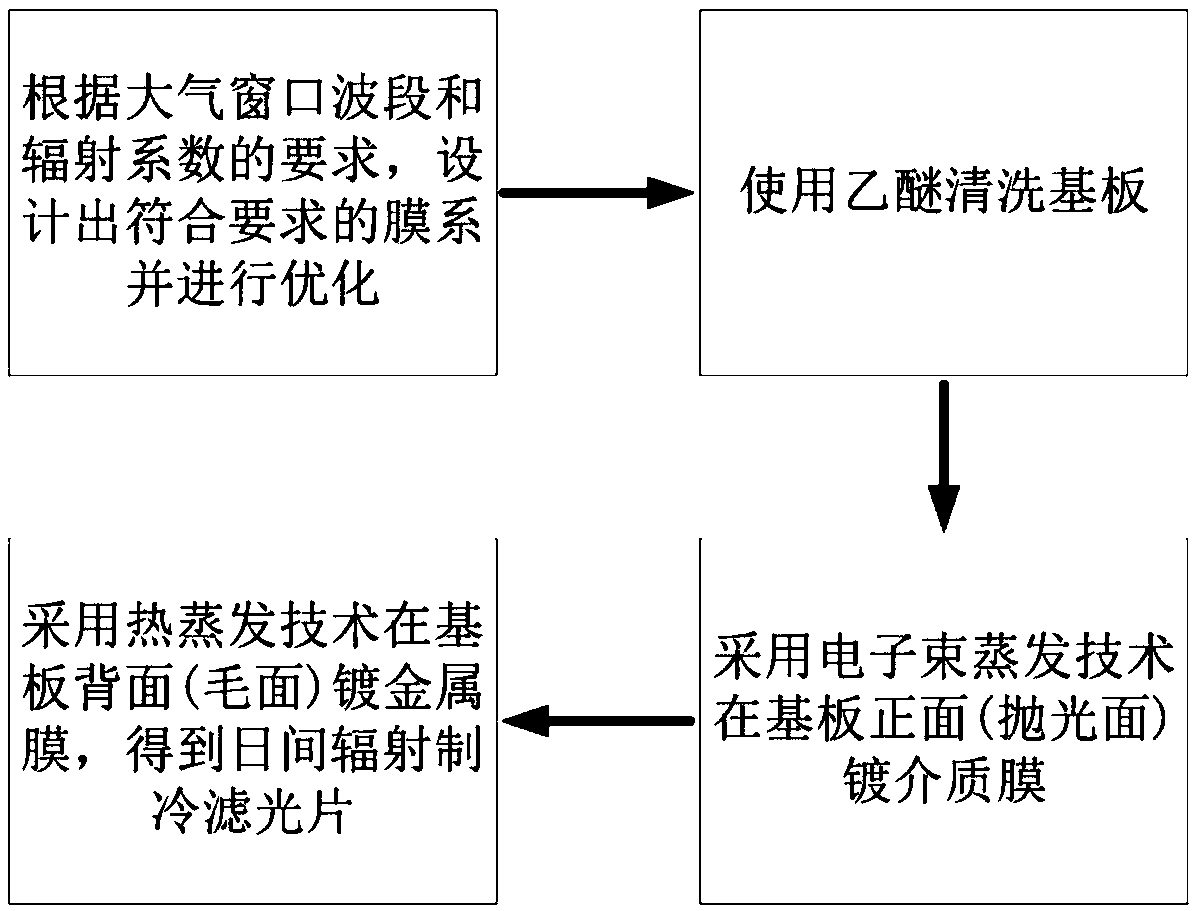

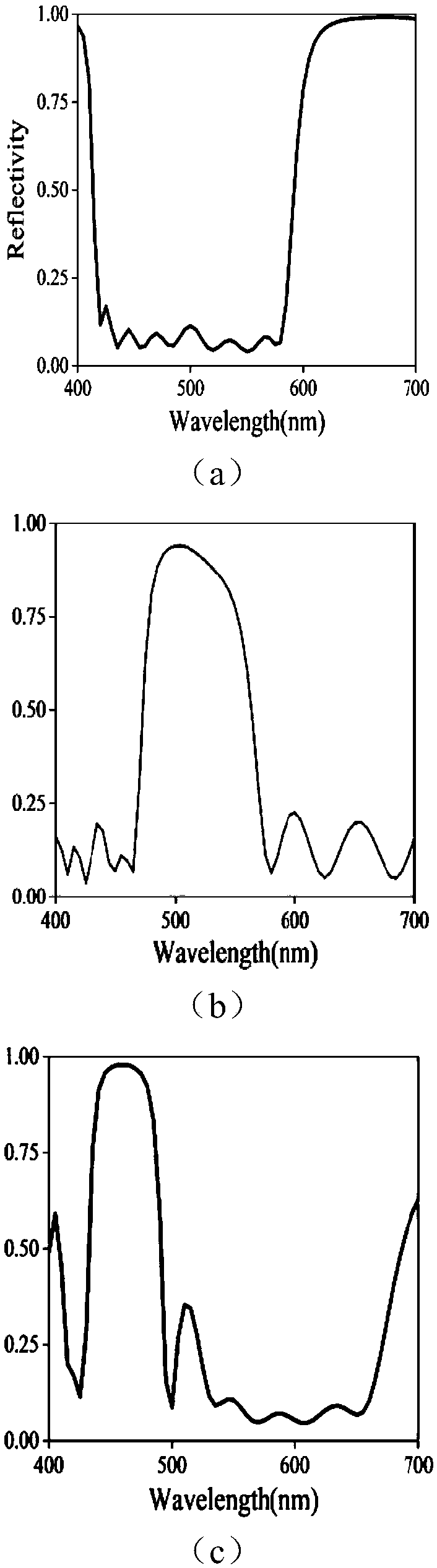

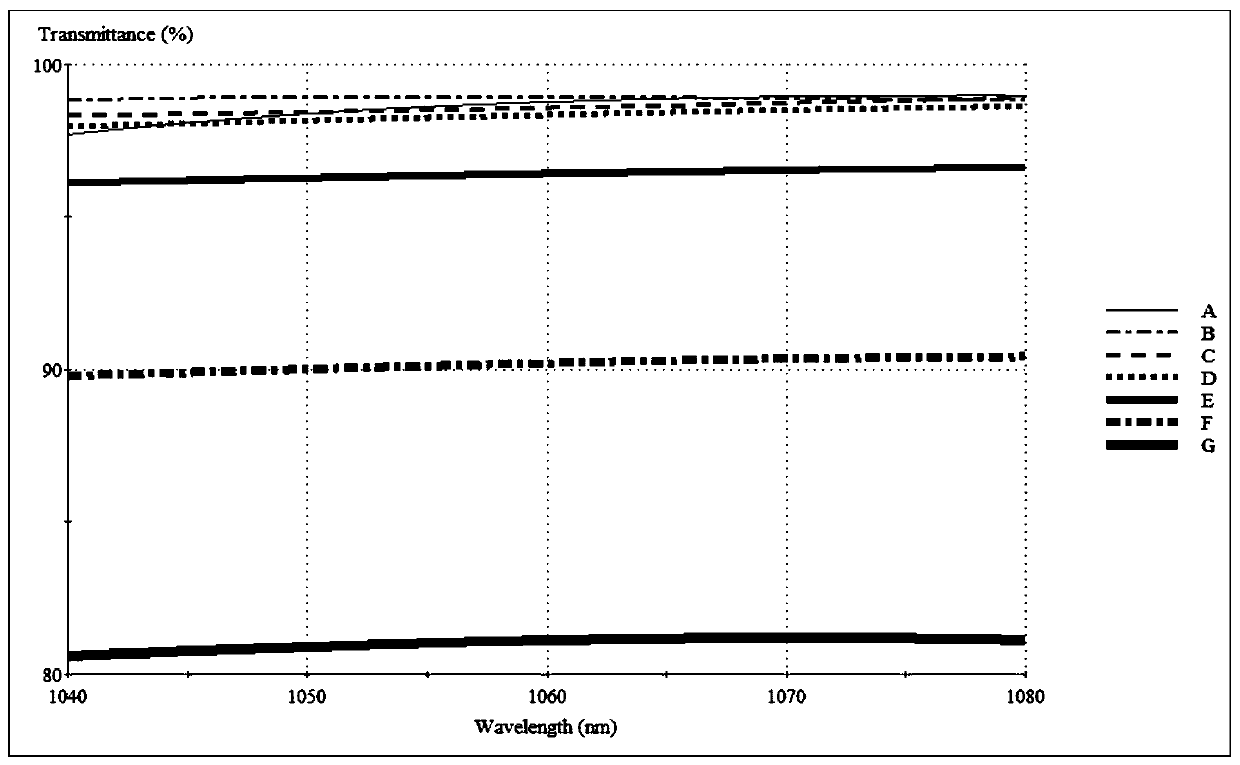

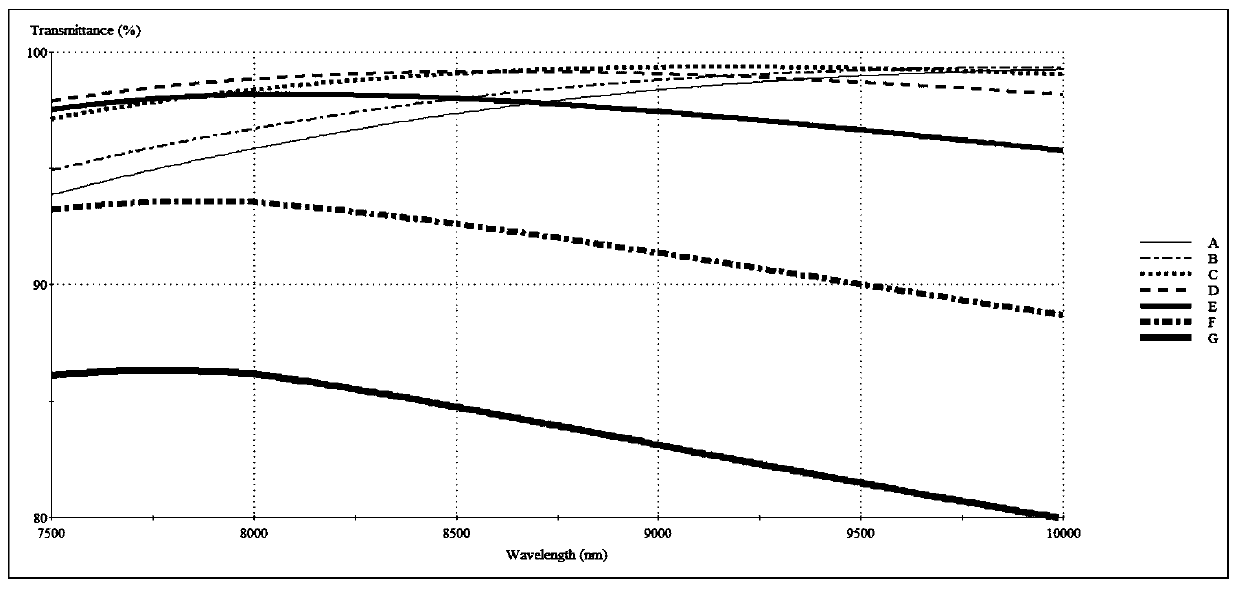

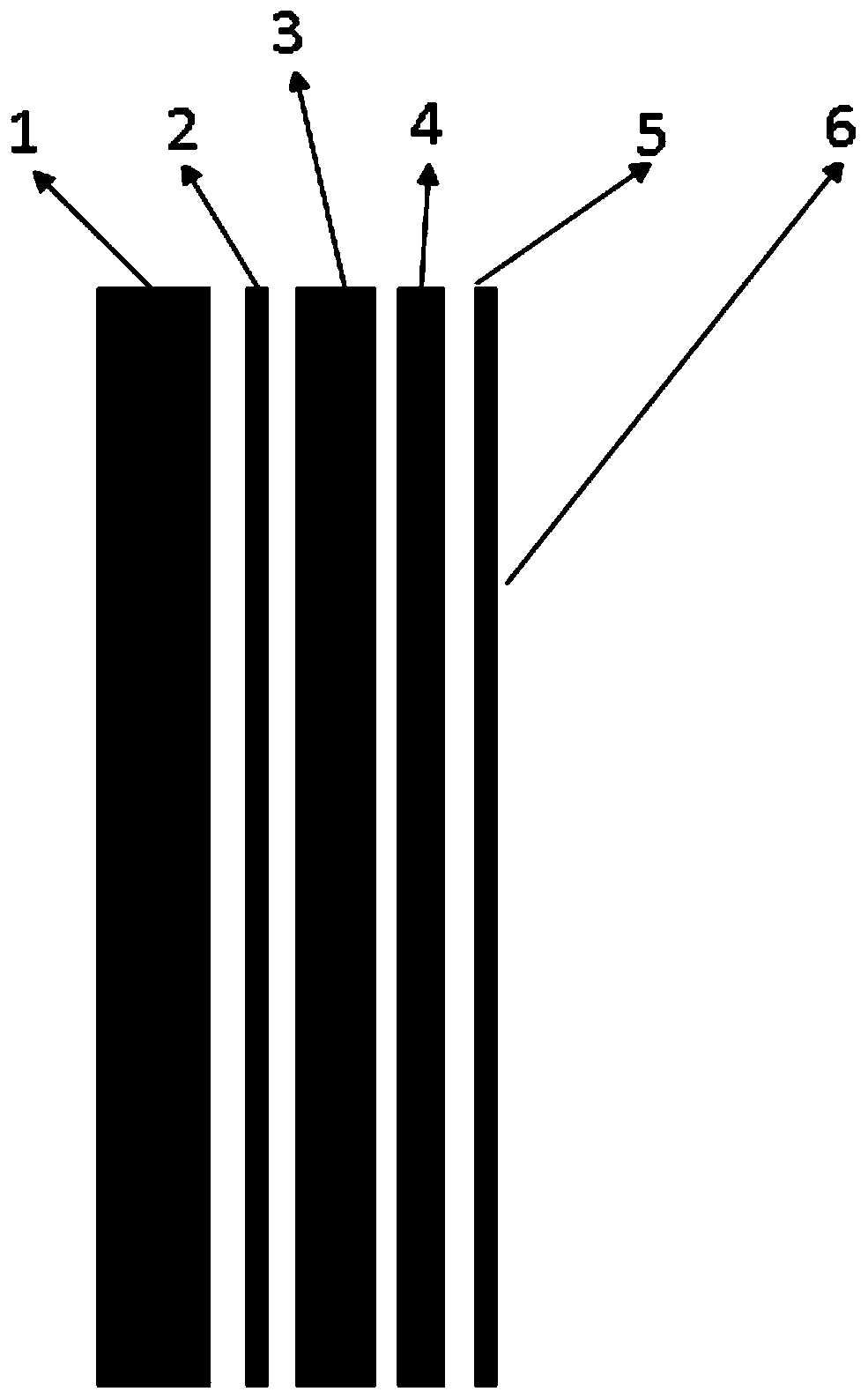

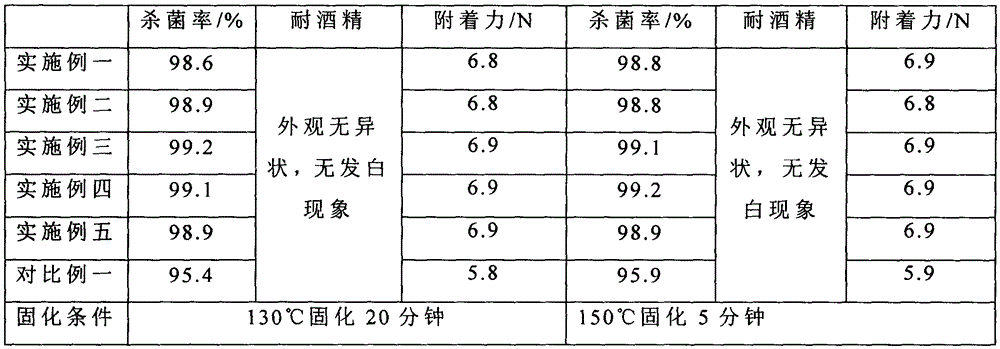

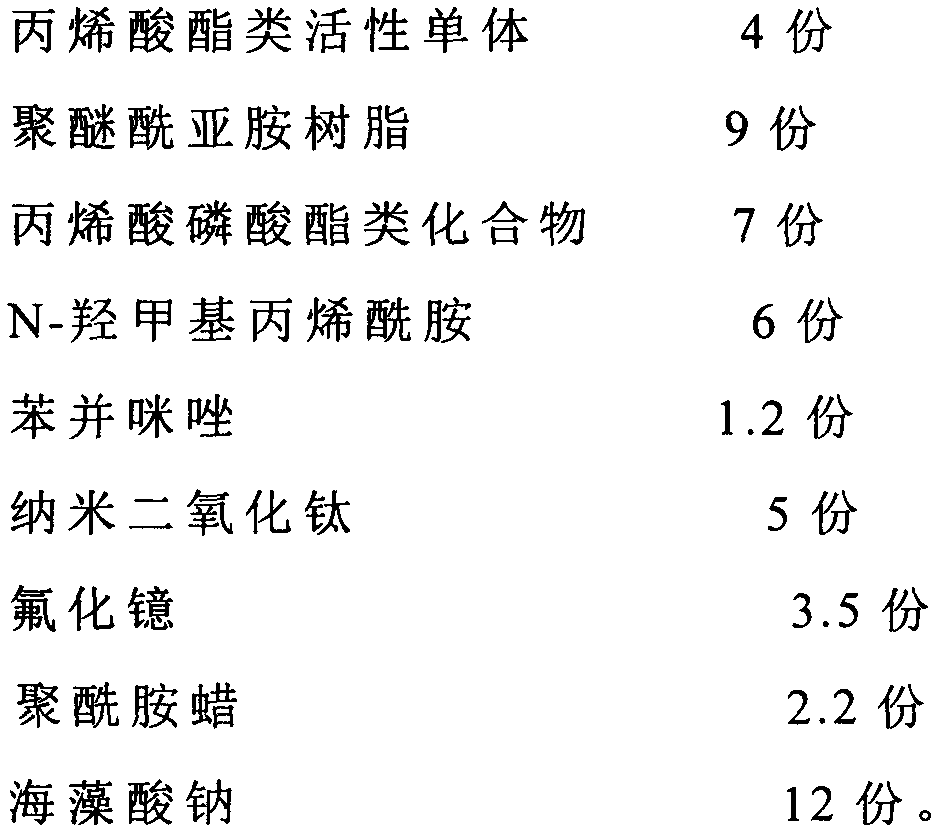

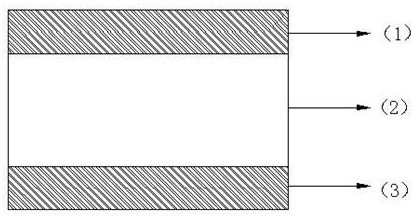

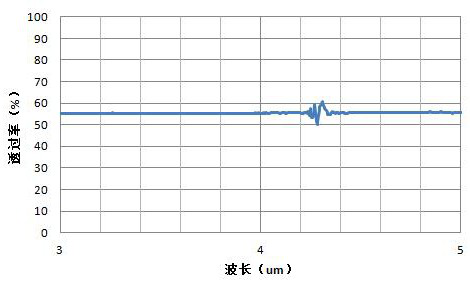

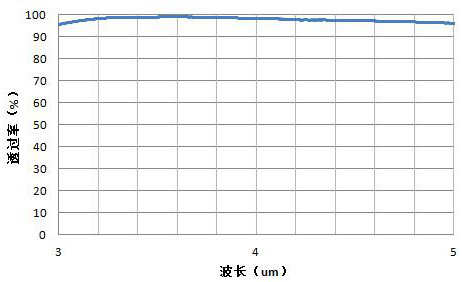

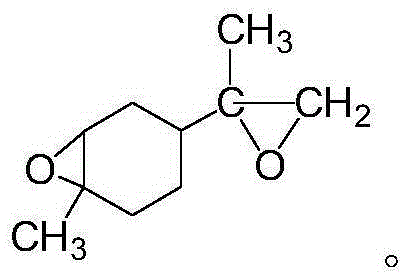

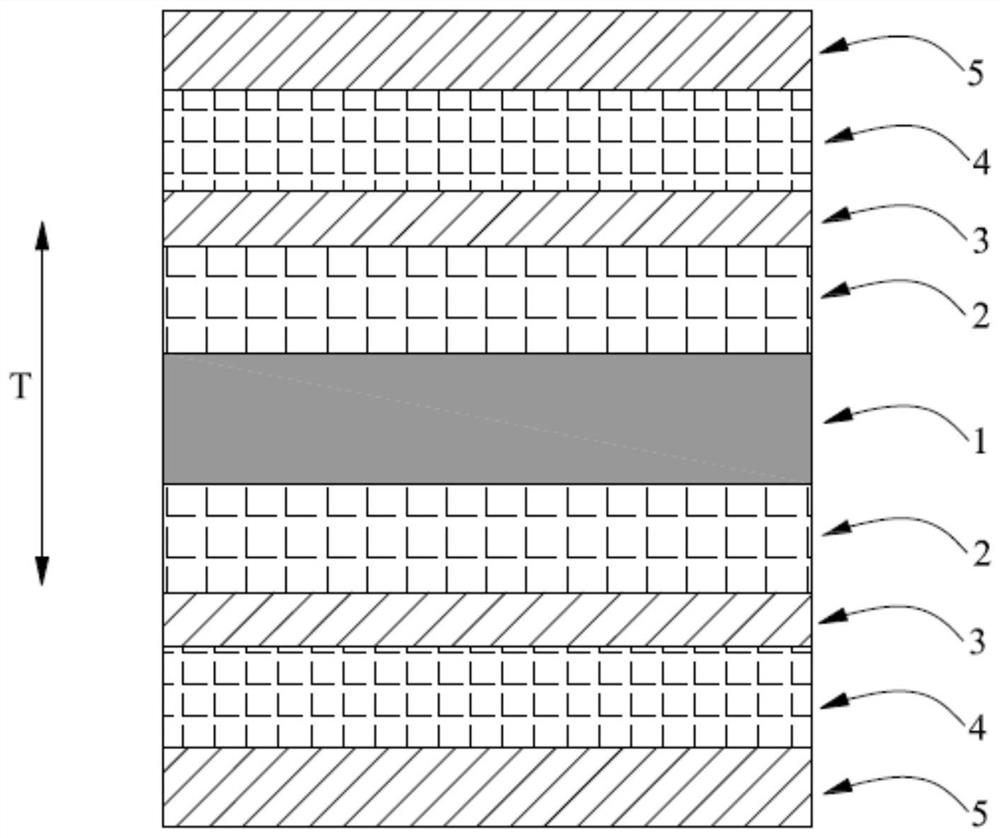

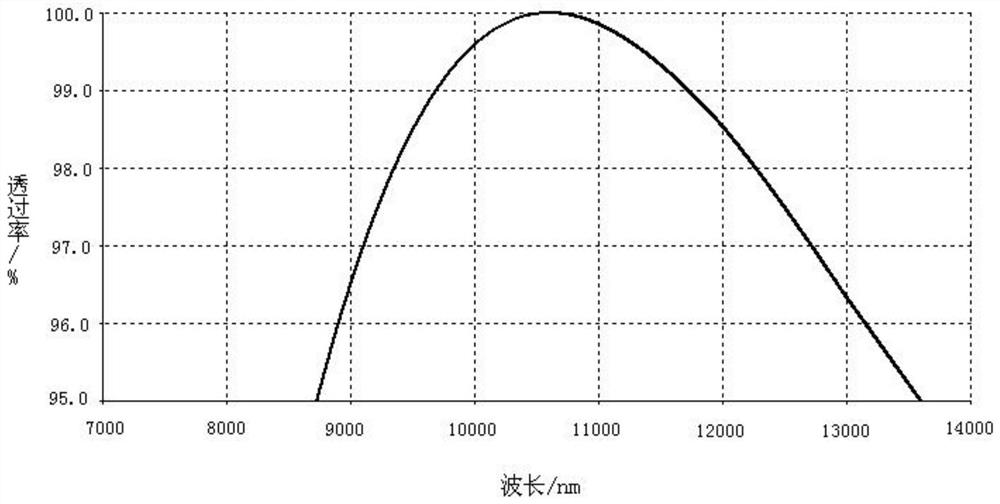

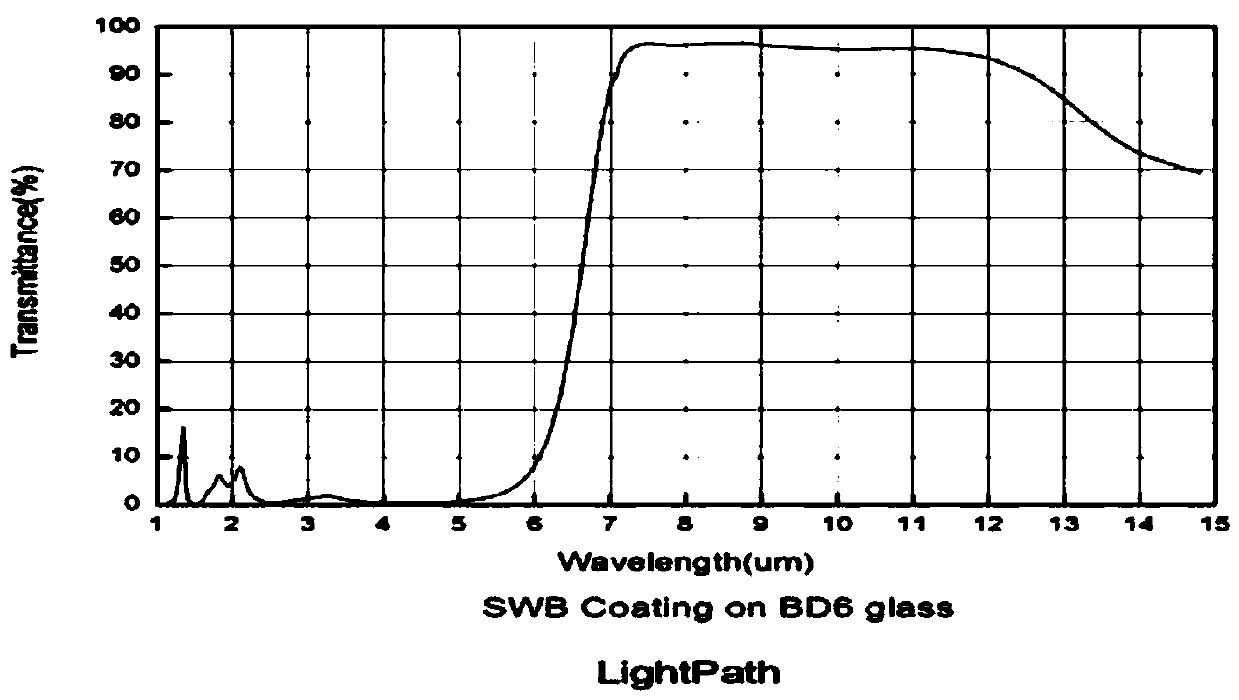

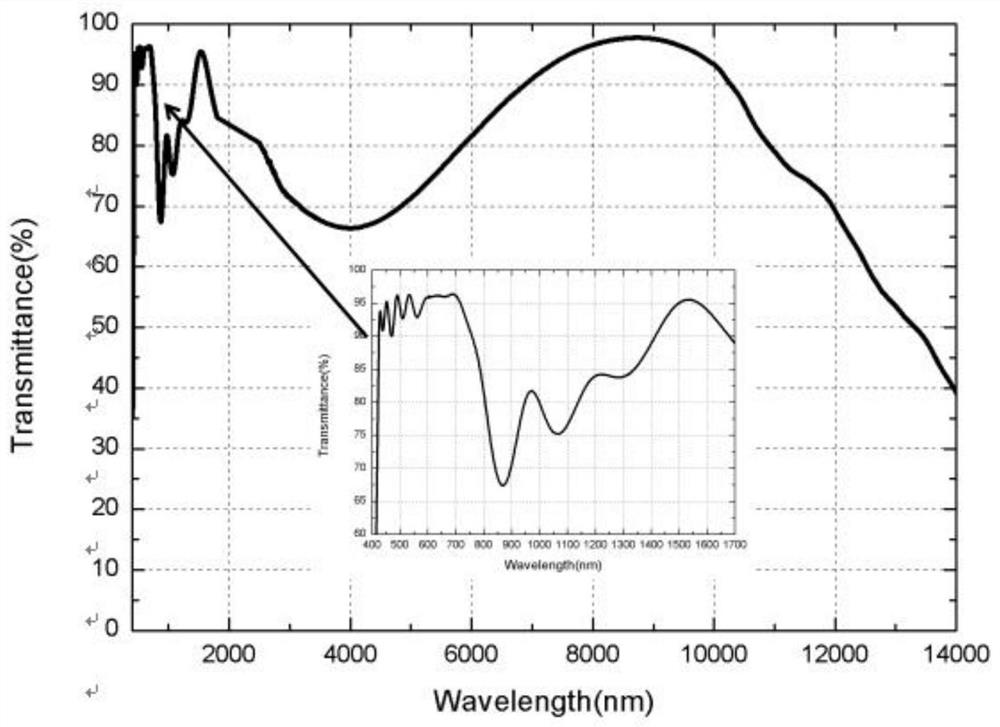

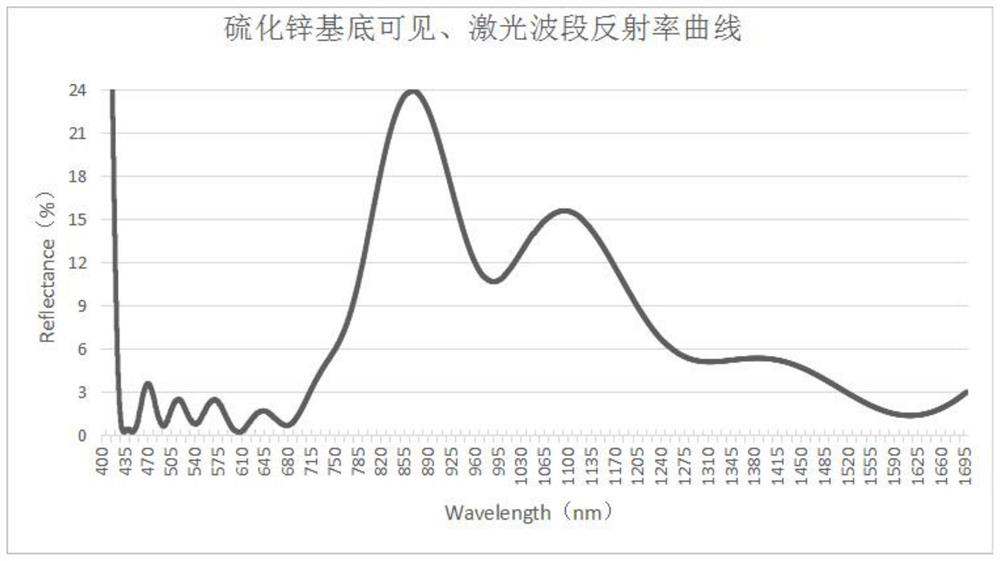

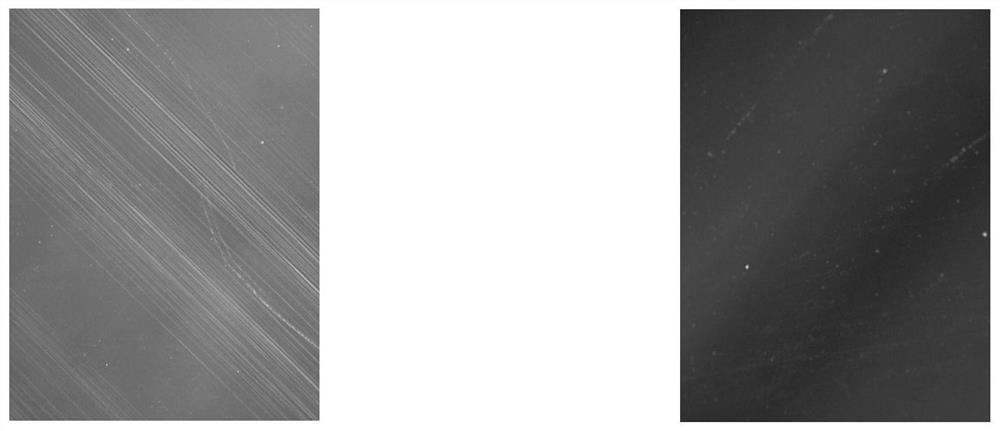

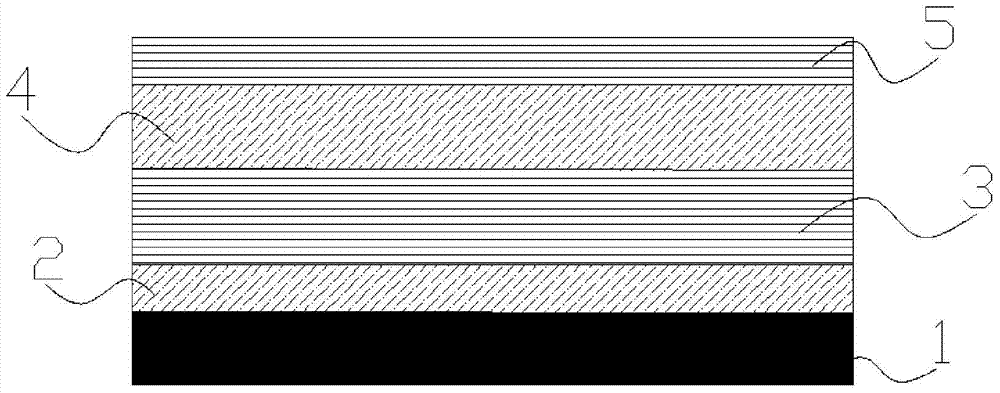

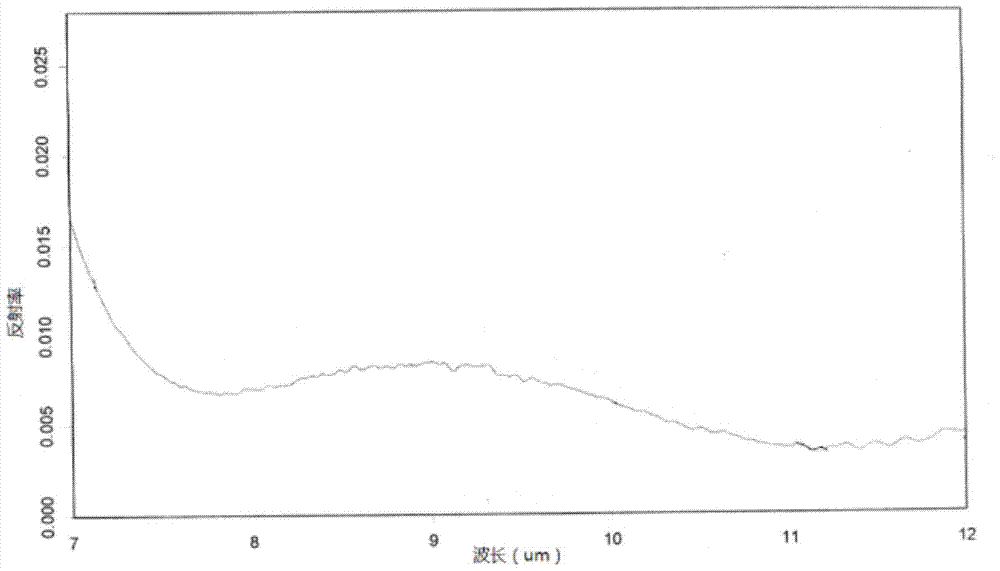

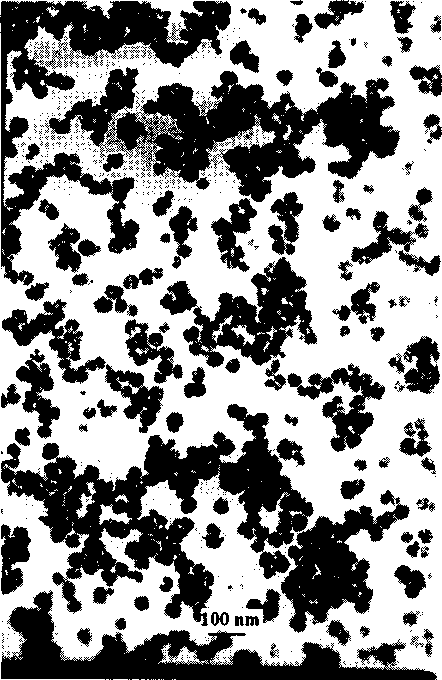

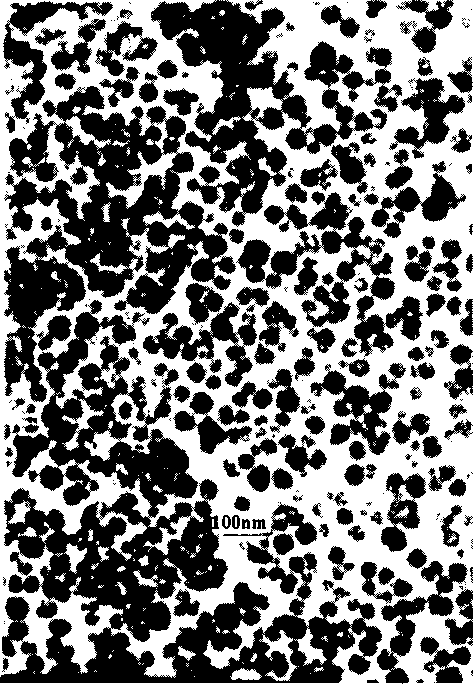

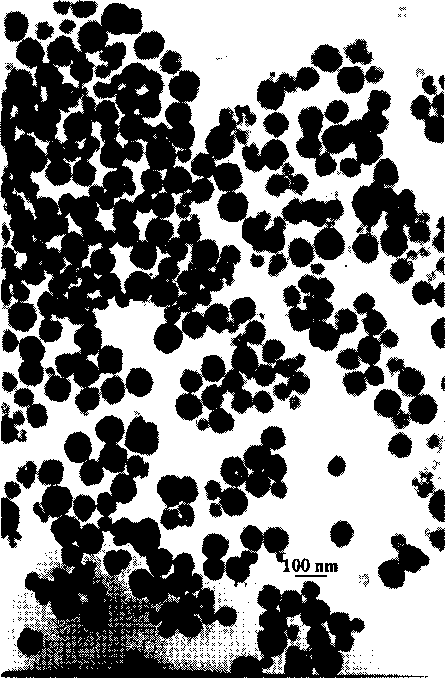

