Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

99 results about "Neodymium chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Neodymium(III) chloride or neodymium trichloride is a chemical compound of neodymium and chlorine with the formula NdCl3. This anhydrous compound is a mauve-colored solid that rapidly absorbs water on exposure to air to form a purple-colored hexahydrate, NdCl3·6H2O.

Rare-earth catalyst for diolefin polymerization and its prepn.

This invention is attributed to the rare earth catalyst for diene polymerization and its preparation method. The catalyst is composed of neodymium chloride electron donor complex and organic methylaluminoxane with a molar ratio of 1:20~200. Monomers can be also added, with a neodymium chloride electron donor complex / monomer molar ratio of 1:5~40. The preparation method is simple and the obtained rare earth catalyst has high catalytic activity. With this catalyst, polybutadiene with a cis-1, 4-butadiene content of over 95%, polyisopentadiene and butadiene / isopentadiene copolymer can be obtained and the polymers uniquely have narrow molecular weight distributions, i.e., the ratio of weight-average molecular weight to number-average molecular weight is not larger than 2.0.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

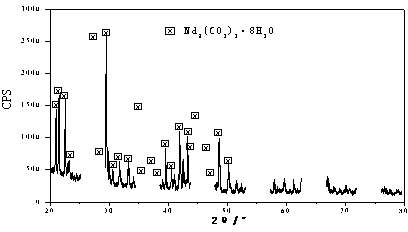

Method for preparing large-particle and flaky praseodymium neodymium oxide

InactiveCN102502760AEvenly distributedGood dispersionNanotechnologyRare earth metal compoundsMaterials preparationNeodymium chloride

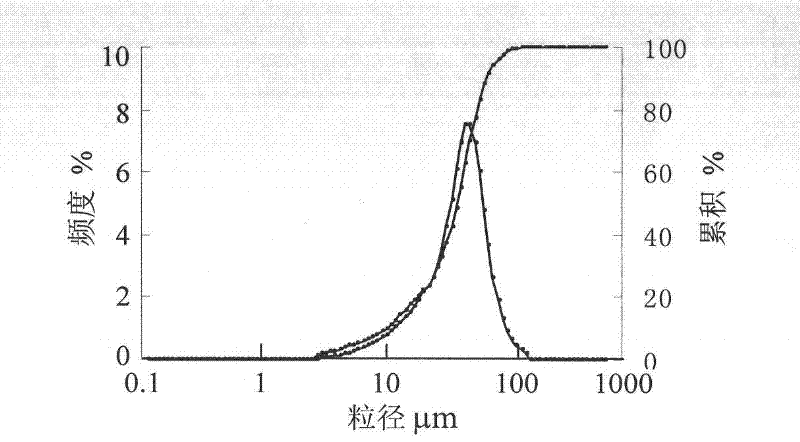

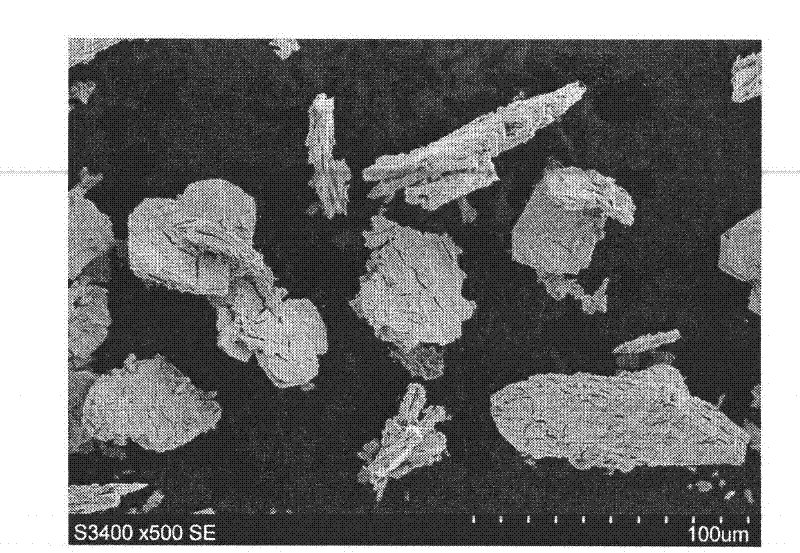

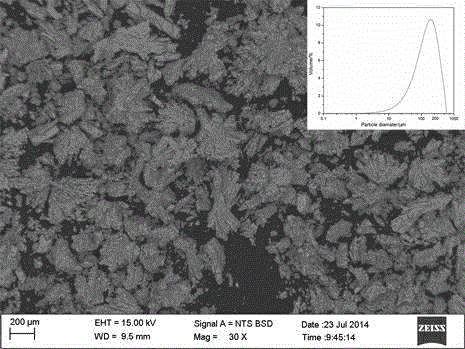

The invention relates to a method for preparing large-particle and flaky praseodymium neodymium oxide, and belongs to a material preparation technology. The method comprises the following steps of: preparing praseodymium neodymium carbonate by using a praseodymium neodymium chloride solution as a raw material and using ammonium hydrogen carbonate as a precipitating agent, washing, filtering, centrifugally drying and firing the praseodymium neodymium carbonate sediment, and thus obtaining the flaky praseodymium neodymium oxide product with the central particle size of 25 to 45 microns. The precipitation temperature and the concentration of the praseodymium neodymium carbonate are the key, the precipitation temperature is controlled to be 60 DEG C, and the concentration of the praseodymium neodymium chloride solution is controlled to be 0.15-0.5mol / L; the large-particle praseodymium neodymium oxide product of which the central particle size is 25 to 45 microns, is produced by using a conventional praseodymium neodymium carbonate precipitating procedure in a factory; and the product is uniform in particle distribution, good in dispersibility and flaky.

