Preparation method of high hardness zirconium nitride hard coat

A hard coating and zirconium nitride technology, which is applied in the coating, metal material coating process, ion implantation plating, etc., can solve the problems of poor crystallinity of the film layer, unguaranteed service life, and insufficient compactness, etc., to achieve Increased compactness, increased hardness, and increased hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Substrate pretreatment: (1) Grinding and polishing: The cemented carbide substrate is subjected to sufficient rough grinding and fine grinding on the 600-mesh and 1200-mesh diamond grinding discs respectively. min, between coarse and fine grinding, the sample should be fully ultrasonically cleaned (ultrasonic cleaning time is 2min) and dried in an oven to remove abrasive dust and oil; after the sample is ground, use W2.5 The diamond polishing powder is used for polishing, and the polishing time is 10 minutes. (2) Ultrasonic cleaning: The polished substrate was cleaned in the following order, acetone ultrasonic cleaning for 5 minutes → absolute ethanol ultrasonic cleaning for 5 minutes → drying for use. (3) Ion source cleaning: Before sputtering deposition, use Hall ion source to clean the substrate, and the pressure of ion cleaning is 2×10 -2 Pa, substrate temperature 300°C, argon flux 10sccm, bias voltage of negative 100V, cathode current and voltage of 29.5A and 1...

Embodiment 2

[0028]1. Substrate pretreatment: (1) Grinding and polishing: Same as Example 1. (2) ultrasonic cleaning: with embodiment 1. (3) ion source cleaning: with embodiment 1.

[0029] 2. Pre-sputtering: same as embodiment 1.

[0030] 3. Sputtering deposition: After the pre-sputtering, argon and nitrogen are introduced, and the flow rate of nitrogen is 20%, the working pressure of deposition is 0.3Pa, the DC power of Zr target is 275W, the sputtering time is 100min, the substrate The temperature is 375°C and the substrate bias is negative 75V. After the deposition is complete, the sample is taken out and stored in a desiccator, pending characterization and analysis. After the deposition is complete, the sample is taken out and stored in a desiccator, pending characterization and analysis.

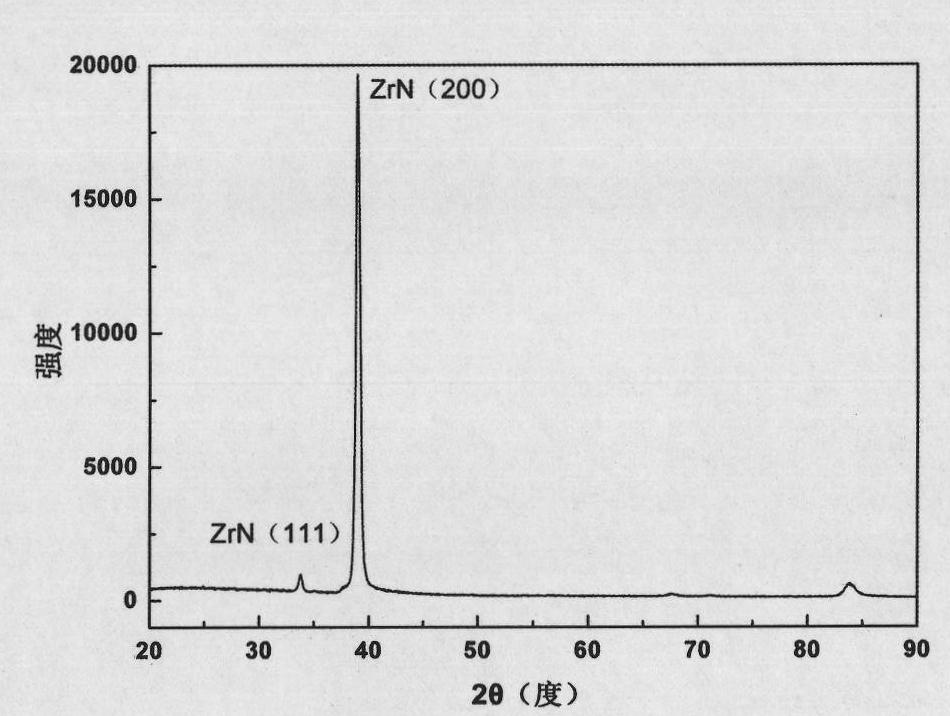

[0031] image 3 It is the XRD spectrum of the coating, indicating that the prepared coating is a coating with a face-centered cubic structure.

[0032] 4. The chemical composition of the coat...

Embodiment 3

[0035] 1. Substrate pretreatment: (1) Grinding and polishing: Same as Example 1. (2) ultrasonic cleaning: with embodiment 1. (3) ion source cleaning: with embodiment 1.

[0036] 2. Pre-sputtering: same as embodiment 1.

[0037] 3. Sputtering deposition: after the pre-sputtering, argon and nitrogen are introduced, the flow rate of nitrogen is 15%, the working pressure of deposition is 0.5Pa, the DC power of Zr target is 300W, the sputtering time is 110min, the substrate The temperature is 450°C and the substrate bias is negative 75V. After the deposition is complete, the sample is taken out and stored in a desiccator, pending characterization and analysis. After the deposition is complete, the sample is taken out and stored in a desiccator, pending characterization and analysis.