Film system structure of ZnS substrate with inverse 0.5-0.8[Mu]m visible light, laser with 1.064[Mu]m and transparent medium wave infrared colour separation with 3.7-4.8[Mu]m

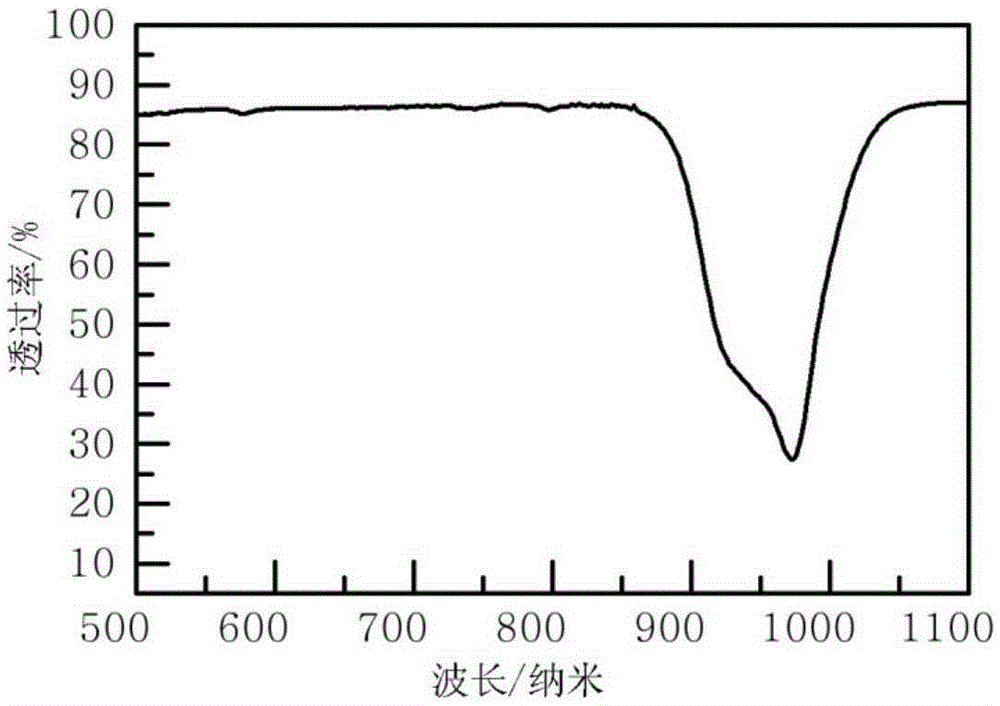

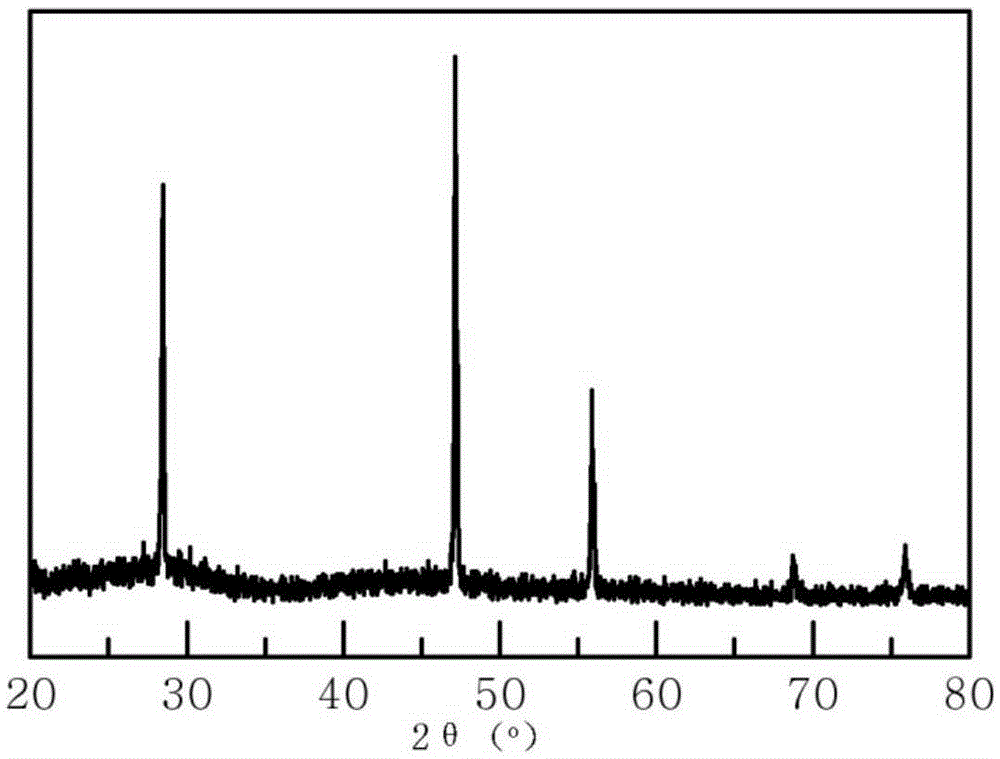

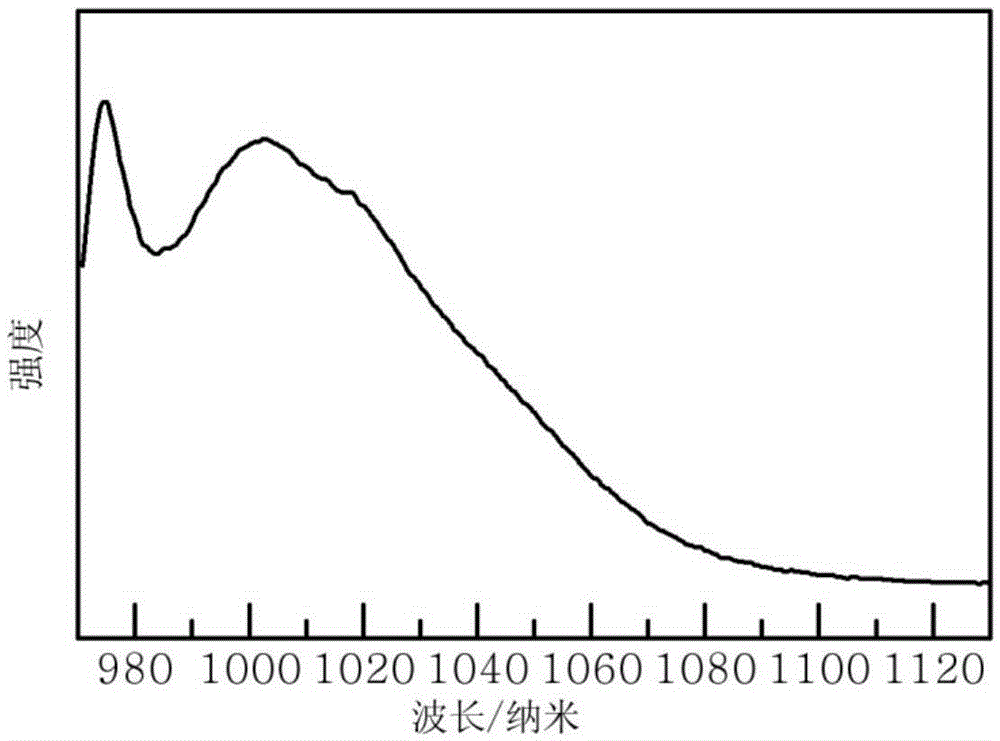

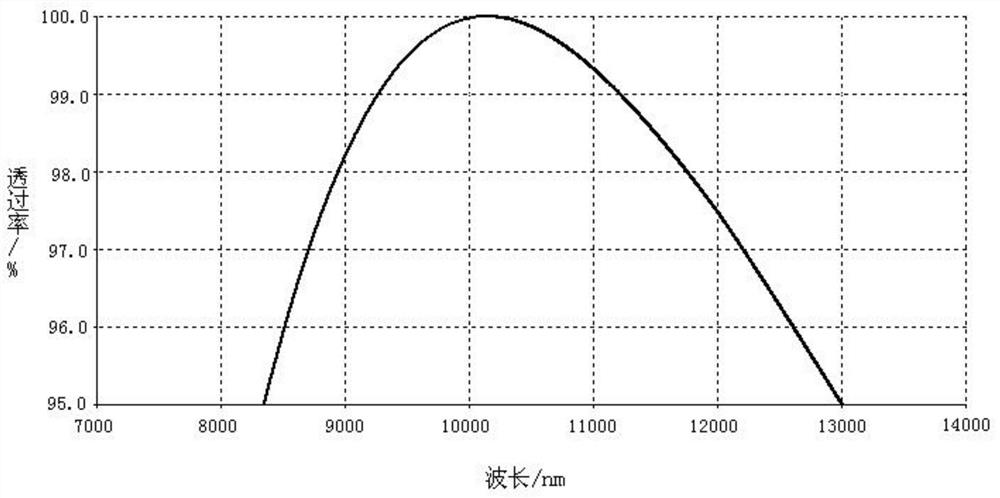

The present invention provides a film system structure of ZnS substrate with inverse 0.5-0.8[Mu]m visible light, laser with 1.064[Mu]m and transparent medium wave infrared colour separation with 3.7-4.8[Mu]m. The film system structure comprises a ZnS substrate and a color separation film system, and the color separation film system is made of three film materials; the number of the film layers is 51, wherein the first layer and the 51th layer are oxidation zirconium film layer, the even layers from the second layer to the 50th layer are ytterbium fluoride film layers and the odd layers from the second layer to the 50th layer are zinc sulfide film layers. The transmittance is smaller than 2% with the waveband from 0.5 to 0.8 [Mu]m; the transmittance is smaller than 1% with the laser waveband of 1.064 [Mu]m; and the transmittance is larger than 95% with the medium wave infrared band from 3.7 to 4.8 [Mu]m. The film system structure is small in the number of layers, small in thickness, low in plating difficulty, good in technology repeatability, high in obtained film firmness and good in spectral property, is able to satisfy the use requirement of multi-waveband co-window optoelectronic system and the work requirement in the condition of the inclination with 45 degrees, and stand against the environment tests such as high and low temperature storage, temperature impact and the like, the adhesion test and the moderate friction test.

