Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

266 results about "Zirconium nitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zirconium nitride (ZrN) is an inorganic compound used in a variety of ways due to its properties.

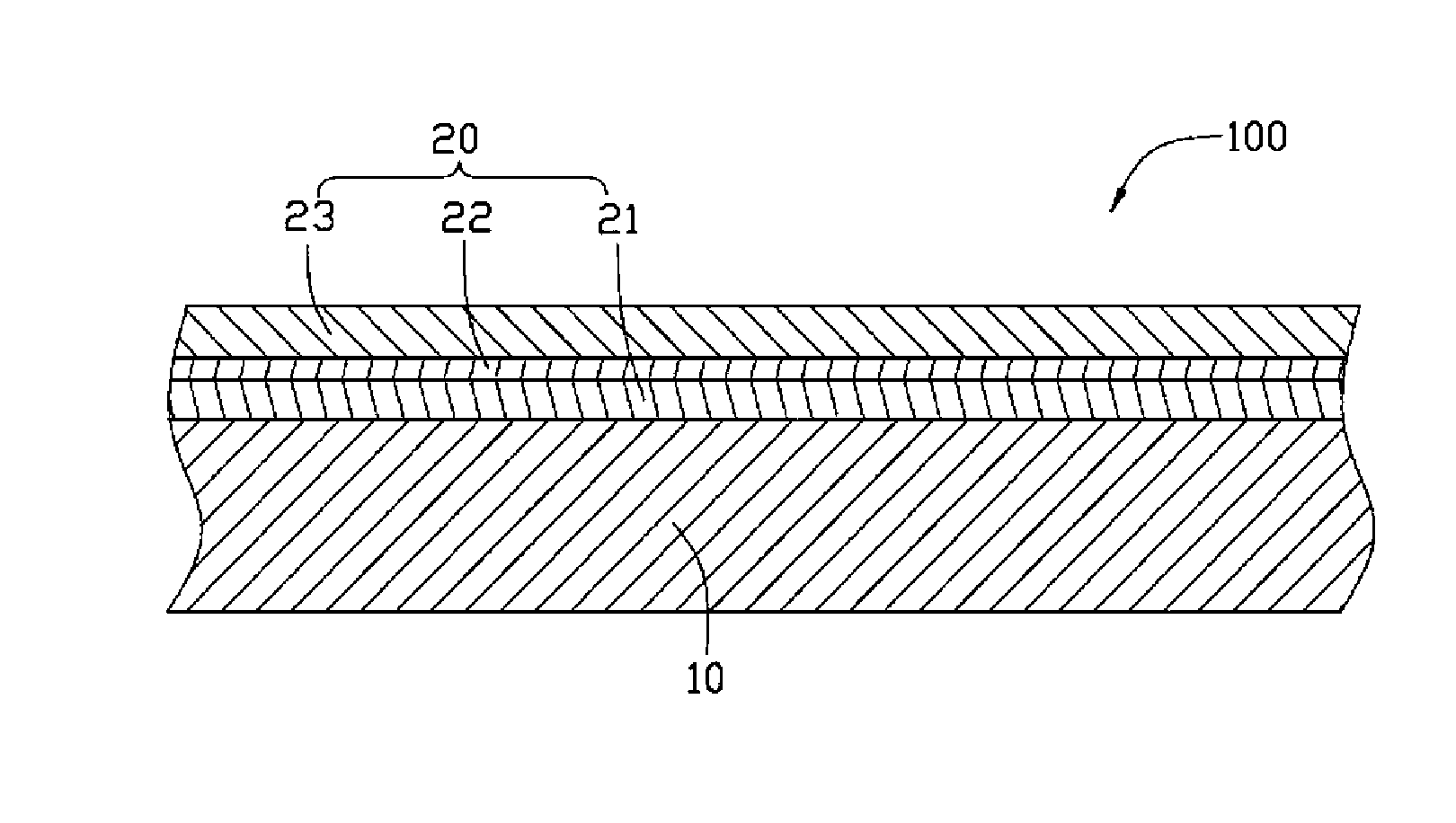

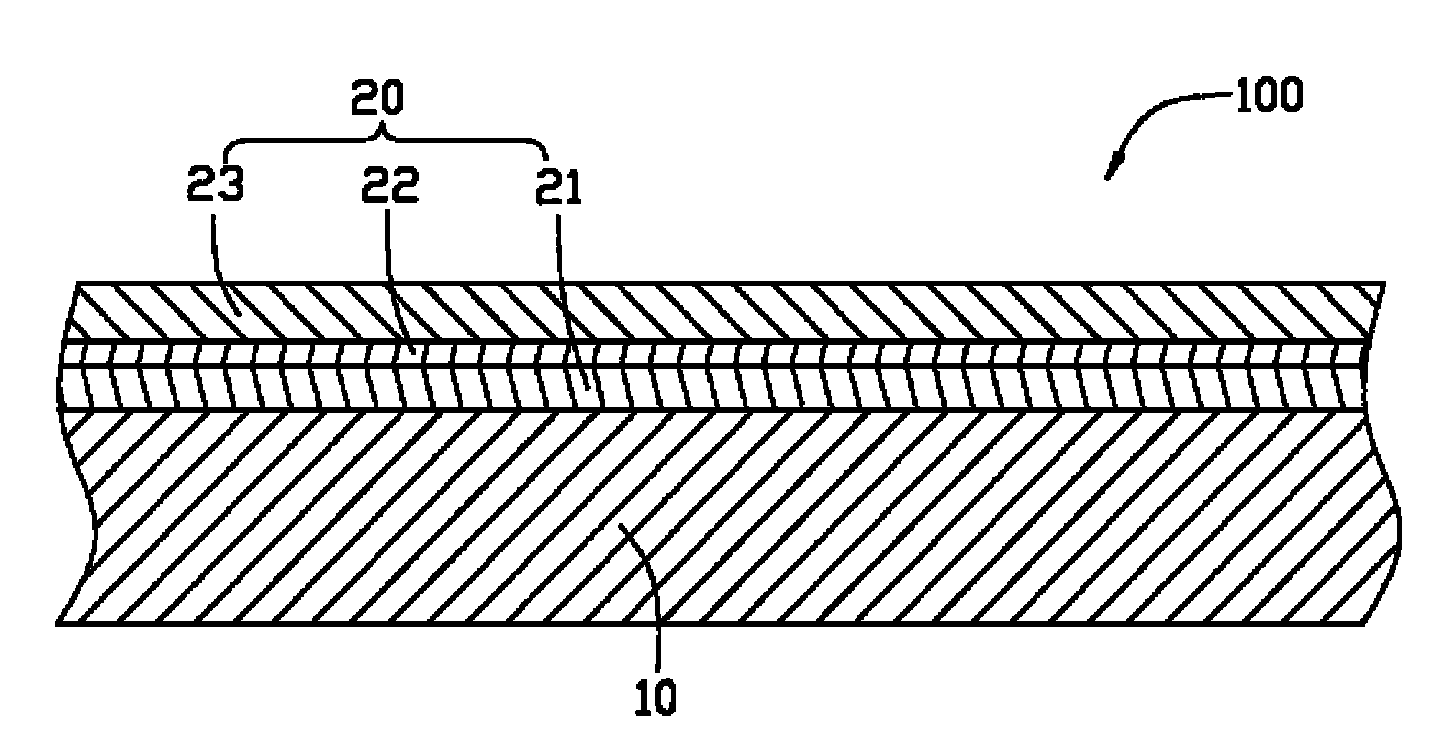

Heat treatable coated article with diamond-like carbon (DLC) and/or zirconium in coating