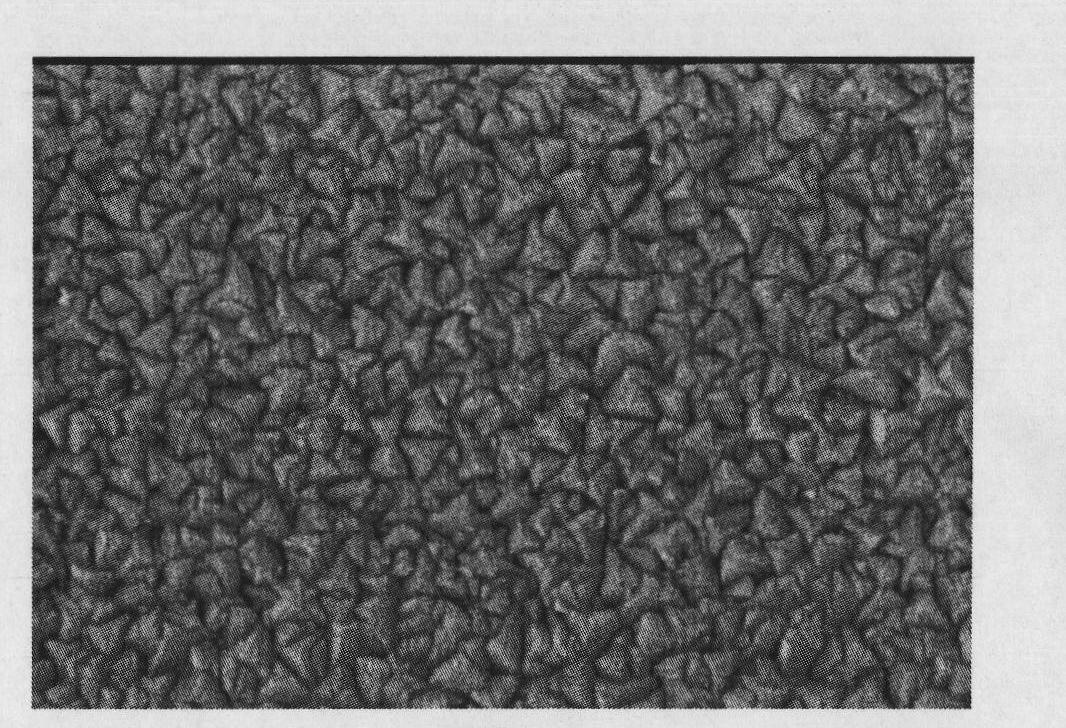

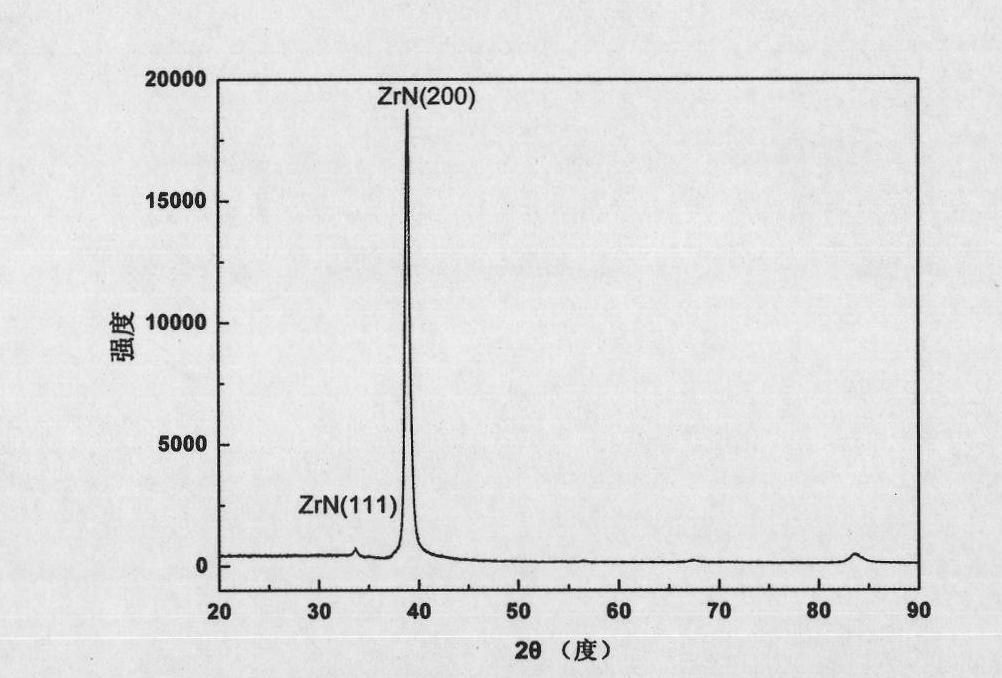

[0038] Figure 4 It is the XRD spectrum of the coating, indicating that the prepared coating is a coating with a face-centered cubic structure. Figure 5 It is the surface SEM morphology of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com