Owner:西安应用光学研究所

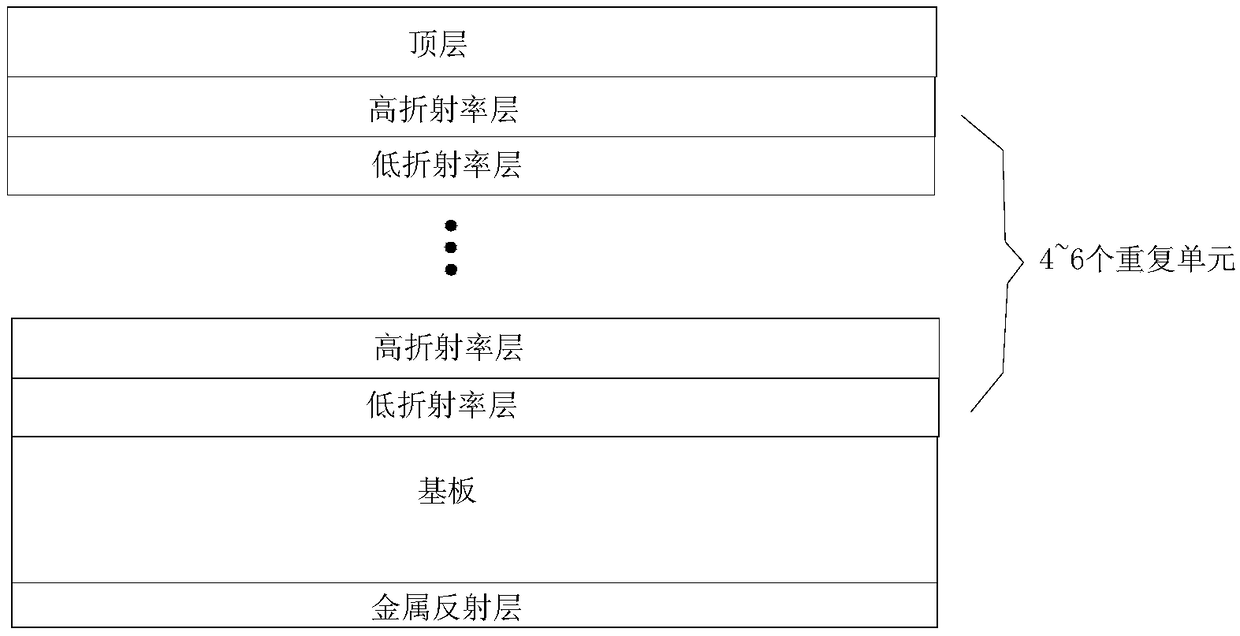

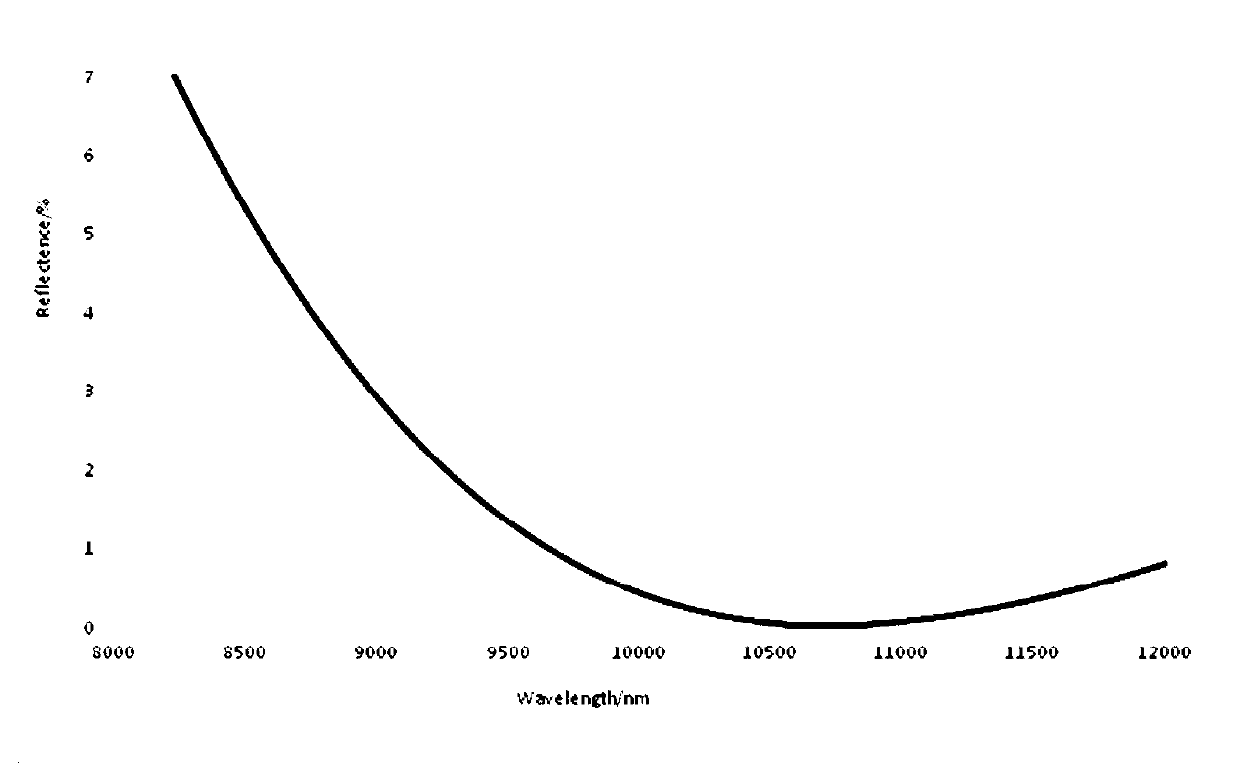

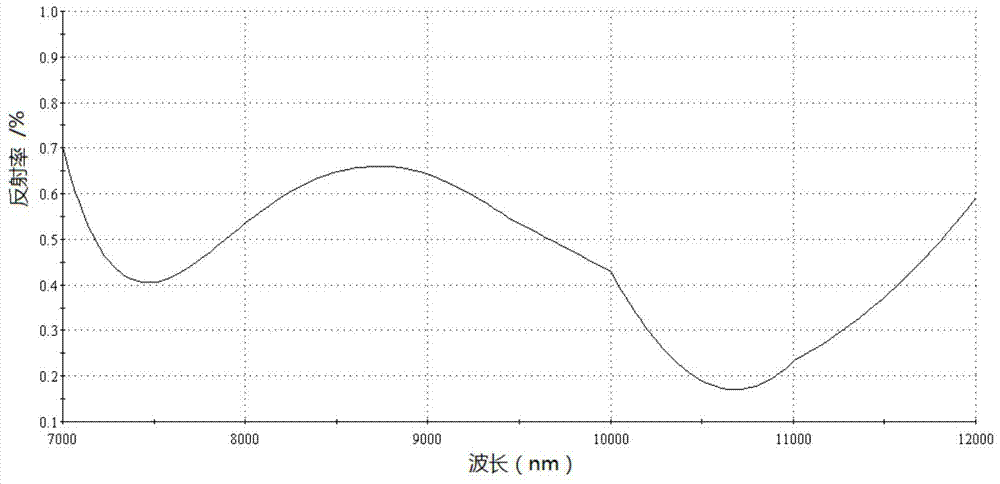

Radiation refrigeration optical filter, method for preparing same and application of radiation refrigeration optical filter

ActiveCN108710169ASimple structureReduce manufacturing costMountingsSilicon dioxideResonant absorption

The invention discloses a radiation refrigeration optical filter which comprises a substrate. A single surface of the substrate is polished, a metal reflecting layer is arranged on a rough surface ofthe substrate, and an intermediate layer and a top layer are sequentially arranged on the polished surface of the substrate; the intermediate layer comprises layers A and layers B which are alternately arranged; the thicknesses of each layer A and each layer B are 50-400 nm; the layers A are made of silicon dioxide or aluminum oxide, and the layers B are made of titanium dioxide or silicon nitrideor silicon carbide; alternatively, the layers A are made of titanium dioxide or aluminum oxide, and the layers B are made of silicon dioxide or silicon nitride or silicon carbide; the top layer is made of ytterbium fluoride or yttrium fluoride or zinc sulfide; multi-resonant absorption enhancers in wavebands of atmospheric transparent windows (with the wavebands of 8-13 micrometers) are jointly formed by the intermediate layer and the top layer. Compared with the traditional optical filters, the radiation refrigeration optical filter has the advantages that the radiation refrigeration opticalfilter can work in intense light for a long time, and radiation refrigeration can be passively implemented by the radiation refrigeration optical filter.