Owner:INNER MONGOLIA UNIV OF SCI & TECH +1

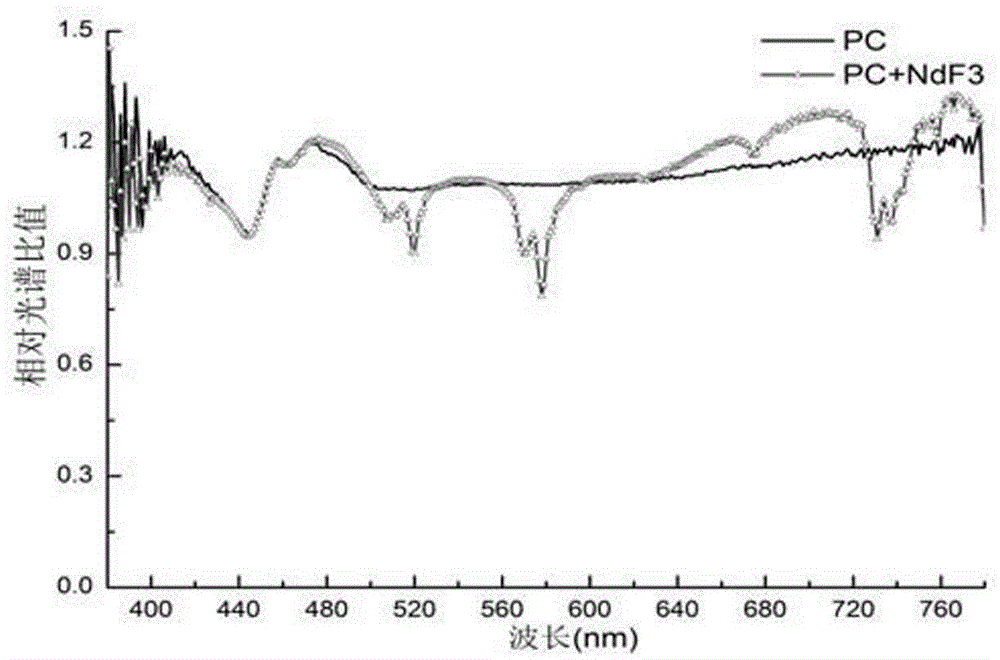

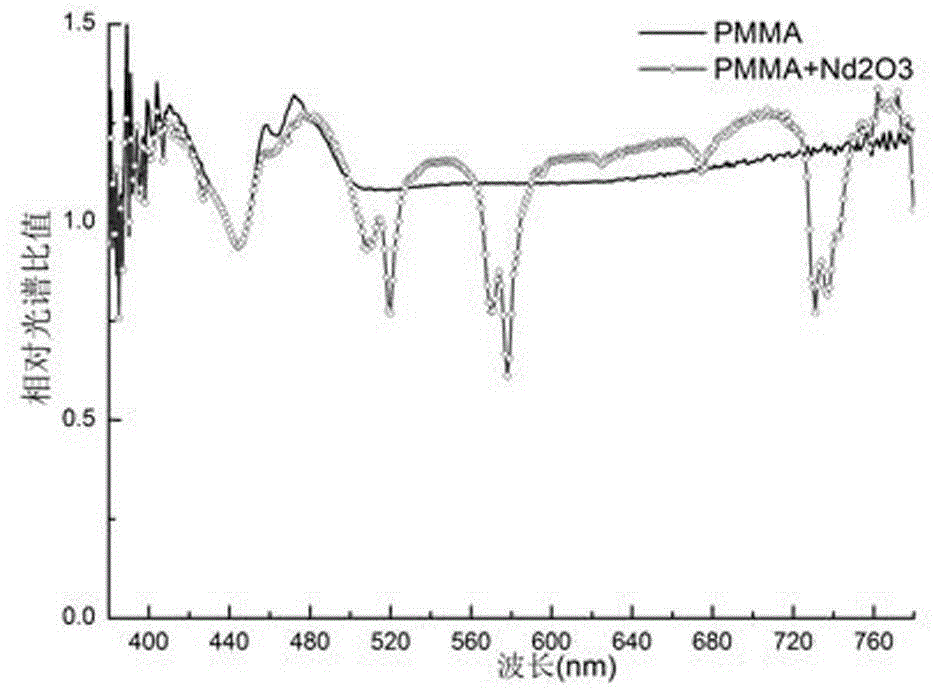

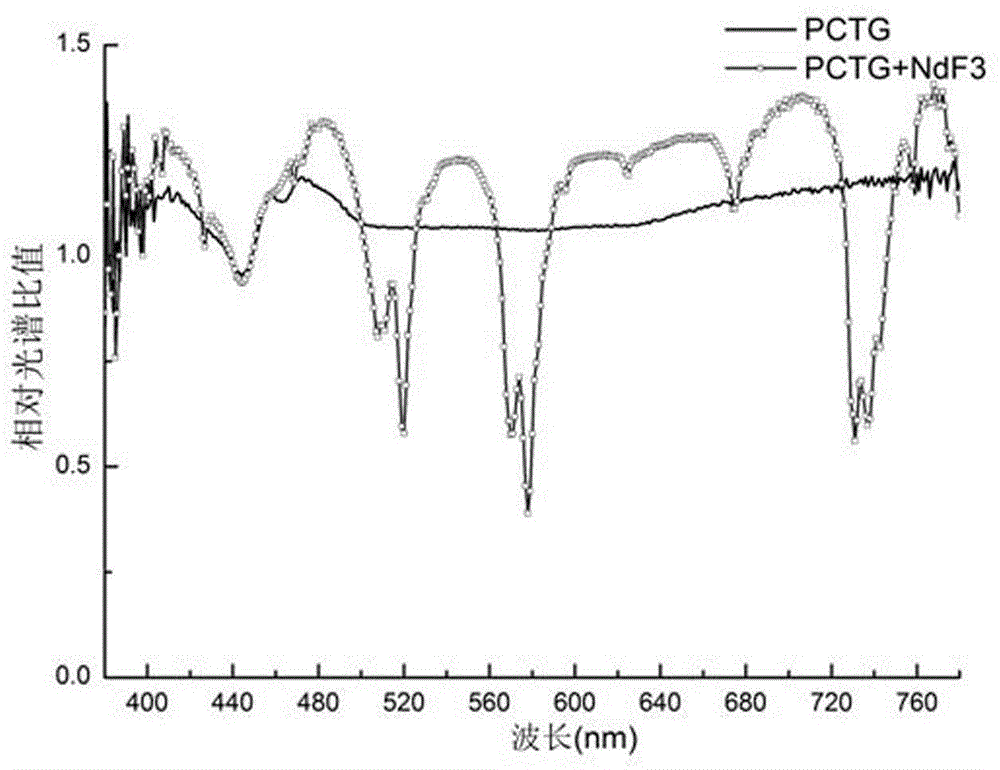

LED material for filtering yellow light and preparation method thereof

ActiveCN104650568AHigh light transmittanceExcellent optical properties such as hazePhysical chemistryOptical transmittance

The invention relates to the technical field of high-molecular materials and particularly relates to an LED material for filtering yellow light and a preparation method thereof. The LED material for filtering yellow light is prepared from the following raw materials in parts by mass: 60-100 parts of a base material, 1-13 parts of a yellow light filtration aid, 0.1-1.0 part of a light diffusing agent, 0.1-0.8 part of an antioxidant, 0.2-0.4 part of a dispersant DP310 and 2-26 parts of deionized water, wherein the yellow light filtration aid is one or more than one of neodymium fluoride, neodymium oxide, neodymium chloride and neodymium nitrate. The LED material for filtering yellow light, prepared by the method disclosed by the invention, is excellent in optical performances such as yellow light filtration property, light transmittance and haze and can be used for effectively filtering and eliminating yellow light generated by an LED lamp so as to relieve the fatigue of eyes and preventing the eyes from damages of yellow light. The preparation method of the LED material is simple in process, convenient to operate and control, stable in quality, high in yield, high in production efficiency and low in production cost.

Owner:DONGGUAN ZOYO ELECTRONICS TECH CO LTD

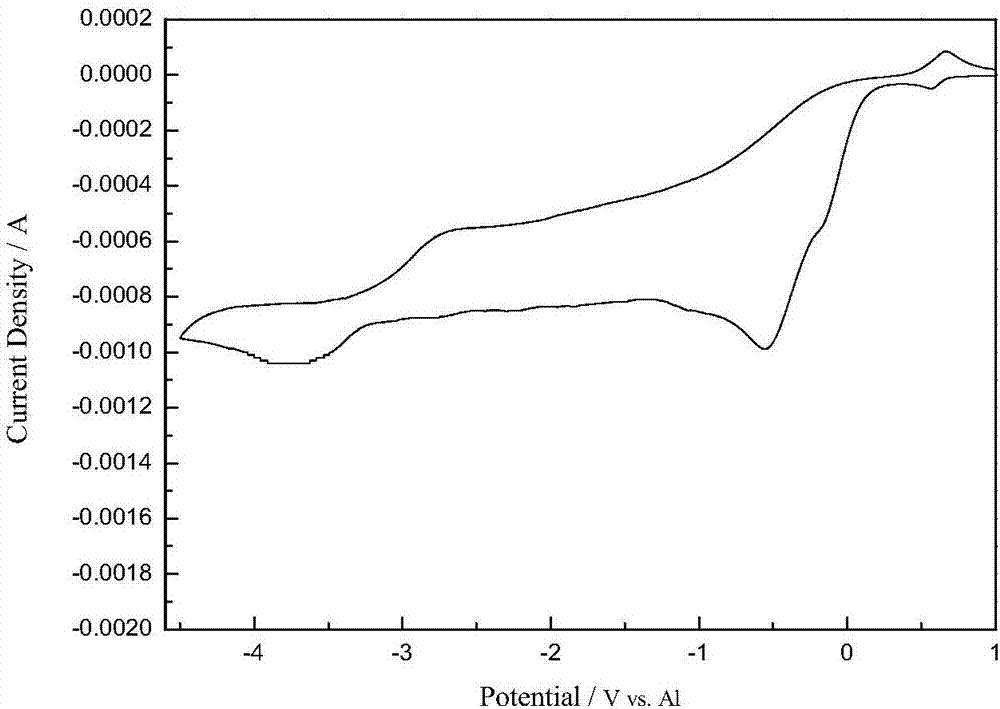

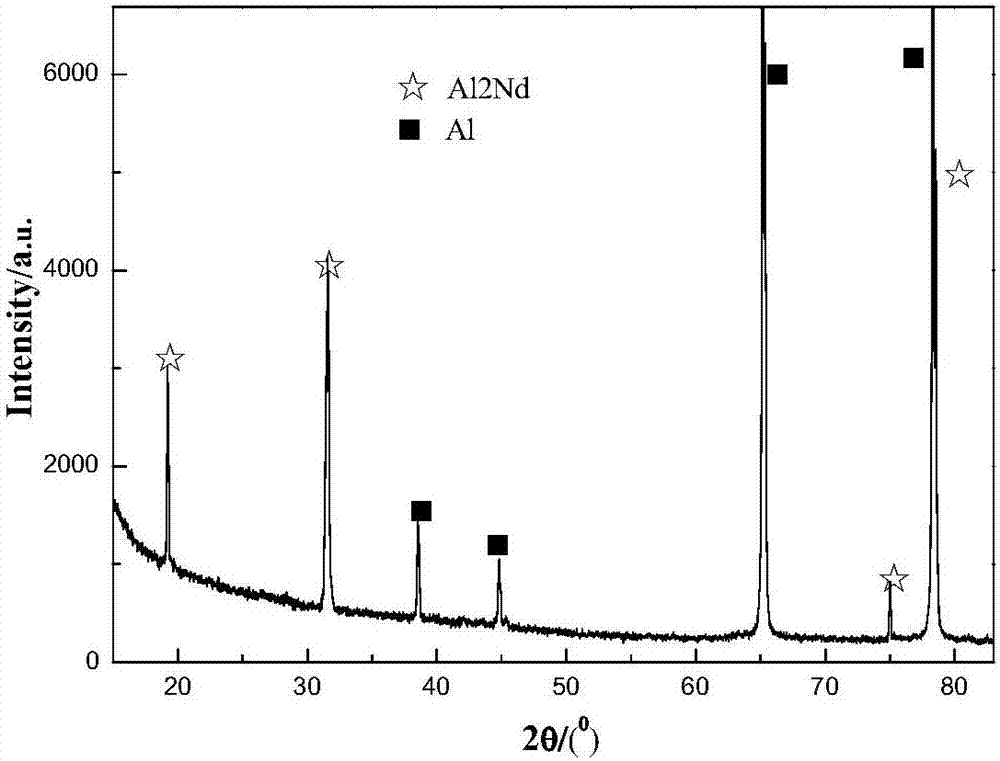

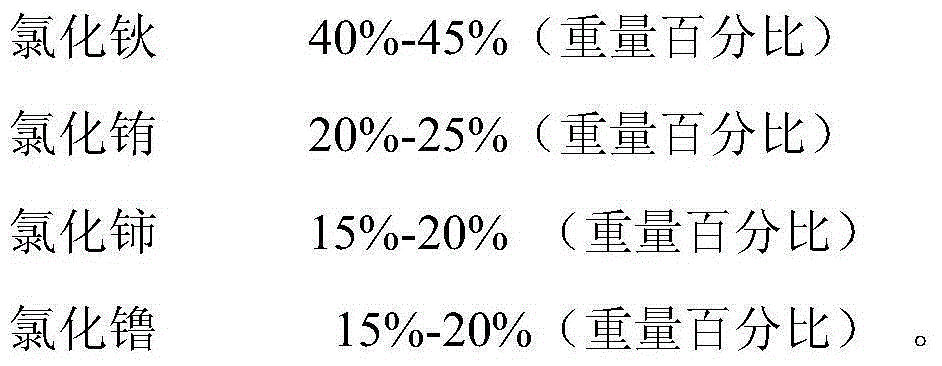

Method for preparing aluminum-based rare earth alloy through near-room-temperature electrolysis

The invention belongs to the field of low-temperature electrochemical extraction and particularly relates to a method for preparing an aluminum-based rare earth alloy through near-room-temperature electrolysis. The method for preparing the aluminum-based rare earth alloy through near-room-temperature electrolysis is an electrolytic method, and a electrolyte adopted by the electrolytic method is formed by rare earth chloride and ionic liquid, wherein the ionic liquid accounts for 96-98% of the total mass of the electrolyte, the rare earth chloride accounts for 2-4% of the total mass, and the rare earth chloride is one of neodymium chloride, lanthanum chloride, cerium chloride, scandium chloride, yttrium chloride, praseodymium chloride, samarium chloride, europium chloride, gadolinium chloride and terbium chloride. According to the technological for preparing the aluminum-based rare earth alloy through near-room-temperature electrolysis, operation is easy, and cost is low; and the technological reserve and theoretical support are provided for green extraction of the low-cost aluminum-based rare earth alloy.