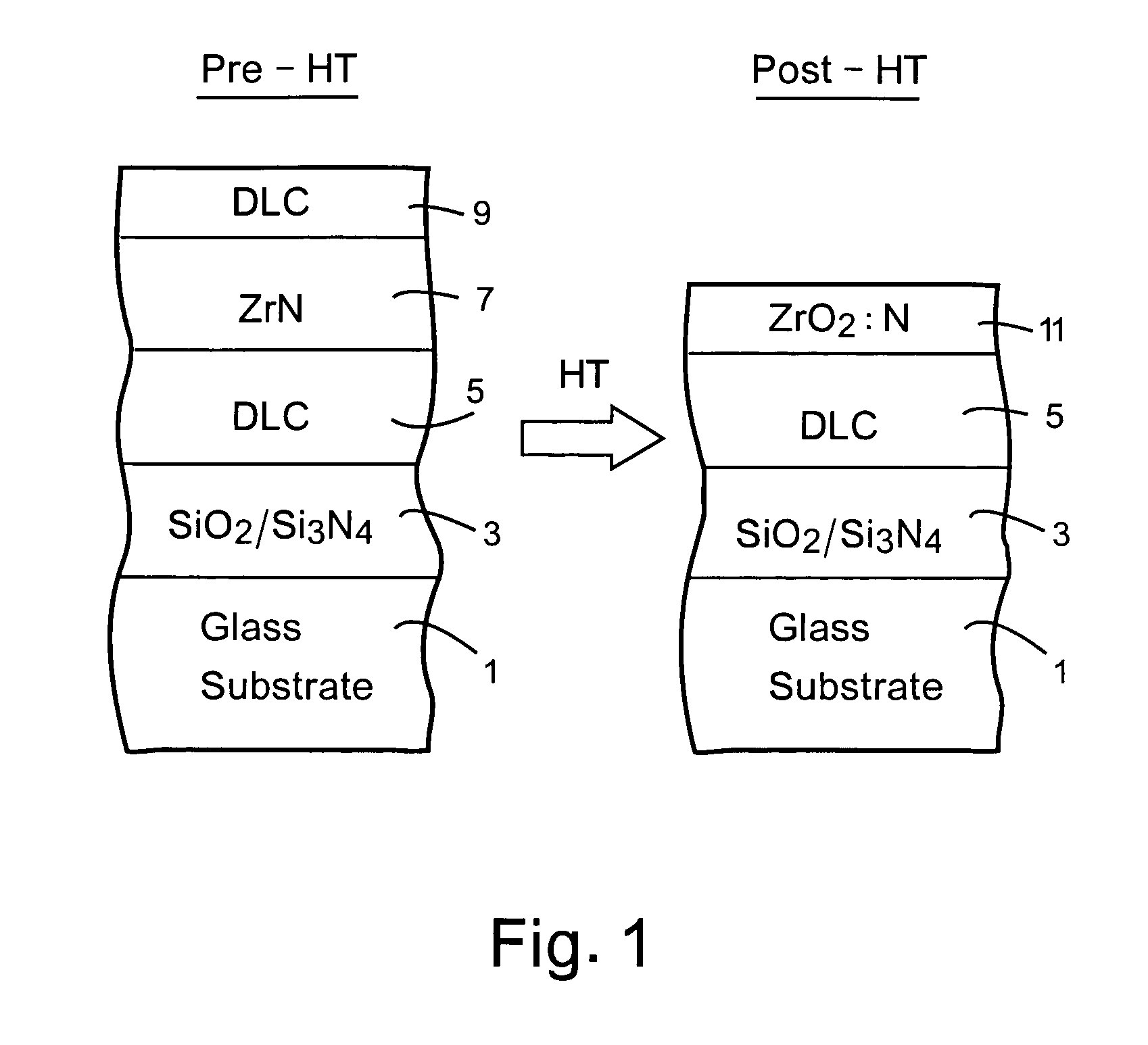

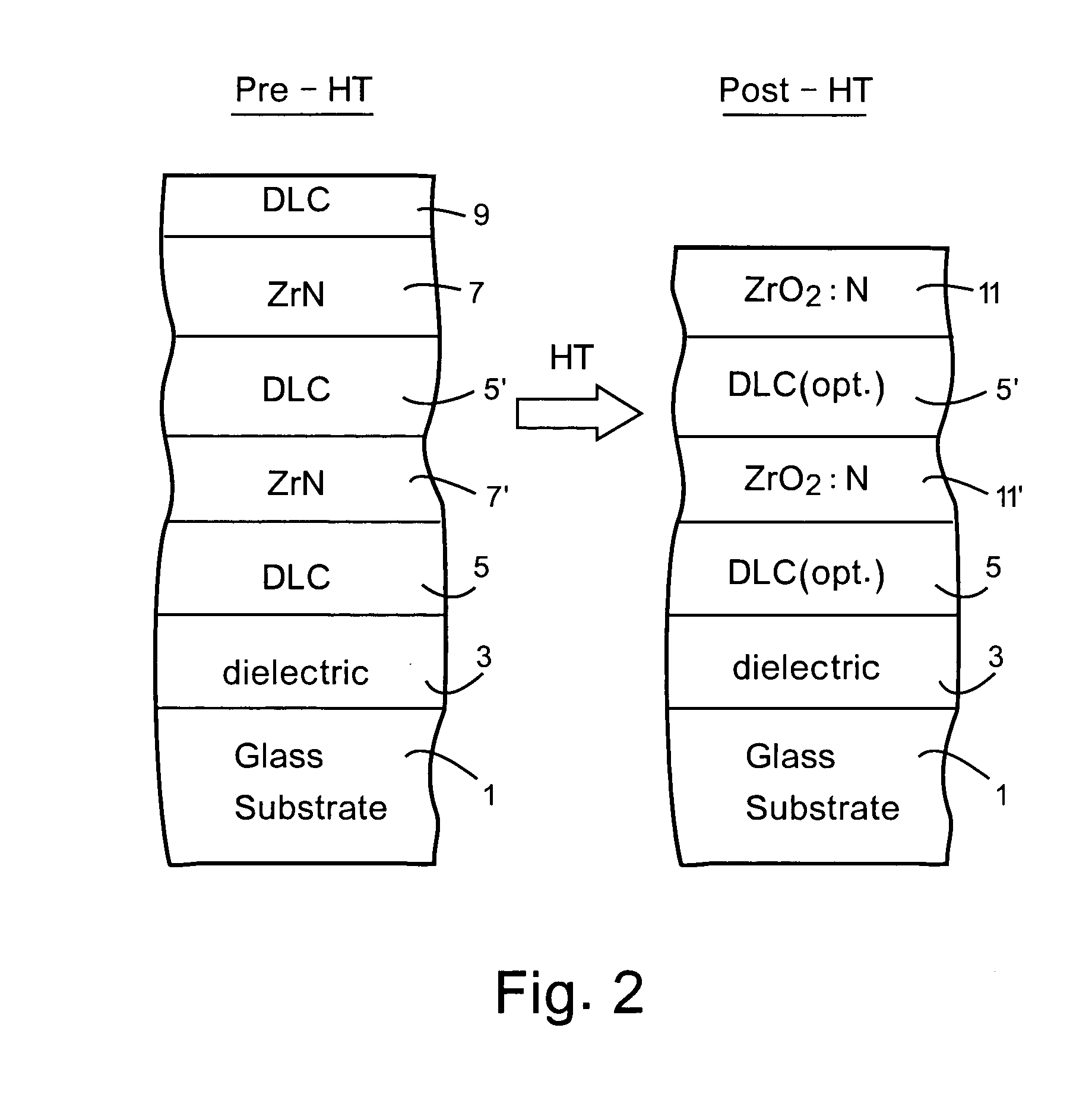

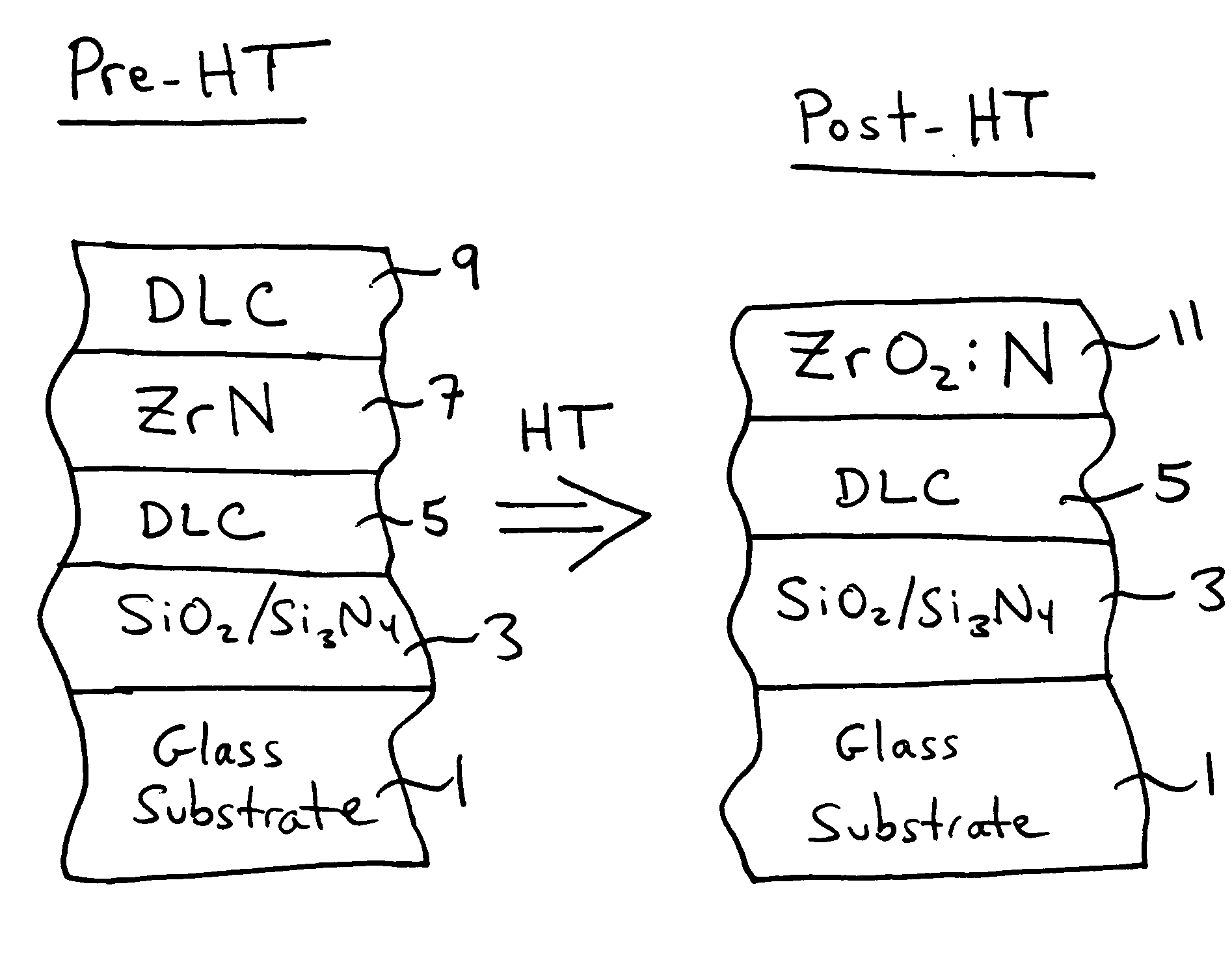

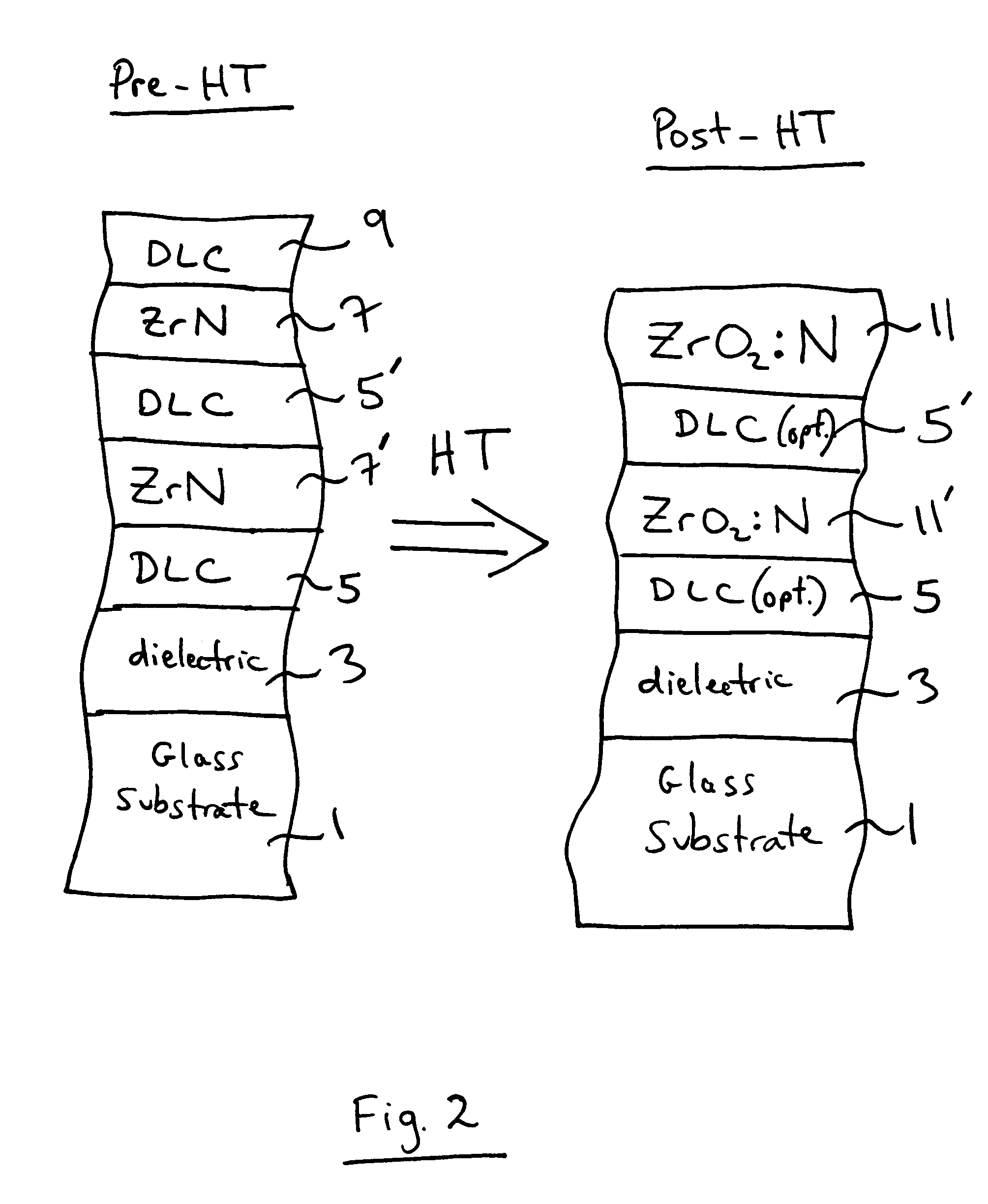

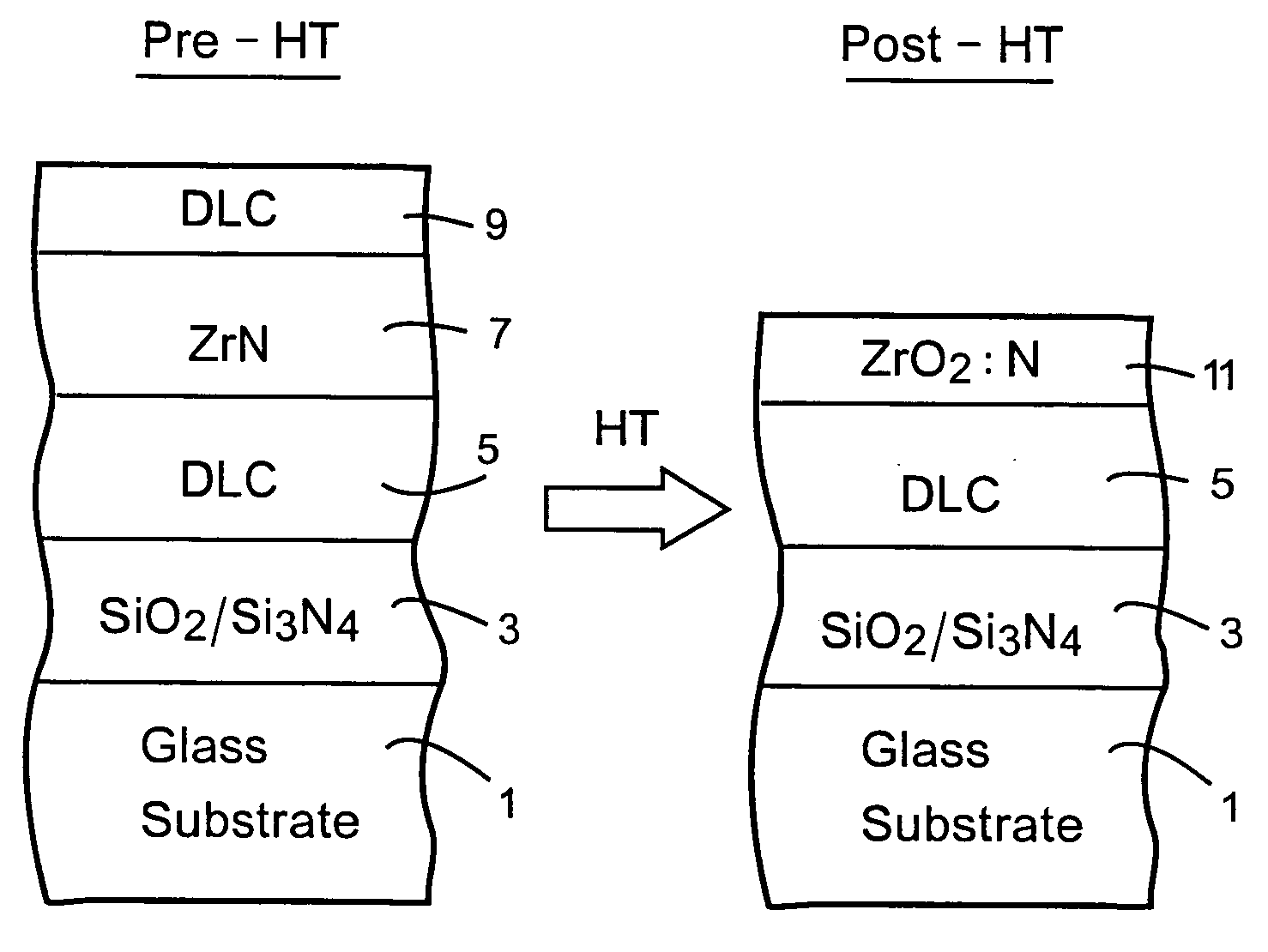

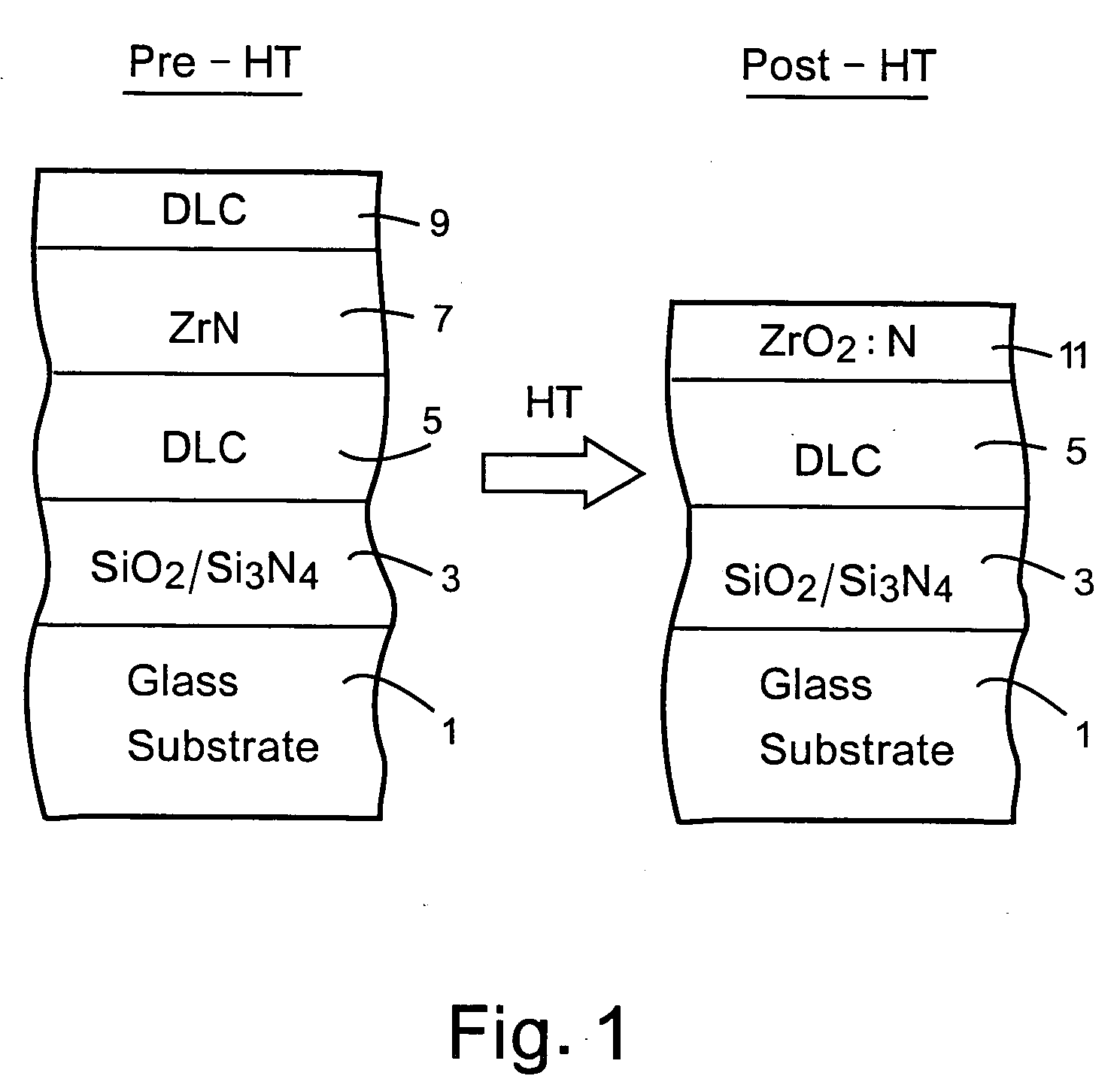

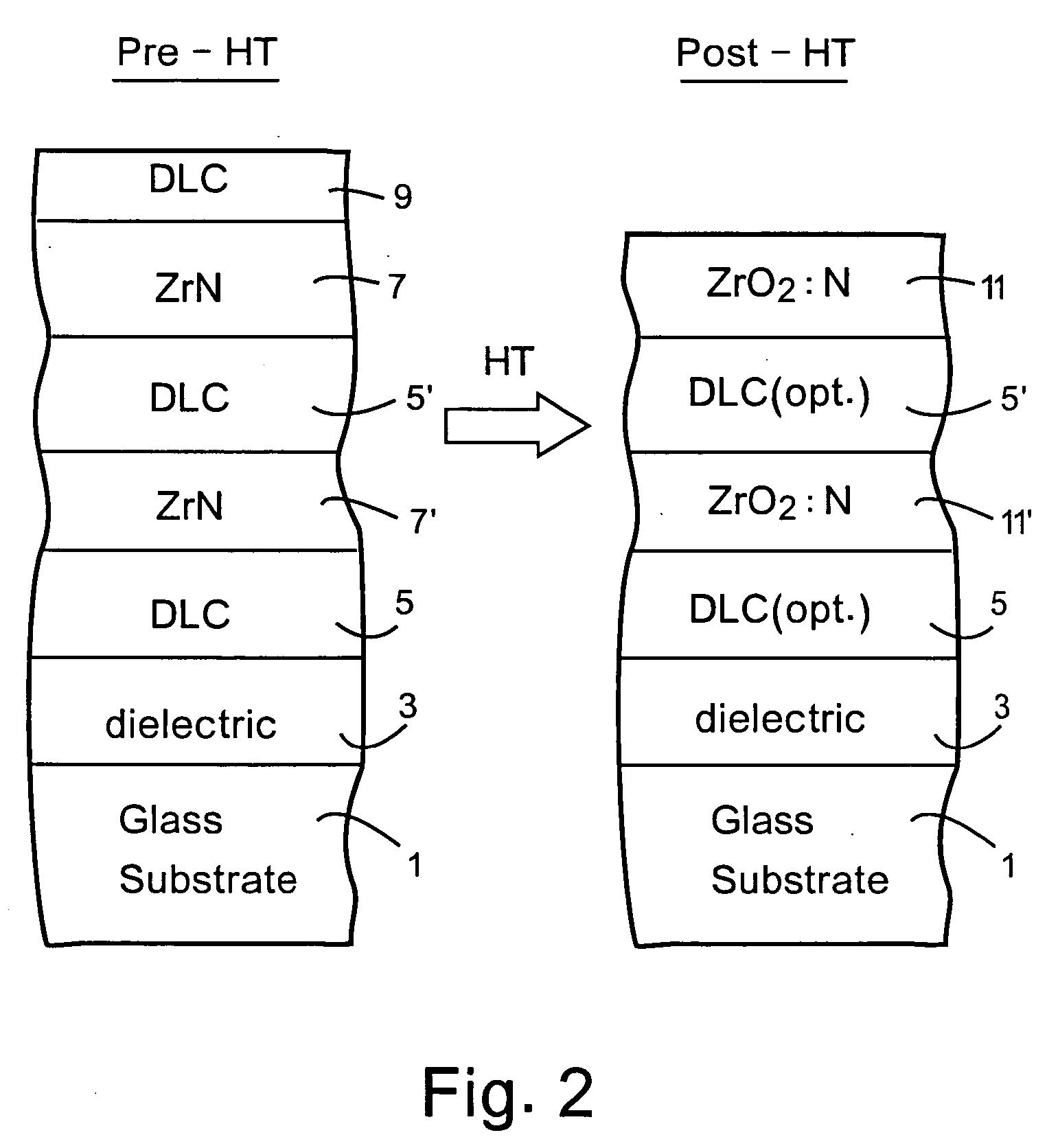

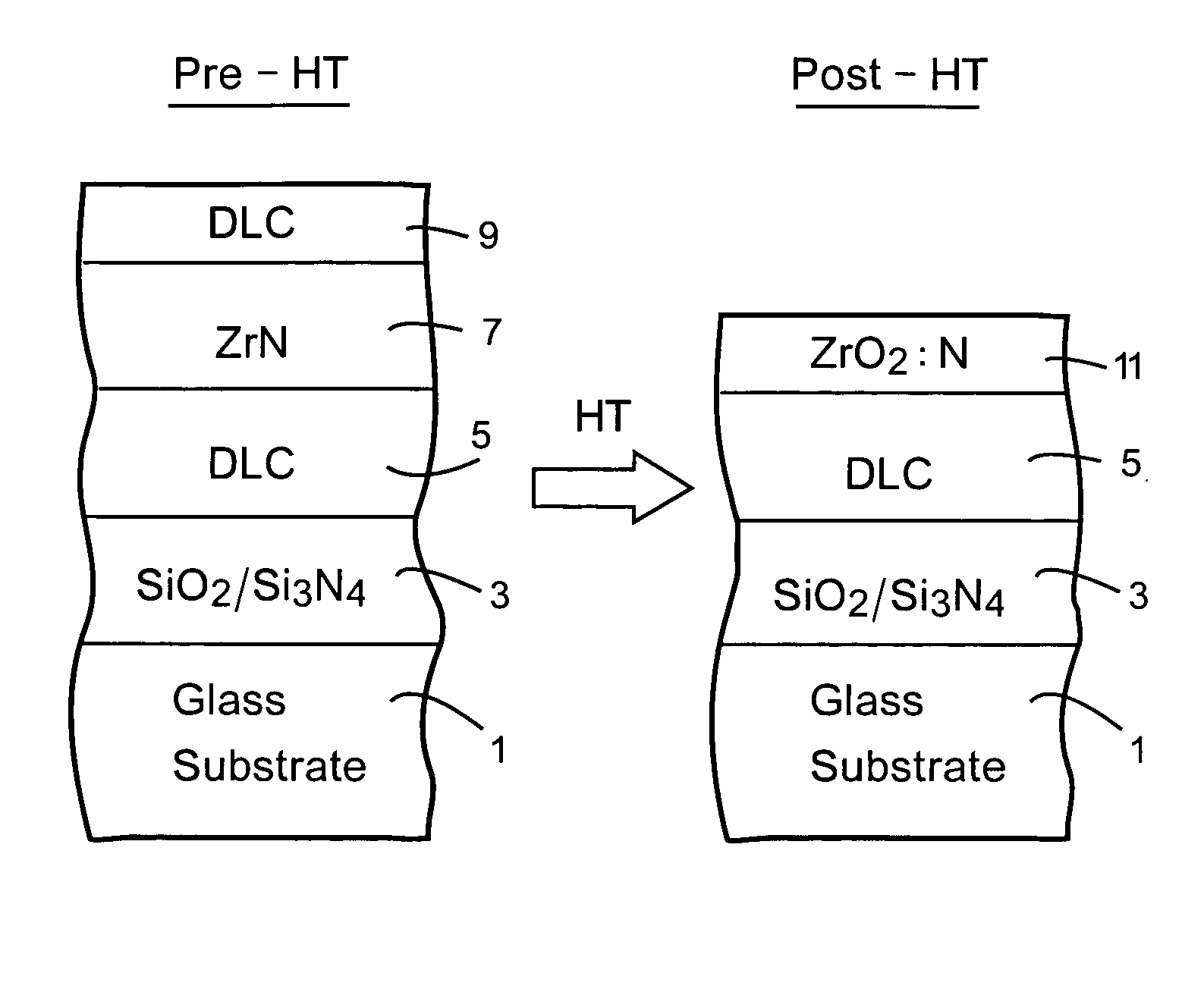

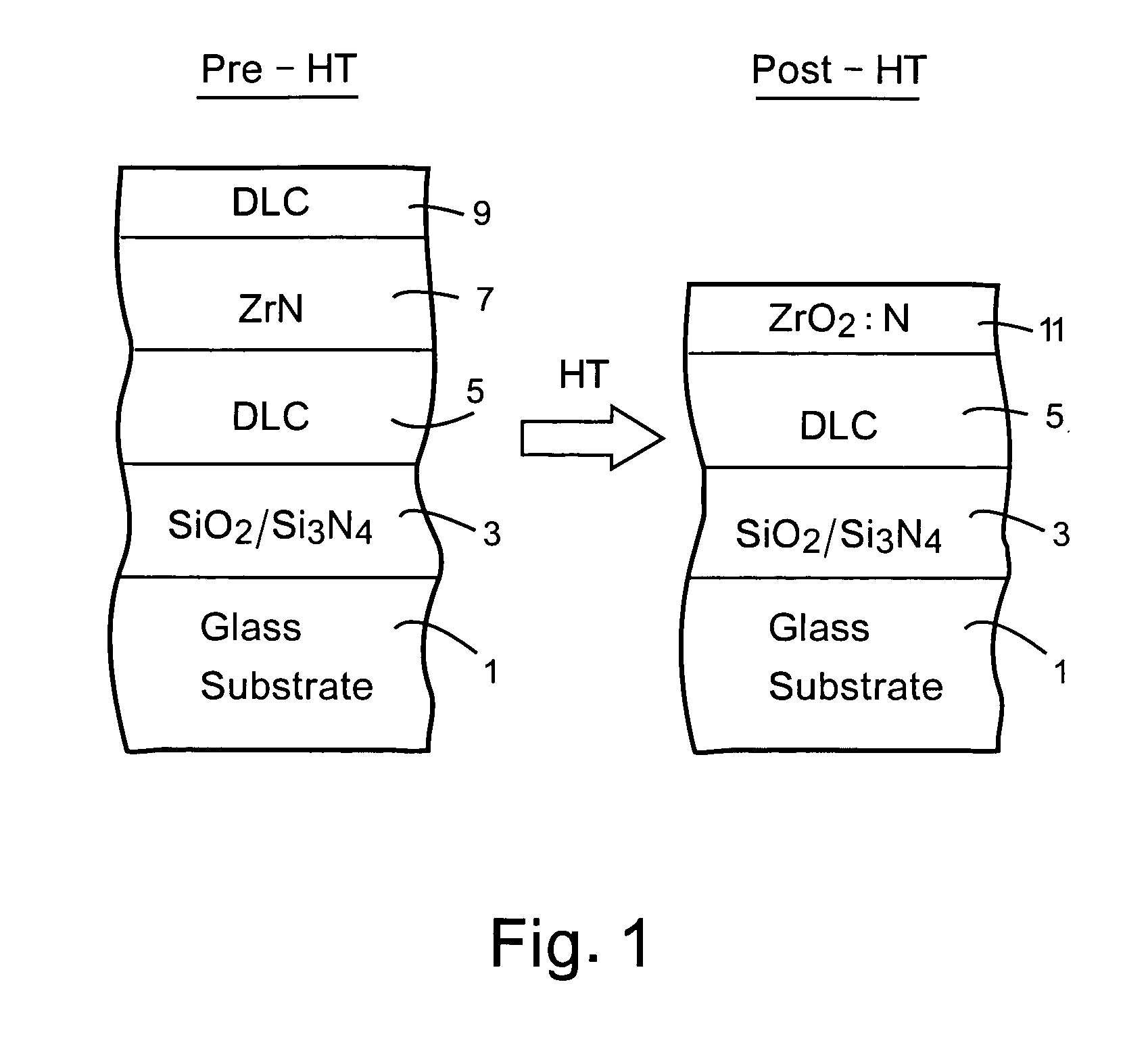

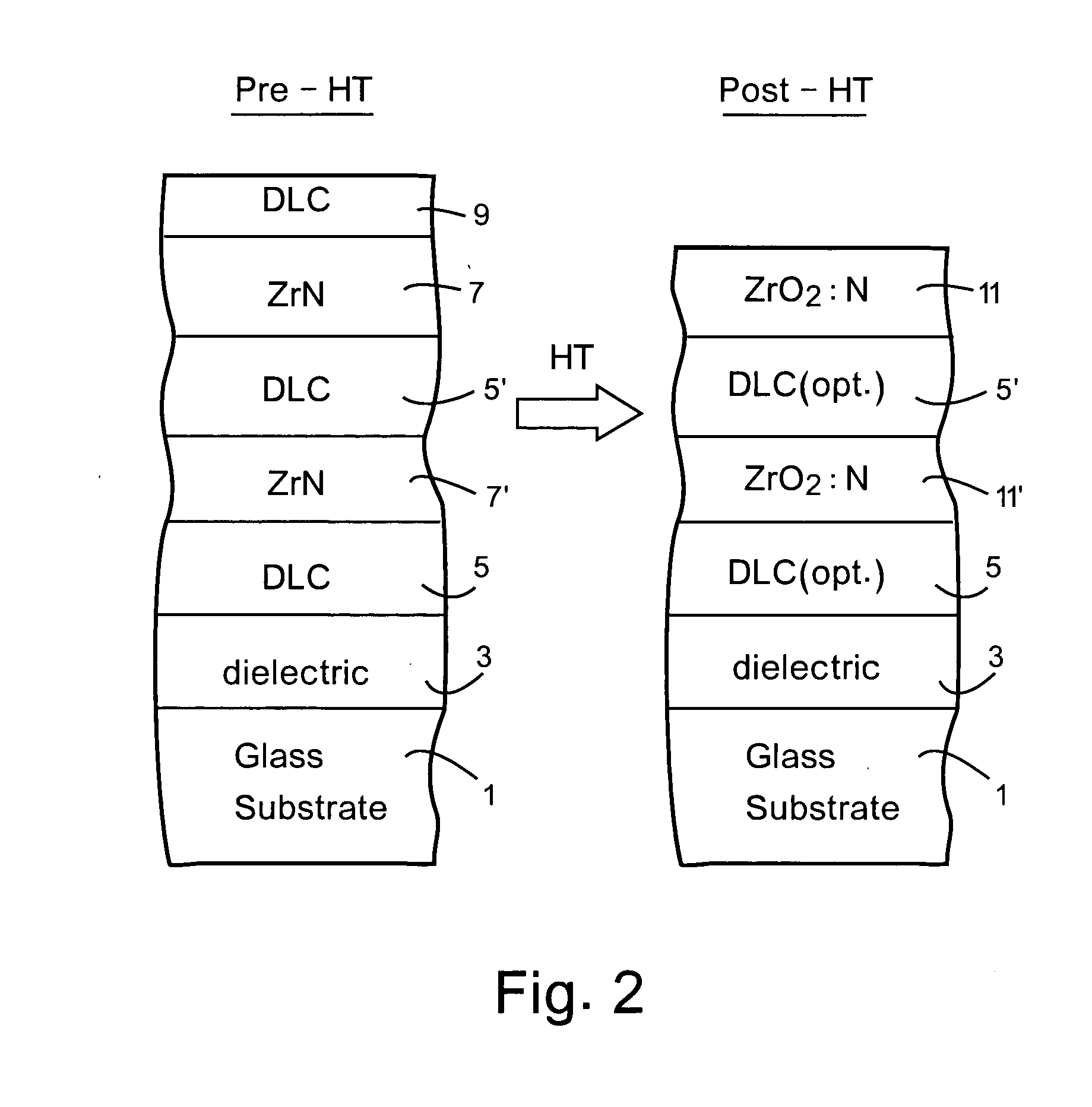

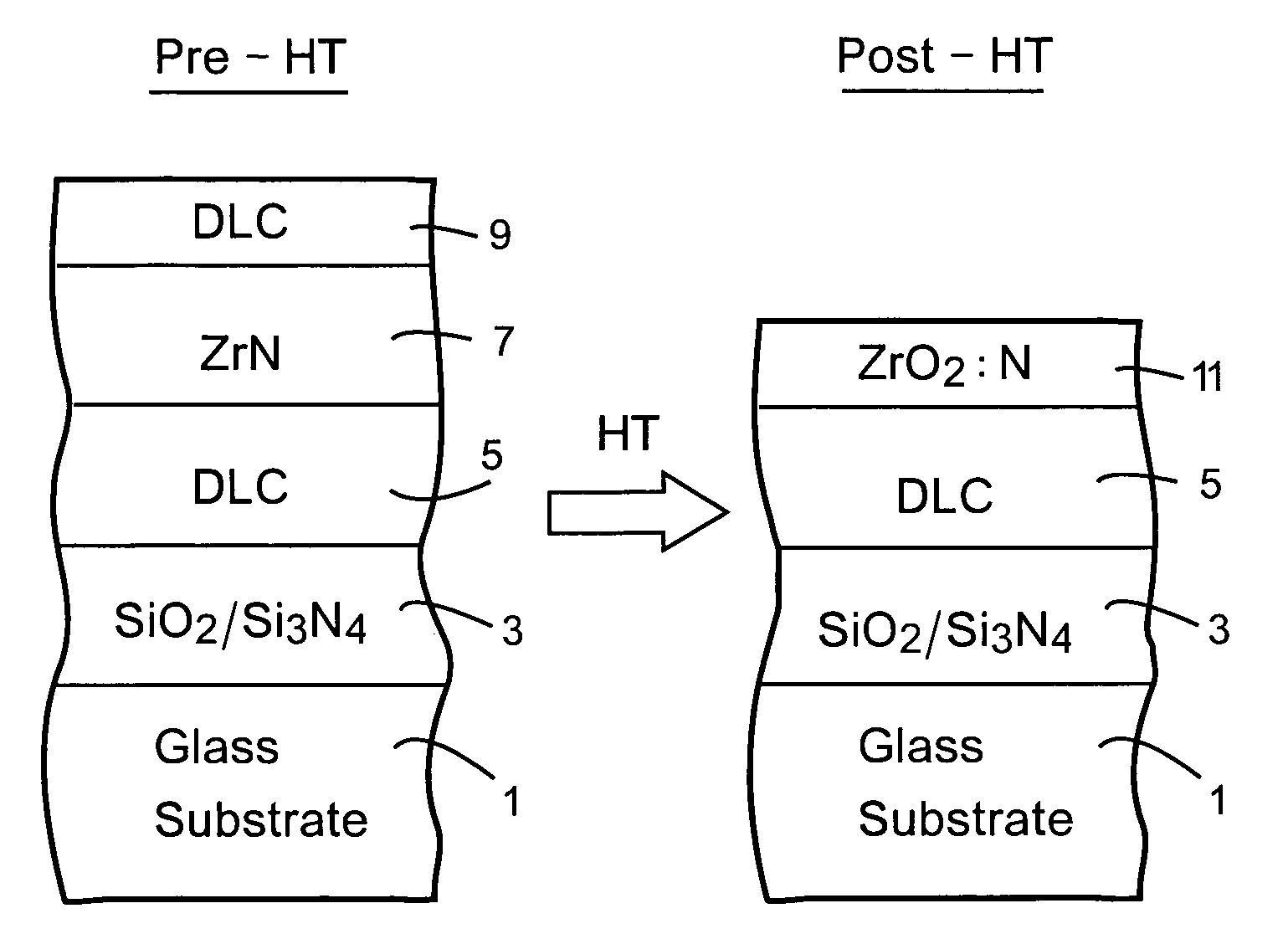

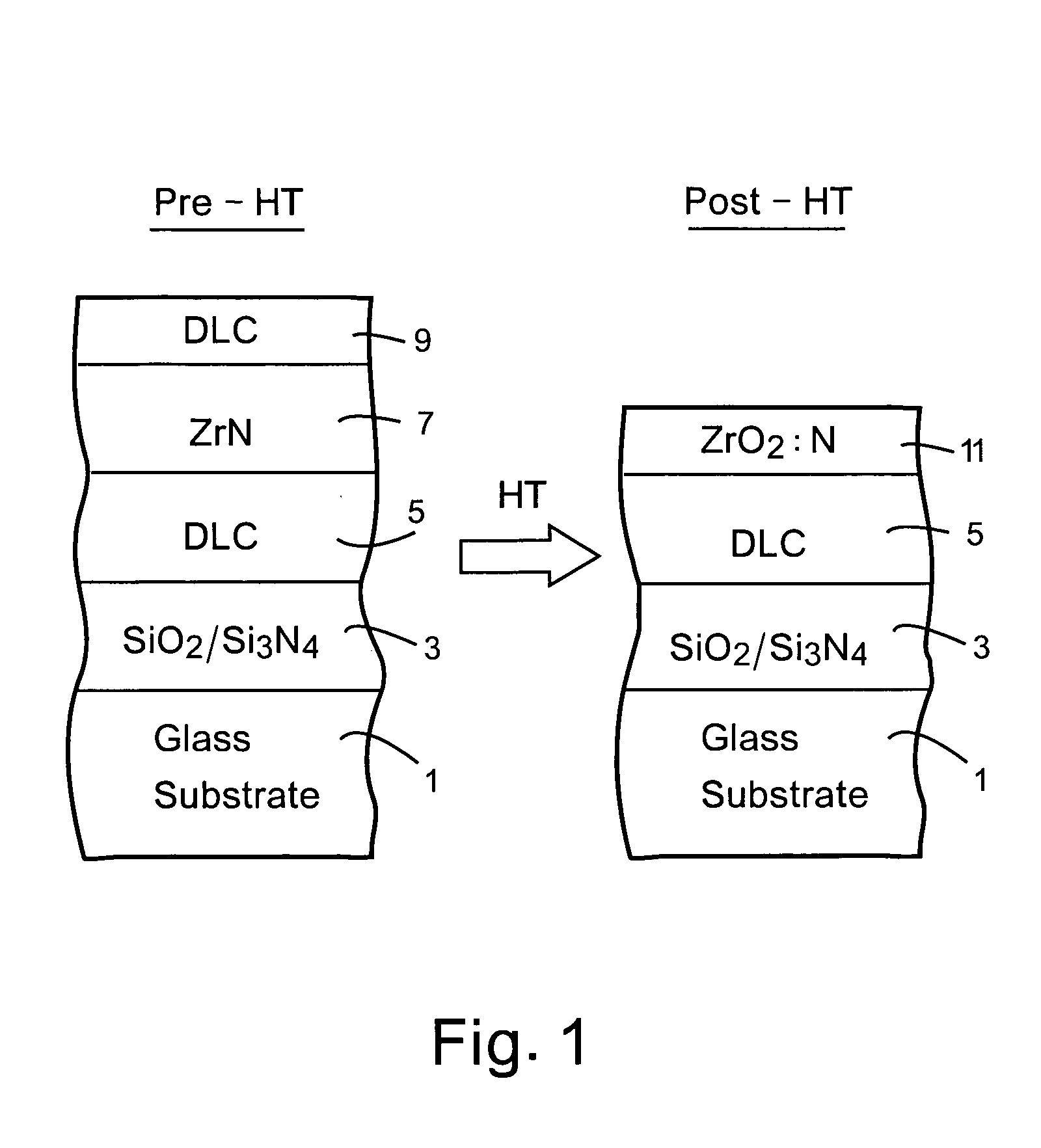

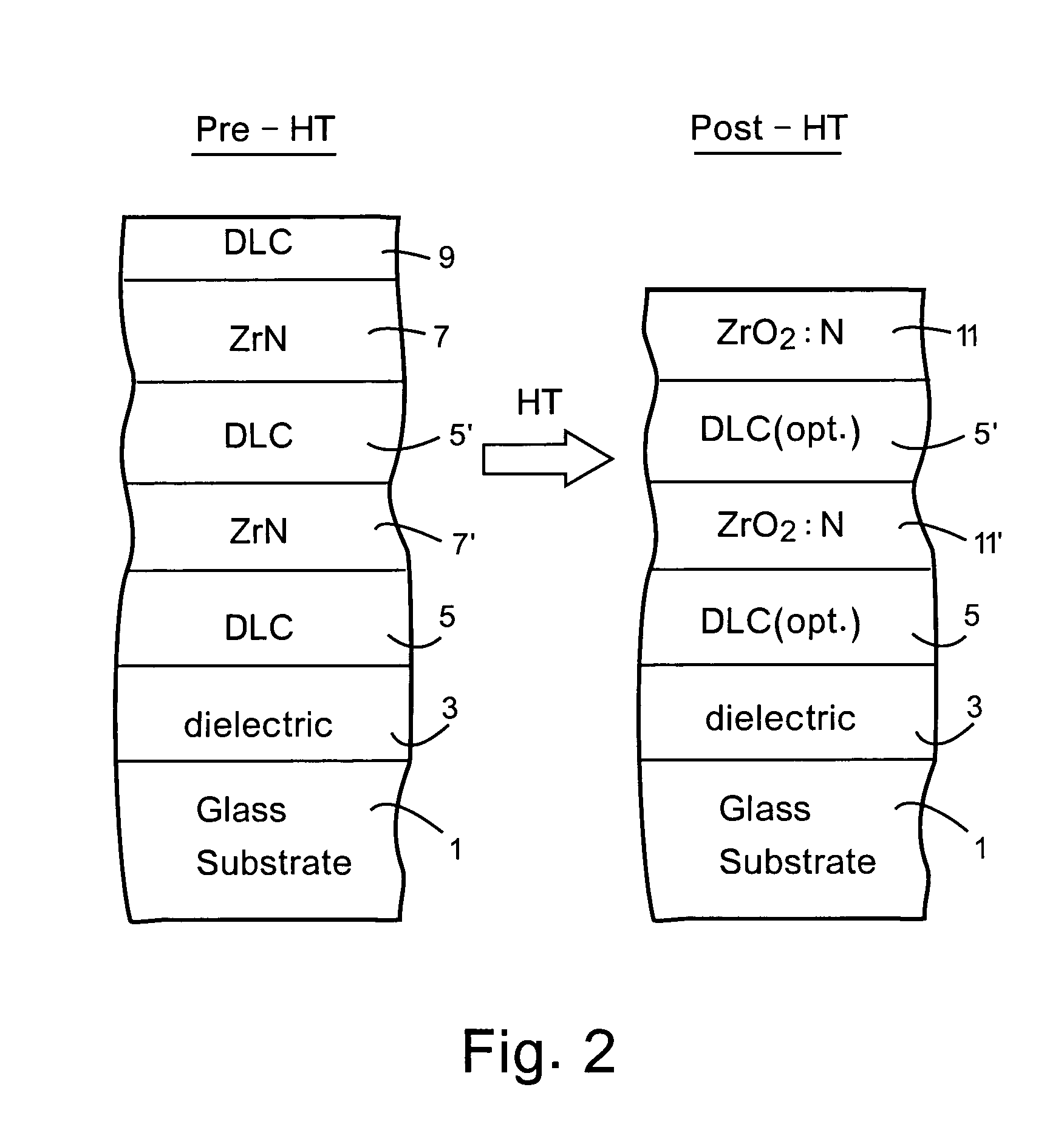

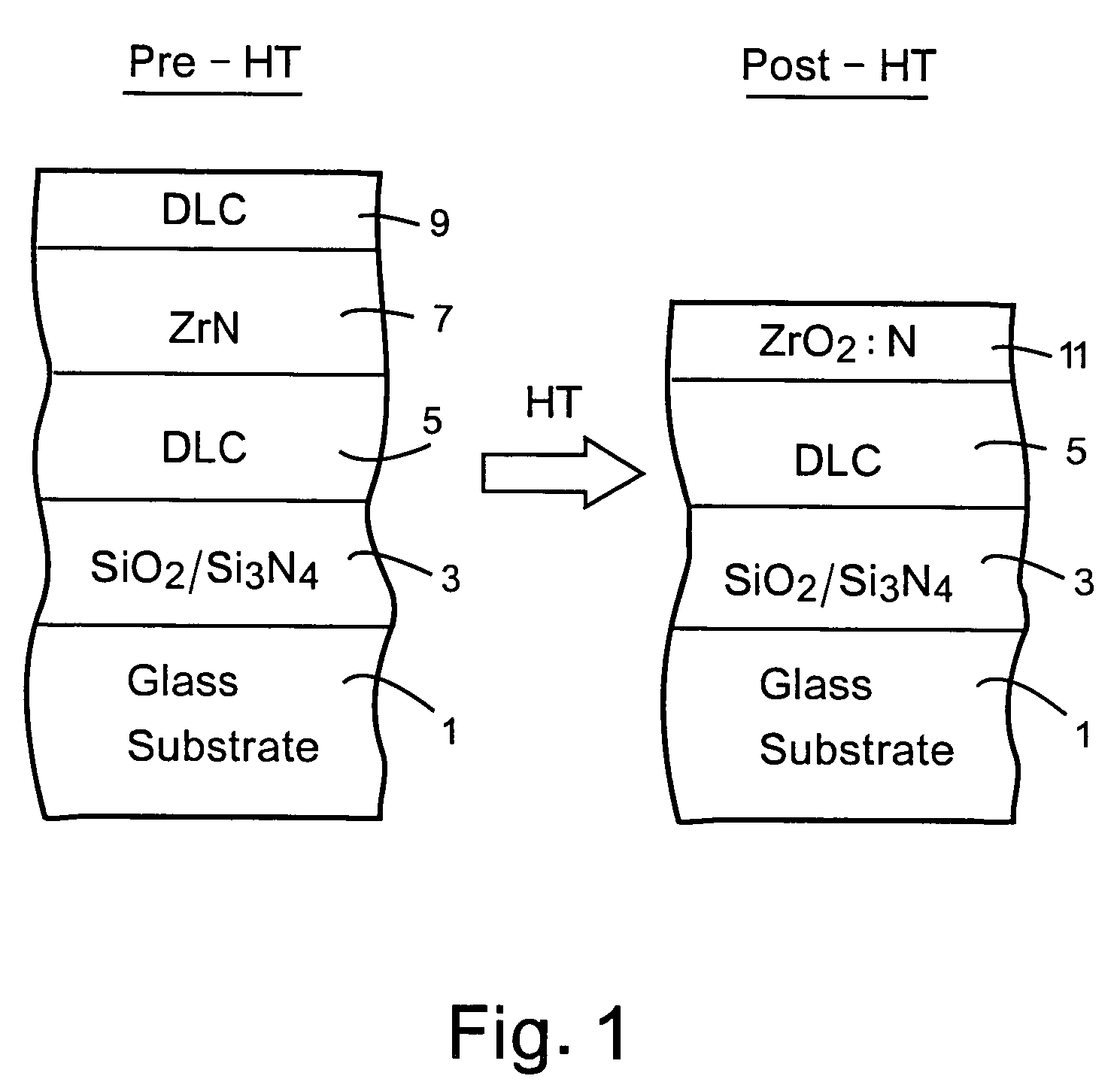

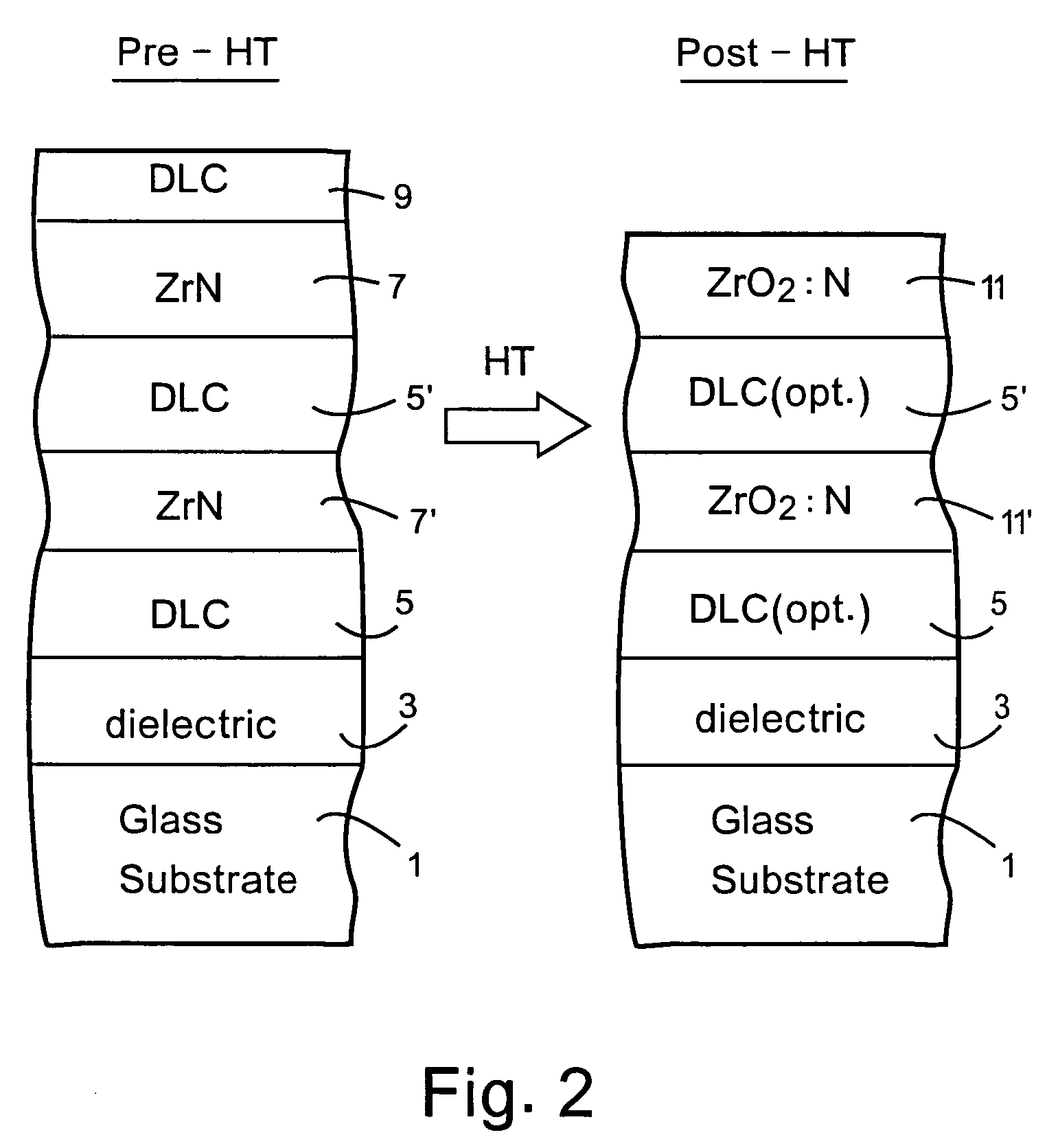

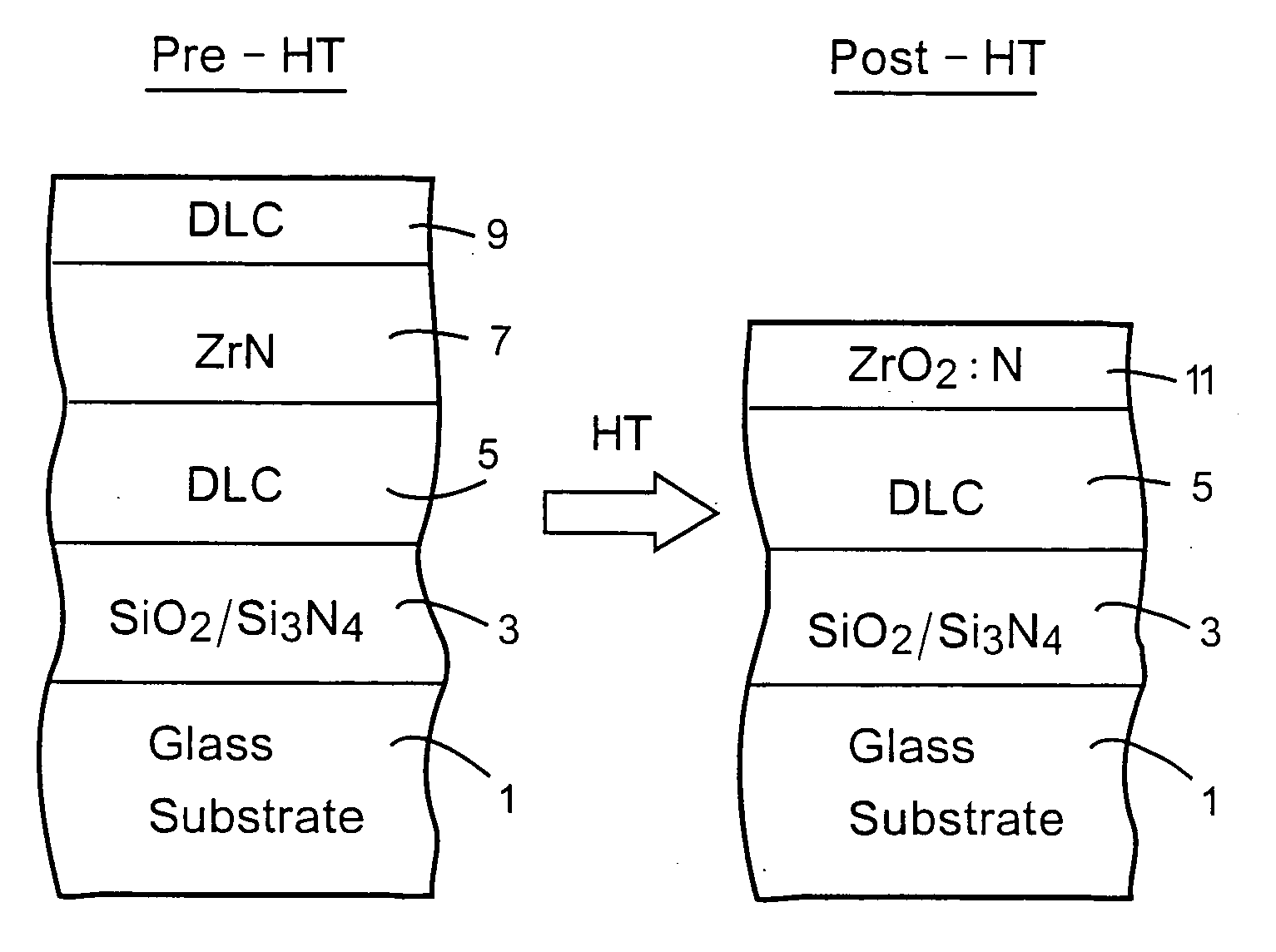

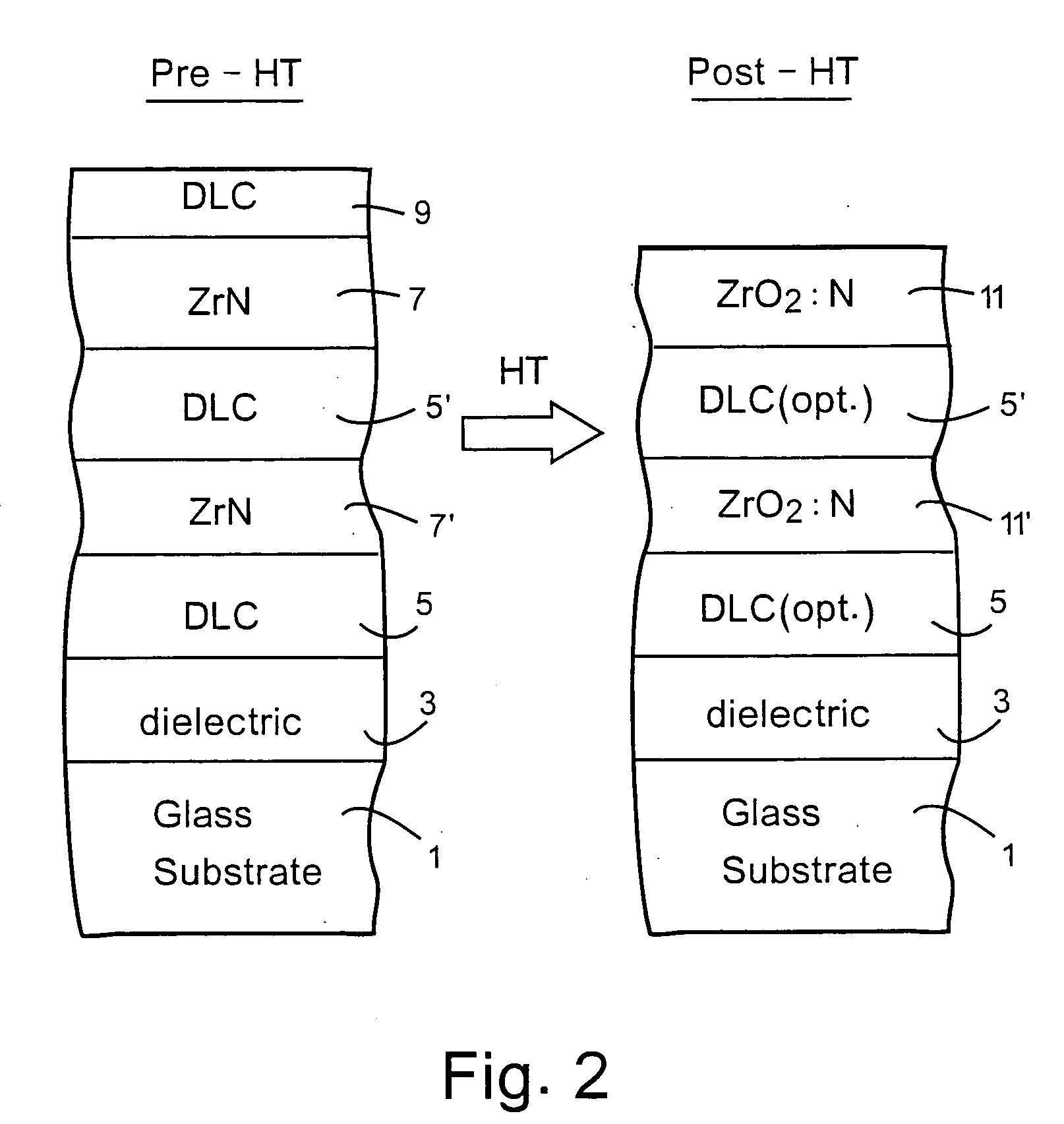

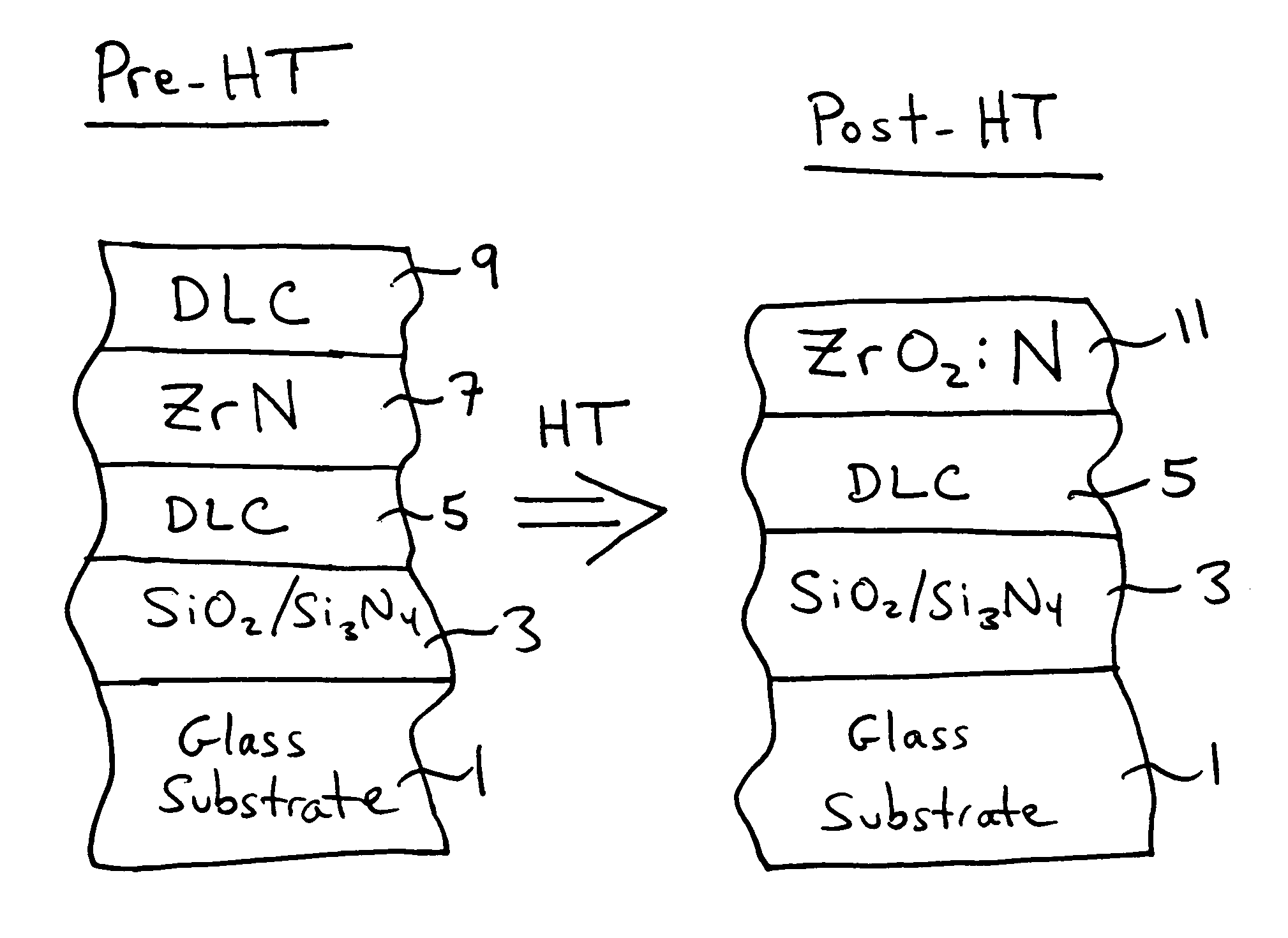

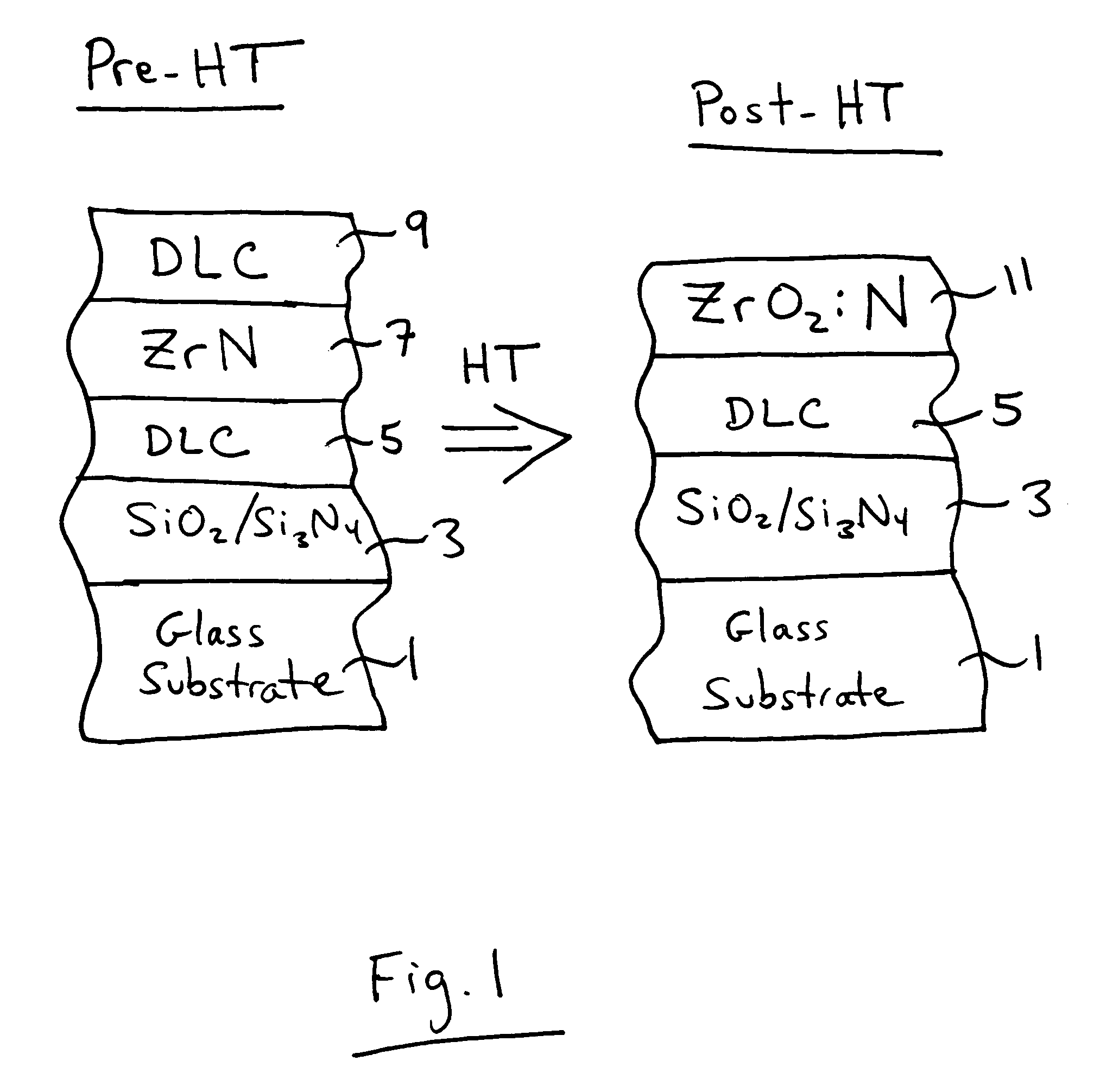

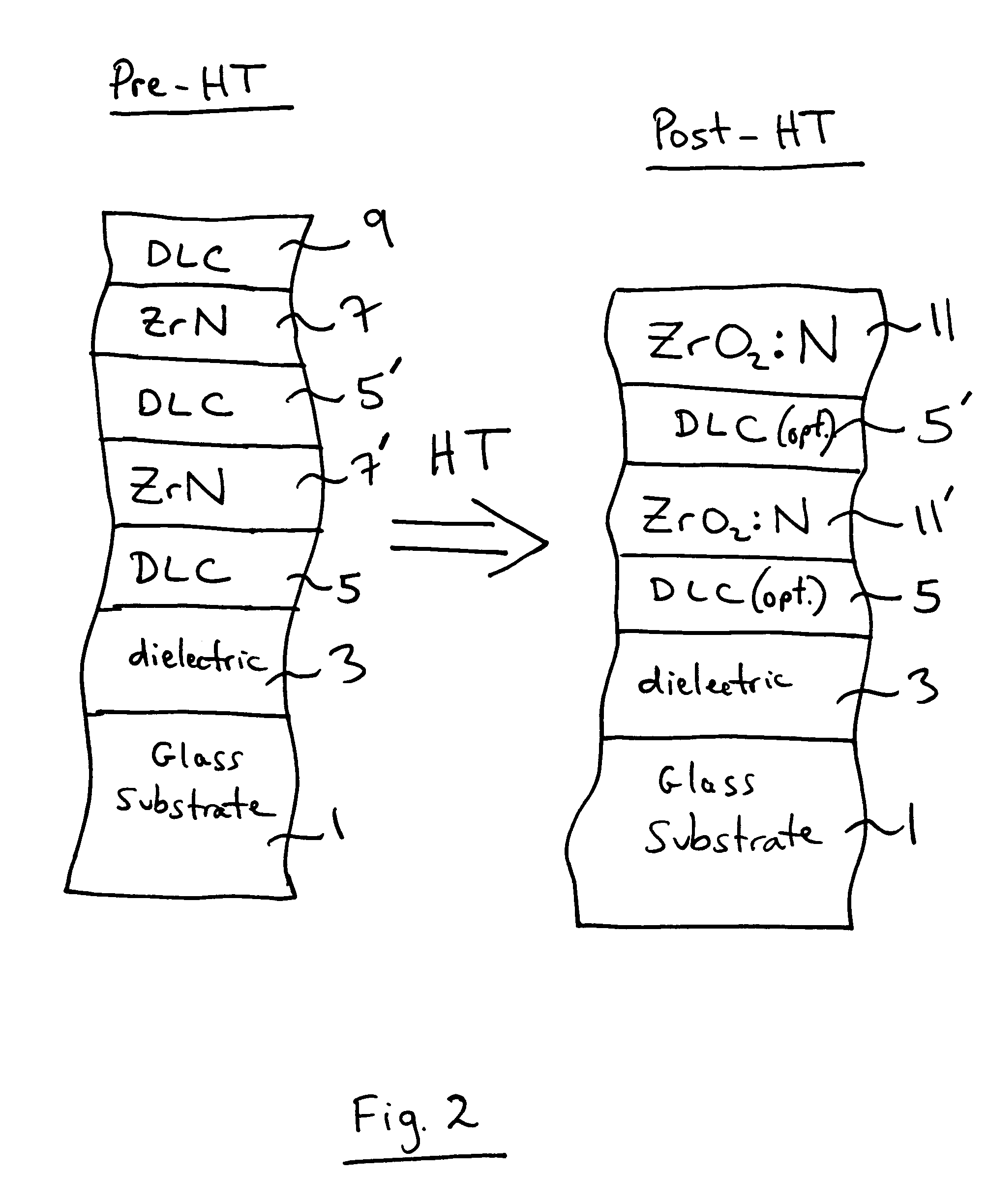

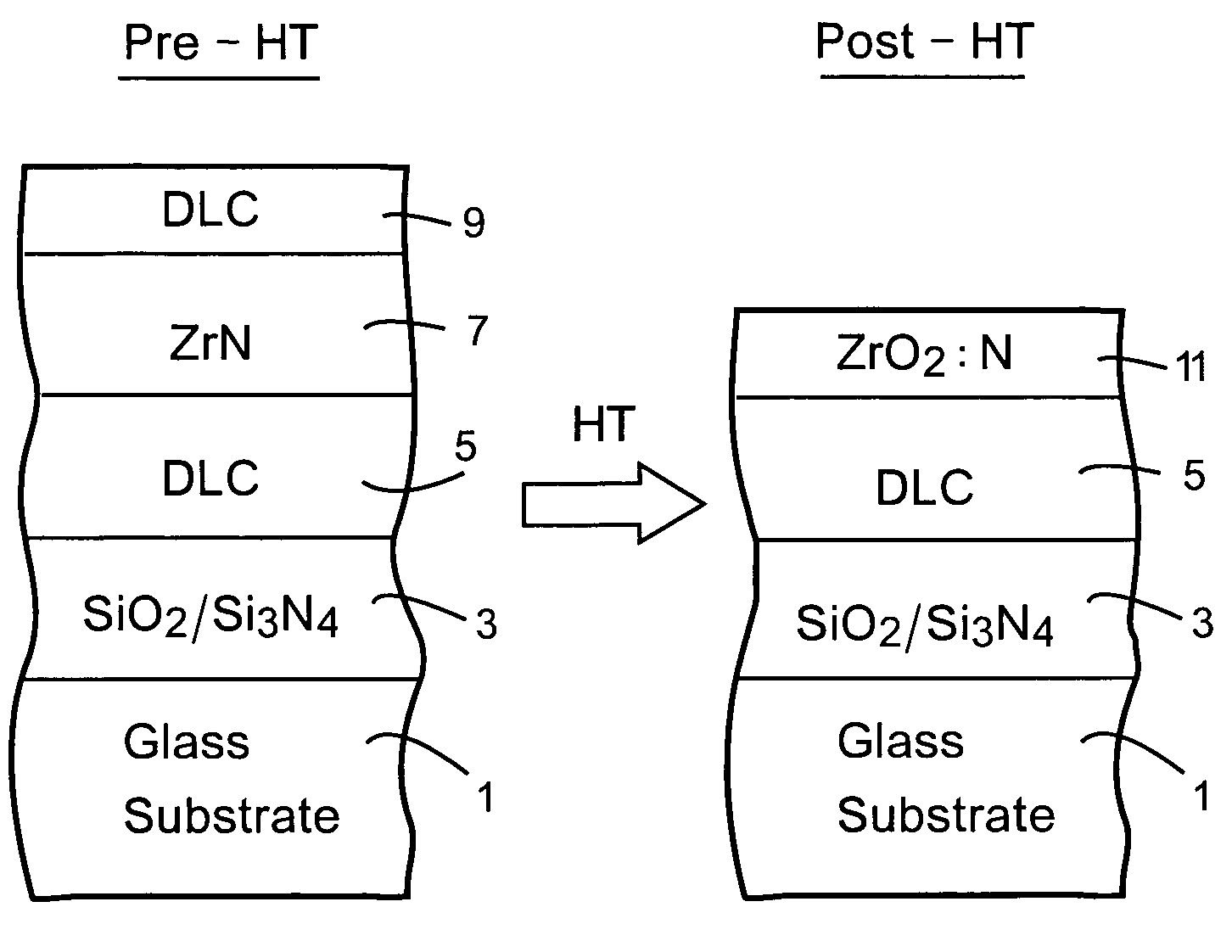

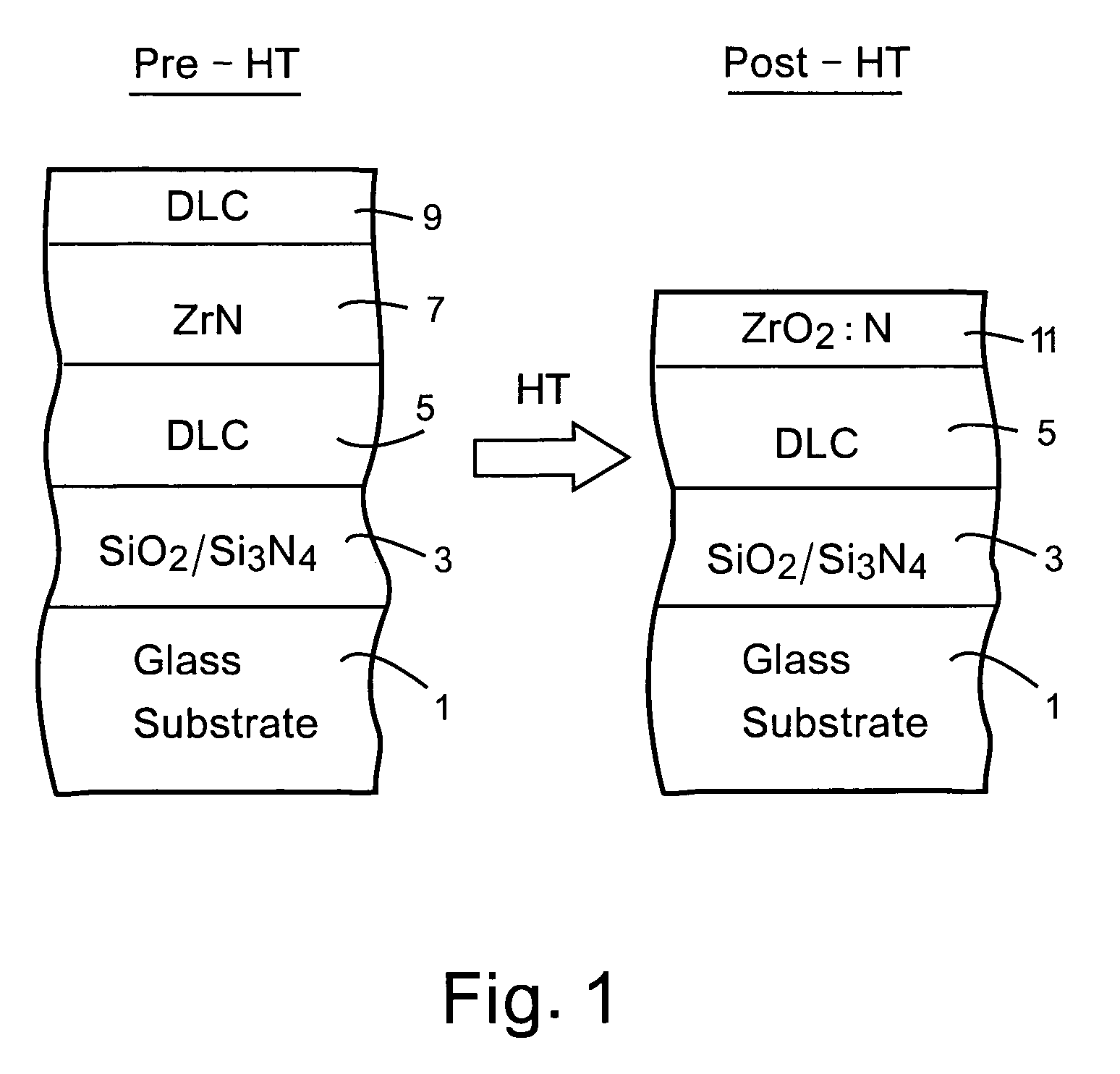

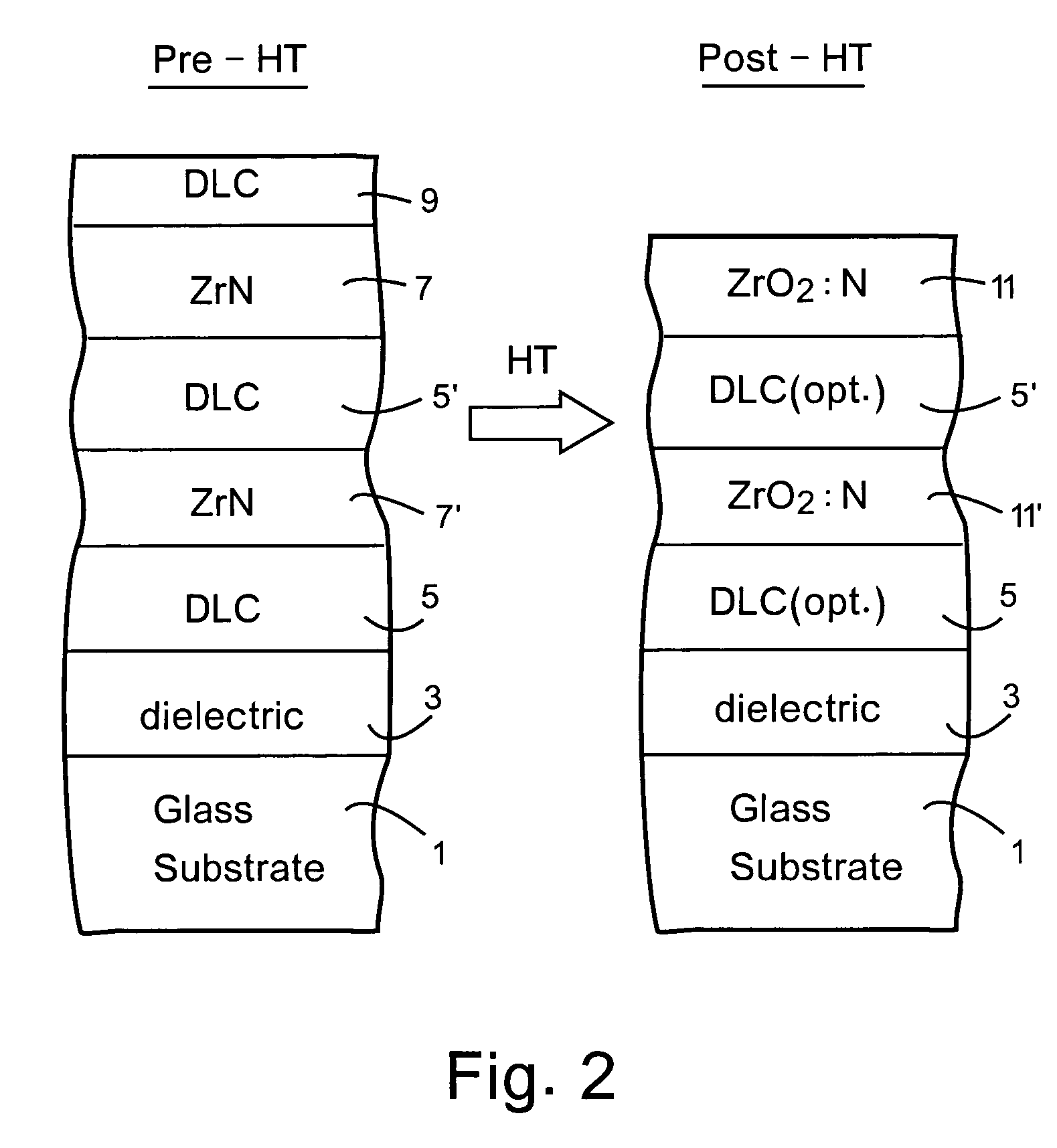

In certain example embodiments, a coated article includes respective layers including diamond-like carbon (DLC) and zirconium nitride before heat treatment (HT). During HT, the hydrogenated DLC acts as a fuel which upon combustion with oxygen produces carbon dioxide and / or water. The high temperature developed during this combustion heats the zirconium nitride to a temperature(s) well above the heat treating temperature, thereby causing the zirconium nitride to be transformed into a new post-HT layer including zirconium oxide that is scratch resistant and durable.