Owner:ZHEJIANG UNIV

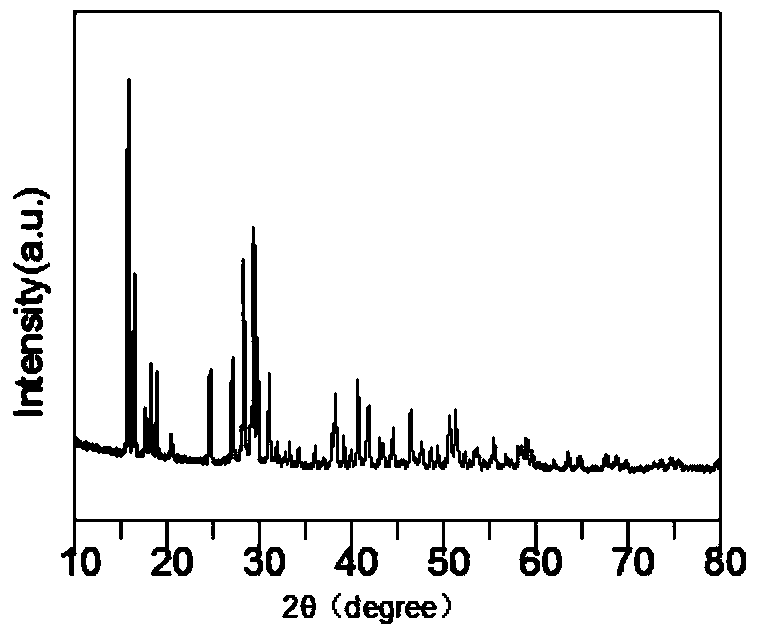

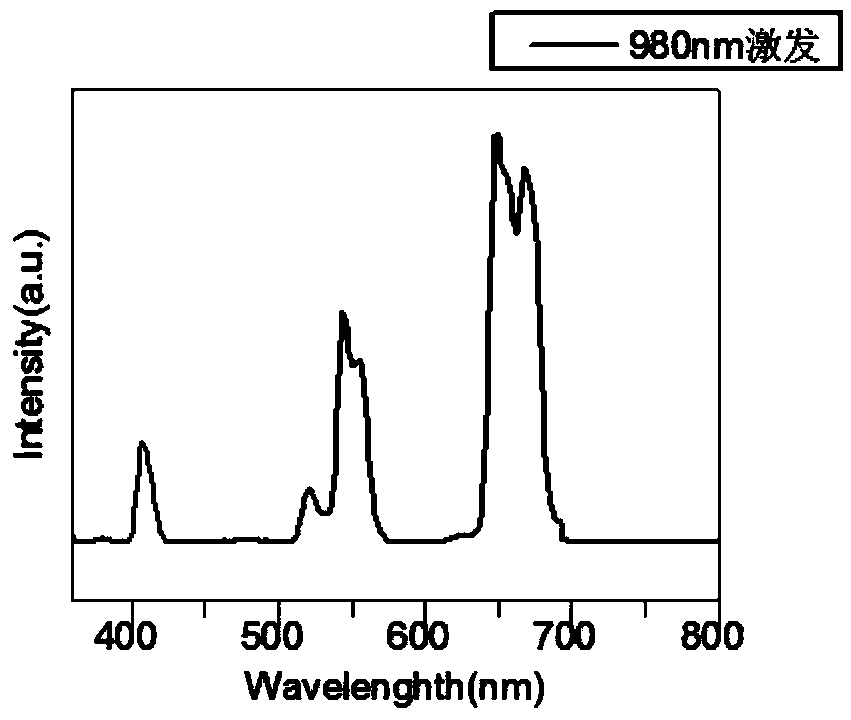

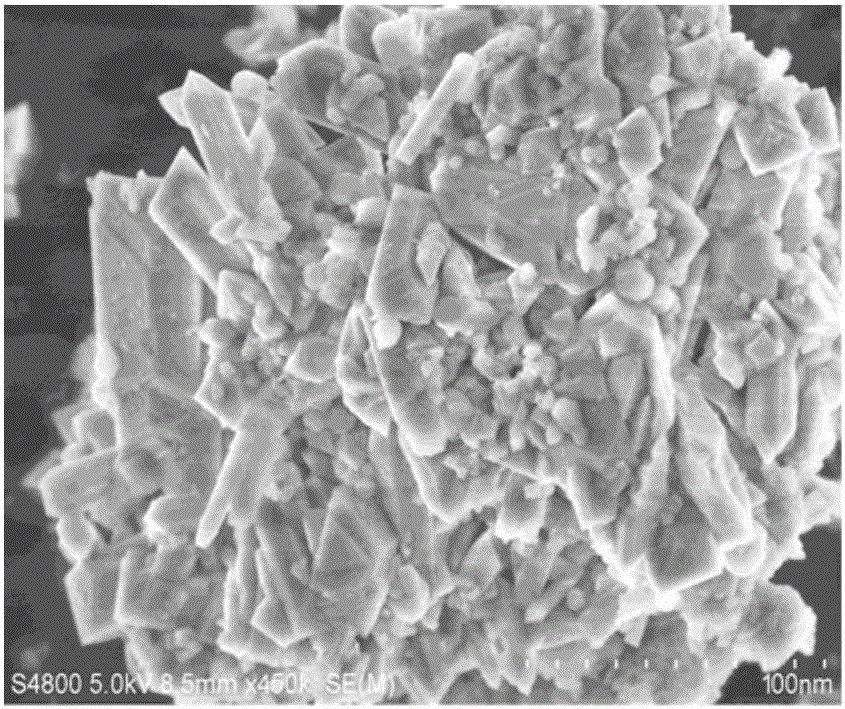

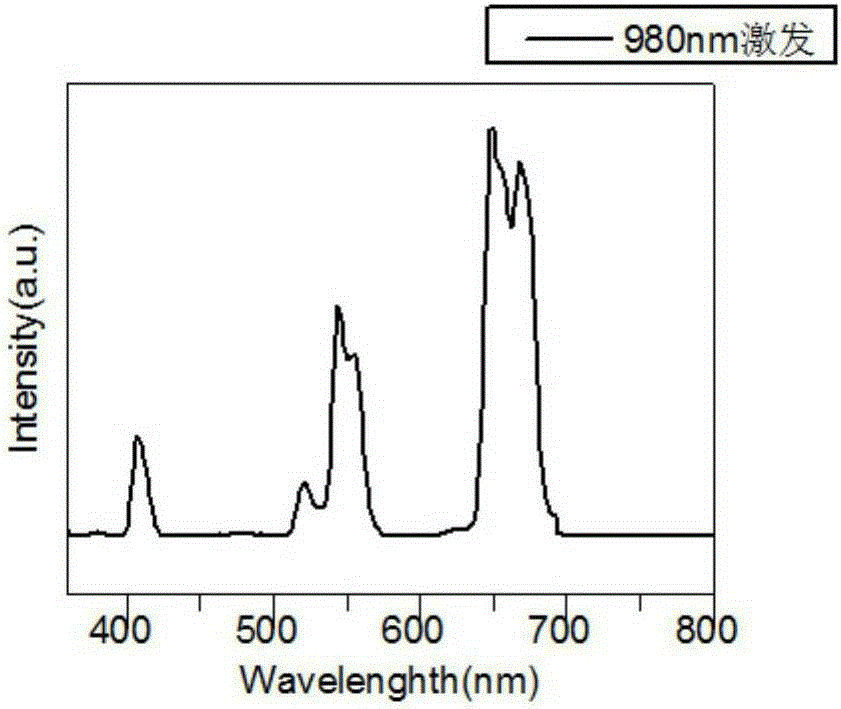

Method for preparing rare-earth doped potassium yttrium fluoride up-conversion luminescence nano material

InactiveCN104327855AHigh crystallinityHigh luminous intensityLuminescent compositionsQuantum yieldPotassium

The invention relates to a method for preparing a rare-earth doped potassium yttrium fluoride up-conversion luminescence nano material. The method comprises the following steps: 1) weighing yttrium oxide, sylvite and a fluorine source, adding in an oleic acid / oleylamine-containing solvent system, stirring and mixing, thus obtaining a first uniform solution; 2) weighing ytterbium fluoride and a rare-earth activator, adding in the oleic acid / oleylamine-containing solvent system, stirring and mixing, thus obtaining a second uniform solution; 3) rapidly heating the first uniform solution to a high temperature, and meanwhile rapidly filling the second uniform solution, and sufficiently stirring to react, thus obtaining a third uniform solution; and 4) cooling the obtained solution to room temperature, performing centrifugal separation, washing, and drying, thus obtaining the rare-earth doped potassium yttrium fluoride up-conversion luminescence nano material. The method has the beneficial effects that the preparation period of the material is effectively shortened, new ideas and ways are provided for preparing the up-conversion luminescence nano material, large-scale popularization and application are facilitated, and the purposes of controllable the monodisperse particle size, high quantum yield and the like are solved.

Owner:WUHAN UNIV OF TECH

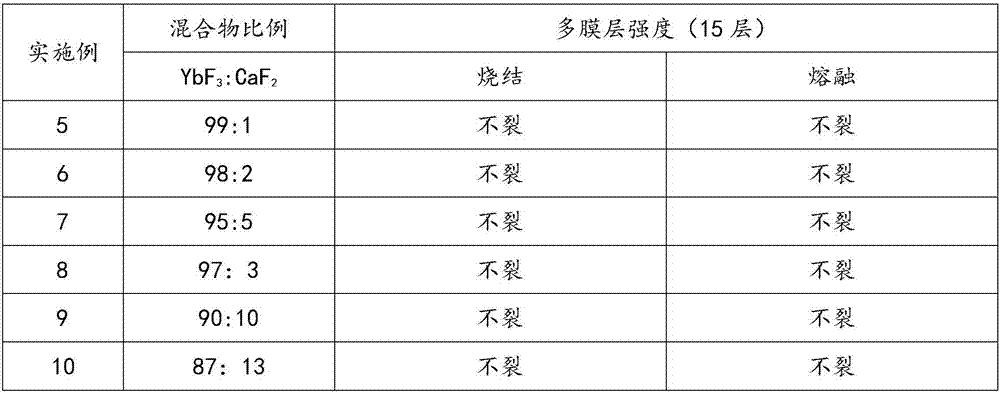

Low-refractive-index infrared optical coating material and preparing method thereof

ActiveCN107881467AEnsure stabilitySolve the problem of membrane ruptureVacuum evaporation coatingSputtering coatingYtterbium fluorideOptical coating

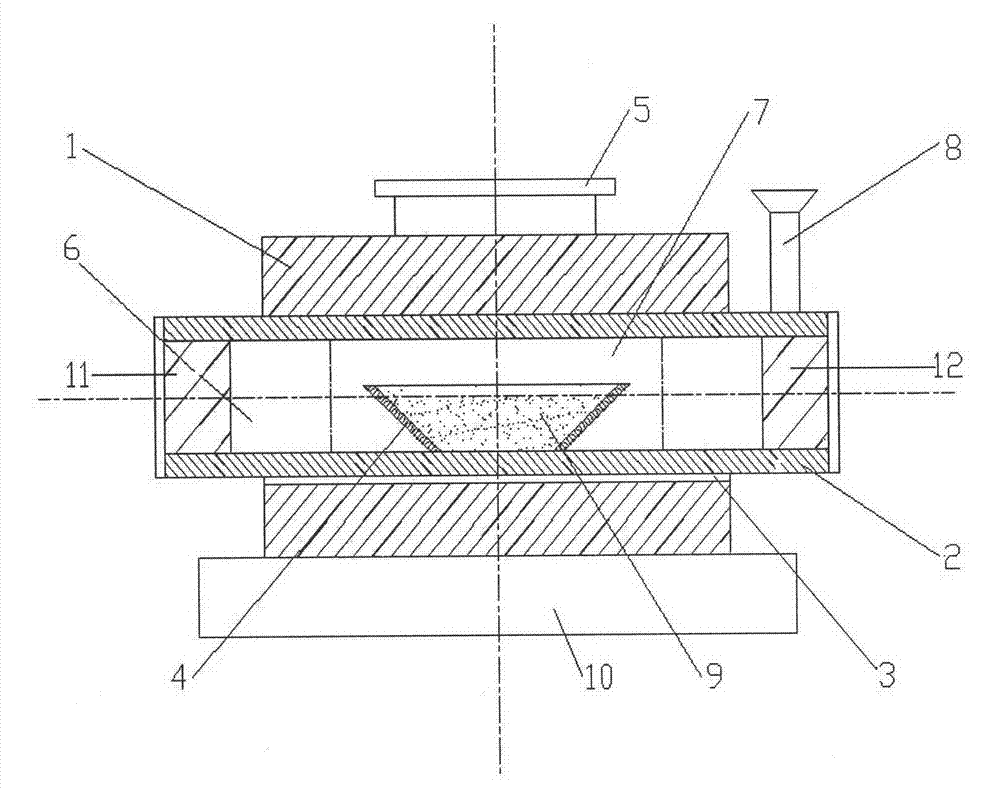

The invention relates to a low-refractive-index infrared optical coating material and a preparing method thereof, and belongs to the technical field of optical coating materials. According to the weight proportions of ytterbium fluoride and calcium fluoride, the ytterbium fluoride ranges from 85%-99.5%, the calcium fluoride ranges from 0.5%-15%, a ytterbium fluoride and calcium fluoride mixture obtained after proportioning is sintered, the sintering temperature is 700 DEG C-1250 DEG C, and the fusion step is executed; and the sintered sintering mixture is subject to vacuum fusion for 3 h to 6h at above 1260 DEG C, and a ytterbium fluoride and calcium fluoride fusion mixture is obtained. The low-refractive-index infrared optical coating material has the beneficial effects that in the ytterbium fluoride material, a certain amount of calcium fluoride is guided in, the ytterbium fluoride and the calcium fluoride evaporate at the same time and are deposited on the optical surface, due to the difference of crystalline forms of the calcium fluoride and the ytterbium fluoride, the directional growth condition in the original single ytterbium fluoride deposition process is prevented, and an even optical film layer with the small internal stress is formed; and as the internal stress is reduced, when a multi-layer film is plated, stability of the multi-layer film is guaranteed, and the problem of film cracking of the multi-layer film is solved.

Owner:凯永(固安)光电技术有限公司

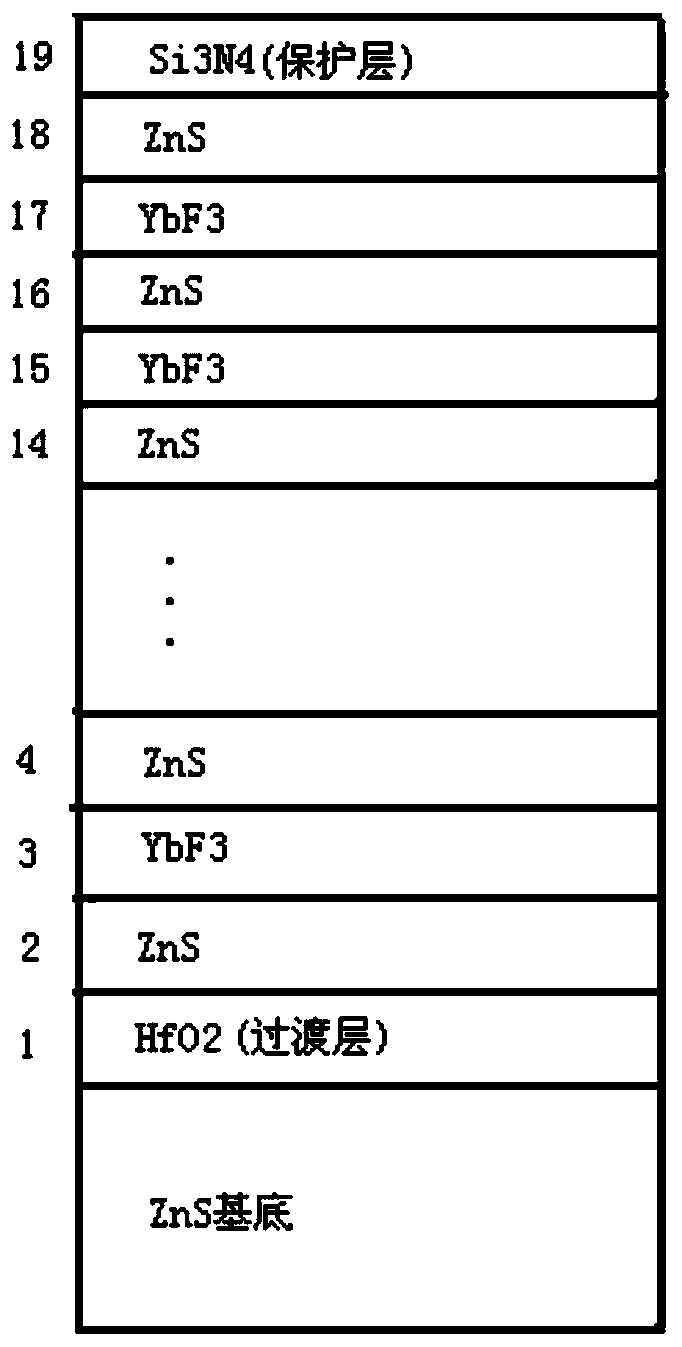

Film system structure of ultra-wide-angle laser and long-wave infrared dual-band high-strength antireflection film

The invention provides a film system structure of an ultra-wide-angle laser and long-wave infrared dual-band high-strength antireflection film. The film system structure is composed of a zinc sulfidesubstrate and an antireflection film system. The antireflection film system is formed by superposing film layers prepared from four thin film materials, wherein the total number of the film layers is19, and, from the zinc sulfide substrate, the first layer is hafnium oxide, odd layers from the second layer to the eighteenth layer are ytterbium fluoride film layers, even layers are zinc sulfide film layers, and the nineteenth layer is a silicon nitride film layer. According to the invention, high transmission of 1.064 [mu]m laser and 7.5-10.0 [mu]m long-wave infrared rays in an ultra-wide angle range of 0-76 degrees can be realized; the film layers are firm and high strength is achieved; the structure can pass severe environment tests such as wind tunnels, sand dust, raining, salt mist, damp heat, temperature impact and the like in national military standard GJB 150-2009; the structure can meet the application requirements of multi-spectral zinc sulfide optical windows of radar stealthhigh-speed weapon platforms and can be applied to stealth optical windows of multi-band common-optical-path optical systems of stealth airborne and stealth ship-based high-speed weapon platforms.

Owner:西安应用光学研究所

Ge-As-Se infrared glass with anti-reflection film and preparation method thereof

ActiveCN105388542AImprove permeabilityReduce surface residual reflectivityOptical elementsYtterbium fluorideZinc sulfide

The invention discloses Ge-As-Se infrared glass with an anti-reflection film and a preparation method thereof. The Ge-As-Se infrared glass with the anti-reflection film comprises a Ge-As-Se infrared glass base layer, the Ge-As-Se infrared glass base layer is composed of 12% of Ge, 28% of As and 60% of Se by weight, and a first ytterbium fluoride layer, a first zinc sulfide layer, a second ytterbium fluoride layer and a second zinc sulfide layer are deposited on the Ge-As-Se infrared glass base layer successively. The Ge-As-Se infrared glass of the invention can effectively prevent the anti-reflection film from falloff, and the reflectivity of the infrared glass is reduced.