Owner:NORTHEASTERN UNIV

Security inks containing infrared absorbing metal compounds

ActiveUS8157905B2Easy to detectNot easy to detectNon-fibrous pulp additionLayered productsNeodymium chlorideLanthanum hexaboride

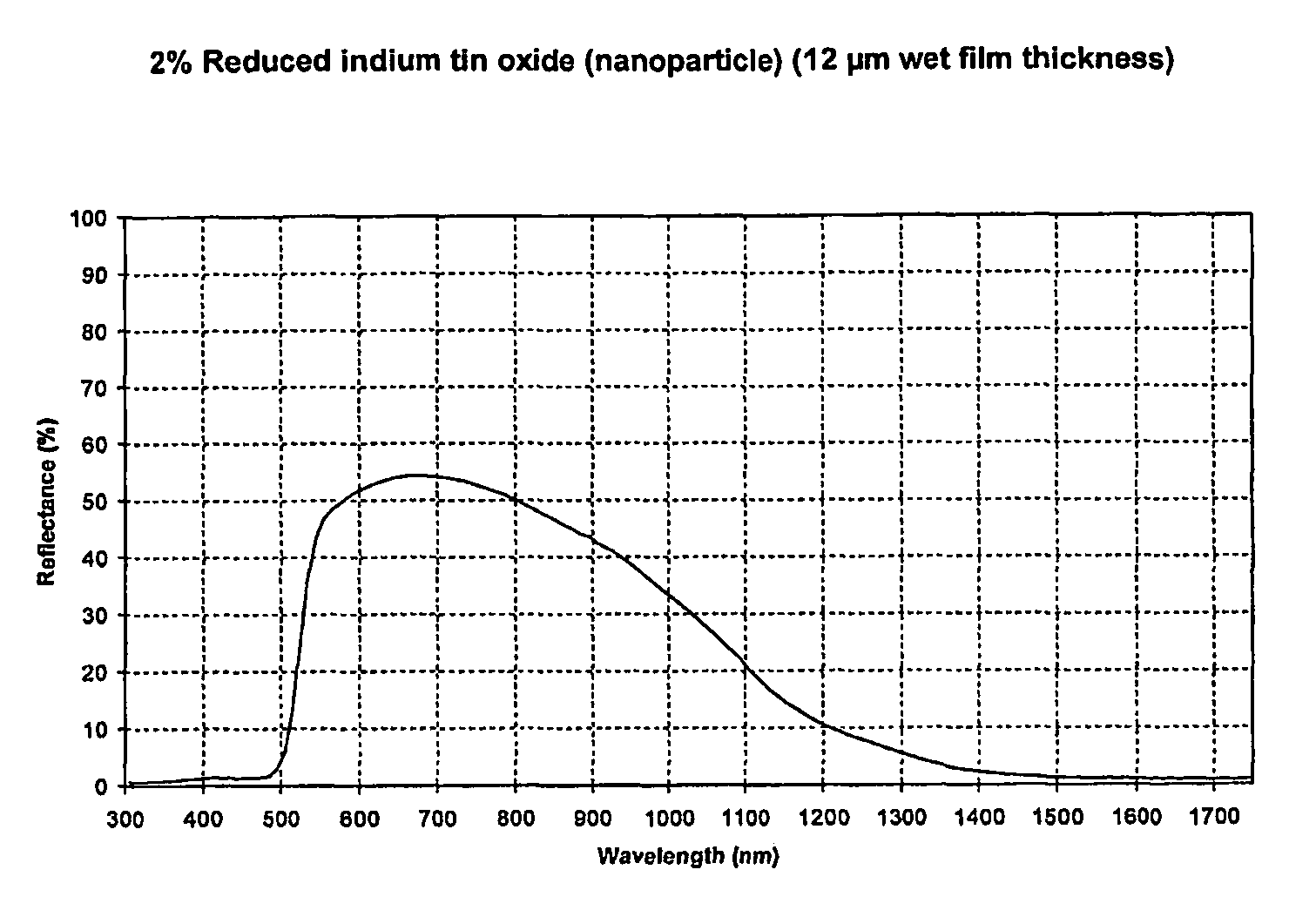

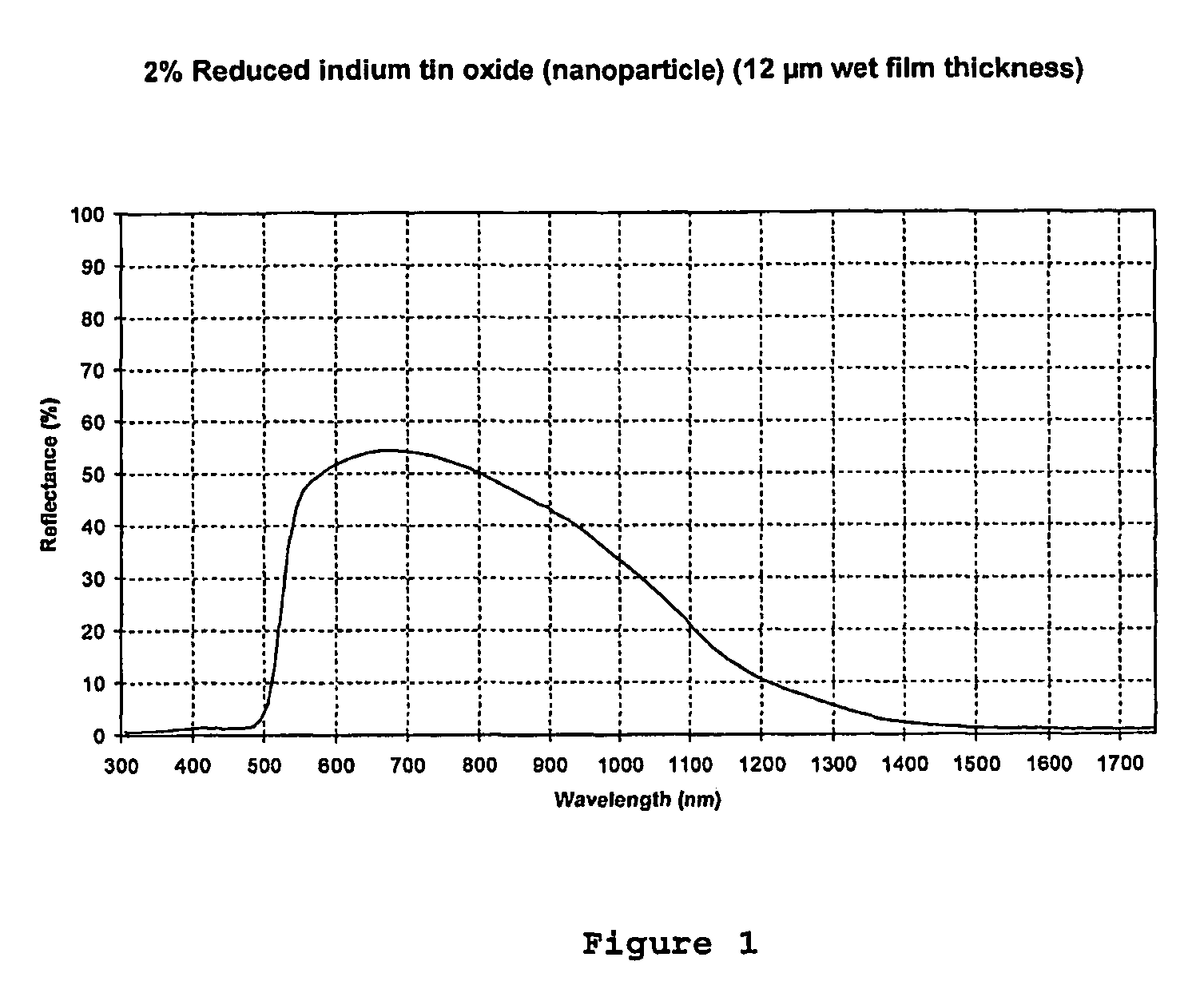

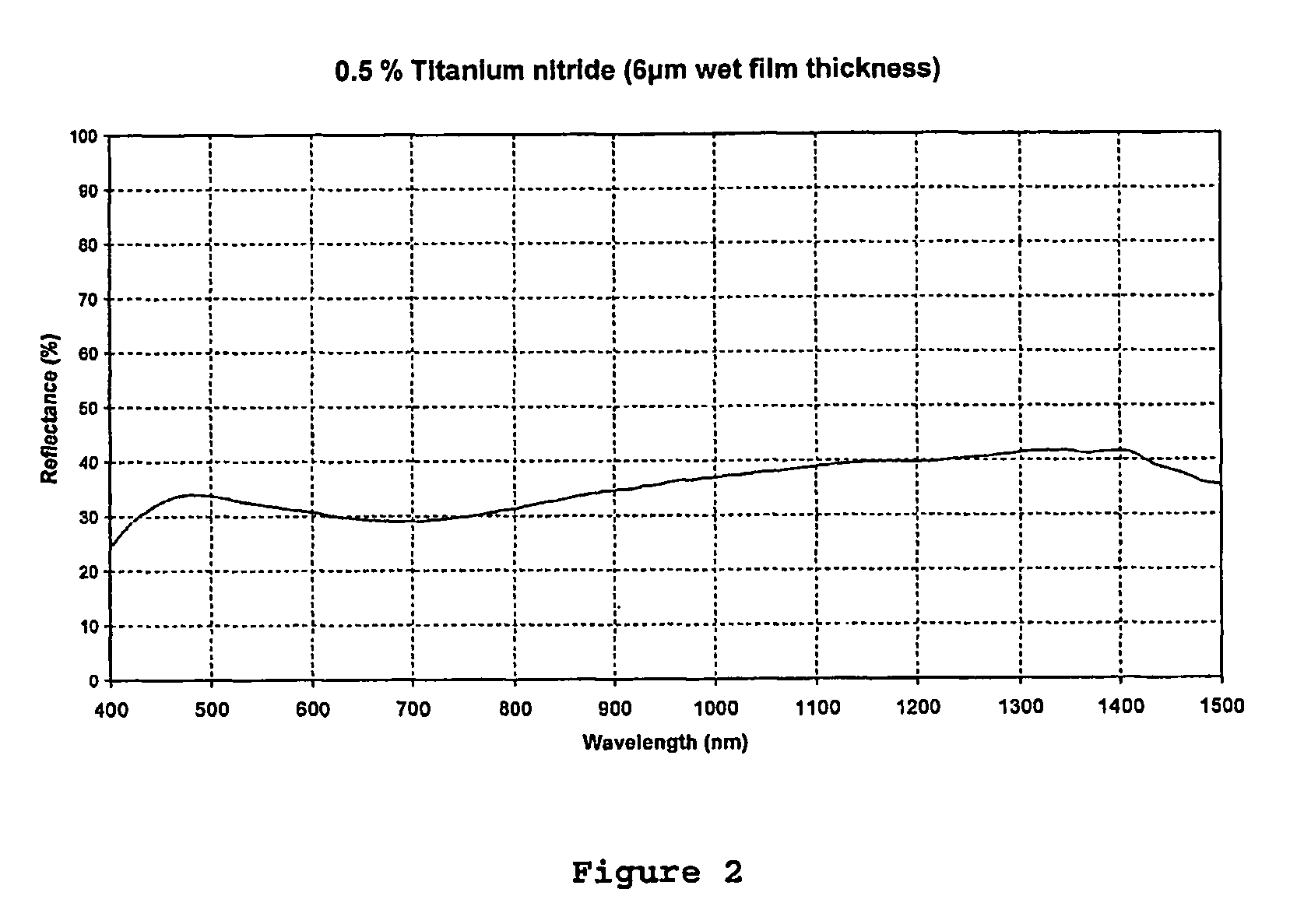

Composition including an oleophilic base ink composition having dispersed therein particles of an infrared-absorbing material wherein the infrared-absorbing material is selected from reduced indium tin oxide, titanium nitride, zirconium nitride, molybdenum metal, copper chromate, lanthanum hexaboride, neodymium oxide, neodymium chloride, dysprosium oxide and praseodymium oxide.