Owner:GUARDIAN GLASS LLC

Heat treatable coated article with diamond-like carbon (DLC) and/or zirconium in coating

In certain example embodiments, a coated article includes respective layers including hydrogenated diamond-like carbon (DLC) and zirconium nitride before heat treatment (HT). During HT, the hydrogenated DLC acts as a fuel which upon combustion with oxygen produces carbon dioxide and / or water. The high temperature developed during this combustion heats the zirconium nitride to a temperature(s) well above the heat treating temperature, thereby causing the zirconium nitride to be transformed into a new post-HT layer including zirconium oxide that is very scratch resistant and durable.

Owner:GUARDIAN GLASS LLC

Heat treatable coated article with diamond-like carbon (DLC) and/or zirconium in coating

InactiveUS20050191494A1Scratch resistantPretreated surfacesGlass/slag layered productsDiamond-like carbonOxygen

In certain example embodiments, a coated article includes respective layers including diamond-like carbon (DLC) and zirconium nitride before heat treatment (HT). During HT, the hydrogenated DLC acts as a fuel which upon combustion with oxygen produces carbon dioxide and / or water. The high temperature developed during this combustion heats the zirconium nitride to a temperature(s) well above the heat treating temperature, thereby causing the zirconium nitride to be transformed into a new post-HT layer including zirconium oxide that is scratch resistant and durable. In certain example embodiments, the zirconium nitride and / or zirconium oxide may be doped with F and / or C.

Owner:GUARDIAN GLASS LLC

Heat treatable coated article with diamond-like carbon (DLC) and/or zirconium in coating

In certain example embodiments, a coated article includes respective layers including diamond-like carbon (DLC) and zirconium nitride before heat treatment (HT). During HT, the hydrogenated DLC acts as a fuel which upon combustion with oxygen produces carbon dioxide and / or water. The high temperature developed during this combustion heats the zirconium nitride to a temperature(s) well above the heat treating temperature, thereby causing the zirconium nitride to be transformed into a new post-HT layer including zirconium oxide that is scratch resistant and durable.

Owner:GUARDIAN GLASS LLC

Heat treatable coated article with diamond-like carbon (DLC) and/or zirconium in coating

InactiveUS20060057294A1Scratch resistantPretreated surfacesGlass/slag layered productsDiamond-like carbonHeat treated

In certain example embodiments, a coated article includes a zirconium nitride inclusive layer before heat treatment (HT). The coated article is heat treated sufficiently to cause the zirconium nitride based layer to transform into a zirconium oxide based layer that is scratch resistant and / or durable. In certain example embodiments, the zirconium nitride and / or zirconium oxide may be doped with F and / or C.