Owner:CHINA BUILDING MATERIALS ACAD

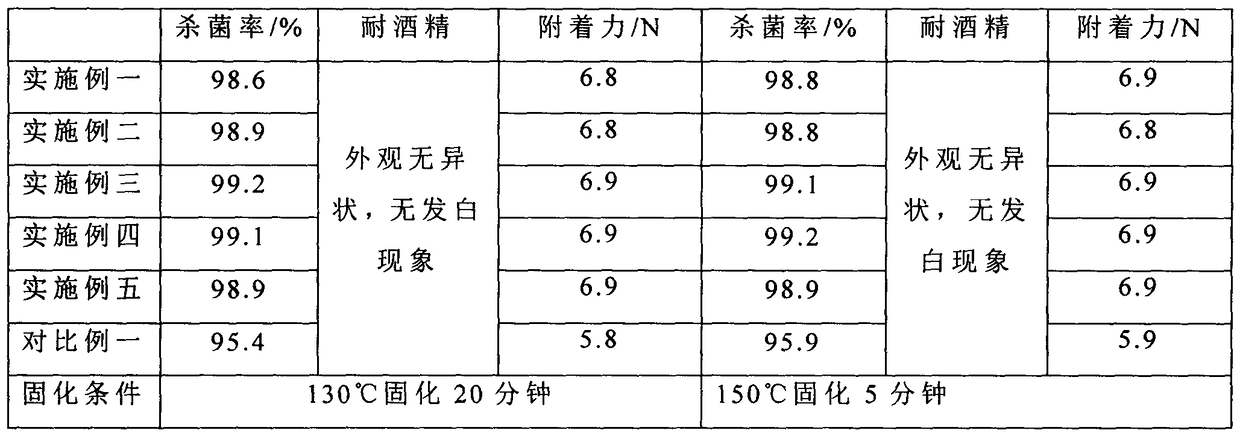

Preparation method for anti-microbial cotton material

InactiveCN105178012AReasonable compositionImprove antibacterial propertiesFibre treatmentYtterbium fluoridePolymer science

The invention relates to a preparation method for an anti-microbial cotton material. Cotton fibers are placed in a finishing liquid comprising amino-terminated hyperbranched polymers, micromolecule functional agents, ytterbium fluoride and nano-titanium dioxide, dipping treatment is carried out, and anti-microbial cotton fibers are obtained. The cotton fibers finished through the method has good hand feeling, air permeability and fastness to washing and has strong anti-microbial endurance. Treatment is convenient, the method is simple, and operation is easy.

Owner:SUZHOU KEMIAO NEW MATERIAL

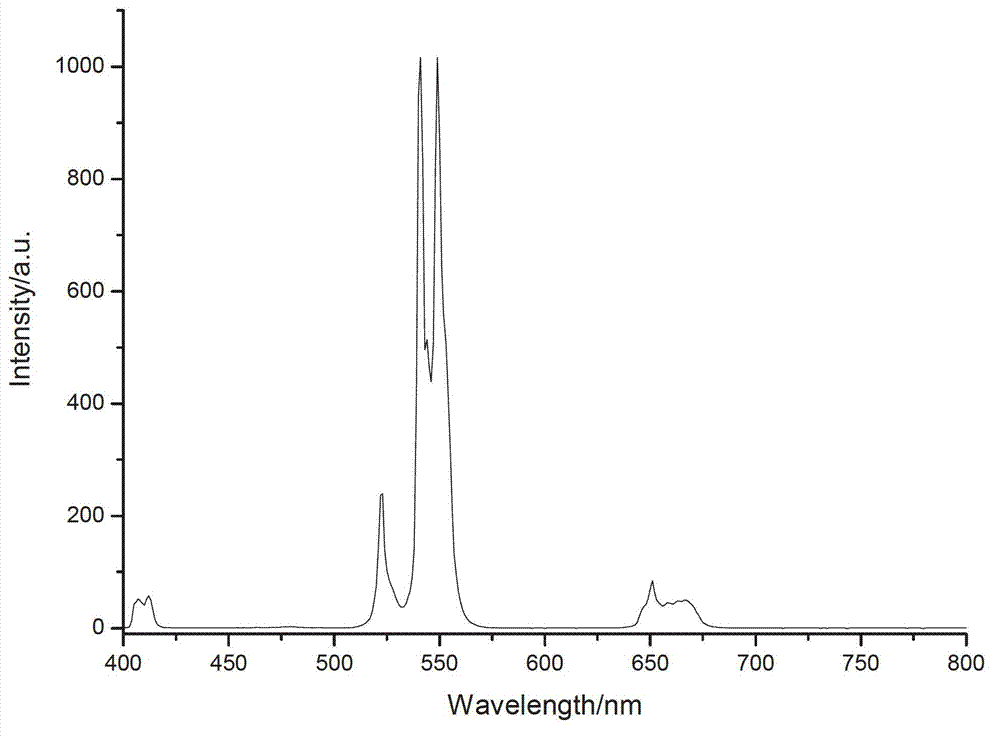

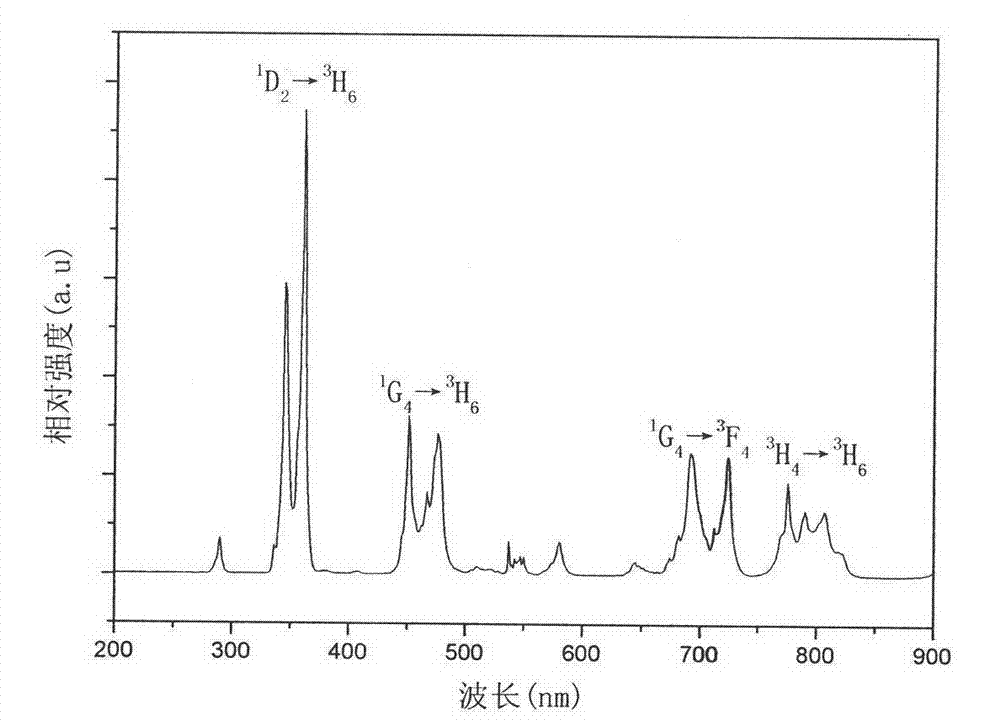

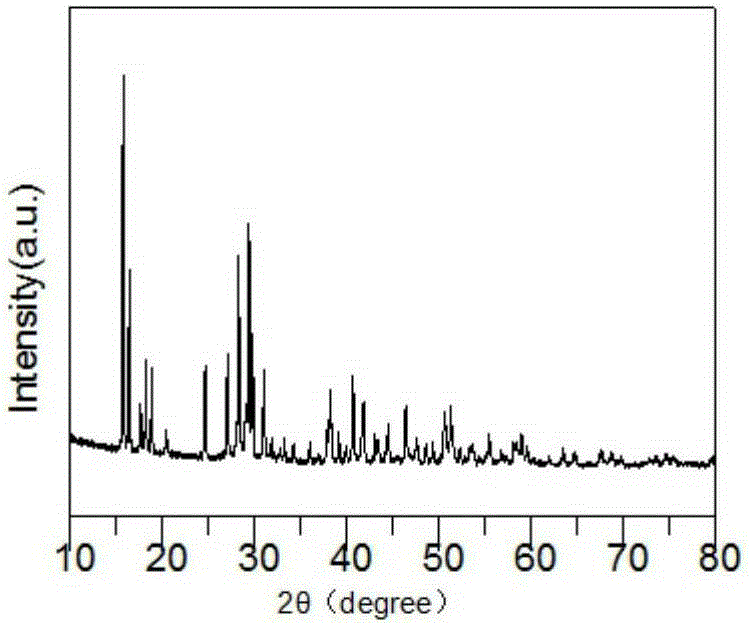

Barium fluoride up-conversion transparent ceramic and preparation method thereof

InactiveCN102826850AImprove up-conversion luminous efficiencyLow phonon energyRare earthUp conversion

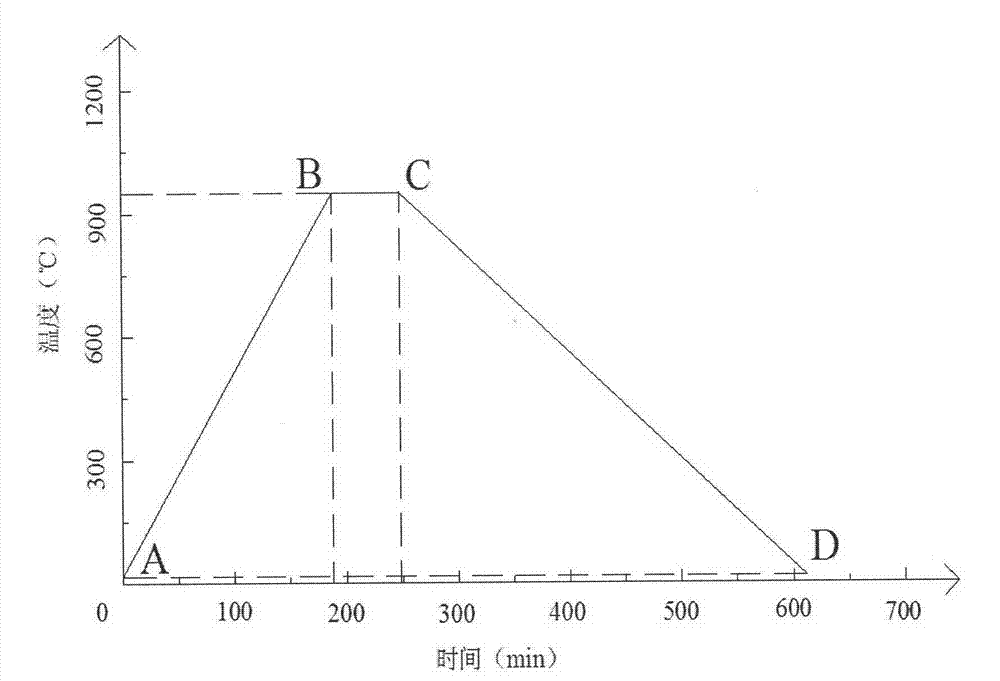

The invention discloses a barium fluoride up-conversion transparent ceramic and a preparation method thereof, and belongs to the technical field of optically functional materials. The existing alumina up-conversion transparent ceramic has low up-conversion luminous efficiency and is prepared difficultly. The barium fluoride up-conversion transparent ceramic utilizes barium fluoride transparent ceramic as a matrix and comprises: by mole, 60 to 89% of barium fluoride, 10 to 25% of ytterbium fluoride, and 1 to 15% of one or more of fluorides of erbium, holmium, neodymium, thulium and promethium. The preparation method comprises the following steps of blending raw material nanometer powder according to the mole percentage, wherein barium fluoride powder has particle sizes of 20 to 80nm and rare earth fluoride powder has particle sizes of 10 to 90nm, pressing the blended raw material nanometer powder into a biscuit, pre-sintering the biscuit at a temperature of 500 to 800 DEG C for 0.5 to 5 hours, carrying out vacuum sintering of the pre-sintered biscuit under the conditions of pressure of 50 to 500MPa, a vacuum degree of 10<-2> to 10<-3>Pa, a heating rate of 1 to 20 DEG C / min, a sintering temperature of 600 to 1200 DEG C and sintering time of 0.5 to 5 hours, and cooling to a room temperature at a rate of 1 to 20 DEG C / min to obtain the barium fluoride up-conversion transparent ceramic.

Owner:CHANGCHUN UNIV OF SCI & TECH

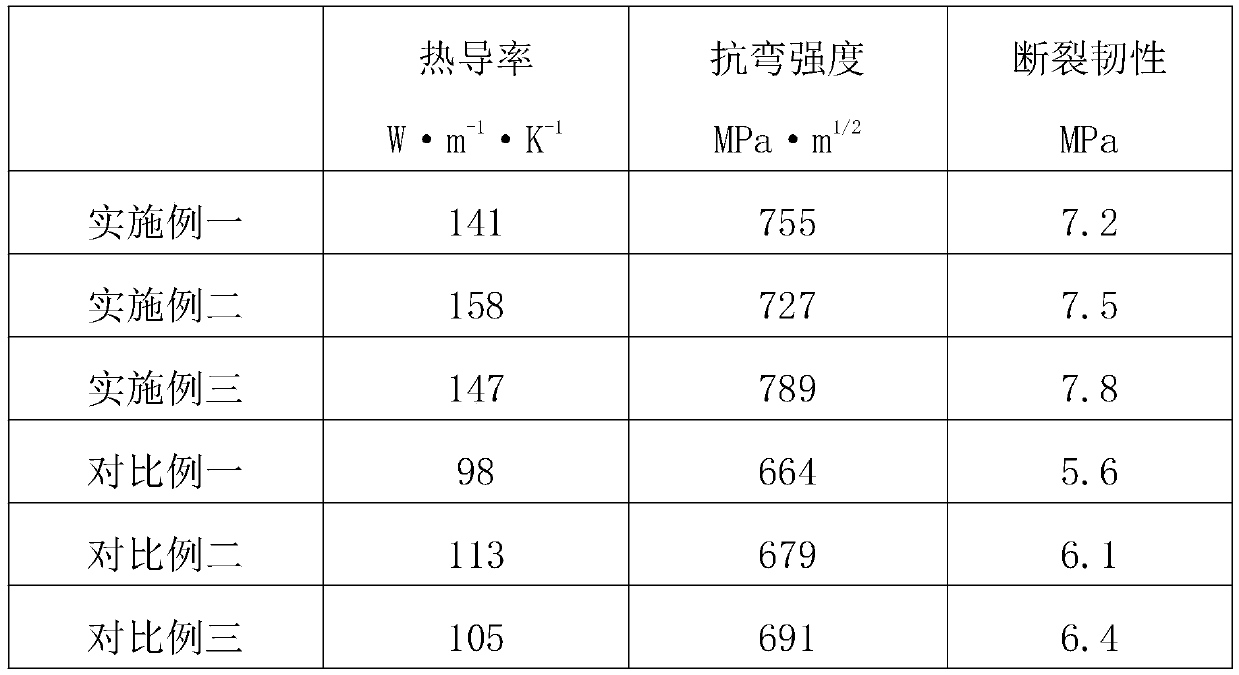

High-thermal-conductivity silicon nitride ceramic and preparation method thereof

The invention relates to the technical field of ceramic material preparation, provides high-thermal-conductivity silicon nitride ceramic and a preparation method thereof, and solves the problem of lowthermal conductivity of silicon nitride ceramic in the prior art. The silicon nitride ceramic comprises the following components in parts by weight: 60-90 parts of silicon nitride, 8-12 parts of silicon carbide, 3-5 parts of rare earth chloride, 0.2-1 part of ytterbium fluoride, 0.5-2 parts of zirconium nitride and 5-10 parts of dispersing agent. According to the preparation method, the rare earth chloride is added, so that the sintering activity of the silicon nitride powder is improved under the condition of not additionally introducing oxygen, and densification of the silicon nitride ceramic is realized; the ytterbium fluoride can promote diffusion of Si and N and react with oxygen impurities in silicon nitride crystal lattices, so that the content of dissolved oxygen in the silicon nitride crystal lattices is effectively reduced, and the heat conductivity of silicon nitride is improved; zirconium ions in the zirconium nitride have strong affinity to oxygen and can absorb part of oxygen impurities in crystal lattices. Rare earth chloride, ytterbium fluoride and zirconium nitride are matched with one another, the size of silicon nitride grains can be increased, and oxygen impurities can be discharged.