Owner:INOVINK

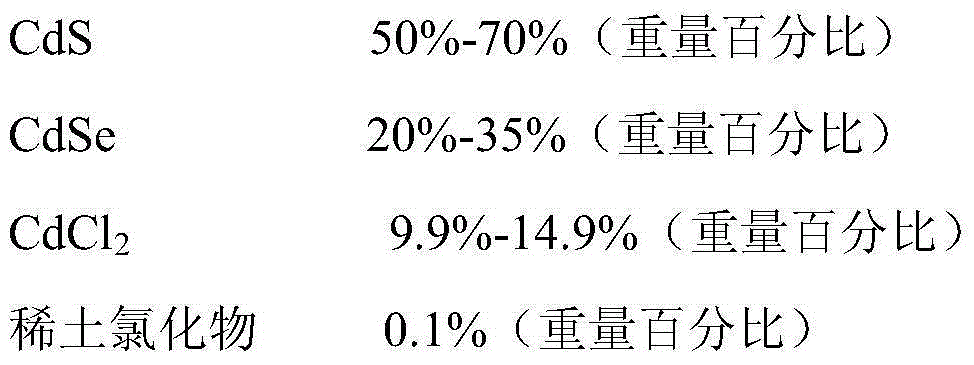

Visible light photosensitive resistor and manufacturing method thereof

ActiveCN105206700AIncrease dark resistanceReduce bright resistanceFinal product manufactureSemiconductor devicesRare earthDysprosium

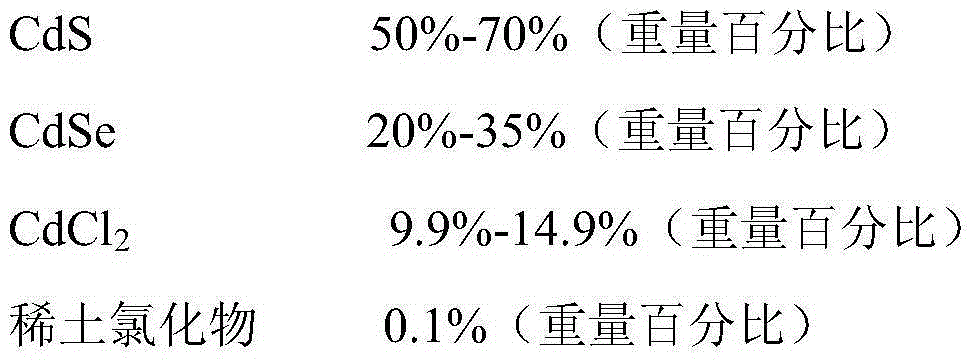

The invention discloses a visible light photosensitive resistor and a manufacturing method thereof. Rare-earth chloride is adopted to replace CyCl2, the rare-earth chloride with the weight percentage being 0.1% is added in photosensitive layer materials comprising CdS, CdSe and CdCl2 and is the mixture of one or two or more of holmium chloride, neodymium chloride, dysprosium chloride and samarium chloride, the matching ratio of the CdS to the CdSe to the CdCl2 is adjusted, and the content of the rare-earth chloride is quite small so that the material cost of the visible light photosensitive resistor cannot be affected; by combining the rare-earth chloride with the materials comprising the CdS, the CdSe and the CdCl2, the dark resistance of the visible light photosensitive resistor can be increased, and the bright resistance of the visible light photosensitive resistor can be reduced. The visible light photosensitive resistor has the advantages that the sensitivity of the visible light photosensitive resistor can be improved, the rare-earth chloride is high in stability, the visible light photosensitive resistor is not likely to be changed in the aging process, other performance parameters of the visible light photosensitive resistor are not reduced, the stability of the visible light photosensitive resistor is high in the aging process, and the rejection rate is greatly reduced.