Owner:GUARDIAN GLASS LLC

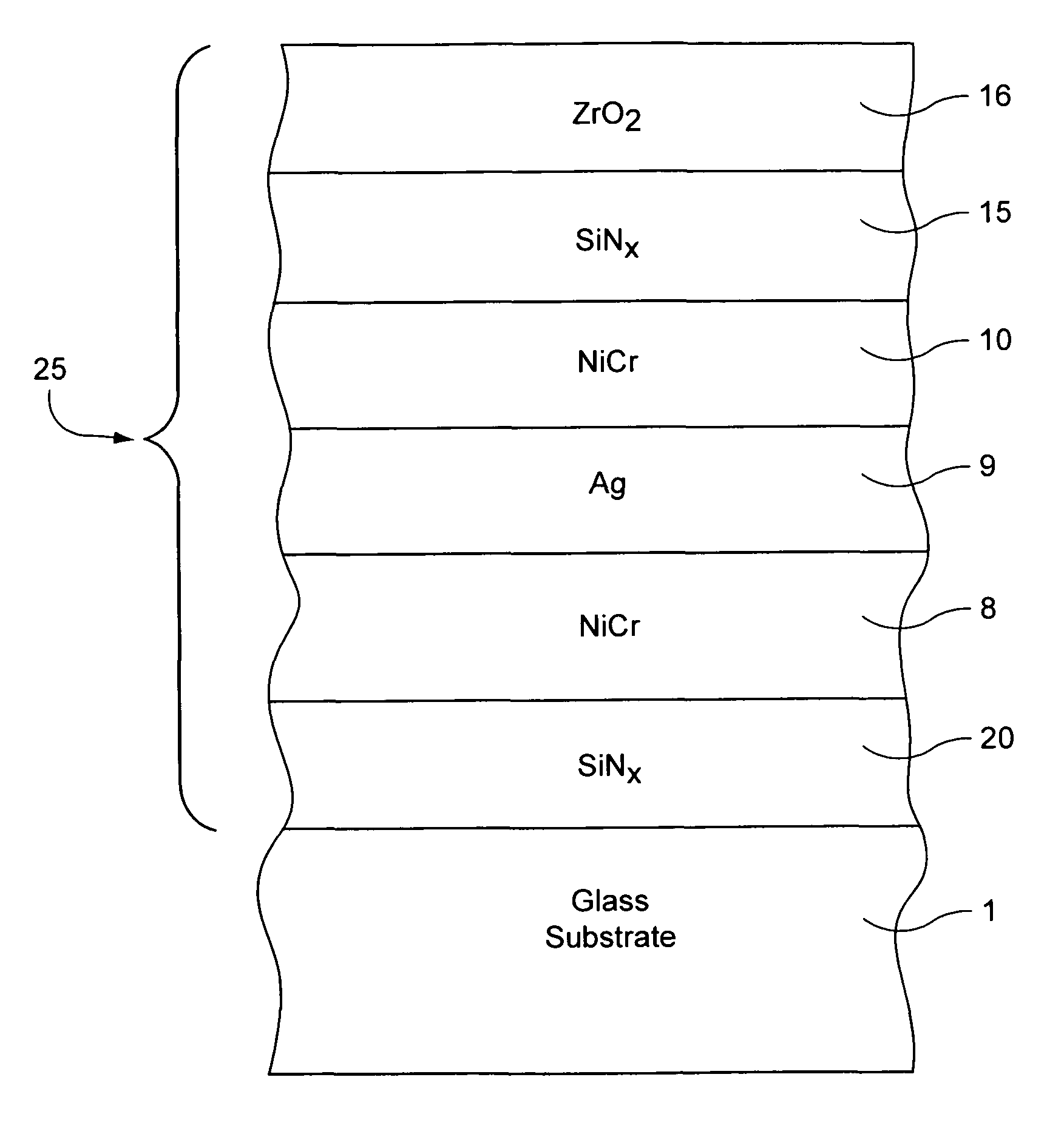

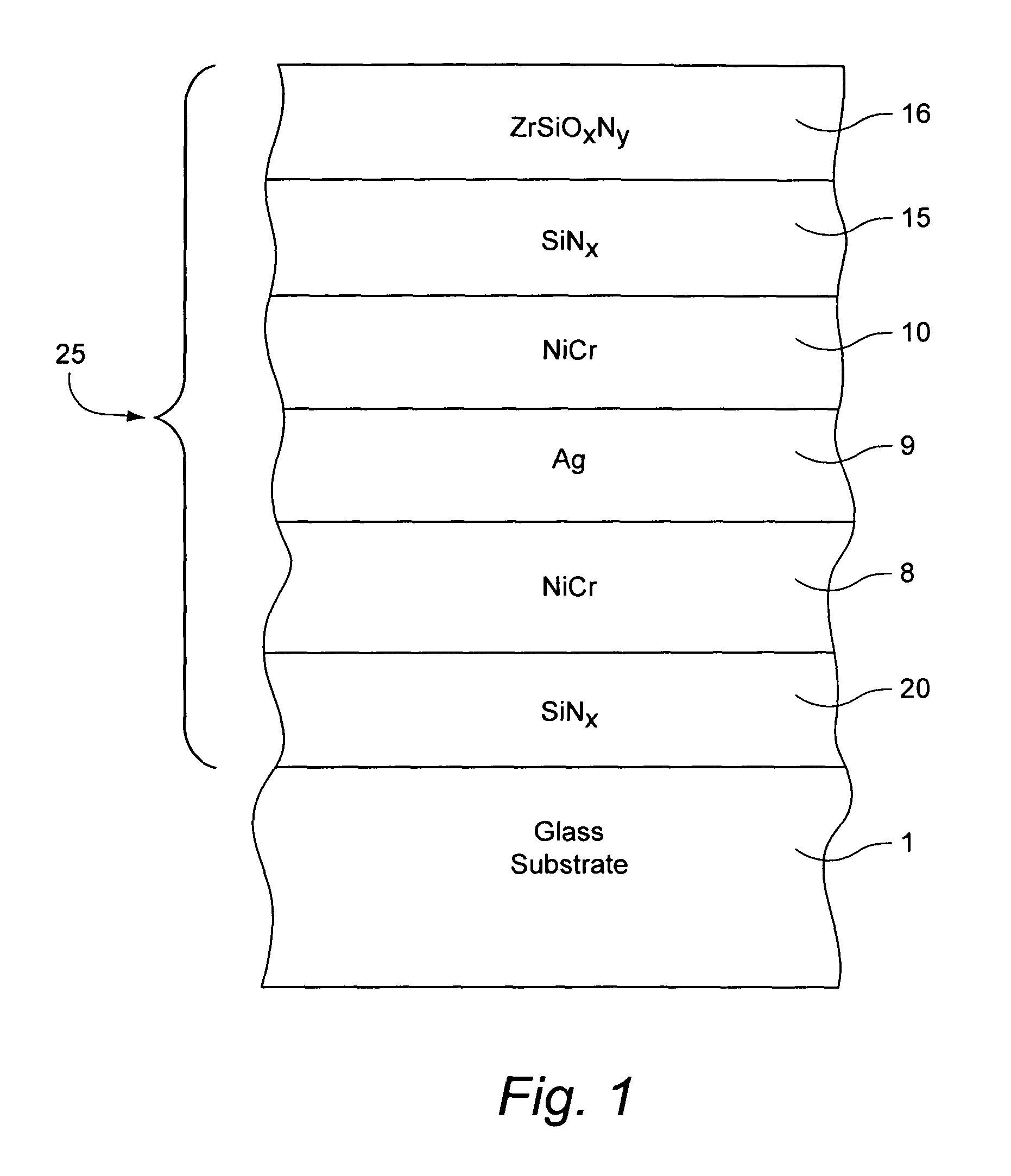

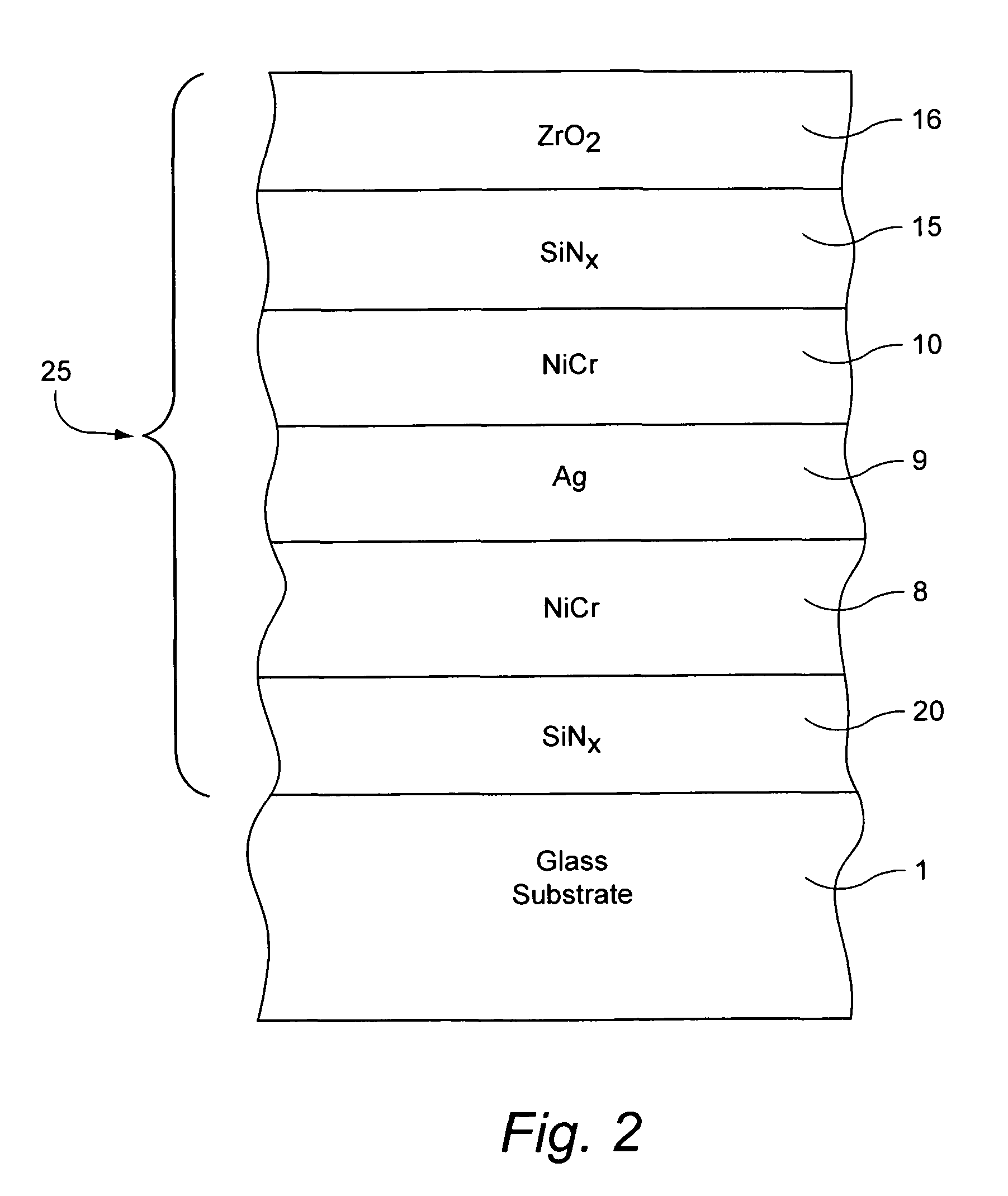

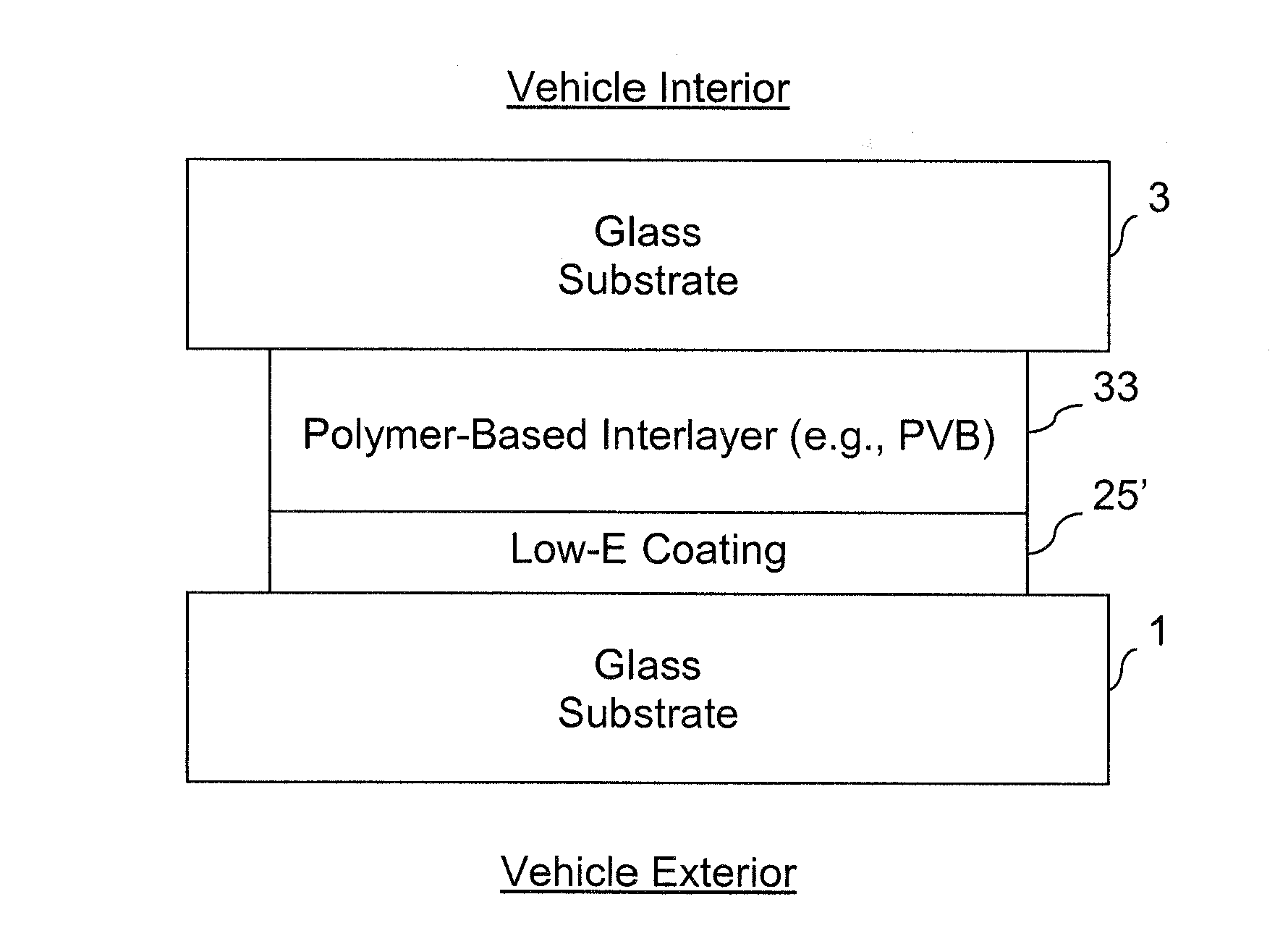

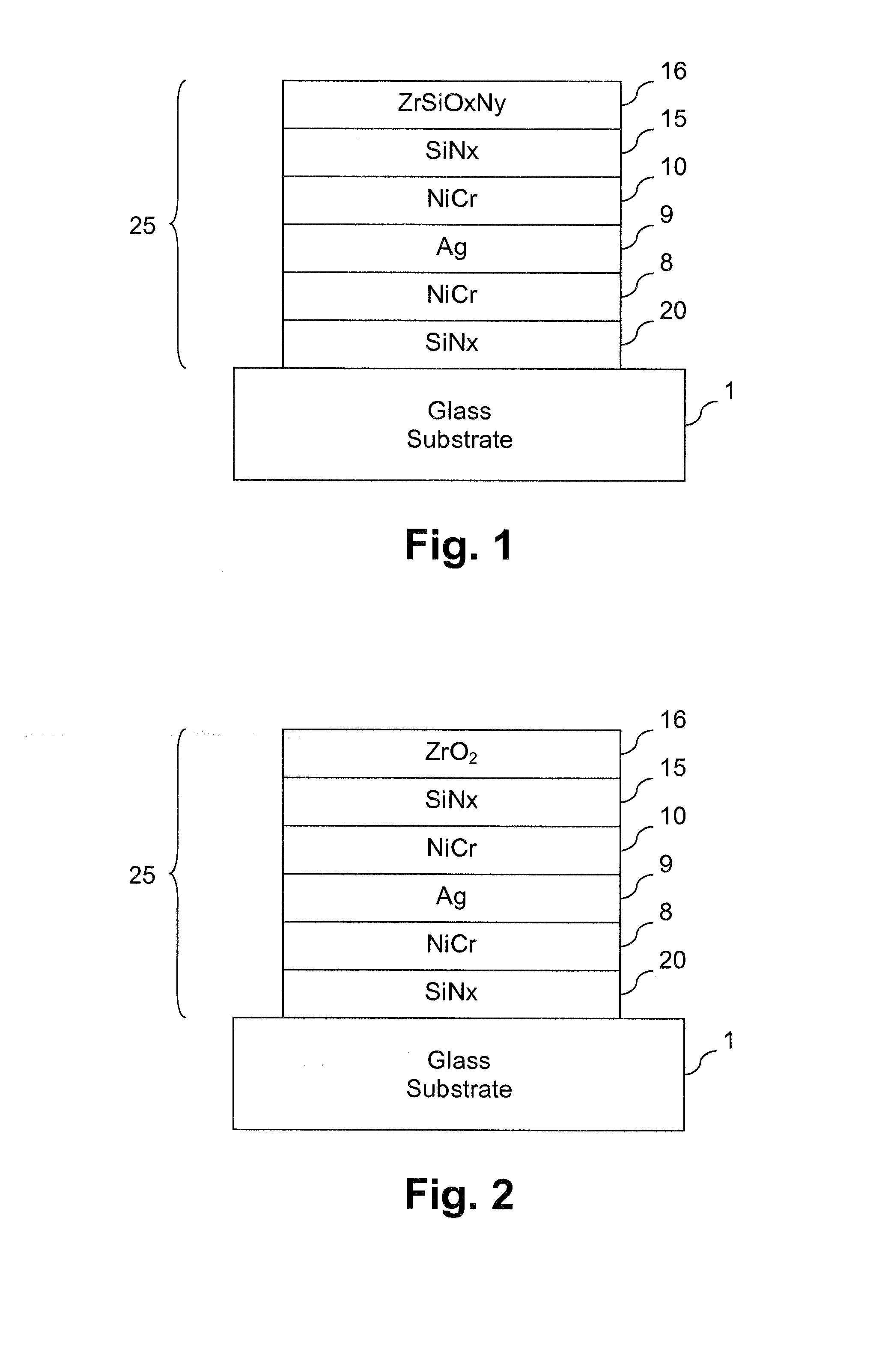

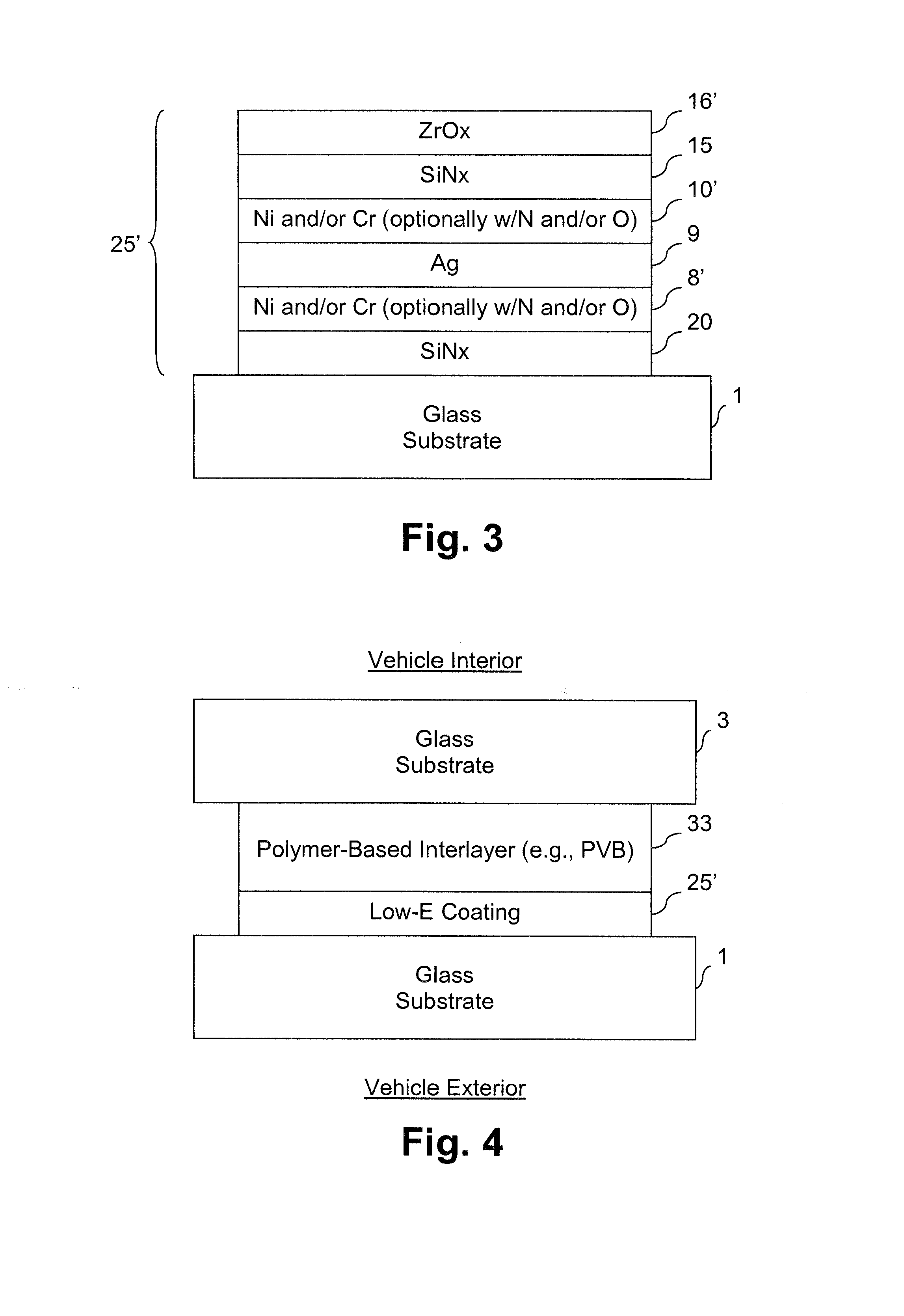

Coated article with low-E coating including zirconium oxide and/or zirconium silicon oxynitride and methods of making same

InactiveUS8263227B2High refractive index and ultraviolet (UV) absorptionImprove stabilityGlass/slag layered productsCoatingsInsulated glazingHeat stability

This application relates to a coated article including at least one infrared (IR) reflecting layer of a material such as silver or the like in a low-E coating. In certain embodiments, at least one layer of the coating is of or includes zirconium oxide (e.g., ZrO2) or zirconium silicon oxynitride (e.g., ZrSiOxNy). When a layer comprising zirconium oxide or zirconium silicon oxynitride is provided as the uppermost or overcoat layer of the coated article (e.g., over a silicon nitride based layer), this results in improved chemical and heat stability in certain example embodiments. Coated articles herein may be used in the context of insulating glass (IG) window units, vehicle windows, or in other suitable applications such as monolithic window applications, laminated windows, and / or the like.

Owner:GUARDIAN GLASS LLC

Heat treatable coated article with diamond-like carbon (DLC) and/or zirconium in coating

In certain example embodiments, a coated article includes respective layers including diamond-like carbon (DLC) and zirconium nitride before heat treatment (HT). During HT, the hydrogenated DLC acts as a fuel which upon combustion with oxygen produces carbon dioxide and / or water. The high temperature developed during this combustion heats the zirconium nitride to a temperature(s) well above the heat treating temperature, thereby causing the zirconium nitride to be transformed into a new post-HT layer including zirconium oxide that is scratch resistant and durable. In certain example embodiments, the zirconium nitride and / or zirconium oxide may be doped with F and / or C.

Owner:GUARDIAN GLASS LLC

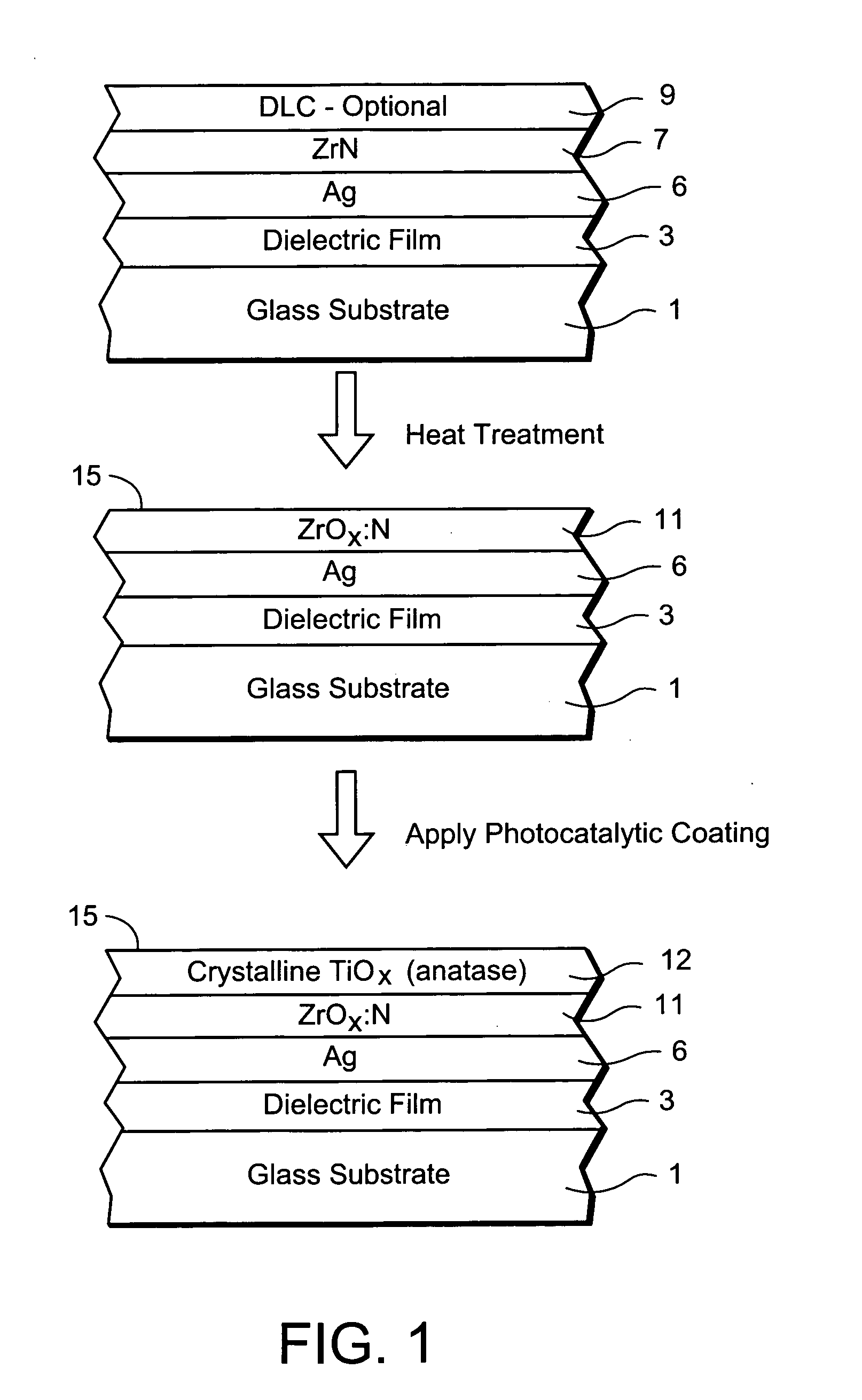

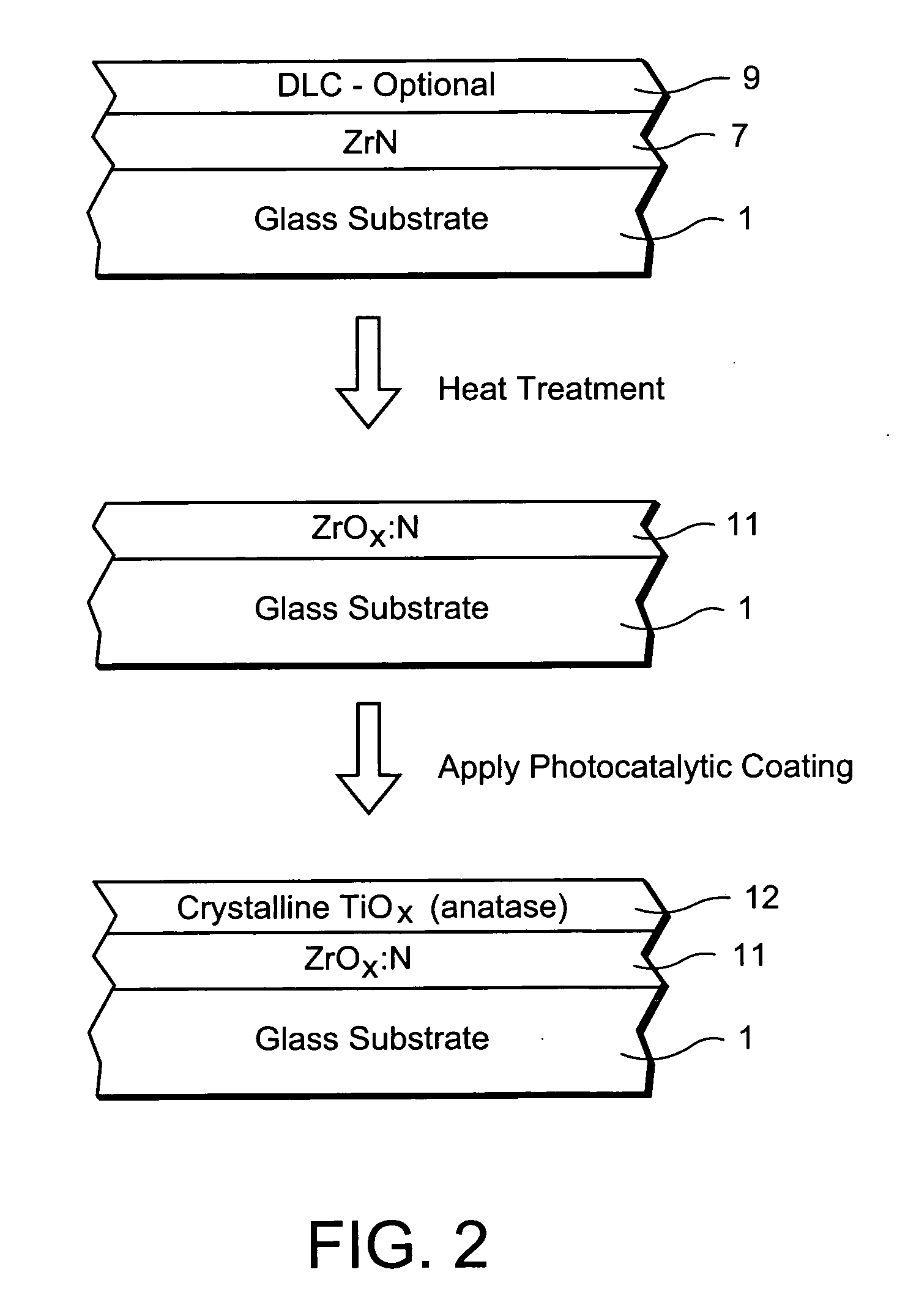

Photocatalytic window and method of making same

InactiveUS20070254164A1Increase visible transmissionIncreased durabilityPretreated surfacesGlass/slag layered productsTitaniumHeat treated