Owner:FUJIAN HUAQING ELECTRONICS MATERIAL TECH

Ytterbium doped calcium fluoride microcrystal and fluorophosphate glass composite and preparation method thereof

The invention provides an ytterbium doped calcium fluoride microcrystal and fluorophosphate glass composite and a preparation method thereof. The composite is formed through uniformly dispersing ytterbium doped calcium fluoride microcrystals into the fluorophosphate glass body, wherein the ytterbium doped calcium fluoride microcrystals accounts for 10%-50% in weight ratio, and the particle size of the microcrystals is 10-20 micrometers. According to the invention, the powder mixture of fluorophosphate glass, calcium fluoride and ytterbium fluoride is subjected to high temperature thermal treatment and then low temperature quenching, the preparation flow is simple, convenient and safe, the crystalline phase is high in content, and expensive equipment is not needed.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

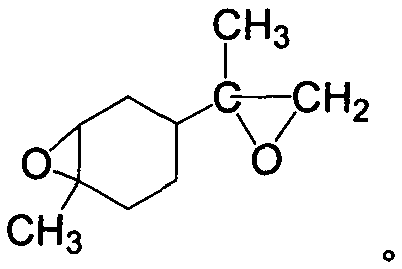

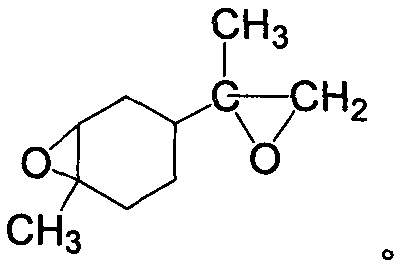

Ultrathin film material for electronic product and preparation method thereof

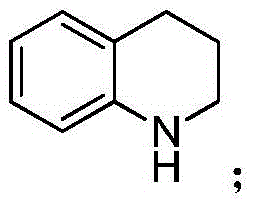

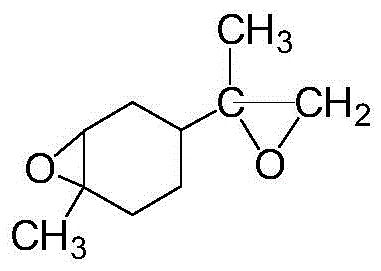

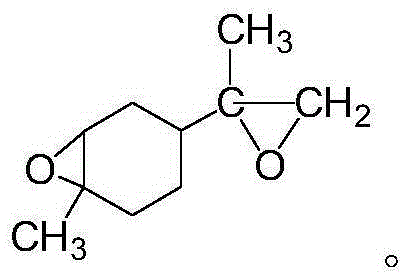

The invention relates to an ultrathin film material for electronic product and a preparation method thereof. The method is as below: first reacting diisoprene diepoxide with 3-tridecylfluorooctyl propylene in the presence of diisopropyl peroxydicarbonate to obtain an epoxy substance containing fluorine; then mixing N-methylphenethylamine ytterbium fluoride, and zirconia, then adding a tetrahydroquinoline compound and graphite; finally adding the fluorine-containing epoxy substance and trimethylsilyl chloride to obtain a film material precursor; f dissolving the film material precursor in a composite solvent to prepare a mixed solution with solid content of 75%; then spraying the mixed solution on a substrate, drying at 93 DEG C, curing at 180 DEG C to obtain the ultrathin film material for electronic products. The disclosed preparation method has wide source of raw materials, and simple and controllable manufacturing process only requiring routine operation, and is easy for industrialization.

Owner:WUJIANG XINTA FORWARD HARDWARE FACTORY

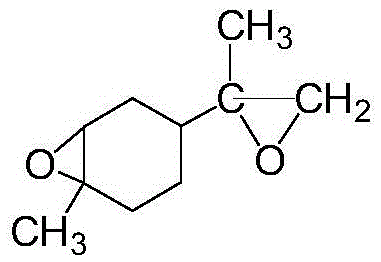

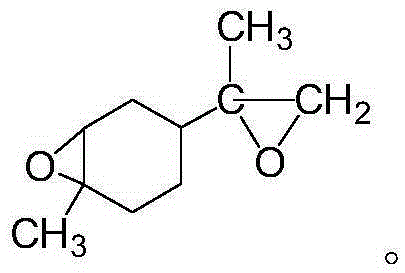

Heat-conducting electronic alloy material

The invention discloses a heat-conducting electronic alloy material. The heat-conducting electronic alloy material comprises the following components of, in parts by weight, 20-30 parts of copper, 10-15 parts of iron, 3-10 parts of silicon, 1-6 parts of nickel, 0.1-1 part of zinc, 0.5-1 parts of phosphorus, 3-10 parts of graphite powder, 0.5-1 parts of ytterbium fluoride, 0.5-1 parts of titanium dioxide, 8-10 parts of epoxy resin and 4-6 parts of alicyclic epoxy resin. The heat-conducting electronic alloy material has good heat-conducting property and mechanical property, and the development and application of the heat-conducting electronic material composition can be met. The electronic material is reasonable in formula design and simple in manufacturing method, the mechanical strength and the anti-corrosion effect of the material are improved while the conductive performance of the material is ensured, and meanwhile, the production cost is reduced, the anti-fatigue performance of theelectronic material is improved, so that the electronic alloy material with excellent bending processability is obtained; the electronic alloy material has the advantages of being high in stability,good in corrosion resistance and good in heat conductivity.

Owner:贵州顽熊电子科技有限公司

Method for quickly preparing ultraviolet phosphors

ActiveCN102775990ANo pollutionHigh purityLuminescent compositionsUpconversion luminescenceYtterbium fluoride

The invention relates to a method for quickly preparing ultraviolet phosphors. The method comprises the following steps of: adopting aluminum fluoride, ytterbium fluoride and thulium fluoride as raw materials, mixing, calcining, grinding, sieving and detecting so as to finally prepare an ultraviolet phosphors product, which can emit ultraviolet. The preparation method has short process flow, use equipment is less, the environment can not be polluted, the product has high purity reaching to 96.7 percent, a particle diameter of powder is small and is less than or equal to 38 mum, the luminescence property is good, the ultraviolet phosphors can light on a blue light, a green light and a red light in a conversion manner, and the method is a very ideal method for quickly preparing ultraviolet phosphors excited by infrared light.

Owner:SHANXI FEIHONG MICRO NANO PHOTOELECTRONICS SCI & TECH

High-temperature-resisting CO2 laser antireflection film and preparing method thereof

ActiveCN110004408AExtended service lifeSimple structureFinal product manufactureVacuum evaporation coatingYtterbium fluorideZinc selenide

The invention discloses a high-temperature-resisting CO2 laser antireflection film and a preparing method thereof. The high-temperature-resisting CO2 laser antireflection film comprises a base layer,a first yttrium fluoride layer, a ytterbium fluoride calcium layer, a zinc selenide layer and a second yttrium fluoride layer are sequentially deposited on the base layer, and the coverage area of each of the first yttrium fluoride layer, the ytterbium fluoride calcium layer, the zinc selenide layer and the second yttrium fluoride layer accounts for 95% or above of the surface area of the base layer. The high-temperature-resisting CO2 laser antireflection film is simple in structure and exquisite in design, through combination of the four layers including the first yttrium fluoride layer, theytterbium fluoride calcium layer, the zinc selenide layer and the second yttrium fluoride layer, the characteristics that high temperature resistance is achieved, the transmittance rate is high, filmlayers are firm, stress between the film layers is complementary, and the film layers are not prone to fracture are achieved, and the situation of continuous work of elements under the high-temperature condition can be achieved; and materials used in various layers are free of radioactivity, and harm cannot be caused to operators or the environment.

Owner:NANJING WAVELENGTH OPTO ELECTRONICS SCI & TECH CO LTD

Ytterbium fluoride mixed coating material and preparation method thereof

ActiveCN111592231AInhibit sheddingImprove crack resistanceVacuum evaporation coatingSputtering coatingYtterbium fluorideRefractive index

The invention discloses an ytterbium fluoride mixed coating material and a preparation method thereof, and relates to the field of ytterbium fluoride mixed materials. The preparation method comprisesthe following steps: firstly, washing a quartz substrate, immersing the quartz substrate into tin dioxide sol containing potassium acetate, filtering and drying after the dipping to obtain a pretreated quartz substrate, mixing ytterbium fluoride with calcium fluoride, adding titanium dioxide, mixing and sintering, melting to obtain a mixed coating material, carrying out vacuum coating on the surface of the pretreated quartz substrate with the mixed coating material in a coating machine to obtain an ytterbium fluoride mixed coating material blank, and sintering the ytterbium fluoride mixed coating material blank to obtain the ytterbium fluoride mixed coating material. The ytterbium fluoride mixed coating material prepared by the invention has excellent anti-cracking performance, and has less influence on the optical refractive index of ytterbium fluoride.

Owner:南京睿扬光电技术有限公司

Method for reducing oxygen component and carbon component in fluoride

InactiveUS7033563B2Reduce amountSimple processRare earth metal halidesMagnesium halidesYtterbium fluorideCerium

A method for reducing oxygen and carbon components in high-purity fluoride such as calcium fluoride and barium fluoride (a high-purity fluoride that is not limited to calcium fluoride and barium fluoride), or in rare-earth fluorides such as ytterbium fluoride and cerium fluoride used for an optical fiber, a coating material, and so on. The oxygen and carbon components contained in the high-purity fluoride are reduced by a fluorine gas treatment.

Owner:STELLA CHEMIFA CORP

Method for reducing oxygen component and carbon component in fluoride

InactiveCN1491300AAdd lessAdvances in Thin Film TechnologyPolycrystalline material growthAfter-treatment detailsYtterbium fluorideRare earth

To provide a method for reducing oxygen and carbon components in high-purity fluoride such as calcium fluoride and barium fluoride (high-purity fluoride is not limited to calcium fluoride and barium fluoride), or in rare-earth fluoride such as ytterbium fluoride and cerium fluoride used for an optical fiber, a coating material, and so on. It is characterized in that the oxygen and carbon components contained in the high-purity fluoride are reduced by a fluorine gas treatment.

Owner:STELLA CHEMIFA CORP

Preparation method of composite hard sheet for tropical bubble cap package

ActiveCN106696427AExcellent low temperature curingMeet the development applicationLamination ancillary operationsLayered product treatmentPolyesterPolymer science

The invention relates to a preparation method of a composite hard sheet for tropical bubble cap package. The preparation method comprises the specific steps that a mixture of titanium dioxide, ytterbium fluoride and zirconia is calcined after being ball-milled to obtain a filler; dihexylamine and the filler are mixed, and then N-formyl morpholine, diethyl phosphonate and benzimidazole are mixed; diisoprene bicyclo oxide, polyamide and ethoxylated trimethylolpropane triacrylate are sequentially added into the mixture, and stirring is performed at the temperature of 170 DEG C for 5 minutes to obtain a compound; the compound is added to an extruder; then, a polyester film with the surface subjected to corona treatment is prepared into a composite polyester film through the extruder; the composite polyester film and an aluminum foil are subjected to hot-pressing compounding to obtain an aluminum plastic material; then the aluminum plastic material is prepared into the composite hard sheet for tropical bubble cap package through the extruder. The raw materials adopted in the preparation method are wide in source, the preparation process is simple and controllable, only conventional operation is needed, and industrialization is easy.

Owner:JIANGSU ZHENMEI PACKAGING TECH

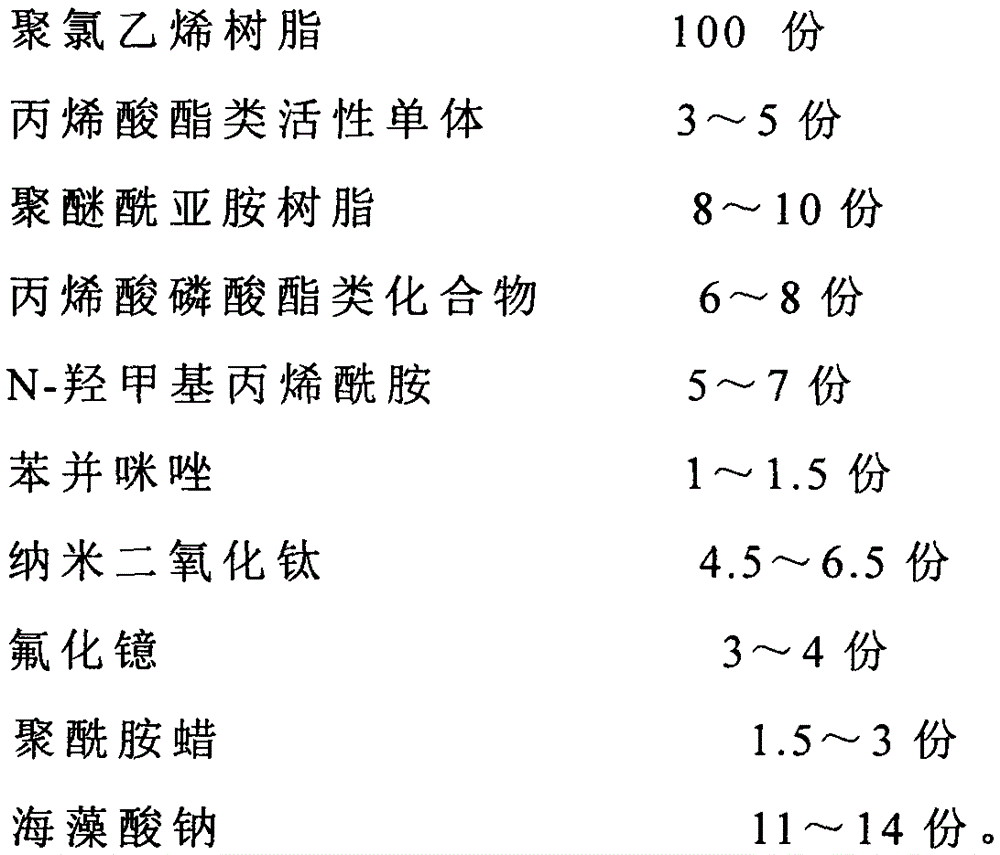

Self-moisture-absorption cold-forming polyvinyl chloride composite material for packaging drugs and preparation method of self-moisture-absorption cold-forming polyvinyl chloride composite material

The invention discloses a self-moisture-absorption cold-forming polyvinyl chloride composite material for packaging drugs, and a preparation method of the self-moisture-absorption cold-forming polyvinyl chloride composite material. The preparation method comprises the following steps: successively adding an acylate-phosphate compound, an acrylate active monomer and N-hydroxymethyl acrylamide into a container, and reacting for 2 hours at 90 DEG C; adding benzimidazole and polyamide wax, and reacting for one hour at 120 DEG C; adding nano titanium dioxide and sodium alginate, and reacting for 0.5 hour at 140 DEG C; naturally cooling to obtain a modifier; mixing the modifier, polyvinyl chloride resin, polyetherimide resin and ytterbium fluoride in a screw extruder, and extruding to obtain polyvinyl chloride composite particles; and performing calendaring molding on the polyvinyl chloride composite particles to obtain the self-moisture-absorption cold-forming polyvinyl chloride composite material for packaging the drugs. The self-moisture-absorption cold-forming polyvinyl chloride composite material solves the problems that the existing polyvinyl chloride transparent membrane is poor in adhesion and low in moisture absorption rate, can meet the requirement of the drug packaging industry and facilitates the prolonging of the drug quality guarantee period.