Owner:NANYANG NORMAL UNIV

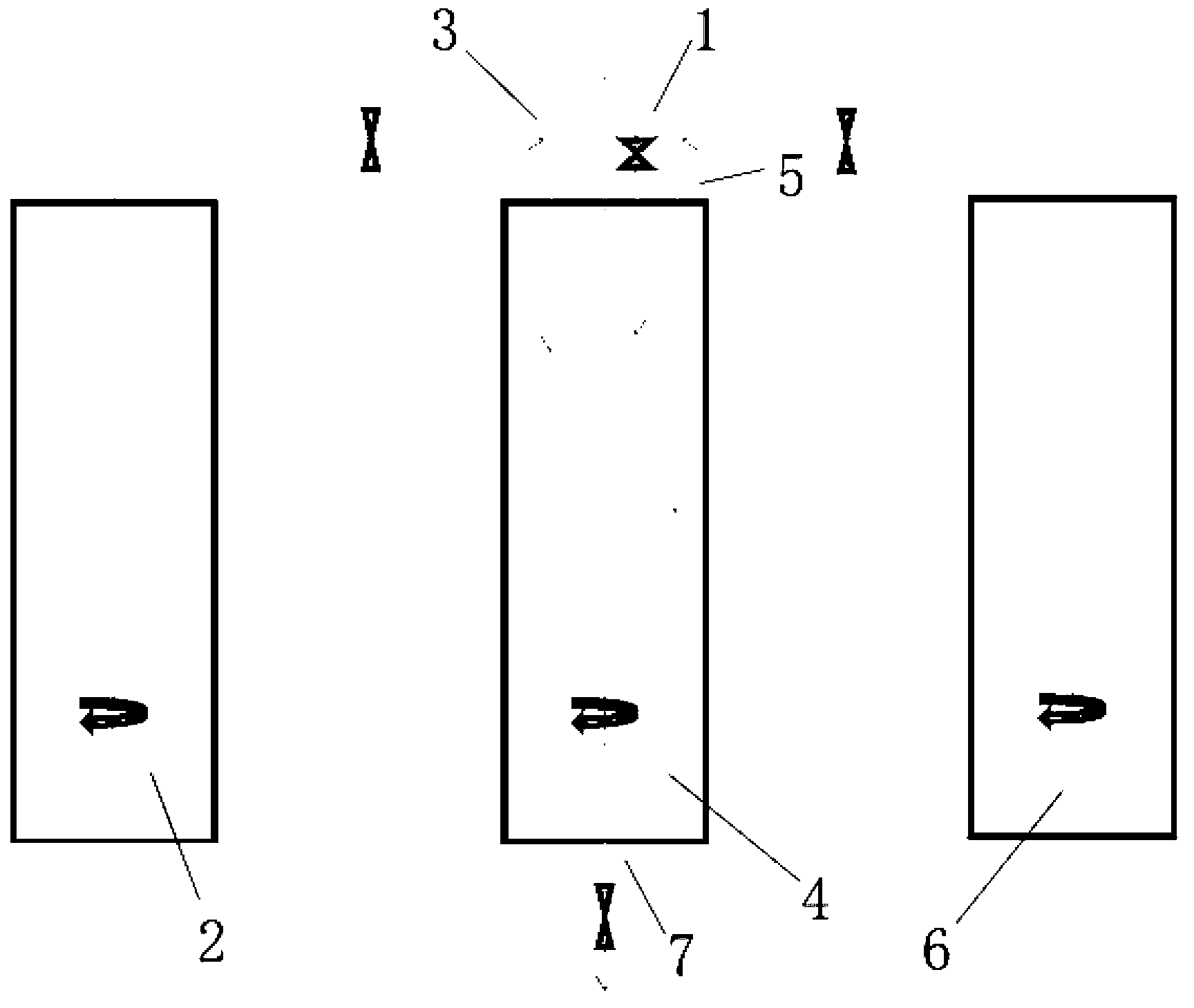

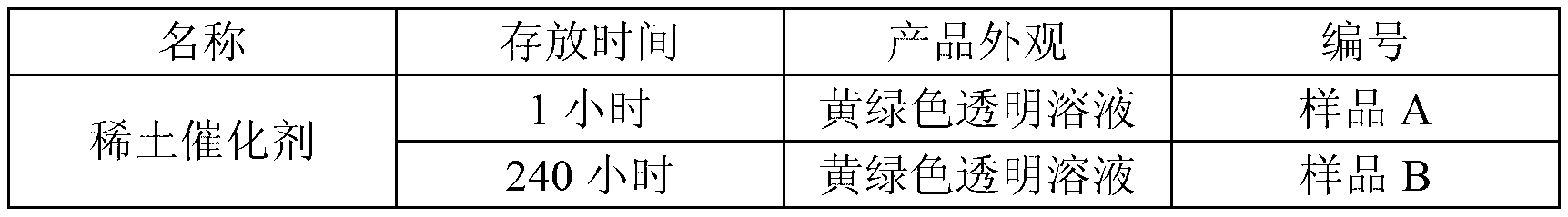

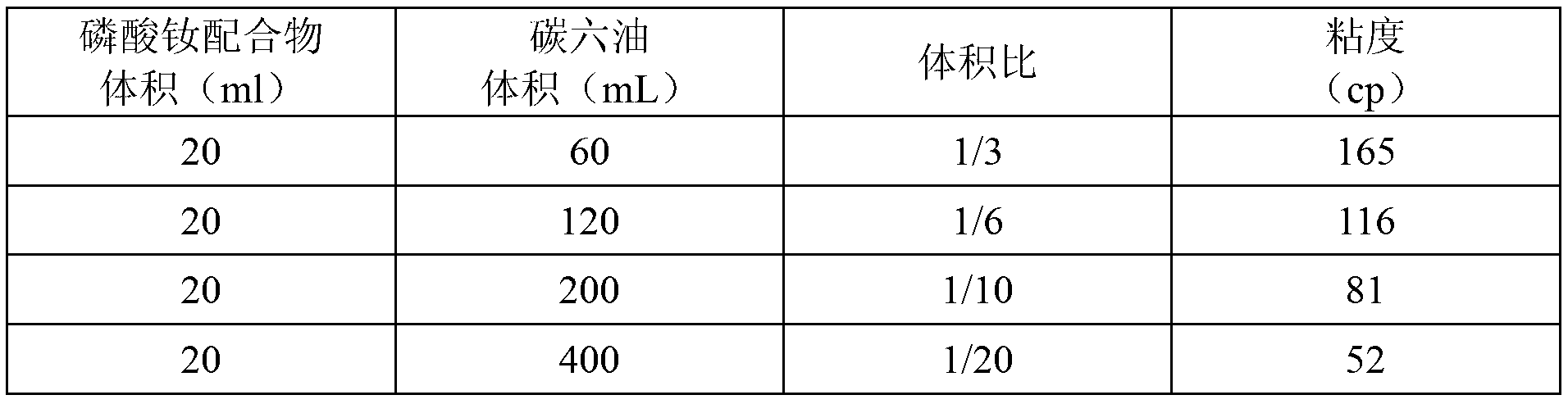

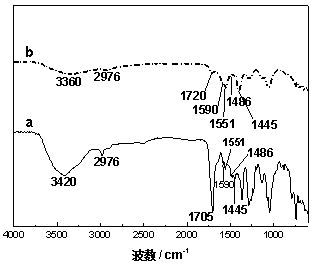

Method for synthesis of solution type neodymium phosphate complex

ActiveCN103224517AFree agingEmission safetyGroup 5/15 element organic compoundsAlkanePhosphoric Acid Esters

The invention relates to a method for synthesis of a solution type neodymium phosphate complex. The method comprises the steps of: preparing neodymium chloride into a neodymium chloride aqueous solution; mixing acidic phosphoric ester with an organic solvent to obtain a phosphoric ester solution, adding an alkaline solution into the phosphoric ester solution to undergo a saponification reaction to obtain a saponified liquid; adding the neodymium chloride aqueous solution into the saponified liquid to undergo a reaction, then performing separation to obtain a first oil phase; adding a complex into the first oil phase, stirring them, and then performing separation to obtain a second oil phase, which is the solution type neodymium phosphate complex. The product of the method provided by the invention is solution type neodymium phosphate, and the product is miscible with alkane, arene and other solvents in arbitrary proportion. In a multicomponent catalyst aging process, more and freer aging modes can be selected. In addition, the method provided in the invention has an obviously simple production process and a low production cost, and the sodium chloride aqueous solution obtained in a layering process can be safely discharged after treatment and does not cause environmental pollution.

Owner:PETROCHINA CO LTD

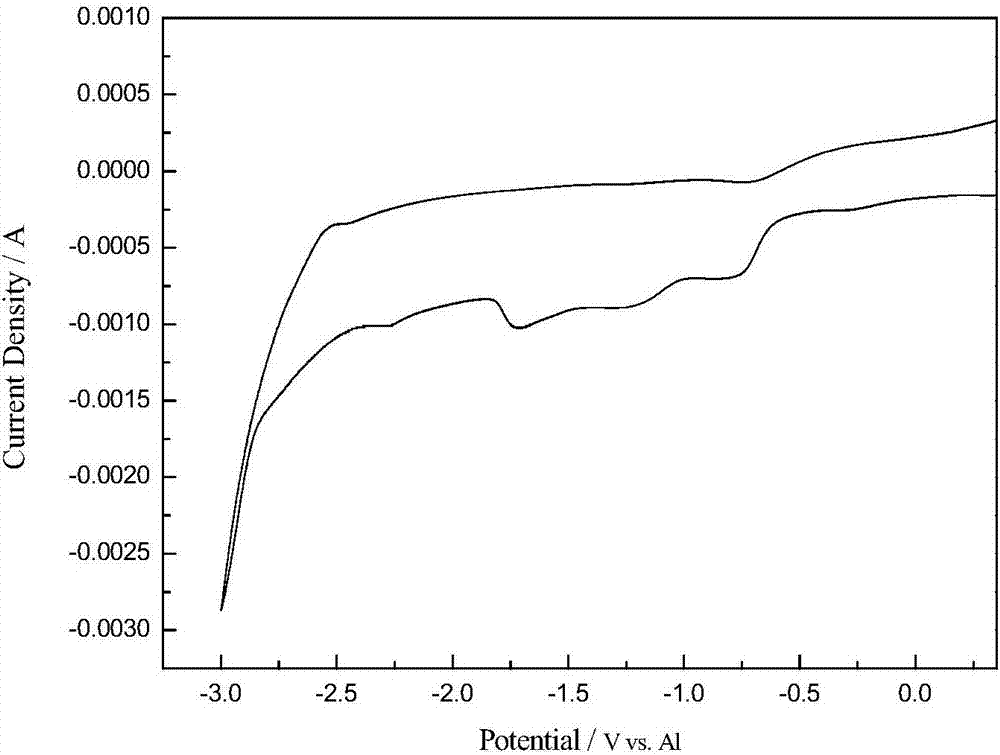

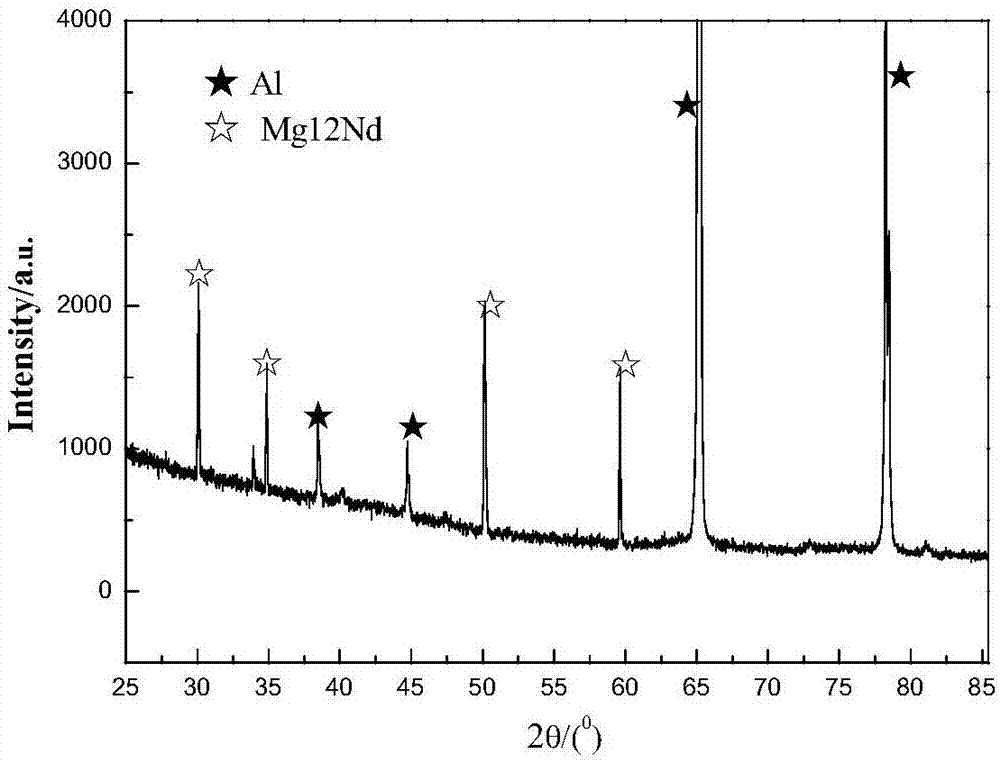

Method for co-depositing magnesium-neodymium mother alloy near room temperature

The invention belongs to the field of non-ferrous metal alloy low-temperature extraction and particularly relates to a method for co-depositing a magnesium-neodymium mother alloy near the room temperature. According to the method for co-depositing the magnesium-neodymium mother alloy near the room temperature, an electrolytic method is adopted. An electrolyte used according to the electrolytic method is composed of neodymium chloride, magnesium chloride, lithium chloride and ion-like liquid, wherein the ion-like liquid accounts for (95-97)% of the total mass of the electrolyte, the neodymium chloride and the magnesium chloride account for (2-4)% of the total mass of the electrolyte, the lithium chloride accounts for 1% of the total mass of the electrolyte, and the mole ratio of the neodymium chloride to the magnesium chloride is 1:1. The process for co-depositing the magnesium-neodymium mother alloy near the room temperature is easy to operate, low in cost and capable of being applied to development of functional materials and surface engineering. Technical reserve and theoretical support are provided for low-cost extraction of magnesium and neodymium.

Owner:NORTHEASTERN UNIV

Preparation of high-purity anhydrous praseodymium chloride or neodymium chloride by programmed heating method

The invention relates to preparation of high-purity anhydrous praseodymium chloride or neodymium chloride by a programmed heating method, and belongs to the field of preparation of rare-earth materials. PrCl3.6H2O or NdCl3.6H2O and ammonium chloride are mixed in a weight ratio of 2:1, and vacuumizing is performed by using a water jet pump; when the vacuum degree reaches 0.08Pa, a heating program is set for heating at the temperature of between room temperature and 350 DEG C, and the sectional heating speed and the heat preservation time are controlled; by analysis and detection, the water content of the obtained anhydrous praseodymium chloride or neodymium chloride is less than 0.1 percent; and the anhydrous praseodymium chloride or neodymium chloride is immediately dissolved when added into water, the aqueous solution obtained after the anhydrous praseodymium chloride or neodymium chloride is dissolved is clear and transparent, and the purity of the product is over 99.9 percent. The method has already been applied to a production line capable of producing 90 kilograms of anhydrous praseodymium chloride or neodymium chloride in each batch in an industrial-scale programmed heating furnace.