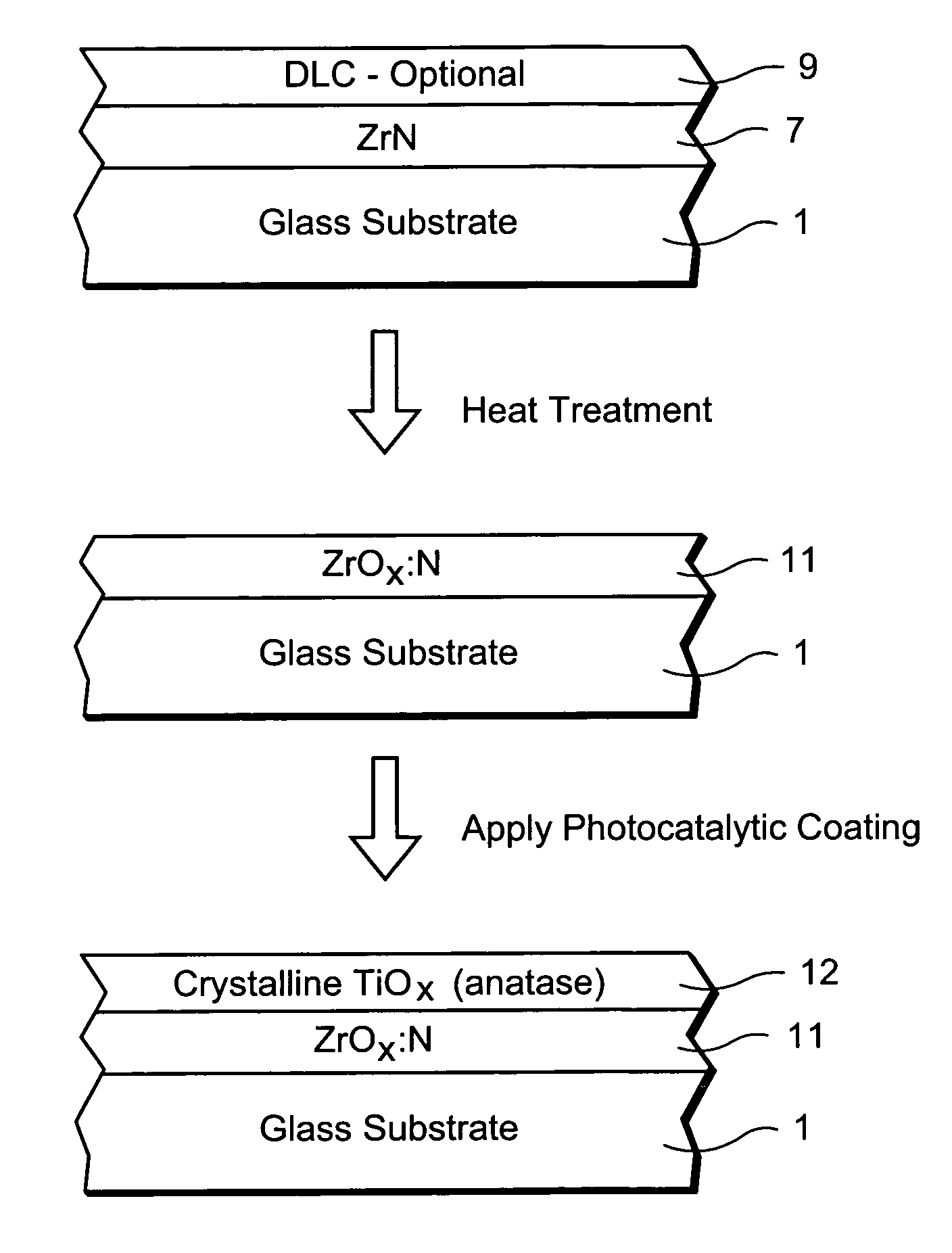

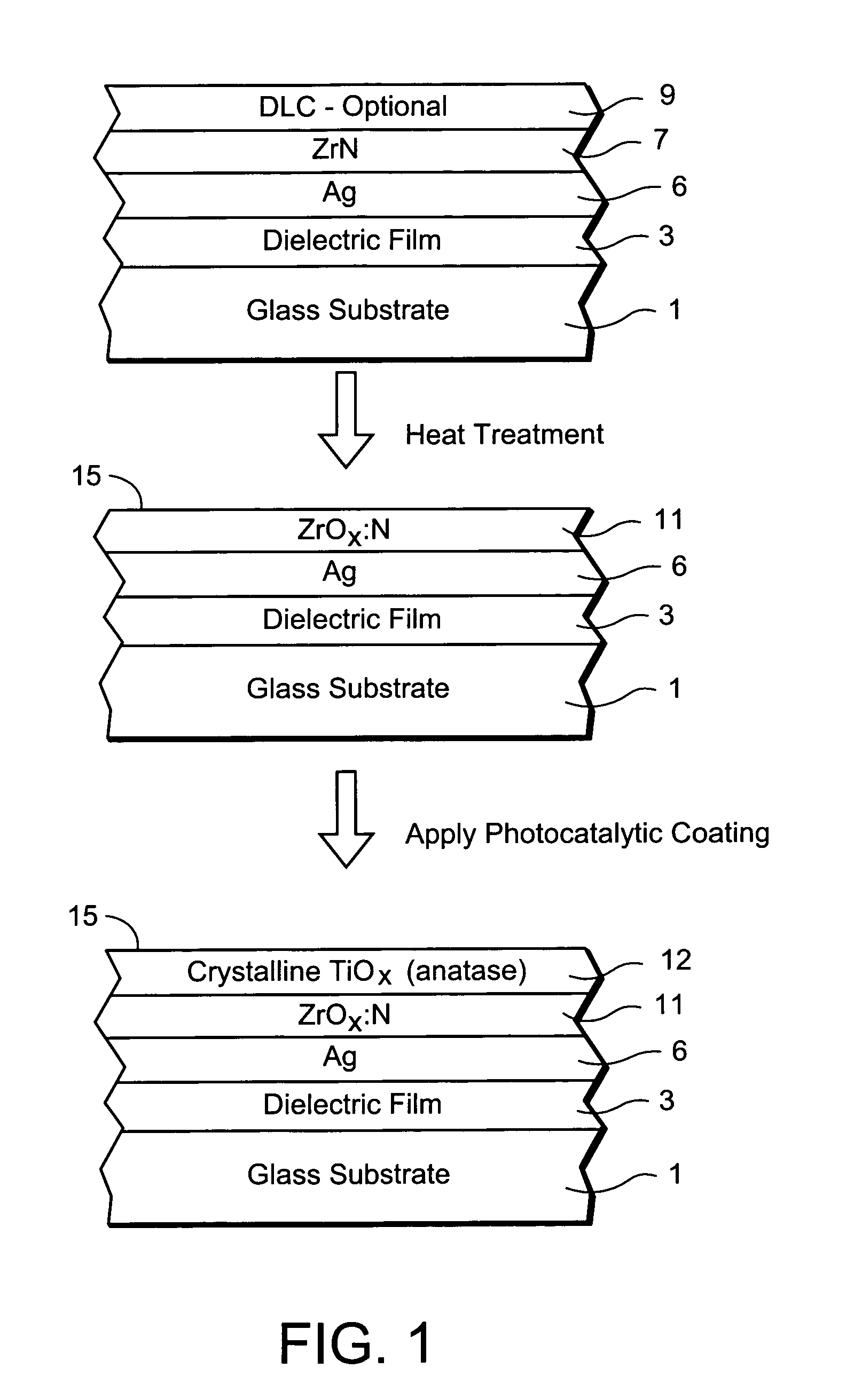

Certain example embodiments of this invention relate to a photocatalytic coated article and a method of making the same. In certain example embodiments, a coated article includes a zirconium nitride and / or oxide inclusive layer before heat treatment (HT). The coated article is heat treated so that following heat treatment (e.g., thermal tempering) a zirconium oxide based layer is provided. A photocatalytic layer (e.g., of an oxide of titanium) may be formed over zirconium oxide based layer following heat treatment.

Owner:GUARDIAN GLASS LLC

Zirconium oxide thermal barrier coating for turbine buckets of gas turbine and preparation method thereof

ActiveCN102094170AProcess parameters are easy to controlComposition controllableBlade accessoriesVacuum evaporation coatingZirconium hydrideThermal barrier coating

The invention relates to a zirconium oxide thermal barrier coating for turbine buckets of a gas turbine and a preparation method thereof. The zirconium oxide thermal barrier coating for the turbine buckets of the gas turbine is characterized in that adhesive layer materials and ceramic layer materials are plated on a metal surface; the adhesive layer materials include the following materials in percentage by weight: 15-30% of Co, 20-30% of Cr, 6-16% of Al, 0.2-1.0% of Y, and the balance of Ni; and the ceramic layer materials are zirconium oxide (ZrO2 / (5-8%)Y2O3) with stable yttrium oxide. The prepared zirconium oxide thermal barrier coating has compactness, good combining capacity with a base body and good thermal cycle resisting capacity and high temperature corrosion resisting capacity.

Owner:沈阳天贺新材料开发有限公司

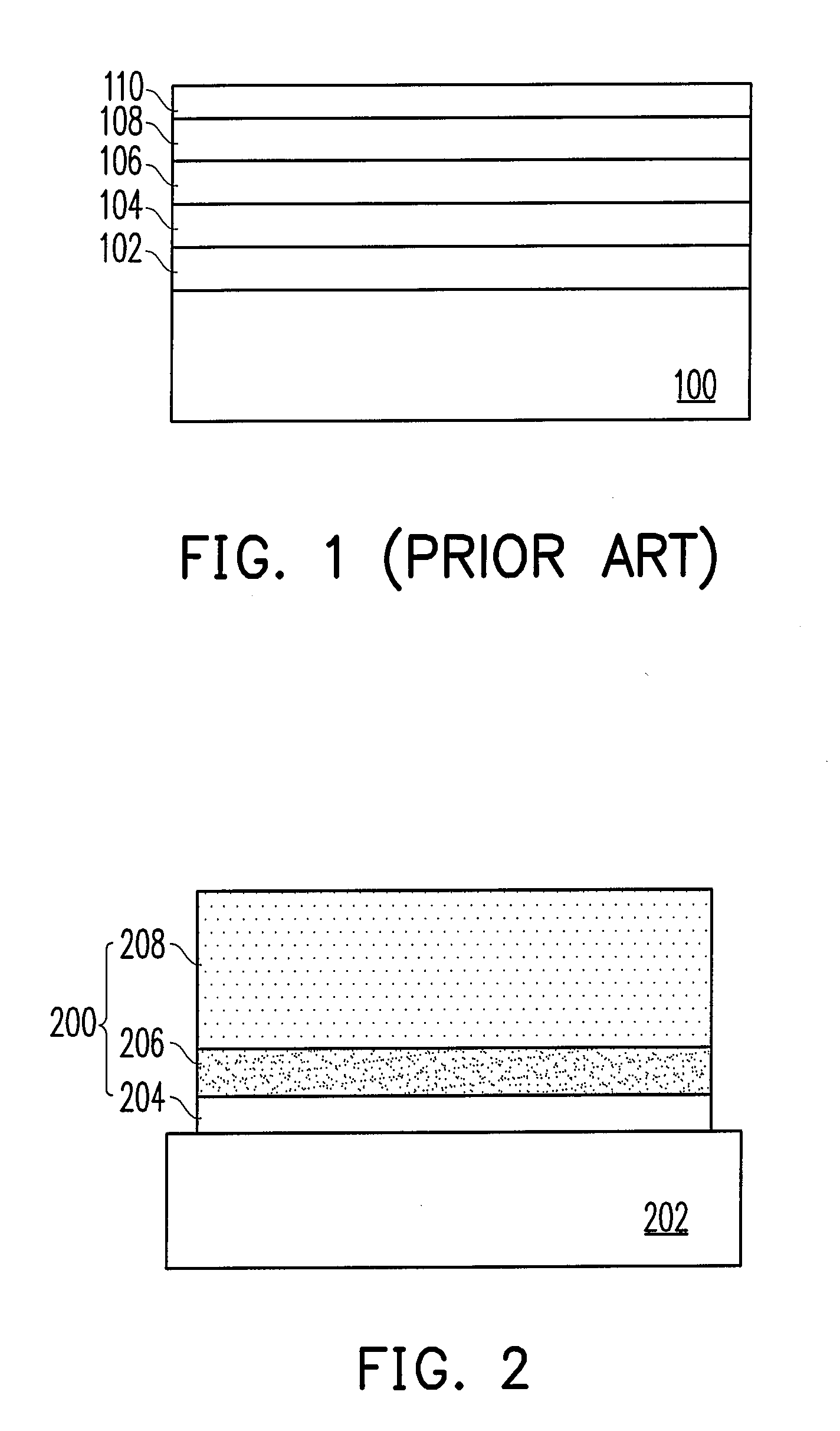

Structural material of diamond like carbon composite layers and method of manufacturing the same

ActiveUS20090169845A1Improve adhesionAvoid fragmentationVacuum evaporation coatingSputtering coatingDiamond-like carbonVanadium nitride

A structural material of diamond like carbon (DLC) composite layers is provided. The structural material includes a composite material which is consisted of a metal layer, a first metal nitride layer, and a DLC thin film. The metal layer includes aluminum (Al), copper (Cu), zirconium (Zr), nickel (Ni), or vanadium (V). The first metal nitride layer includes aluminum nitride (Al—N), zirconium nitride (Zr—N), vanadium nitride (V—N), or nickel nitride (Ni—N). The DLC thin film of the structural material of DLC composite layers has high quality tetragonally bonded amorphous carbon (ta-C) with a sp3(C—C) bonding ratio of more than 30%. Therefore, it is suitable for the work pieces in the mechanical, chemical, electricity, photoelectric, and heat transfer fields.

Owner:IND TECH RES INST

Coated article including low-e coating with improved durability and/or methods of making same

ActiveUS20130015677A1Reduce sheet resistanceImprove transmittanceVehicle seatsGlass/slag layered productsInsulated glazingHeat stability

This application relates to a coated article including at least one infrared (IR) reflecting layer of a material such as silver or the like in a low-E coating. In certain embodiments, at least one layer of the coating is of or includes zirconium oxide (e.g., ZrO2) or zirconium silicon oxynitride (e.g., ZrSiOxNy). When a layer comprising zirconium oxide or zirconium silicon oxynitride is provided as the uppermost or overcoat layer of the coated article (e.g., over a silicon nitride based layer), this results in improved chemical and heat stability in certain example embodiments. Coated articles herein may be used in the context of insulating glass (IG) window units, vehicle windows, or in other suitable applications such as monolithic window applications, laminated windows, and / or the like.

Owner:GUARDIAN EURO S A R L

Heat treatable coated article with diamond-like carbon (DLC) and/or zirconium in coating

Owner:GUARDIAN GLASS LLC

Stick resistant ceramic coating for cookware

InactiveUS7093340B2Improve coating adhesionCooking-vessel materialsMolten spray coatingSurface finishCeramic coating

Owner:CLAD METALS

Method of making heat treatable coated article with diamond-like carbon (DLC) and/or zirconium in coating

In certain example embodiments, a coated article includes respective layers including hydrogenated diamond-like carbon (DLC) and zirconium nitride before heat treatment (HT). During HT, the hydrogenated DLC acts as a fuel which upon combustion with oxygen produces carbon dioxide and / or water. The high temperature developed during this combustion heats the zirconium nitride to a temperature(s) well above the heat treating temperature, thereby causing the zirconium nitride to be transformed into a new post-HT layer including zirconium oxide that is very scratch resistant and durable.

Owner:GUARDIAN GLASS LLC

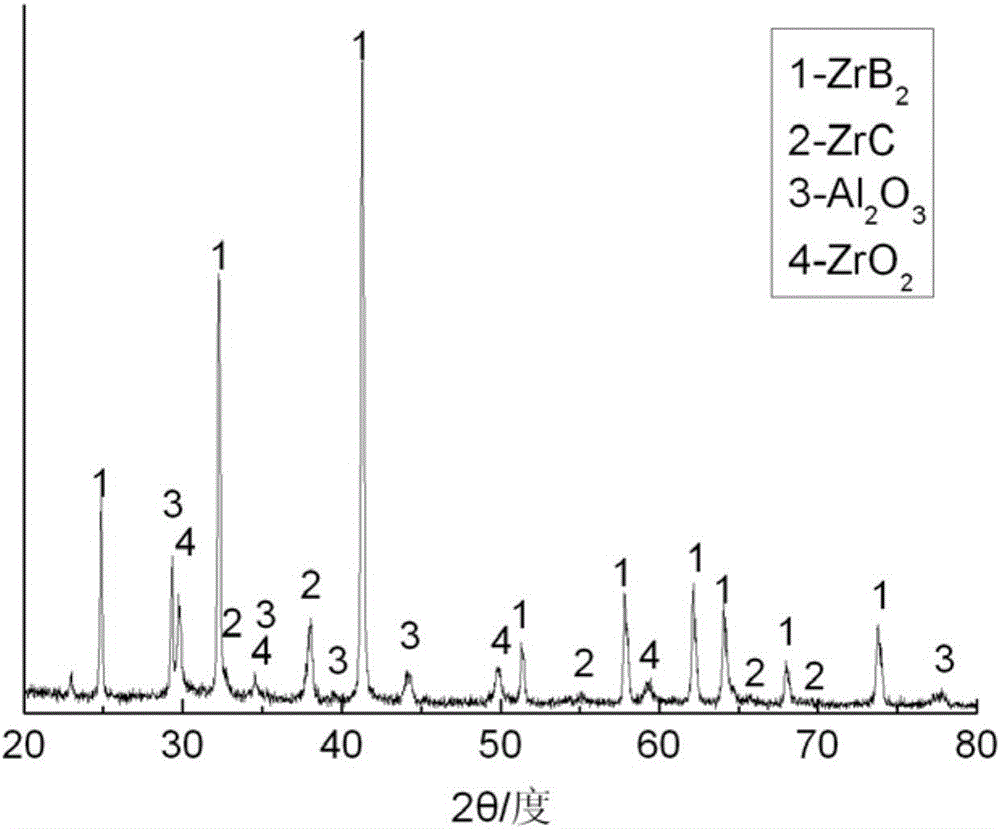

Preparation method for zirconium boride-based coating

The invention relates to a preparation method for a zirconium boride-based coating and relates to plating of a material by a boride. The method of in-situ synthesizing the zirconium boride-based coating comprises the steps of: preparing zirconium oxide / boron carbide / aluminum compound powder for thermal spraying; pre-treating a base material; and spraying the prepared zirconium oxide / boron carbide / aluminum compound powder for thermal spraying to the surface of the pre-treated base material by adopting a thermal spraying method so as to form the zirconium boride-based coating. The method provided by the invention overcomes the defects that in the prior art, the prepared zirconium boride-based coating is high in porosity, poor in uniformity, rough in tissue, low in toughness, small in thickness, poor in bonding force with a matrix, easy to crack and poor in thermal shock resistance; and the defects in the prior art that the preparation process is complicated, the process cost is high, the depositing efficiency is low, the cost of raw materials is high, the energy consumption is great, the efficiency is low, and the preparation method is not suitable for being applied to industrial production on a large scale.

Owner:HEBEI UNIV OF TECH

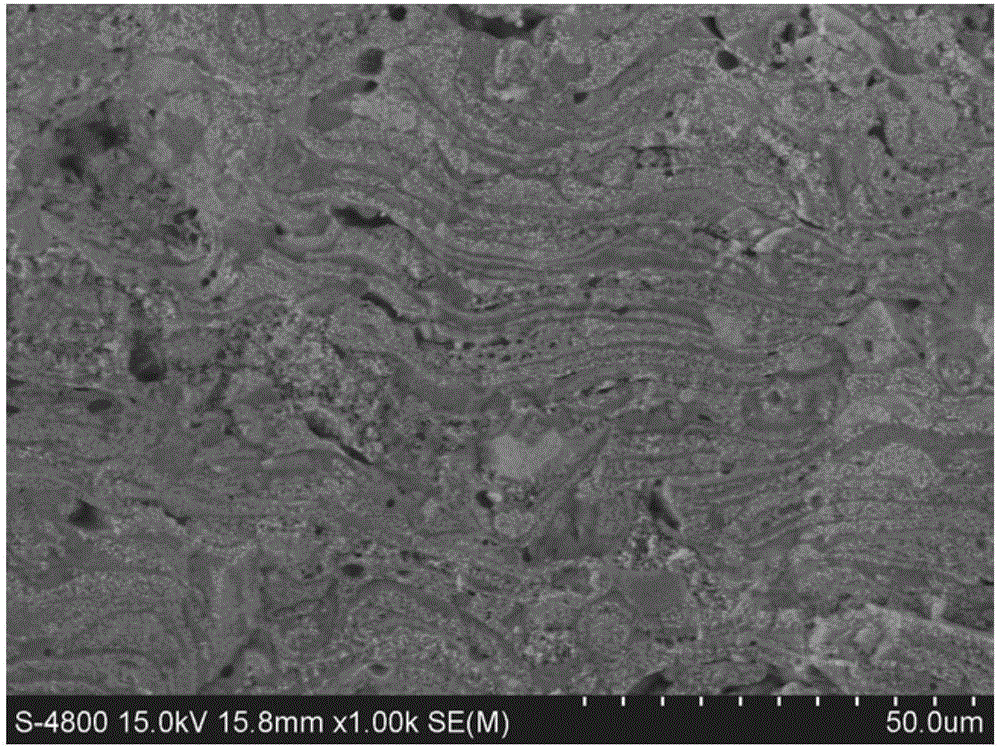

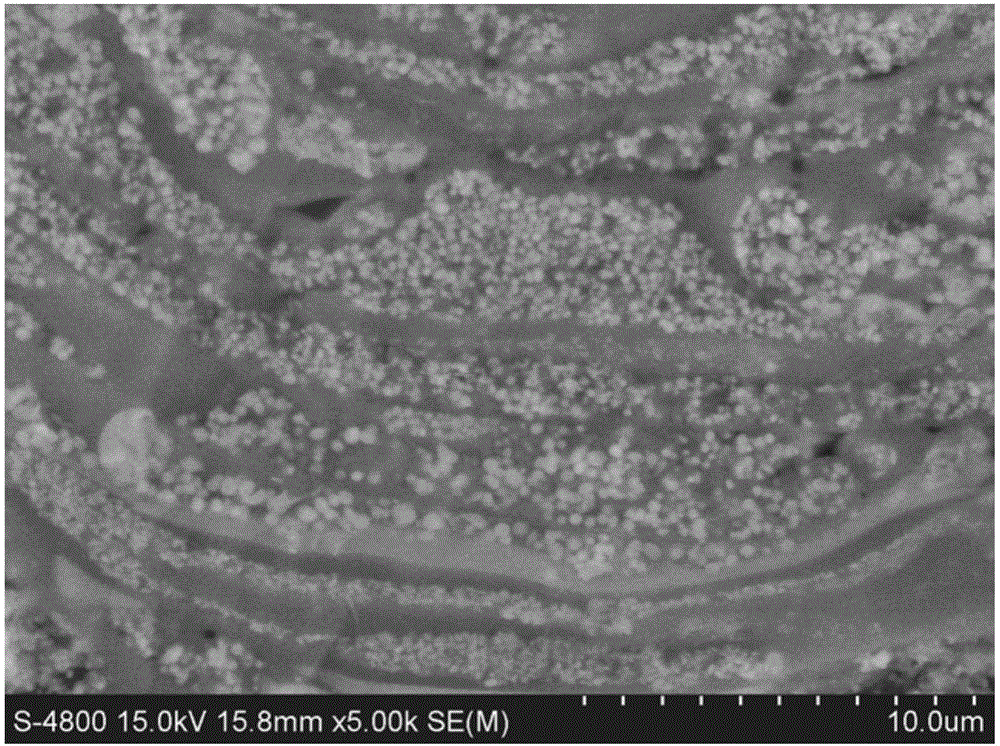

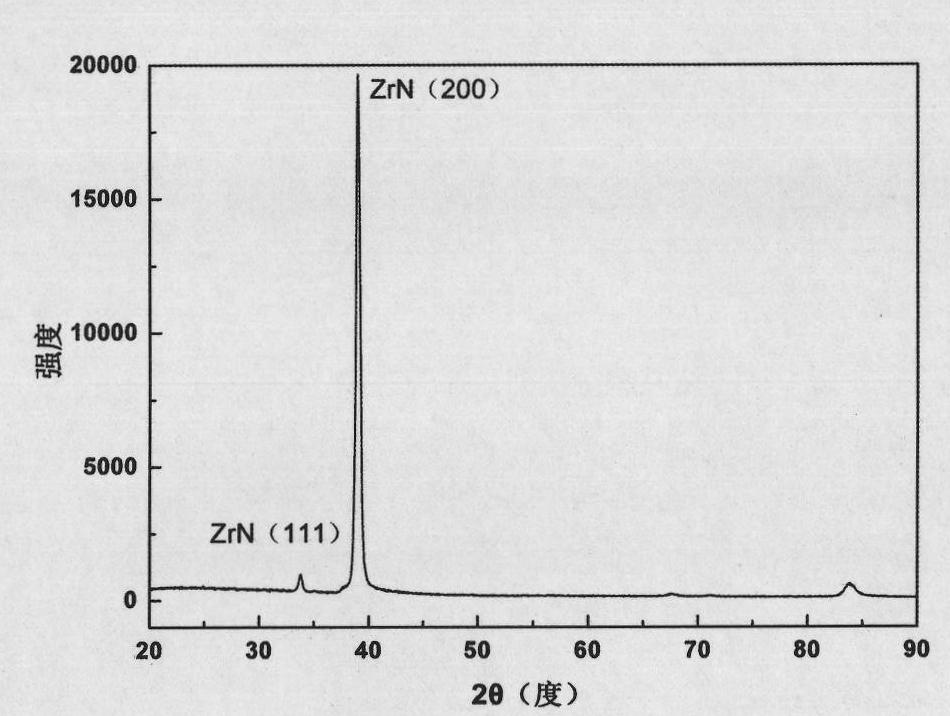

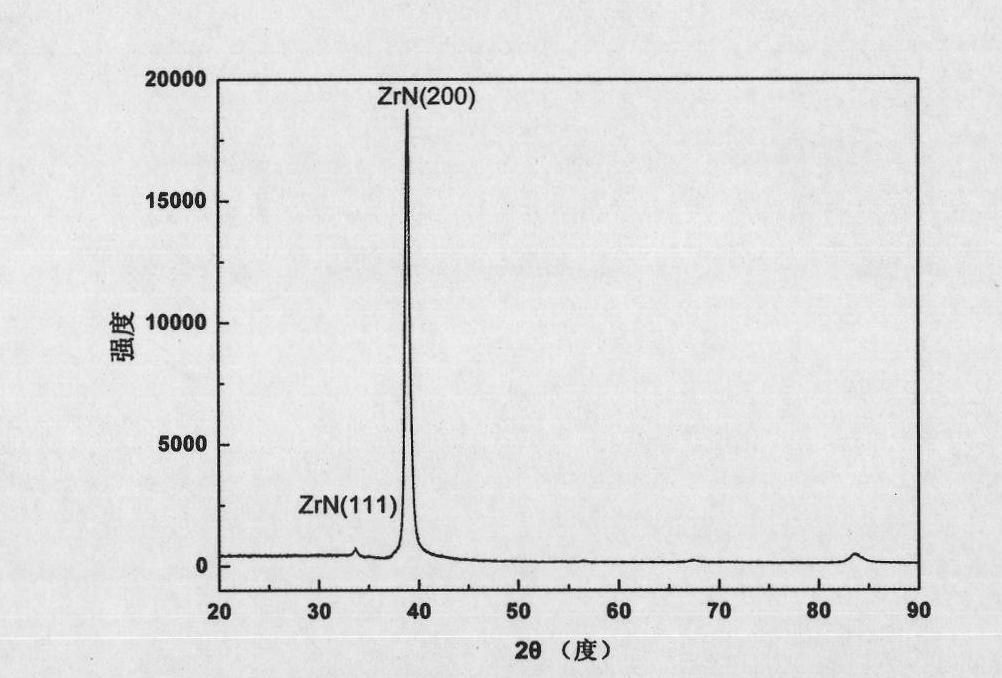

Preparation method of high hardness zirconium nitride hard coat

InactiveCN101775585AHigh hardnessHigh crystallinityVacuum evaporation coatingSputtering coatingNitrogenAlloy

The invention discloses a preparation method of a high hardness zirconium nitride hard coat and relates to a preparation method of a hard coat, which comprises the following steps: matrix pretreatment: hard alloy matrix is washed and dried after being ground and polished; and the sputter deposition is carried out after the pre-sputtering is performed. A method by adopting magnetic control sputtering method to control the process conditions such as the atmosphere, the matrix temperature, the matrix bias and the like of the sputter deposition so as to prepare the zirconium nitride hard coat on the surface of the hard alloy matrix is adopted to improve the hardness of the zirconium nitride coat. DC power is adopted to perform the magnetic control sputter deposition on the surface of the hard alloy matrix which is mechanically polished, washed by ultrasonic and washed and processed by ion source, the total pressure is controlled at 0.3 to 0.5 Pa, the flow rate of the nitrogen is 15 to 20 percent, DC power of the Zr target is 250 to 300W, the matrix temperature is 300 to 450 DEG C, the matrix bias voltage is minus 50 to 100V, the deposition time is 90 to 120 minutes, and the coat has high hardness of more than 30 GPa.

