Shell with colored film layer

A color film and shell technology, applied in the field of shells with a color film, can solve the problems of film peeling, easy wear, poor film adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

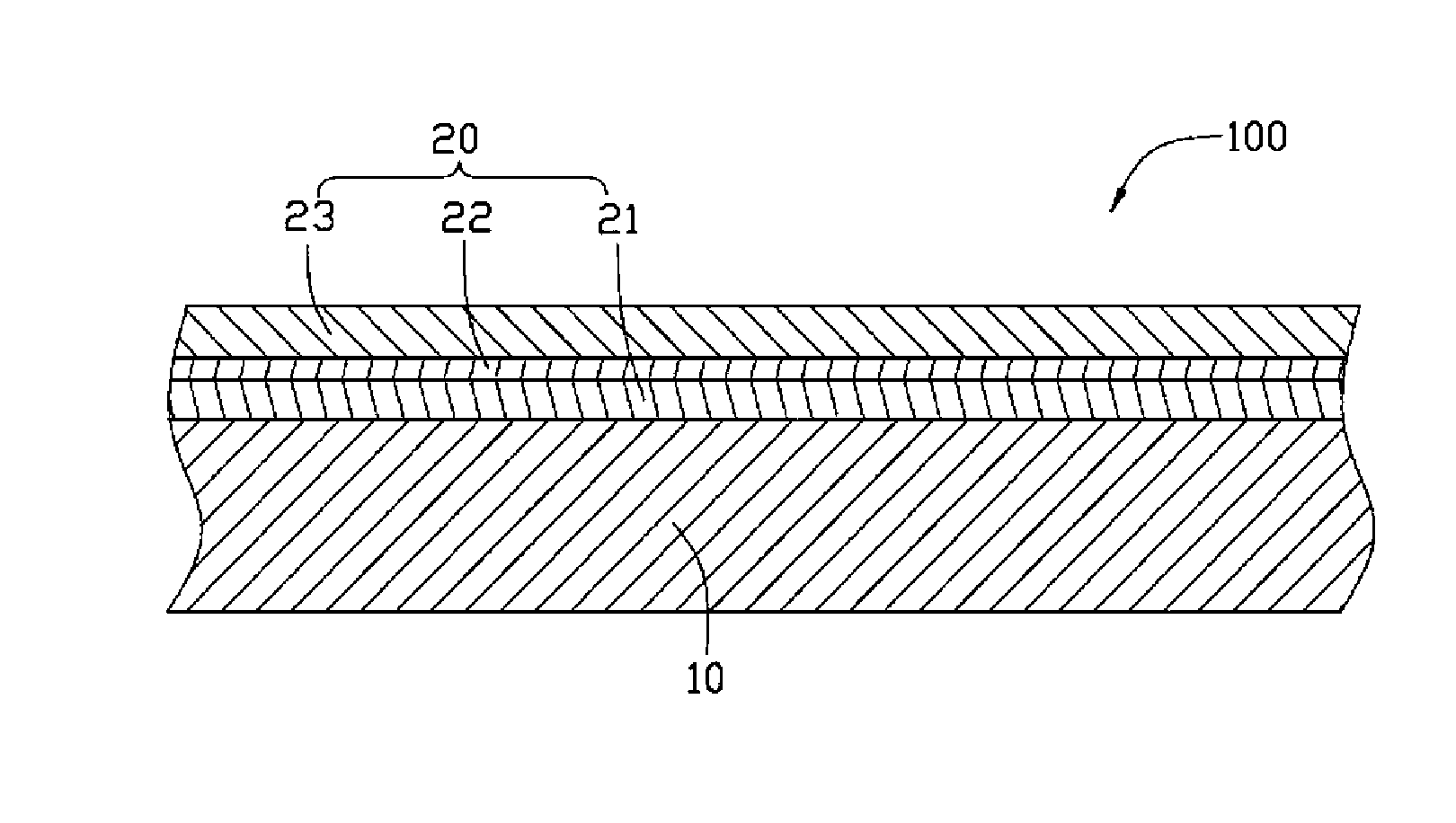

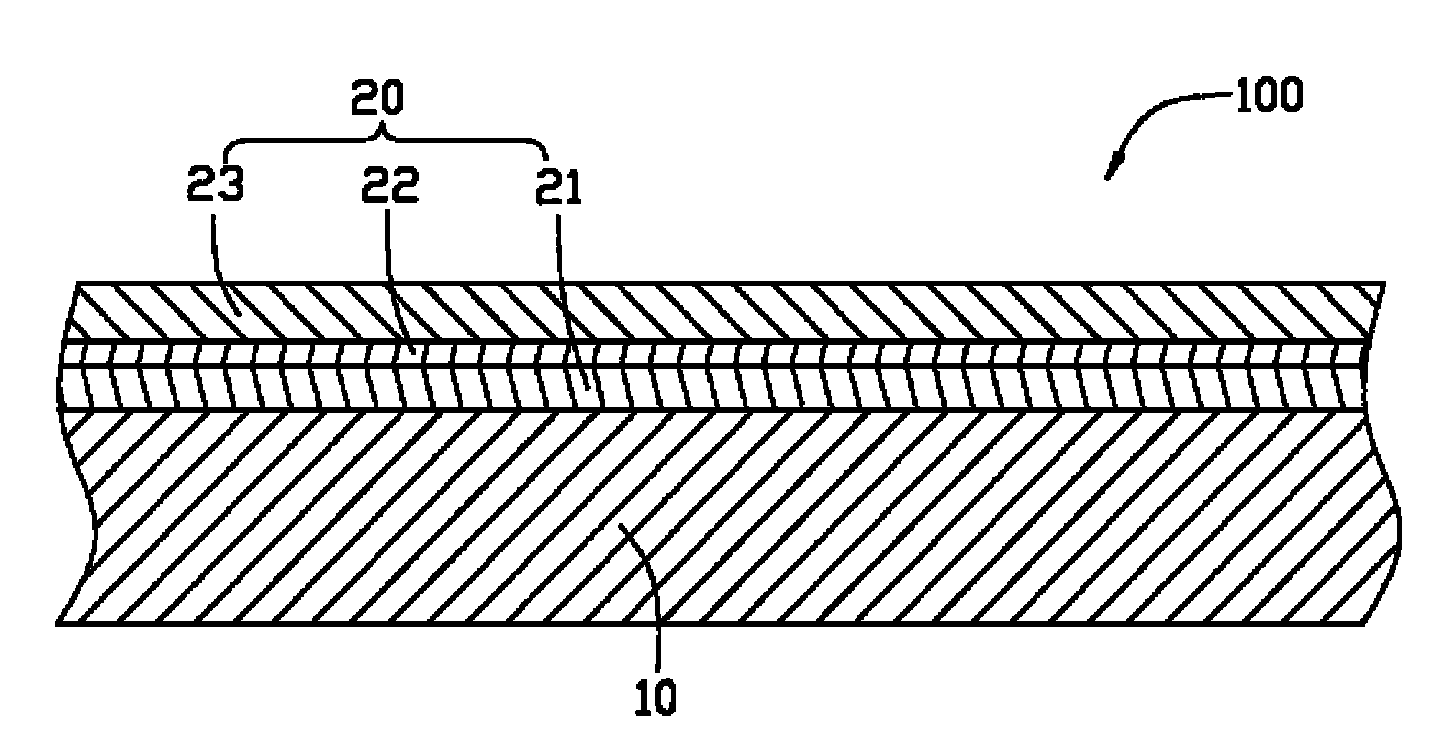

[0009] see figure 1 , the housing 100 with a color film layer of the present invention includes a base material 10 and a composite film layer 20 plated on the base material 10 . The composite film layer 20 includes a color layer 21 covering the substrate 10 , a middle layer 22 covering the color layer 21 , and a protective layer 23 covering the middle layer 22 .

[0010] The substrate 10 can be metal material or glass. The color layer 21 is a layer of colored metal nitride layer, specifically Al 2 o 3 and Cr 2 o 3 A mixture of titanium nitride (TiN), titanium aluminum nitride (TiAlN), zirconium nitride (ZrN), titanium carbide nitride (TiCN), zirconium carbide nitride (ZrCN), or aluminum nitride (AlN). The color layer 21 is used to display colors, and its thickness is between 100 nanometers and 500 nanometers, and the color displayed by the color layer 21 is related to its thickness, and the colors displayed by the color layer 21 with different thicknesses are different. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com