Owner:BAOTOU JINGRUI NEW MATERIAL

Method for preparing anhydrous neodymium chloride under open system

InactiveCN103193259AAvoid hydrolysisSimplify the conditions of the vacuum environmentRare earth metal compoundsNeodymium chlorideMedicinal chemistry

Owner:HEILONGJIANG UNIV

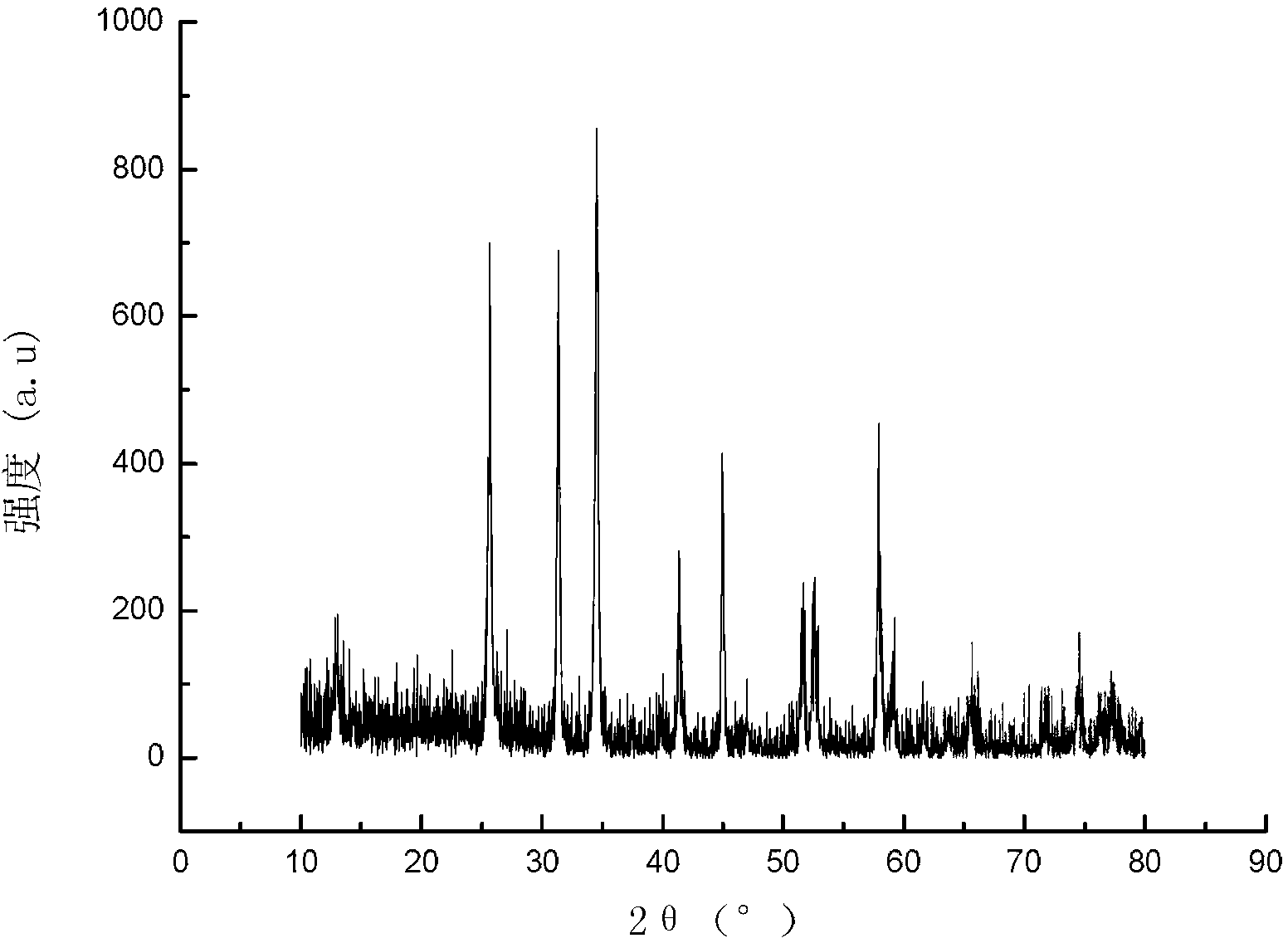

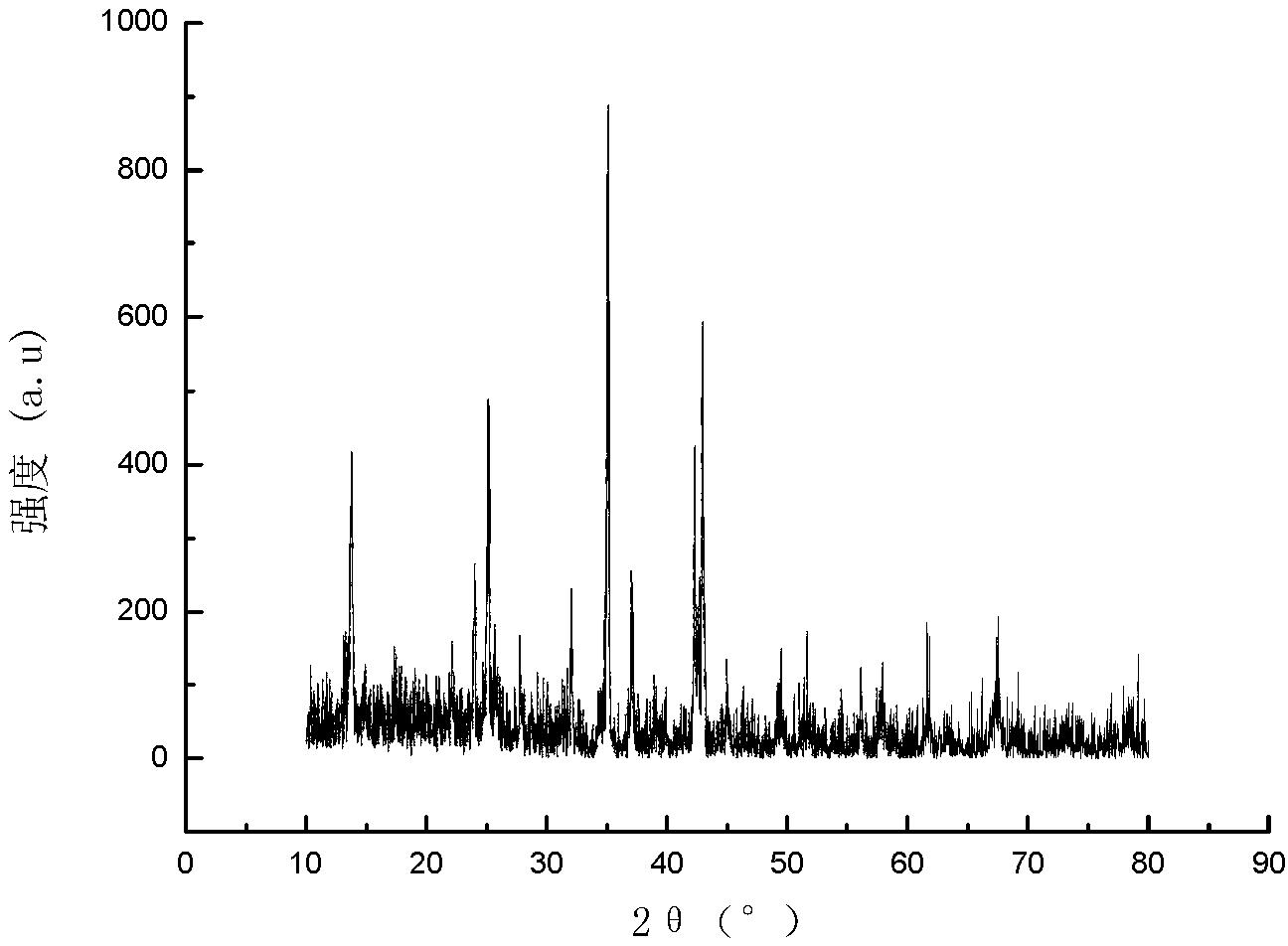

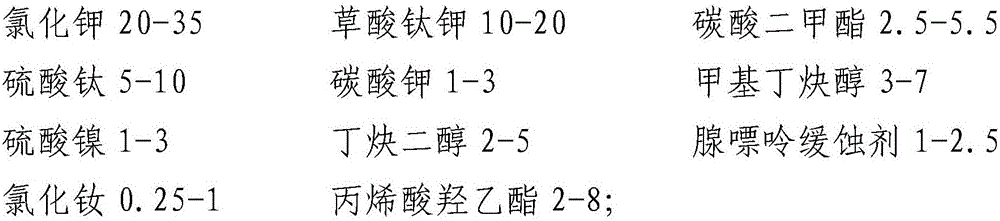

Aluminum alloy surface titanium plating treatment method

ActiveCN106757235AGuaranteed concentration balance requirementsGuaranteed activityAnodisationAcid etchingPotassium

The invention discloses an aluminum alloy surface titanium plating treatment method, and relates to the technical field of aluminum alloy material surface treatment. The treatment process comprises: (a) deoiling; (b) dewaxing; (c) anodic oxidation; (d) acid etching; and (e) titanium plating; and titanium plating treatment liquid is prepared by the following raw materials in parts by weight: 20-35 of potassium chloride, 10-20 of titanium potassium oxalate, 2.5-5.5 of dimethyl carbonate, 5-10 of titanium sulfate, 1-3 of potassium carbonate, 3-7 of methyl butynol, 1-3 of nickel sulfate, 2-5 of butynediol, 1-2.5 of adenine corrosion inhibitor, 0.25-1 of neodymium chloride, and 2-8 of hydroxyethyl acrylate. The method capable of forming a layer of titanium film with high hardness and corrosion resistance on the surface of an aluminum alloy has such characteristics as high efficiency, simple operation and capability of improving the quality of aluminum alloy products, can be used for treating aluminum alloy profiles, also can be used for treating aluminum alloy parts, and in particular, is suitable for treating aluminum alloy shell parts and aluminum alloy panels.