Owner:XIAMEN UNIV

Cutting tool comprising multilayer coating

ActiveCN103201410AImprove wear resistanceExtended service lifeTurning toolsSuperimposed coating processTitanium aluminium nitrideTitanium

The invention relates to a cutting tool comprising a main part and a multilayer coating applied thereon. A first layer A made of a hard material is applied on the main part, said hard material being selected from titanium aluminum nitride (TiAIN), titanium aluminum silicon nitride (TiAISiN), chromium nitride (CrN), aluminum chromium nitride (AICrN), aluminum chromium silicon nitride (AICrSiN), and zirconium nitride (ZrN), and a second layer B made of silicon nitride (Si3N4) is applied directly over the first layer A.

Owner:WALTER AG

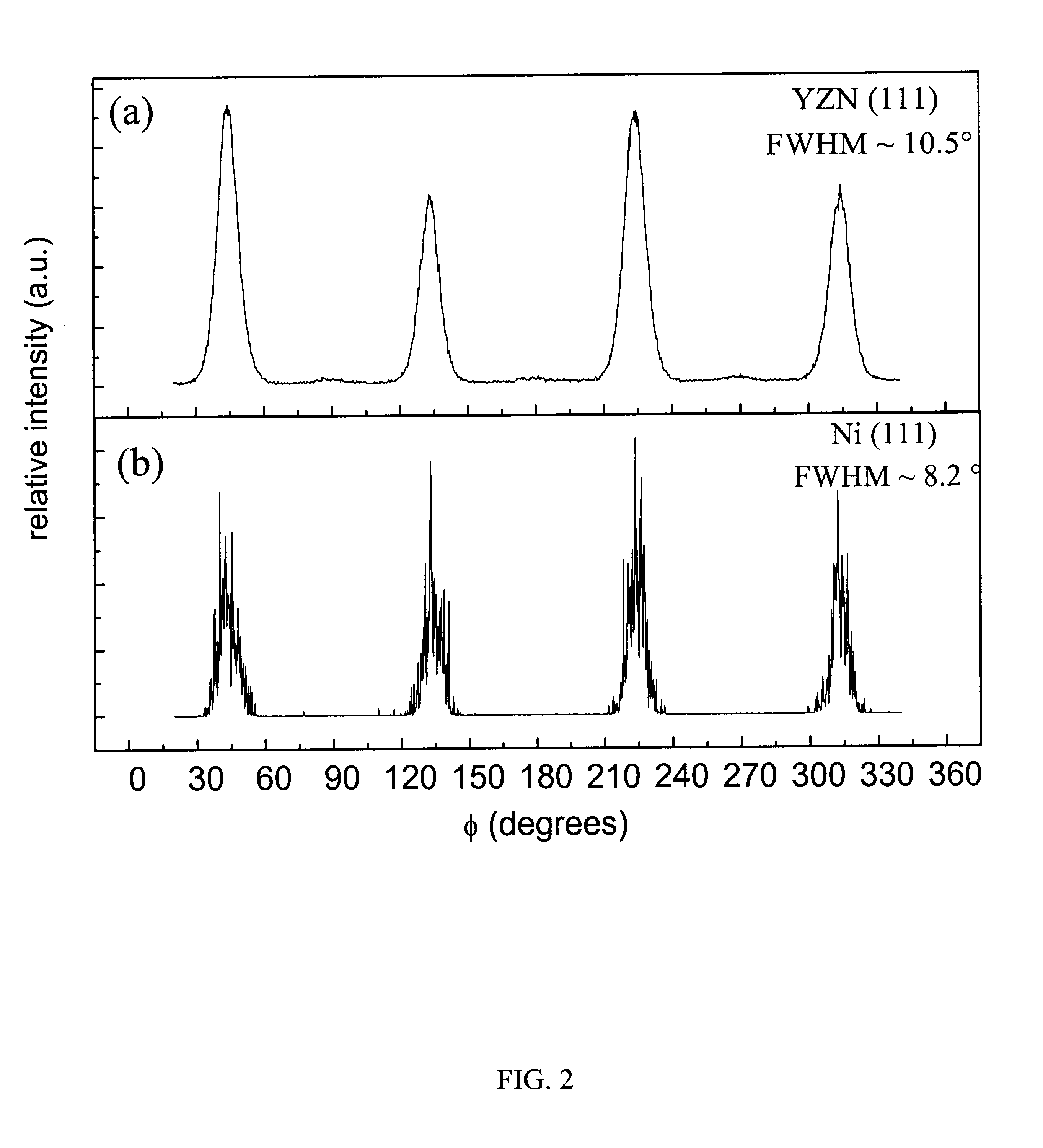

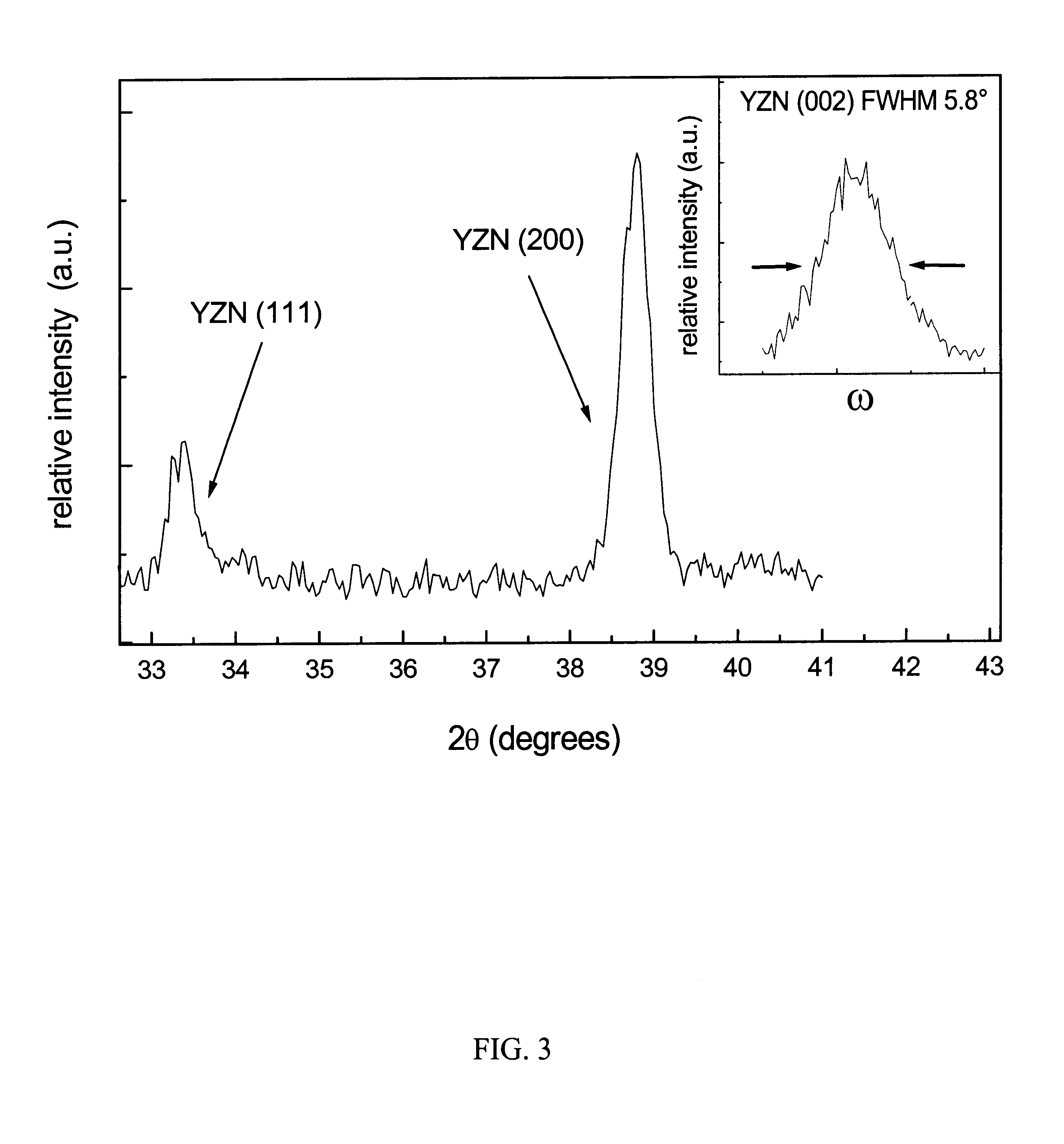

Zirconium nitride and yttrium nitride solid solution composition

InactiveUS6573209B1Small lattice mismatchStraightforward growth processPolycrystalline material growthAfter-treatment detailsYttrium nitrideSolid solution

Owner:APPL THIN FILMS INC

Shell with colored film layer

The invention discloses a shell with a colored film layer, and the shell provided by the invention comprises a substrate and a composite film layer plated on the substrate, wherein the composite film layer comprises a colored layer, a middle layer and a protective layer, the colored layer is combined with the substrate, the middle layer is coated on the colored layer, and the protective layer is coated on the middle layer; the composition of the colored layer is selected from a mixture of aluminum oxides and chromic oxides, titanium nitride, aluminium-titanium nitride, zirconium nitride, titanium carbide nitride, zirconium carbide nitride or aluminium nitride; and the colored layer is used for displaying colors, the middle layer is used for increasing the color saturation of the colored layer, and the protective layer is made of a transparent wear-resisting material and used for protecting the colored layer and the middle layer. The composite film layer not only can display bright colors, but also has the advantages of good adhesiveness and good abrasive resistance.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

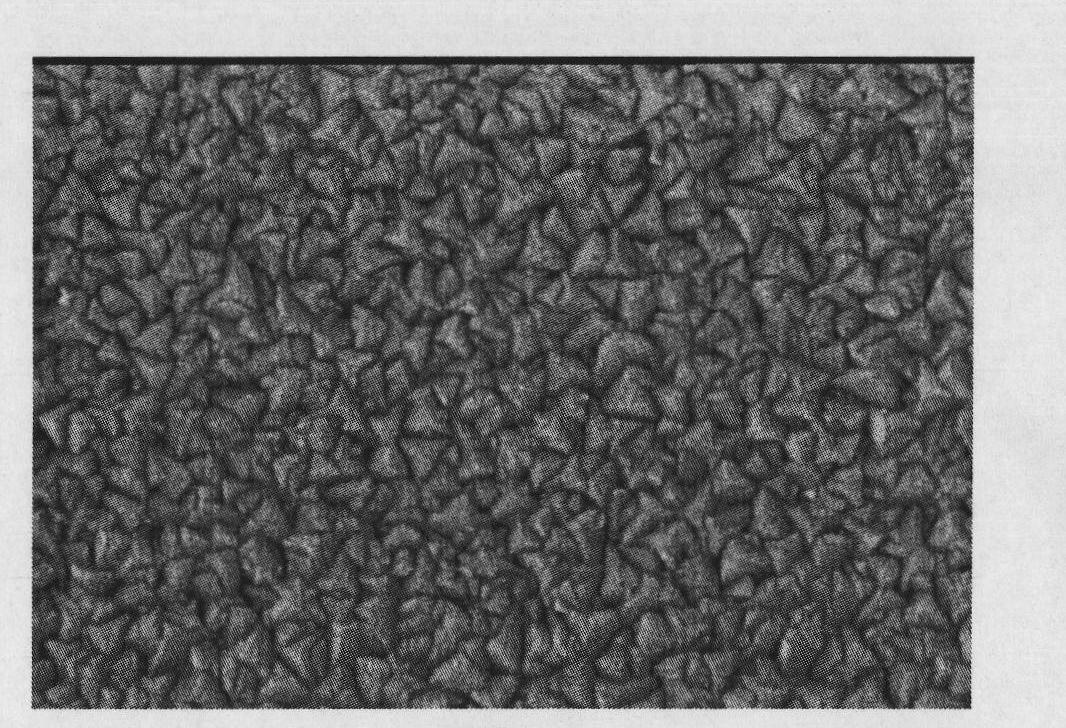

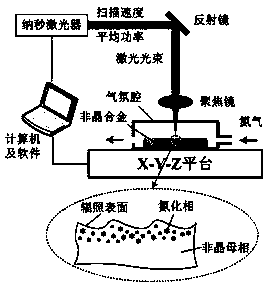

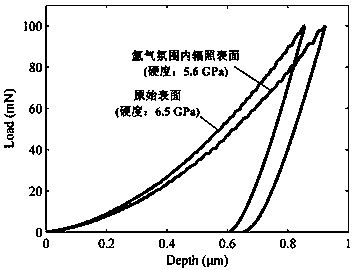

Method for improving zirconium-based or titanium-based amorphous alloy surface hardness through laser irradiation in nitrogen

ActiveCN108546893AHigh hardnessSolve the problem of significant reduction in surface hardnessSolid state diffusion coatingNanosecond laserNitrogen atmosphere

The invention relates to a method for improving zirconium-based or titanium-based amorphous alloy surface hardness through laser irradiation in nitrogen, and belongs to the technical field of amorphous alloy surface modification. Chemical affinity of the zirconium or titanium element and the nitrogen element under the high temperature or other conditions is used, nanosecond laser irradiation is carried out on the zirconium-based or titanium-based amorphous alloy surface in the nitrogen atmosphere, a nitriding phase (zirconium nitride or titanium nitride) is led into an amorphous parent phase of the surface of a zirconium-based or titanium-based amorphous alloy, and the surface hardness of the zirconium-based or titanium-based amorphous alloy is improved. The method effectively solves the problem that when the amorphous alloy surface is treated through an existing laser irradiation method, the surface hardness of the amorphous alloy is obviously reduced. Laser irradiation parameters arechanged, so that regulation and control of the content of the nitriding phase on the amorphous alloy surface are conveniently achieved, and regulation and control of the zirconium-based or titanium-based amorphous alloy surface hardness are achieved. The method is simple in implementation process, high in efficiency and high in practicability, the method can be used for regulating and controllingthe zirconium-based or titanium-based amorphous alloy surface hardness, and function application of the zirconium-based or titanium-based amorphous alloy is strengthened.

Owner:JILIN UNIV

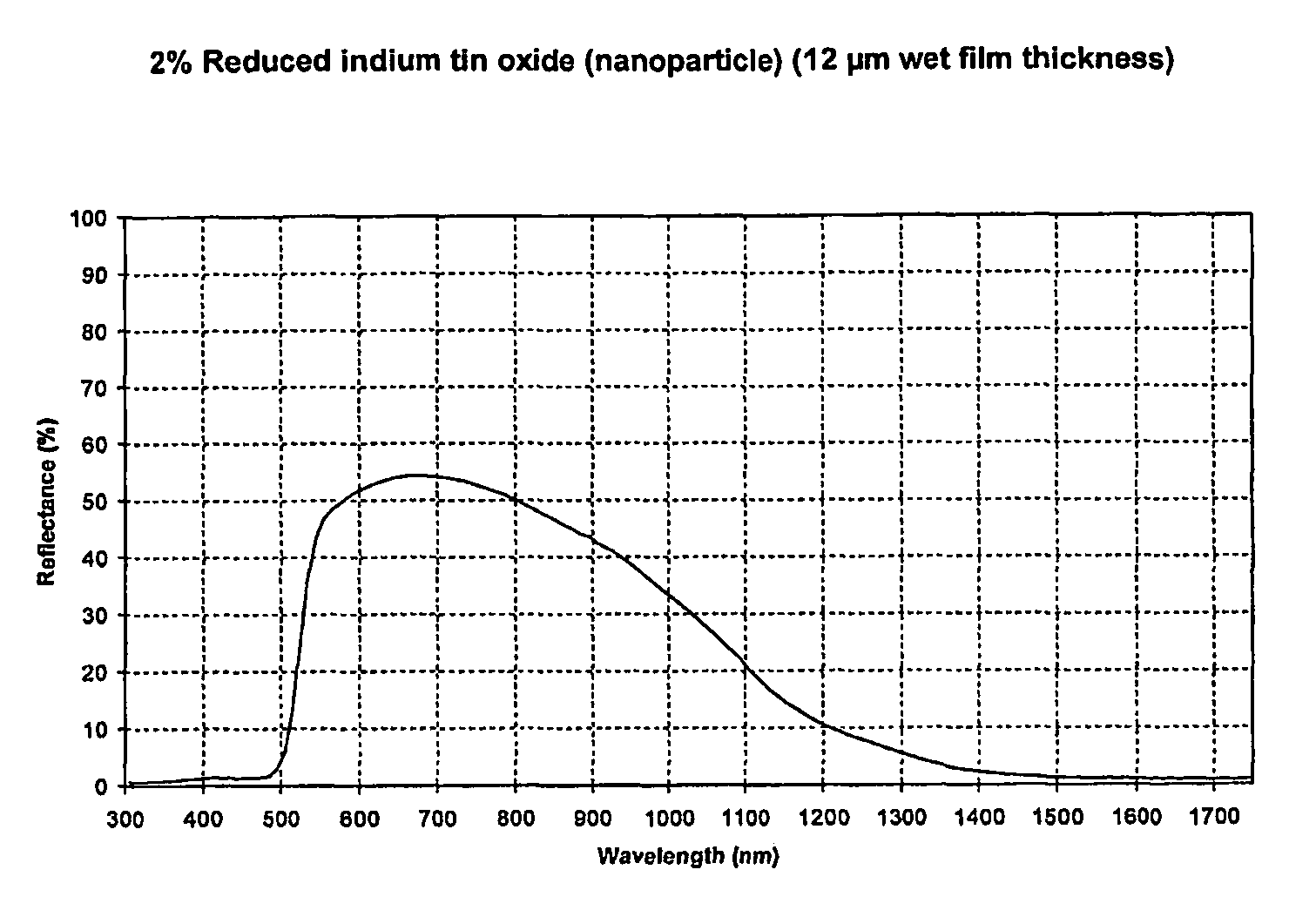

Security inks containing infrared absorbing metal compounds

ActiveUS8157905B2Easy to detectNot easy to detectNon-fibrous pulp additionLayered productsNeodymium chlorideLanthanum hexaboride

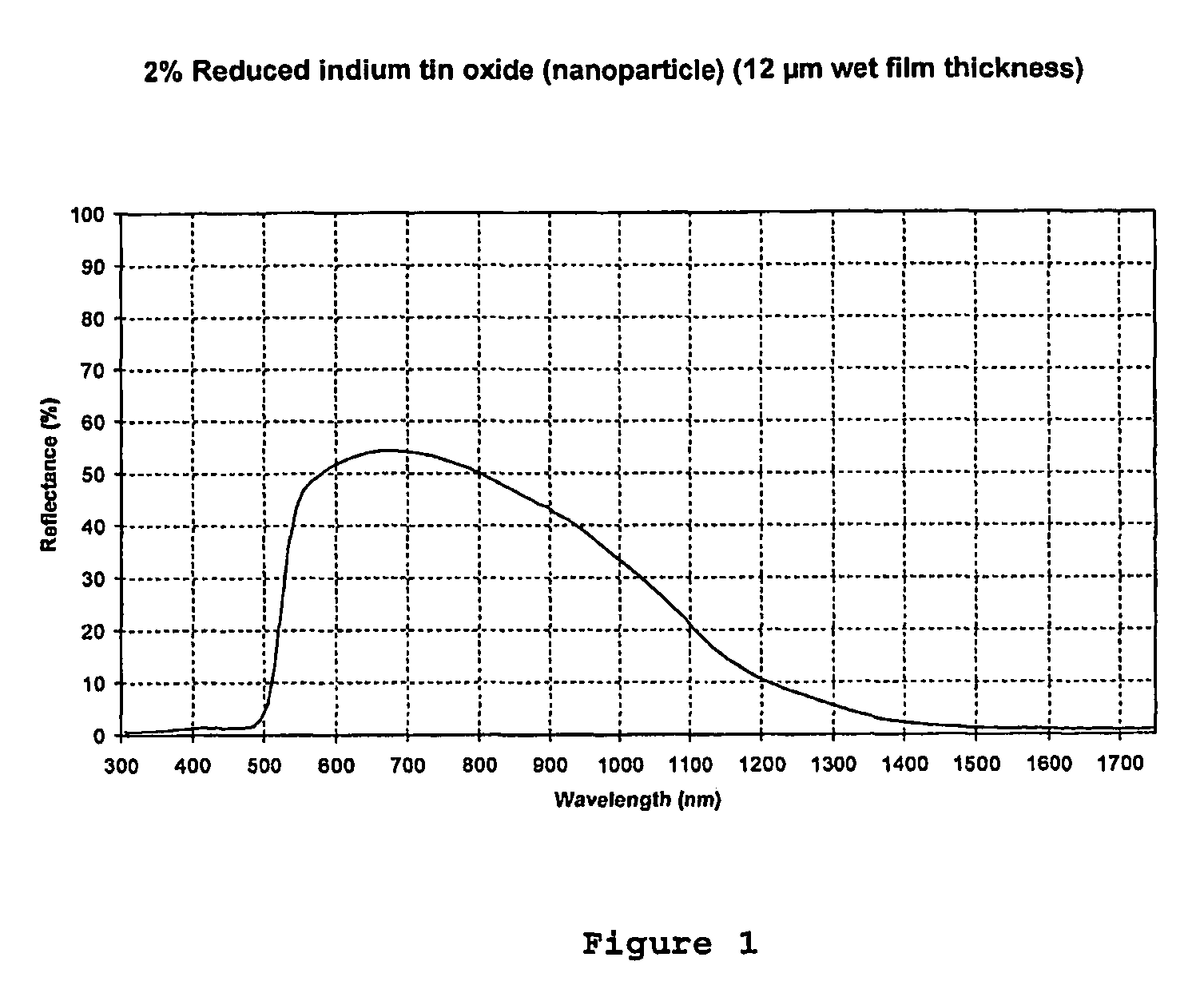

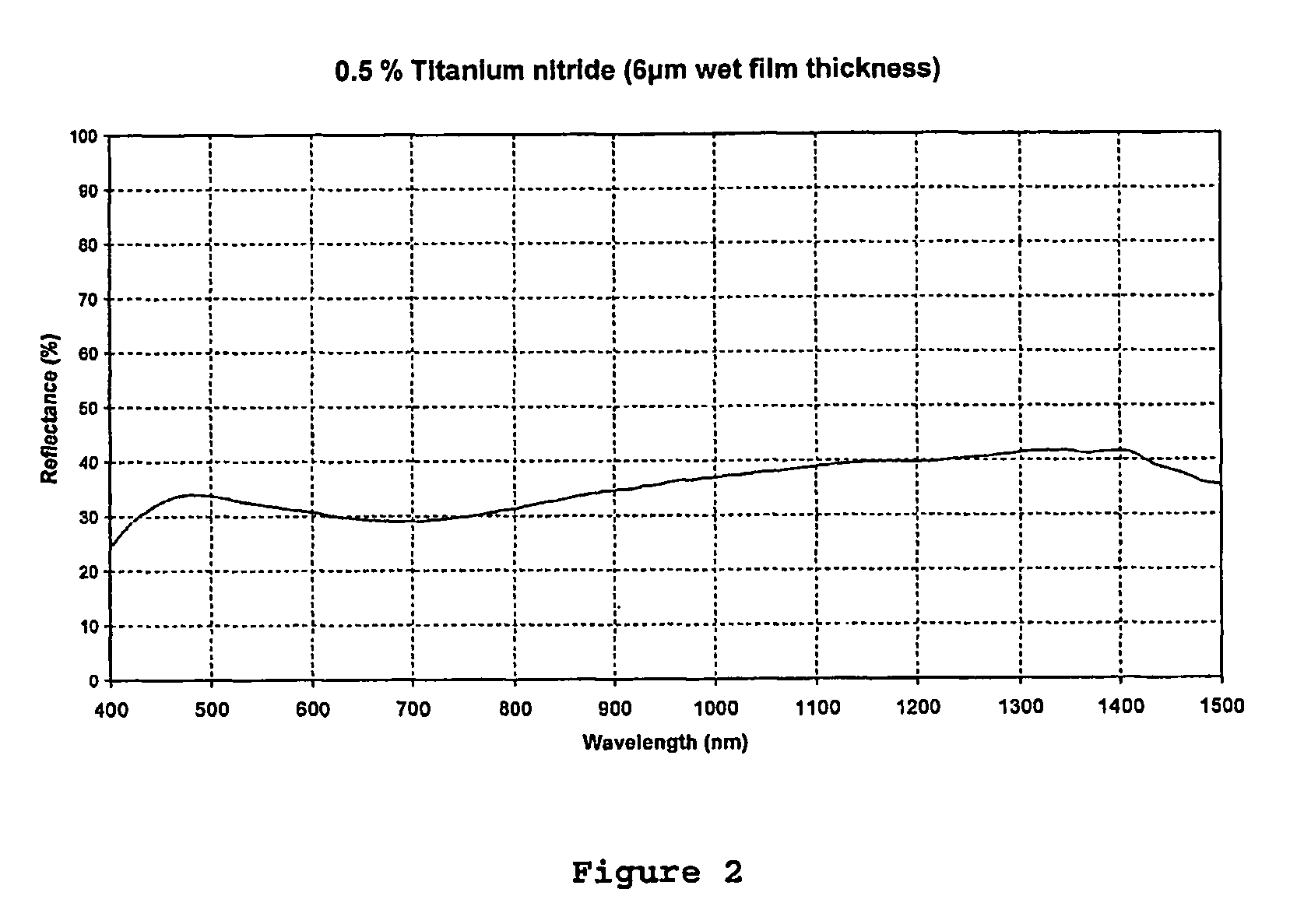

Composition including an oleophilic base ink composition having dispersed therein particles of an infrared-absorbing material wherein the infrared-absorbing material is selected from reduced indium tin oxide, titanium nitride, zirconium nitride, molybdenum metal, copper chromate, lanthanum hexaboride, neodymium oxide, neodymium chloride, dysprosium oxide and praseodymium oxide.