Owner:真美包装科技泰州有限公司

A kind of mid-wave infrared anti-reflection film on silicon substrate and preparation method thereof

ActiveCN110146943BHigh transmittance requirementsImprove transmittanceOptical elementsEvaporation (deposition)Imaging quality

The invention discloses a medium-wave infrared antireflection film on a silicon substrate. The antireflection film uses germanium (Ge) as a high-refractive-index coating material, and uses zinc sulfide (ZnS) and ytterbium fluoride (YbF3) as low-refractive-index coating materials; optical film plating is performed by using a PVD method; and by adopting ion source assisted deposition and specific material evaporation process conditions, 5 irregular film layers are deposited on the two surfaces of the substrate. The antireflection film can enable a silicon window to have an excellent light-transmitting effect within a wavelength range of 3-5 microns, and the average transmittance is greater than 98%. The optical efficiency of an uncooled infrared focal plane detector can be effectively improved, and the imaging quality of an infrared thermal imager is improved. The substrate is a silicon wafer and therefore can be applied to a wafer-level optical packaging window.

Owner:上海欧菲尔光电技术有限公司

Heat-resistant electronic membrane and preparation method thereof

The invention relates to a heat-resistant electronic membrane and a preparation method thereof. The preparation method includes the steps that a mixture of silicon dioxide, ytterbium fluoride, magnesium oxide, calcium carbonate, zirconia and zirconia is subjected to ball milling and calcination, and filler is obtained; amine compound and the filler are mixed for one hour, then N-formyl morpholine, a nitrogen compound and sodium iodide are added and mixed for two hours, and a mixture is obtained; bi-isoprene bicyclo oxide and 2,6-bi-(4-aminophenoxy) cyanobenzene are sequentially added to the mixture and stirred for 5 minutes t the temperature of 170 DEG C, and a compound is obtained; the compound is added to an extruder; then, a polyimide film with the surface subjected to corona treatment passes through the extruder at the speed of 1 m / min, the compound is applied to the polyimide film obtained after treatment through an extrusion die head, and the composite polyimide film is obtained; the heat-resistant electronic membrane is obtained after the composite polyimide film is subjected to forming treatment. The preparation method is wide in raw material source, simple and controllable in preparation process, only conventional operation is needed, and industrialization is facilitated.

Owner:WUJIANG XINTA FORWARD HARDWARE FACTORY

co 2 Laser anti-reflection film and preparation method thereof

ActiveCN112269220BLess heat productionExtended service lifeVacuum evaporation coatingSputtering coatingYtterbium fluorideZinc sulfide

The present disclosure provides a CO 2 Laser anti-reflection film and preparation method thereof, the CO 2 The laser anti-reflection coating is composed of a base layer, a first ytterbium fluoride layer, a first zinc sulfide layer, a second ytterbium fluoride layer and a second zinc sulfide layer, on the surface of the base layer along the thickness direction of the base layer The first ytterbium fluoride layer, the first zinc sulfide layer, the second ytterbium fluoride layer and the second zinc sulfide layer are arranged in sequence; the film thickness of the first ytterbium fluoride layer and the second fluoride The sum of the film thickness of the ytterbium oxide layer is greater than the sum of the film thickness of the first zinc sulfide layer and the film thickness of the second zinc sulfide layer. Therefore, through the design of the membrane structure, the CO 2 When the laser anti-reflection coating is used, its own heat generation is low and at the same time it achieves high transmittance to improve CO 2 The service life of the laser anti-reflection coating.

Owner:安徽中飞科技有限公司

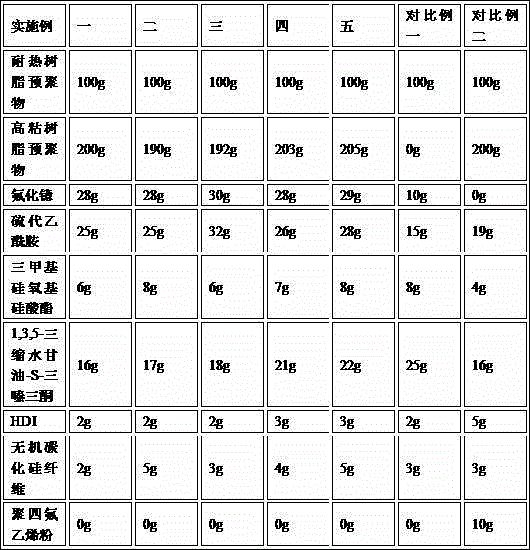

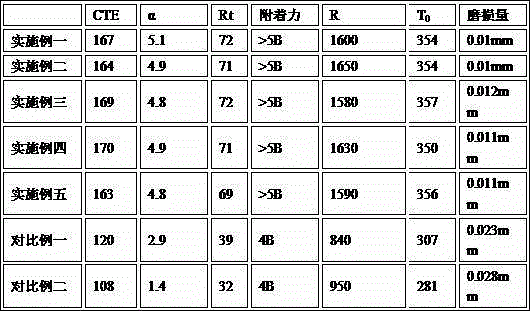

Wear-resistant composite material

The invention relates to a wear-resistant composite material. According to the invention, ytterbium fluoride, thioacetamide and trimethylsilyloxy silicate are well mixed, such that a mixture is obtained; 1,3,5-triglycidyl-S-triazine trione and inorganic fiber are added into the mixture, and the mixture is stirred for 4h; an isocyanate curing agent is added, and the mixture is stirred for 2h under a temperature of 60 DEG C; a heat-resistant resin prepolymer and a high-viscosity resin prepolymer are added into the mixture, and the mixture is stirred for 6h under a temperature of 120 DEG C, such that a mold pressing composition is obtained; the mold pressing composition is placed into a mold, and is subjected to a mold pressing process with conditions of 150 DEG C / 2h + 180 DEG C / 1h, such that the wear-resistant composite material is obtained. With the preparation method provided by the invention, the sources of raw materials are wide; the preparation process is simple and controllable; and only conventional operations are required. Therefore, the method is easy to industrialize.

Owner:SUZHOU KEMIAO NEW MATERIAL

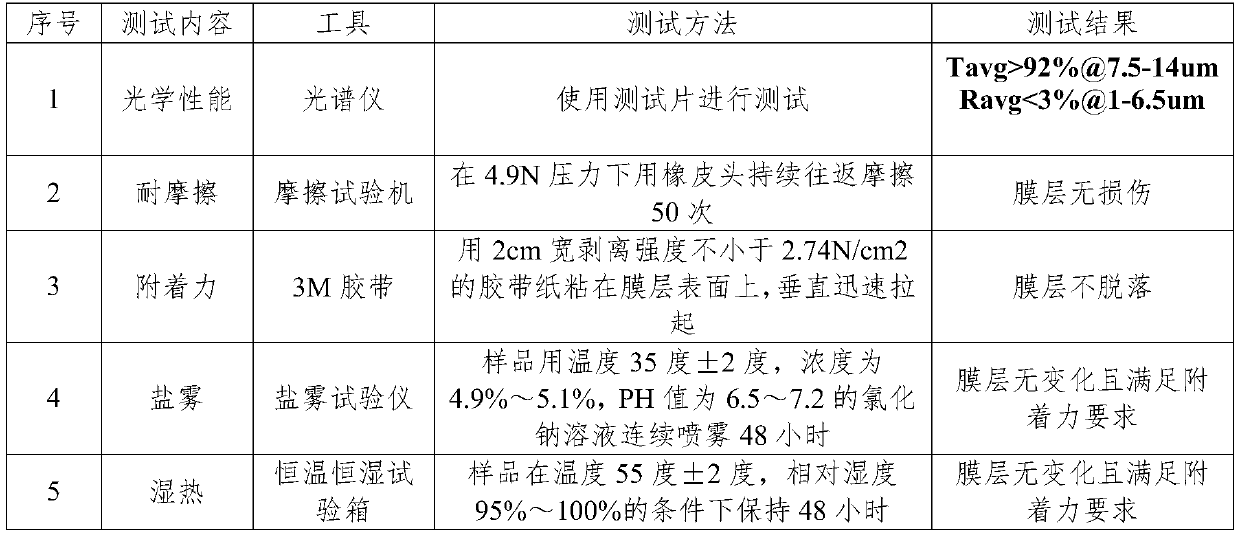

Far-infrared short-wave cut-off film for mould pressing of aspheric lens

InactiveCN111474617AImprove transmittanceHigh cut-off rateOptical filtersYtterbium fluorideAspheric lens

The invention relates to a far-infrared short-wave cut-off film for mould pressing of an aspheric lens. The far-infrared short-wave cut-off film comprises a first optical surface and a second opticalsurface, wherein the first optical surface comprises, by weight, 1-3 parts of yttrium oxide, 65-75 parts of ytterbium fluoride, 5-15 parts of zinc sulfide and 15-25 parts of germanium; and the secondoptical surface comprises, by weight, 1-3 parts of yttrium oxide, 50-60 parts of ytterbium fluoride, 30-40 parts of zinc sulfide and 10-20 parts of germanium. The high transmittance (7.5-14 [mu]m) andthe high cut-off rate (1-6.5 [mu]m) are achieved.

Owner:莱特巴斯光学仪器(镇江)有限公司

Visible infrared window antireflection film based on magnetron sputtering and preparation method

ActiveCN112609158AImprove surface qualityImprove stabilityVacuum evaporation coatingSputtering coatingFilm baseOptical thin film

The invention discloses a visible infrared window antireflection film based on magnetron sputtering and a preparation method, and belongs to the technical field of optical films. A magnetron sputtering coating method is mainly used, a conventional situation that efficient antireflection films are made of ytterbium fluoride, zinc sulfide and other soft film materials with low hardness is abandoned, but yttrium oxide, titanium oxide, aluminum oxide and other hard oxide protective films are used, and the visible, low-light and infrared common-window high-strength antireflection film capable of being used for a zinc sulfide base is formed through design optimization. The reflectivity of the film system can be 5% within the wave band range of 0.4-0.75um and 1.57 um, the transmittance of the film system can be larger than 92% within the wave band range of 7.4-10.7um, the surface quality and the firmness of a film layer are good, and the film system can resist friction tests specified in GJB2485-95 and test requirements of temperature, damp heat, salt mist and the like specified in GJB150A-2009.

Owner:江苏北方湖光光电有限公司

Visible infrared anti-counterfeiting coating and preparation method and application thereof

The present invention discloses a visible-infrared anti-counterfeiting coating and a preparation method and application thereof, the visible-infrared anti-counterfeiting coating comprises the following raw materials in parts by weight: 0.1-3% of a visible-infrared anti-counterfeiting composition, 1-3% of an anti-settling agent and 94-98.9% of ink or polyurethane paint or acrylate paint; and the visible-infrared anti-counterfeiting composition comprises sodium fluoride, fluoride yttrium and fluoride ytterbium. A visible-infrared anti-counterfeiting button prepared from the visible-infrared anti-counterfeiting coating may produce obvious bright spots visible to the naked eyes under infrared light irradiation, and has good anti-counterfeiting effect.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

A preparation method of rare earth-doped yttrium potassium fluoride upconversion luminescent nanomaterial

InactiveCN104327855BShort manufacturing cycleOvercome complex preparation processLuminescent compositionsQuantum yieldPotassium fluoride

The invention relates to a method for preparing a rare-earth doped potassium yttrium fluoride up-conversion luminescence nano material. The method comprises the following steps: 1) weighing yttrium oxide, sylvite and a fluorine source, adding in an oleic acid / oleylamine-containing solvent system, stirring and mixing, thus obtaining a first uniform solution; 2) weighing ytterbium fluoride and a rare-earth activator, adding in the oleic acid / oleylamine-containing solvent system, stirring and mixing, thus obtaining a second uniform solution; 3) rapidly heating the first uniform solution to a high temperature, and meanwhile rapidly filling the second uniform solution, and sufficiently stirring to react, thus obtaining a third uniform solution; and 4) cooling the obtained solution to room temperature, performing centrifugal separation, washing, and drying, thus obtaining the rare-earth doped potassium yttrium fluoride up-conversion luminescence nano material. The method has the beneficial effects that the preparation period of the material is effectively shortened, new ideas and ways are provided for preparing the up-conversion luminescence nano material, large-scale popularization and application are facilitated, and the purposes of controllable the monodisperse particle size, high quantum yield and the like are solved.

Owner:WUHAN UNIV OF TECH

Germanium antimony selenium infrared glass with antireflection film and preparation method thereof

ActiveCN105388542BImprove permeabilityReduce surface residual reflectivityOptical elementsYtterbium fluorideZinc sulfide

The invention discloses Ge-As-Se infrared glass with an anti-reflection film and a preparation method thereof. The Ge-As-Se infrared glass with the anti-reflection film comprises a Ge-As-Se infrared glass base layer, the Ge-As-Se infrared glass base layer is composed of 12% of Ge, 28% of As and 60% of Se by weight, and a first ytterbium fluoride layer, a first zinc sulfide layer, a second ytterbium fluoride layer and a second zinc sulfide layer are deposited on the Ge-As-Se infrared glass base layer successively. The Ge-As-Se infrared glass of the invention can effectively prevent the anti-reflection film from falloff, and the reflectivity of the infrared glass is reduced.

Owner:CHINA BUILDING MATERIALS ACAD

A preparation method of composite hard sheet for tropical blister packaging

ActiveCN106696427BExcellent low temperature curingMeet the development applicationLamination ancillary operationsLayered product treatmentPolyesterPolymer science

The invention relates to a preparation method of a composite hard sheet for tropical bubble cap package. The preparation method comprises the specific steps that a mixture of titanium dioxide, ytterbium fluoride and zirconia is calcined after being ball-milled to obtain a filler; dihexylamine and the filler are mixed, and then N-formyl morpholine, diethyl phosphonate and benzimidazole are mixed; diisoprene bicyclo oxide, polyamide and ethoxylated trimethylolpropane triacrylate are sequentially added into the mixture, and stirring is performed at the temperature of 170 DEG C for 5 minutes to obtain a compound; the compound is added to an extruder; then, a polyester film with the surface subjected to corona treatment is prepared into a composite polyester film through the extruder; the composite polyester film and an aluminum foil are subjected to hot-pressing compounding to obtain an aluminum plastic material; then the aluminum plastic material is prepared into the composite hard sheet for tropical bubble cap package through the extruder. The raw materials adopted in the preparation method are wide in source, the preparation process is simple and controllable, only conventional operation is needed, and industrialization is easy.

Owner:JIANGSU ZHENMEI PACKAGING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Film system structure of ZnS substrate with inverse 0.5-0.8[Mu]m visible light, laser with 1.064[Mu]m and transparent medium wave infrared colour separation with 3.7-4.8[Mu]m Film system structure of ZnS substrate with inverse 0.5-0.8[Mu]m visible light, laser with 1.064[Mu]m and transparent medium wave infrared colour separation with 3.7-4.8[Mu]m](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/ccf59059-14df-43e5-8333-0f40ea1f7297/HDA0000976674960000011.PNG)

![Film system structure of ZnS substrate with inverse 0.5-0.8[Mu]m visible light, laser with 1.064[Mu]m and transparent medium wave infrared colour separation with 3.7-4.8[Mu]m Film system structure of ZnS substrate with inverse 0.5-0.8[Mu]m visible light, laser with 1.064[Mu]m and transparent medium wave infrared colour separation with 3.7-4.8[Mu]m](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/ccf59059-14df-43e5-8333-0f40ea1f7297/HDA0000976674960000012.PNG)

![Film system structure of ZnS substrate with inverse 0.5-0.8[Mu]m visible light, laser with 1.064[Mu]m and transparent medium wave infrared colour separation with 3.7-4.8[Mu]m Film system structure of ZnS substrate with inverse 0.5-0.8[Mu]m visible light, laser with 1.064[Mu]m and transparent medium wave infrared colour separation with 3.7-4.8[Mu]m](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/ccf59059-14df-43e5-8333-0f40ea1f7297/HDA0000976674960000021.PNG)