Owner:QIYANG HONGTAI ALUMINUM IND

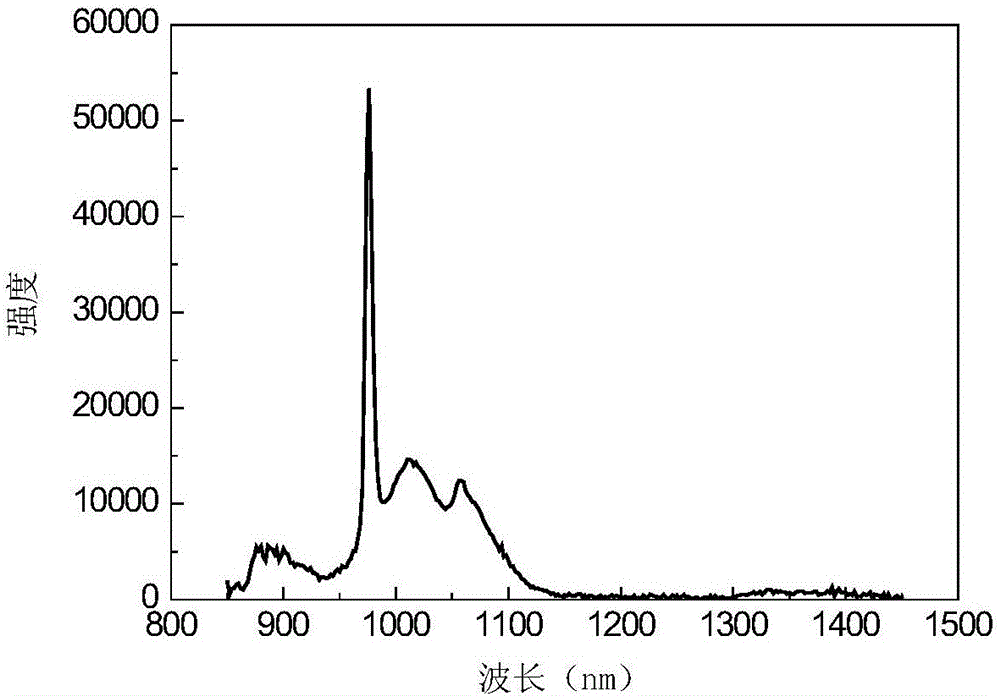

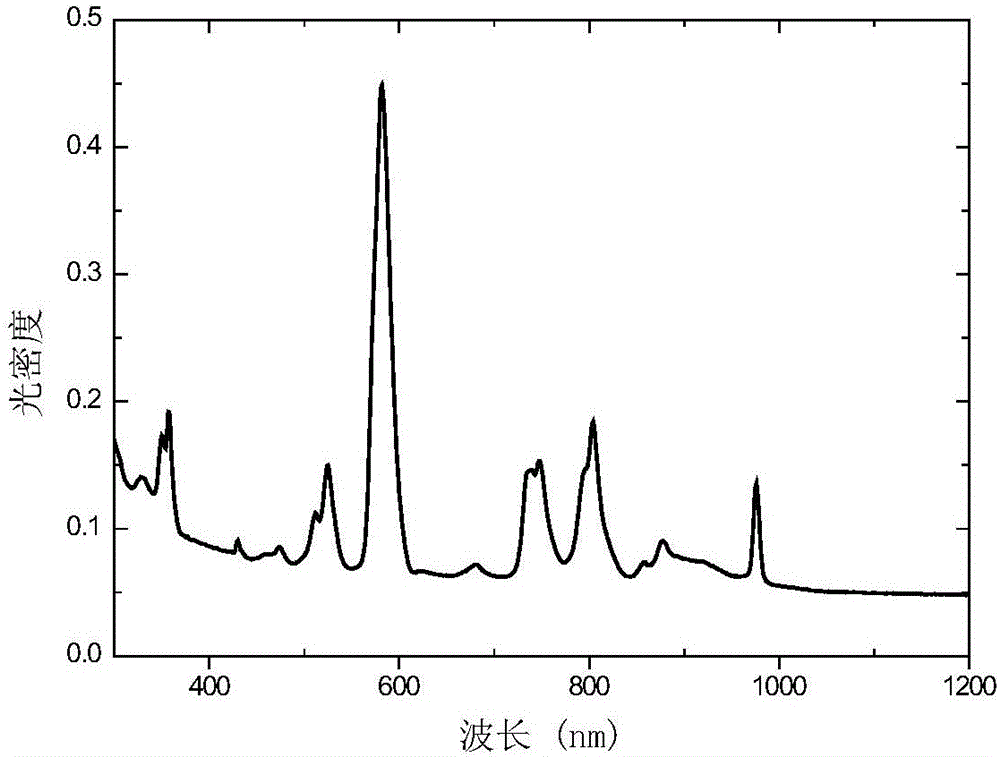

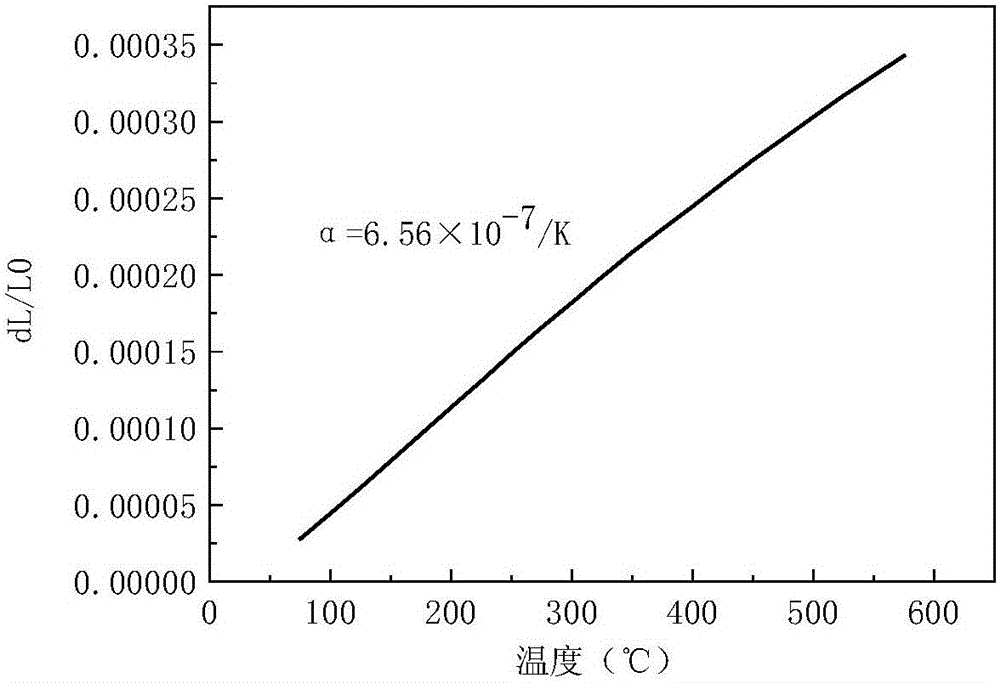

Neodymium and ytterbium co-doped quartz laser glass and preparation method thereof

InactiveCN106495470ASmall coefficient of thermal expansionExcellent high repetition rate thermal shock resistanceFluorescenceGas phase

The invention discloses neodymium and ytterbium co-doped quartz laser glass and a preparation method thereof. The glass comprises, in molar percentage, 89.5-94.75% of SiO2, 2.5-5% of Al2O3, 2.5-5% of P2O5, 0.2-0.4% of Nd2O3 and 0.05-0.1% of Yb2O3. The preparation method includes the steps: placing porous loose powder of silicon dioxide prepared by external vapor deposition process into solution of ytterbium chloride, neodymium chloride, aluminum chloride and phosphoric acid; uniformly co-doped neodymium, ytterbium, aluminum and phosphorus; drying and removing hydroxyl, and performing ball-milling to obtain powder with uniform particle sizes; performing high-temperature sintering vitrification to obtain the neodymium and ytterbium co-doped quartz laser glass. Experiments show that the neodymium and ytterbium co-doped quartz laser glass has low expansion coefficient and ultra-wide fluorescent emission in 1 micrometer wave band. The glass can be used for high-repetition frequency and heat shock resistance laser glass and is applicable to ultra-short and ultra-strong laser glass.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

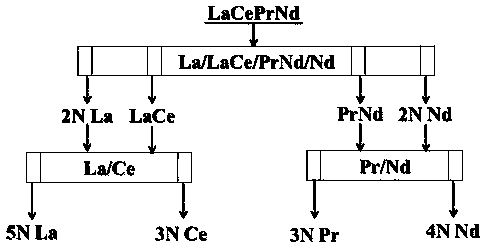

Technology for separating light rare earth from southern ion-absorbing type rare earth ore

InactiveCN110306047AHigh yieldImprove separation efficiencyProcess efficiency improvementRare earthCerium

The invention provides a technology for separating light rare earth from southern ion-absorbing type rare earth ore. The technology is implemented by adopting an aqueous light rare earth chloride solution obtained by grouping separation from the southern ion-absorbing type rare earth ore as a feed liquid and P507 as an extraction agent, and comprises three fractional extraction systems, and the three fractional extraction systems comprise a La / LaCe / PrNd / Nd four-outlet fractional extraction and separation system, a La / Ce two-feed-inlet fractional extraction and separation system and a Pr / Nd two-feed-inlet fractional extraction and separation system. By means of combination of the three fractional extraction systems, four separation products including 5N-grade lanthanum chloride, 3N-grade cerium chloride, 3N-grade praseodymium chloride and 4N-grade neodymium chloride are obtained directly. The technology has the advantages of high purity of a target separation product, high yield of rareearth element, low acid-base consumption, short technological process, low separation cost and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

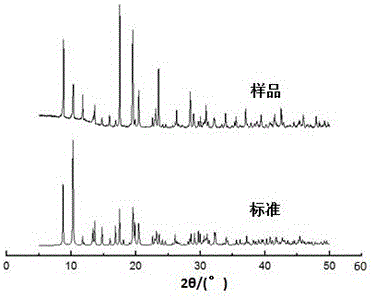

Preparation method of large-particle neodymium oxalate

InactiveCN104649888ALarge particle sizeAchieve recyclingOrganic compound preparationCarboxylic acid salt preparationOxalateNeodymium chloride

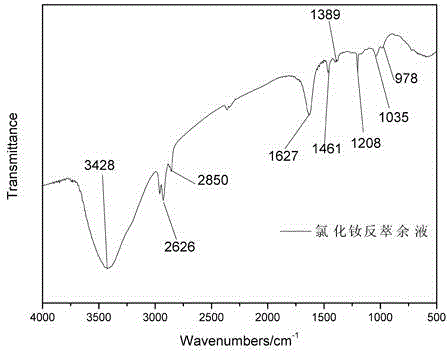

The invention relates to a preparation method of large-particle neodymium oxalate, belonging to the process of powdery materials. The preparation method comprises the following steps: adding an oxalic acid solution serving as a precipitator into neodymium chloride reverse extraction raffinate containing a trace organic phase, adding seed crystals to generate a neodymium oxalate precipitate, aging, washing, filtering and drying to finally obtain neodymium oxalate particles with a central particle size D50 of 55-200mu m, wherein the particle sizes of the neodymium oxalate particles are in normal distribution. The preparation method disclosed by the invention is simple in process and can be put into industrial production easily; the obtained neodymium oxalate can be further used for preparing neodymium oxide with a central particle size D50 of 25-95mu m and uniform particle distribution.