Owner:INOVINK

Heat treatable coated article with diamond-like carbon (DLC) and/or zirconium in coating

InactiveUS7537801B2Pretreated surfacesGlass/slag layered productsDiamond-like carbonMaterials science

In certain example embodiments, a coated article includes a zirconium nitride inclusive layer before heat treatment (HT). The coated article is heat treated sufficiently to cause the zirconium nitride based layer to transform into a zirconium oxide based layer that is scratch resistant and / or durable. In certain example embodiments, the zirconium nitride and / or zirconium oxide may be doped with F and / or C.

Owner:GUARDIAN GLASS LLC

Photocatalytic window and method of making same

InactiveUS7846492B2Increased durabilityFacilitate transmissionPretreated surfacesGlass/slag layered productsTitaniumHeat treated

Certain example embodiments of this invention relate to a photocatalytic coated article and a method of making the same. In certain example embodiments, a coated article includes a zirconium nitride and / or oxide inclusive layer before heat treatment (HT). The coated article is heat treated so that following heat treatment (e.g., thermal tempering) a zirconium oxide based layer is provided. A photocatalytic layer (e.g., of an oxide of titanium) may be formed over zirconium oxide based layer following heat treatment.

Owner:GUARDIAN GLASS LLC

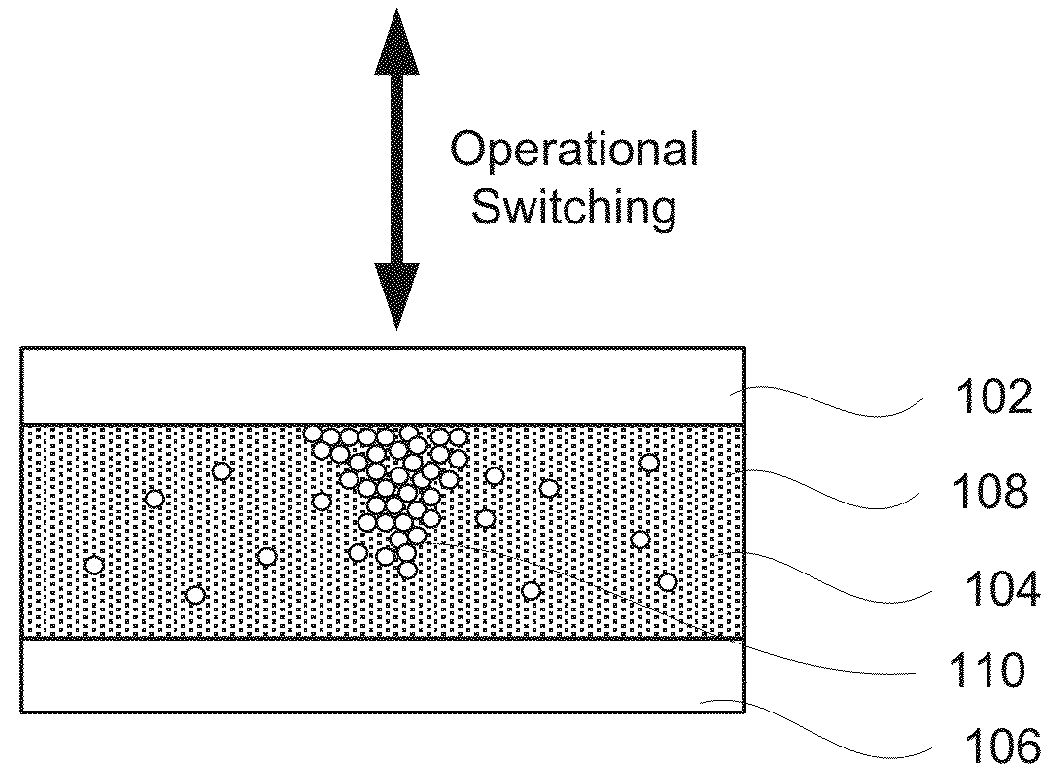

Doped narrow band gap nitrides for embedded resistors of resistive random access memory cells

ActiveUS9231203B1Easy to operateAvoid excessiveSemiconductor/solid-state device manufacturingBulk negative resistance effect devicesNiobiumHafnium

Provided are memory cells, such as resistive random access memory (ReRAM) cells, and methods of fabricating such cells. A cell includes an embedded resistor and resistive switching layer connected in series within the embedded resistor. The embedded resistor prevents excessive electrical currents through the resistive switching layer, especially when the resistive switching layer is switched into its low resistive state. The embedded resistor includes a stoichiometric nitride that has a bandgap of less than 2 eV. The embedded resistor is configured to maintain a substantially constant resistance throughout fabrication and operation of the cell, such as annealing the cell and subjecting the cell to forming and switching signals. The stoichiometric nitride may be one of hafnium nitride, zirconium nitride, or titanium nitride. The embedded resistor may also include a dopant, such as tantalum, niobium, vanadium, tungsten, molybdenum, or chromium.

Owner:INTERMOLECULAR

Zirconium aluminum composite ceramic non-stick pan and preparation technology thereof

InactiveCN103724011ASimple processLess one-time investmentCooking vesselsZirconium hydrideComposite ceramic

The invention belongs to the technical field of zirconium aluminum composite ceramics and particularly relates to a composite ceramic non-stick pan made of zirconium oxide and aluminium oxide and a preparation method thereof. The zirconium aluminum composite ceramic non-stick pan is prepared from the following raw materials in parts by weight: 60-70 parts of zirconium oxide powder, 30-40 parts of aluminium oxide powder, 1-5 parts of yttrium oxide powder and 0.05-0.1 part of a binding agent. The preparation technology of the zirconium aluminum composite ceramic non-stick pan comprises the steps of burdening, grinding, material mixing, pressing of a pan blank, drying, sintering, polishing and end product forming. Compared with the prior art, the technology is simple, less equipment is required, one-time investment is less, the output is large and the production expansion is easy; the prepared zirconium aluminum composite ceramic non-stick pan has the advantages of light weight, excellent tenacity, large density, abrasion resistance, corrosion resistance and non-stick performance.

Owner:SHANDONG UNIV OF SCI & TECH

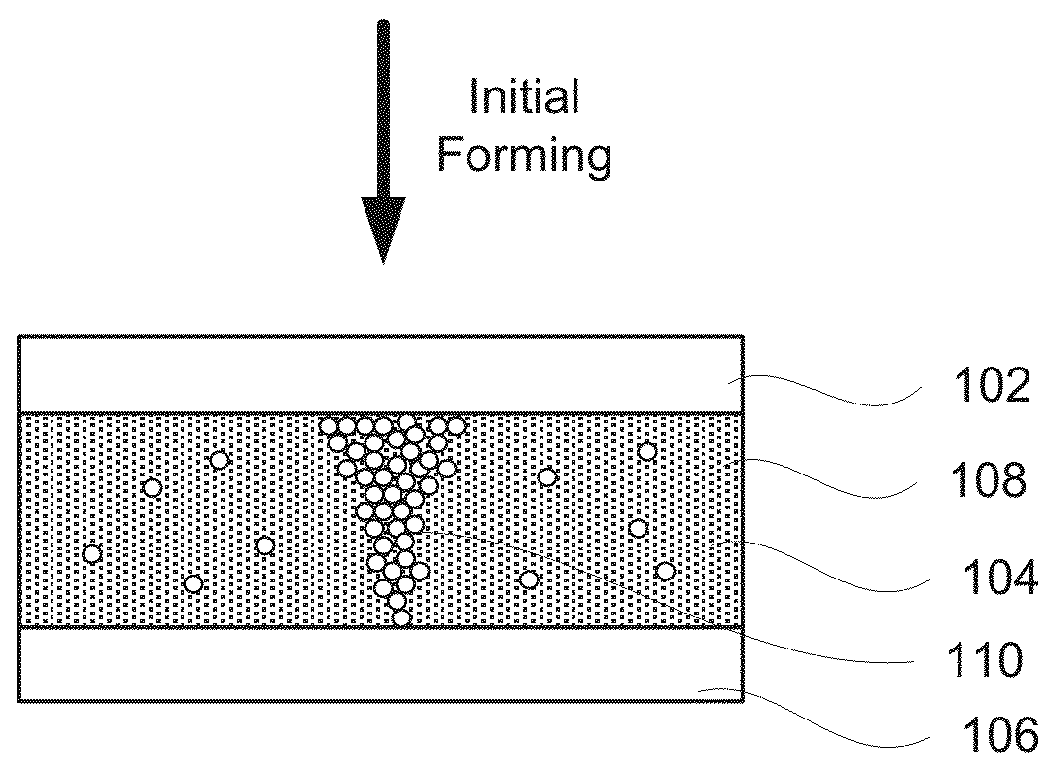

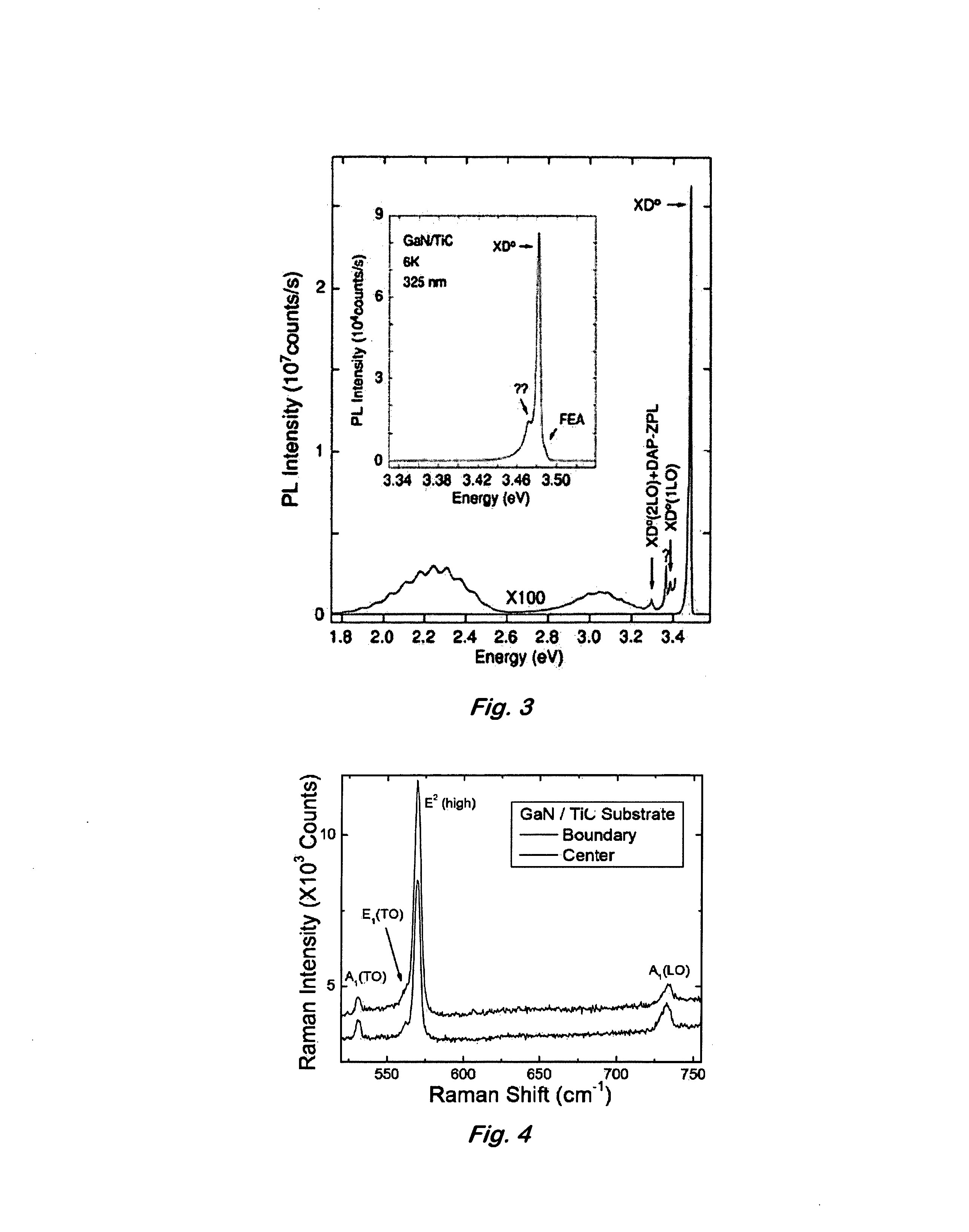

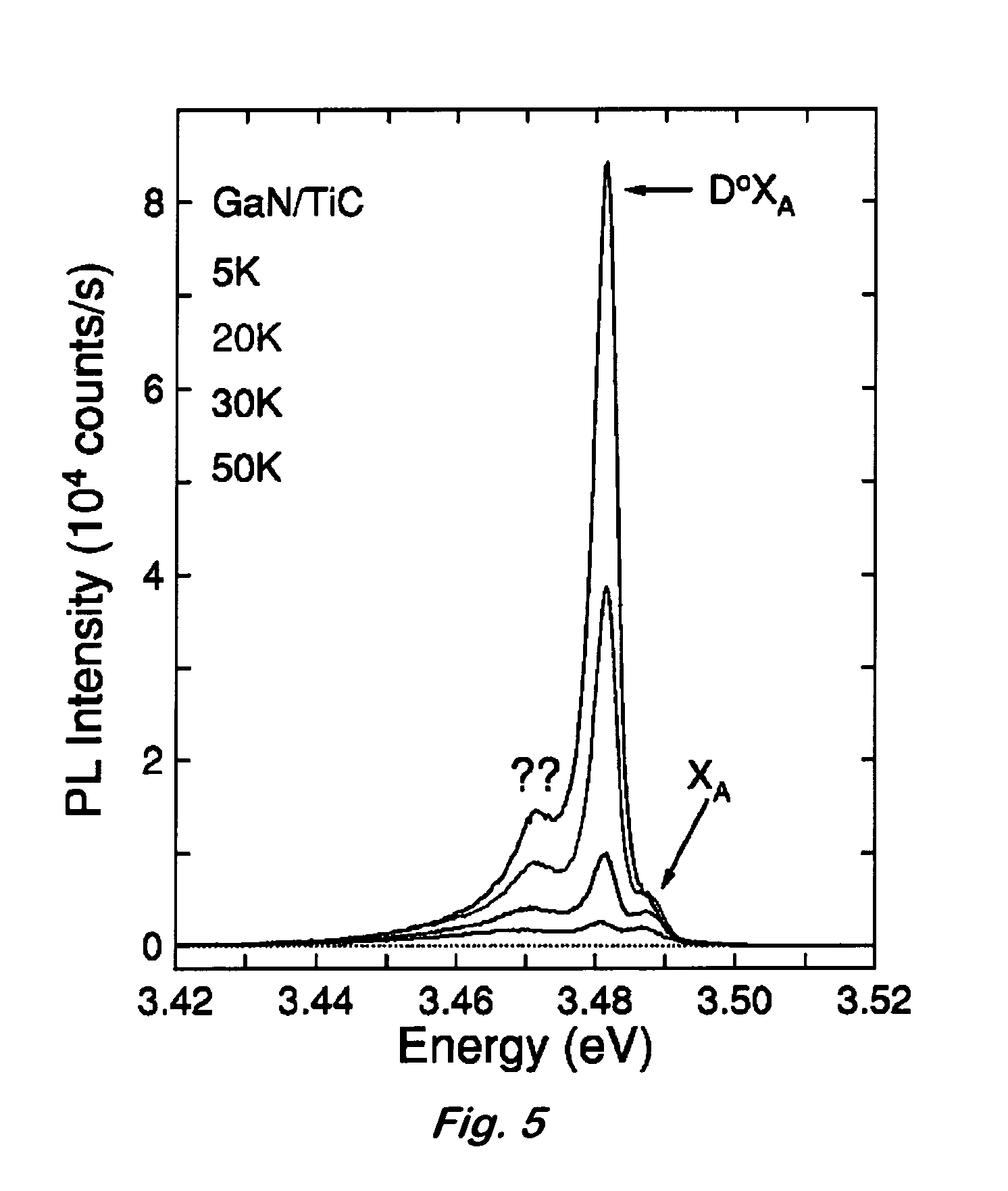

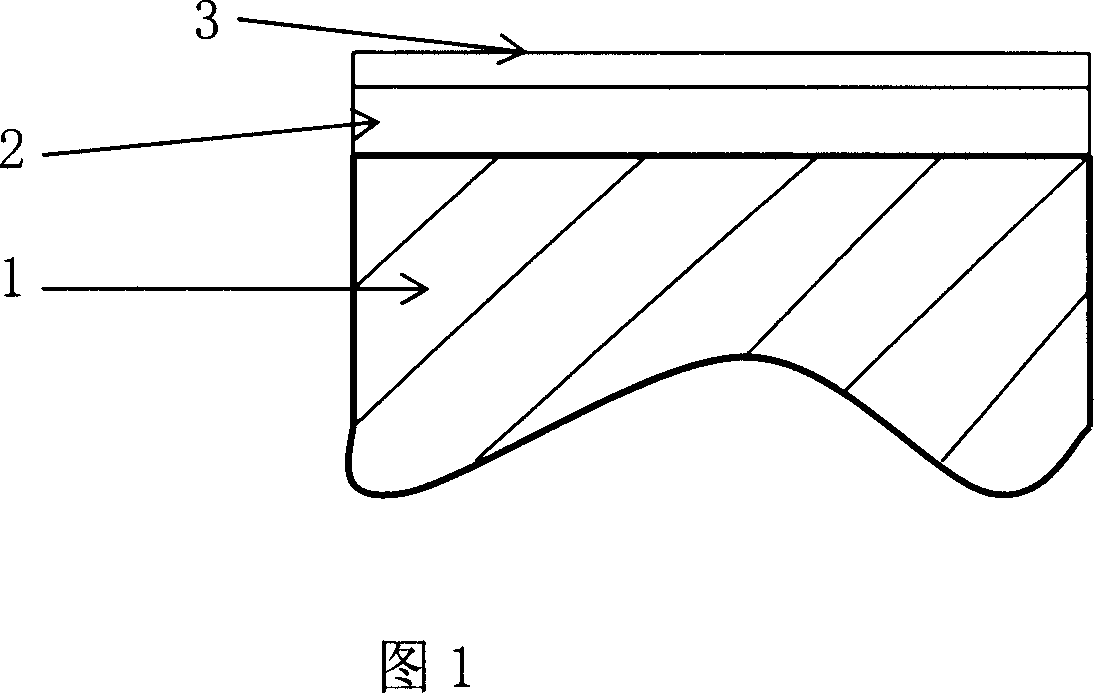

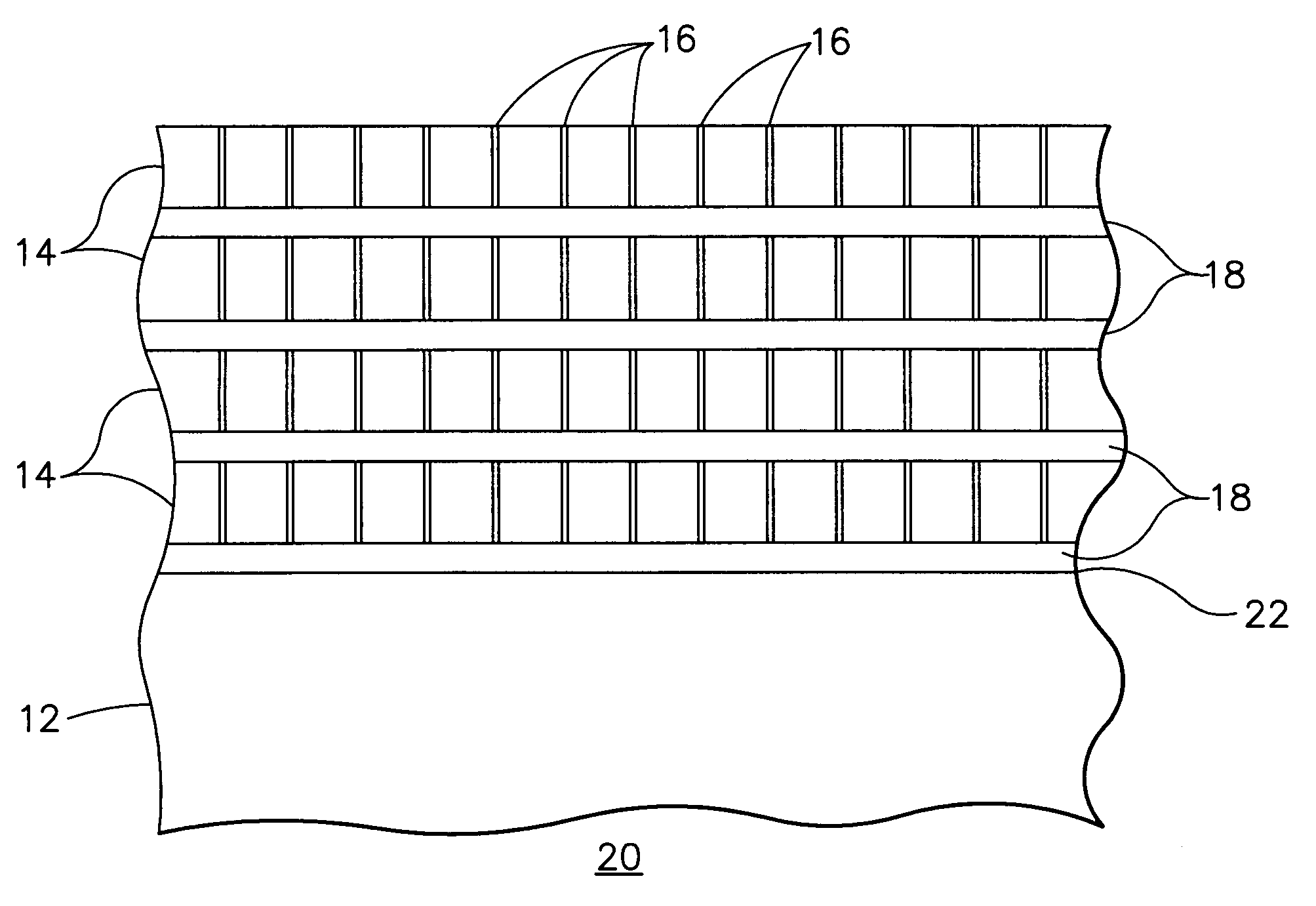

Crystalline III-V nitride films on refractory metal substrates

InactiveUS7482674B1Semiconductor/solid-state device manufacturingSemiconductor devicesHafniumChromium nitride

An article of manufacture having a substrate having a top surface and a first layer on the top surface. The top surface contains titanium carbide, vanadium carbide, zirconium carbide, niobium carbide, hafnium carbide, tantalum carbide, tungsten carbide, chromium nitride, molybdenum nitride, tungsten nitride, titanium nitride, vanadium nitride, zirconium nitride, or a combination thereof. The first layer contains one or more group III-V metal nitrides.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Plastic surface vacuum plating process

InactiveCN1986869AHas a semi-specular glossy textureImprove insulation performanceMovable spraying apparatusVacuum evaporation coatingMegasonic cleaningUltraviolet

The vacuum plating process for plastic surface includes the following steps: ultrasonic cleaning of the plastic workpiece surface, applying one 5-20 microns thick primer onto the surface of the plastic workpiece, ultraviolet ray curing, and vacuum sputtering with metal Zr target material in Ar flow rate of 140 Sccm, plating power of 2-9 Kw and N2 flow rate of 50 Sccm for 3-5 sec to obtain zirconium nitride film of 10-70 nm thickness. The plated film on the surface of plastic part has semi-mirror texture and excellent insulating effect.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

Hard, ductile coating system

InactiveUS7211338B2Improve deposition efficiencyLiquid surface applicatorsEngine manufactureCarbide coatingSurface layer

Owner:HONEYWELL INT INC

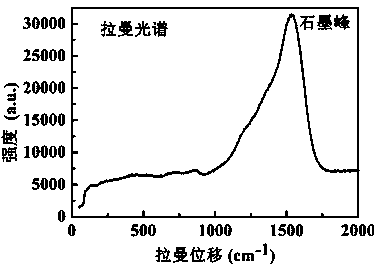

Preparation method of elastic hard lubricating nano composite thin-film material

The invention discloses a preparation method of an elastic hard lubricating nano composite thin-film material. According to the method, the elastic hard lubricating nano composite thin-film material is prepared at low temperature through the combination of the technologies of magnetron sputtering deposition and plasma treatment; the thin film adopts a nitride (such as titanium nitride (TiN), chromium nitride (CrN), zirconium nitride (ZrN), and the like) porous structure as a skeleton, and nanopores are filled with soft matter graphite, so that the hard phase / soft phase composite nano thin film is formed, the surface is smooth, the bonding with a base material is firm, and high hardness and toughness and good lubricating behavior are achieved; and the porous thin film is applicable to the fields of flexible electronic materials, flat panel displays, microelectronic mechanical systems, polymer protection, glass sheets, textile fabrics, antifriction and abrasion-resistant objects, and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process for producing thin hafnium or zirconium nitride coatings

InactiveUS20070042224A1Semiconductor/solid-state device manufacturingNatural mineral layered productsGas phaseCompound (substance)

A process for producing hafnium(III) nitride (HfN) or zirconium nitride coatings by means of the CVD method (chemical vapour deposition) from a reactive gas on a substrate surface, the HfN coating or ZrN coating and their use are described. In the process, a hafnium or zirconium tetrakis(dialkylamide) having the general formula Hf(NR1R2)4 or Zr(NR1R2)4 wherein R1 and R2 denote identical or different, straight-chain or branched C1 to C4 alkyl radicals, is used as the Hf precursor or Zr precursor and a hydrazine derivative having the general formula H2N—NR3R4 wherein R3 denotes a straight-chain or branched C1 to C4 alkyl radical and R4 independently denotes a C1 to C4 alkyl radical or H, is used as the reactive gas.

Owner:H C STARCK GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com