Owner:JIANGXI UNIV OF SCI & TECH

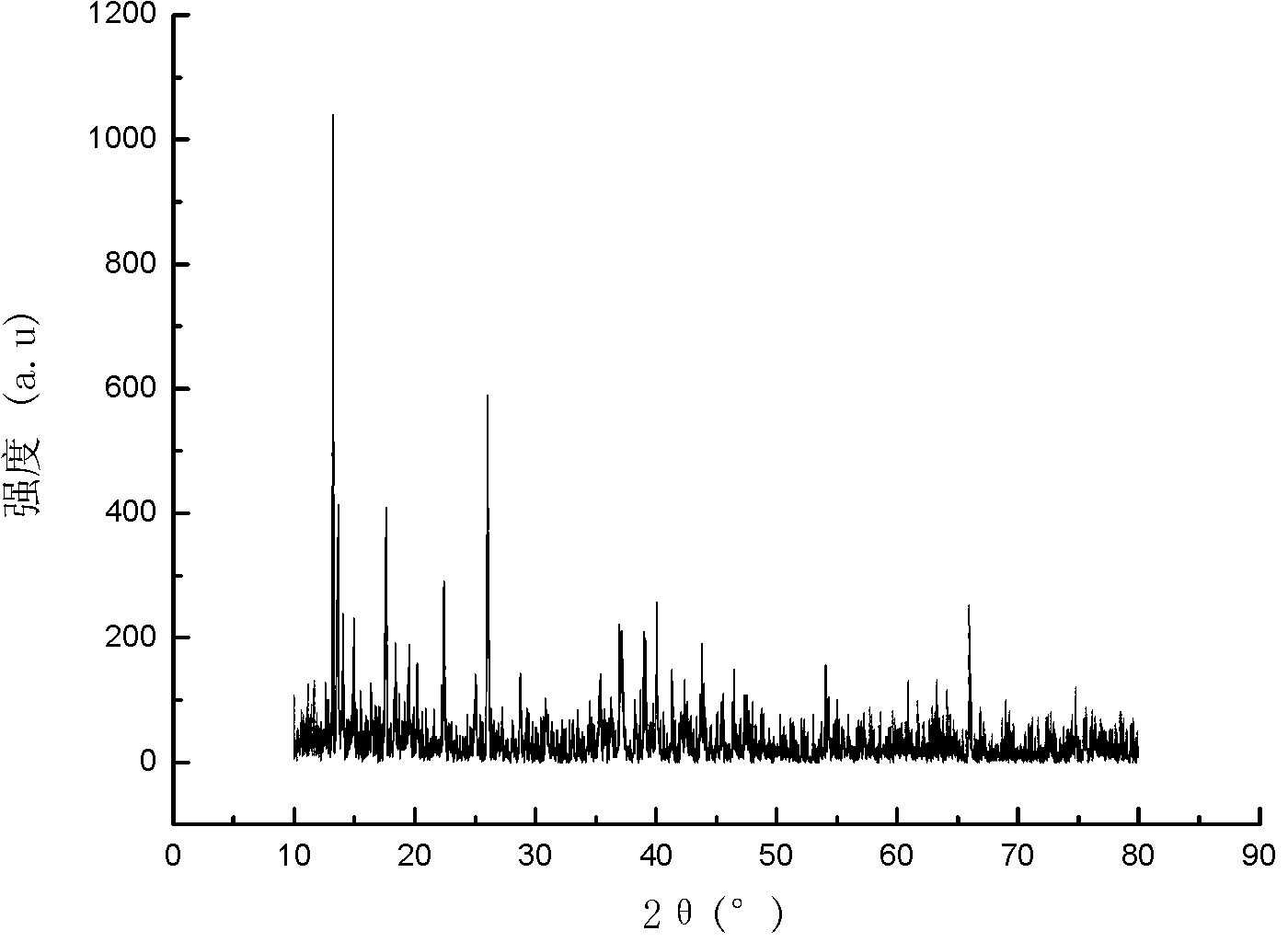

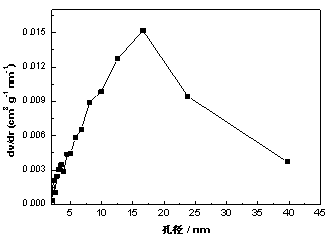

Preparation method and application of Nd-MOFs gas adsorption material

ActiveCN109759020AImprove adsorption capacityOvercoming easy desorptionOther chemical processesDispersed particle separationDesorptionFiltration

The invention discloses a preparation method of an Nd-MOFs gas adsorption material. The preparation method comprises ligand AGE synthesis and material synthesis, and comprises the following specific steps: adding a ligand solution and a neodymium chloride solution into a conical bottle respectively, mixing uniformly, adding N,N-diisopropylethylamine (DIEA) dropwise under a magnetic stirring condition to regulate the pH of the solution to 7 to 8, and stirring for reacting at a room temperature; then performing suction filtration with a vacuum pump, washing the obtained solid with acetone for 2to 5 times, and washing with distilled water for 2 to 4 times; then placing the solid into a drying oven for drying until constant weight to obtain the Nd-MOFs gas adsorption material. The Nd-MOFs gasadsorption material prepared by the method solves the problems of change of multiple factors, degradation in the montmorillonite adsorption performance and the like due to easy desorption of activated carbon under a high temperature environment, incapability of applying a zeolite molecular sieve to adsorption under strong inorganic acid and strong alkali conditions, and the need of strictly controlling the pH value of the solution in the process of chemical modification on the surface of montmorillonite, and has an excellent adsorption effect.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

Mercerized-wool and cotton blended fabric dyeing method using pomegranate bark plant dye

InactiveCN108560284AAvoid damageIncreased dyeing rateDyeing processSodium bicarbonateNeodymium chloride

The invention discloses a mercerized-wool and cotton blended fabric dyeing method using a pomegranate bark plant dye. The mercerized-wool and cotton blended fabric dyeing method includes the followingsteps that 1, 1-3% by weight of sodium bicarbonate and 0.5-5% by weight of wetting agent are added into deionized water and then are uniformly stirred and mixed, mercerized-wool and cotton blended fabric is placed into a mixed solution to be heated to 50-70 DEG C to be processed for 20-30 min, and the bath ratio is 1:(20-30); 2, the pomegranate bark plant dye, dye mordant and a wetting agent areadded into deionized water and then are uniformly mixed and stirred to prepare a dye solution, the mercerized-wool and cotton blended fabric is placed into the dye solution, heating starts at 30-35 DEG C, the heating rate is kept at 2-3 DEG C / min, and the temperature is kept at 50-60 DEG C to carry out processing for 60-80 min, wherein the dye solution is acidic, the bath ratio is 1:(20-30), and the dye mordant is neodymium chloride and / or aluminum potassium sulfate dodecahydrate. By the adoption of the mercerized-wool and cotton blended fabric dyeing method using the pomegranate bark plant dye, neodymium chloride and / or aluminum potassium sulfate dodecahydrate is adopted as the dye mordant, the weakly acidic dyeing solution has little damage on mercerized wool during dyeing, and the dyeing rate and the color fastness are high.

Owner:JIANGSU SUNSHINE

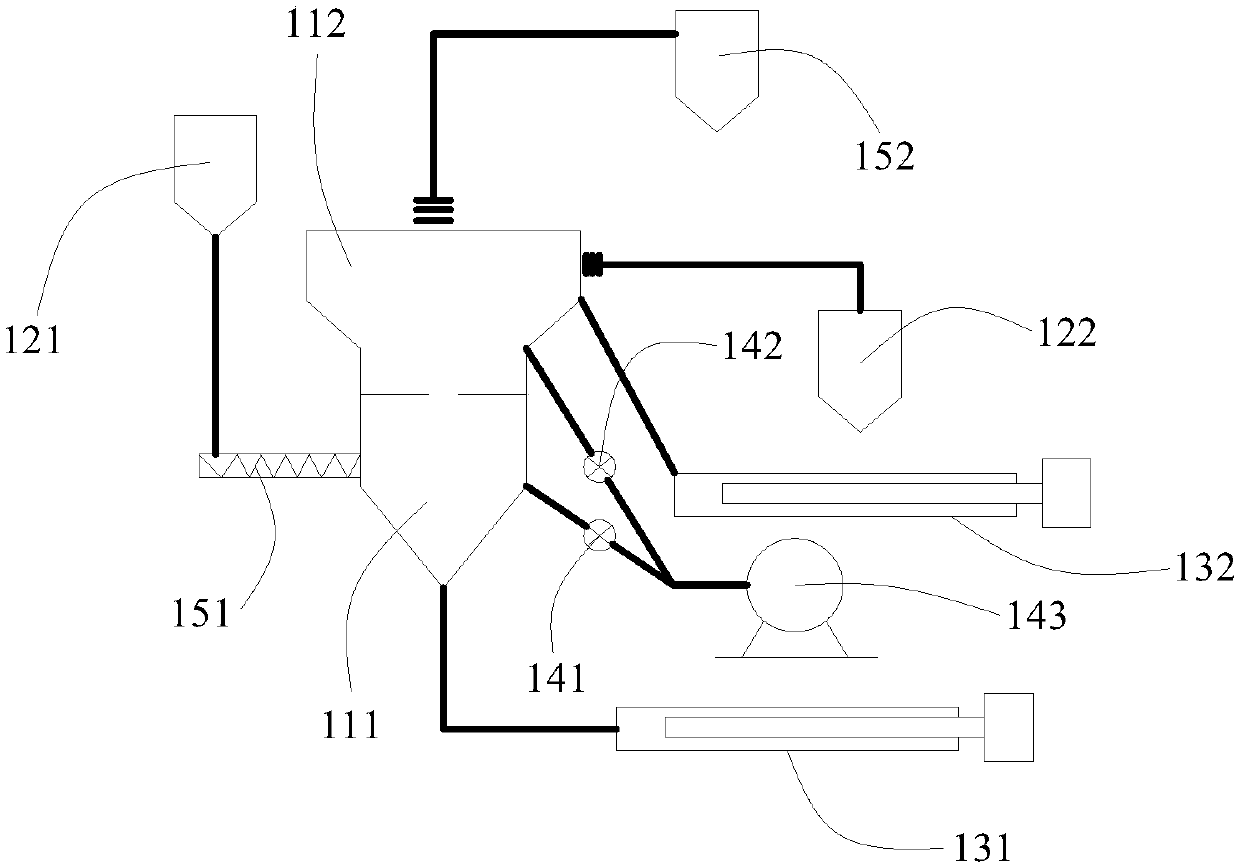

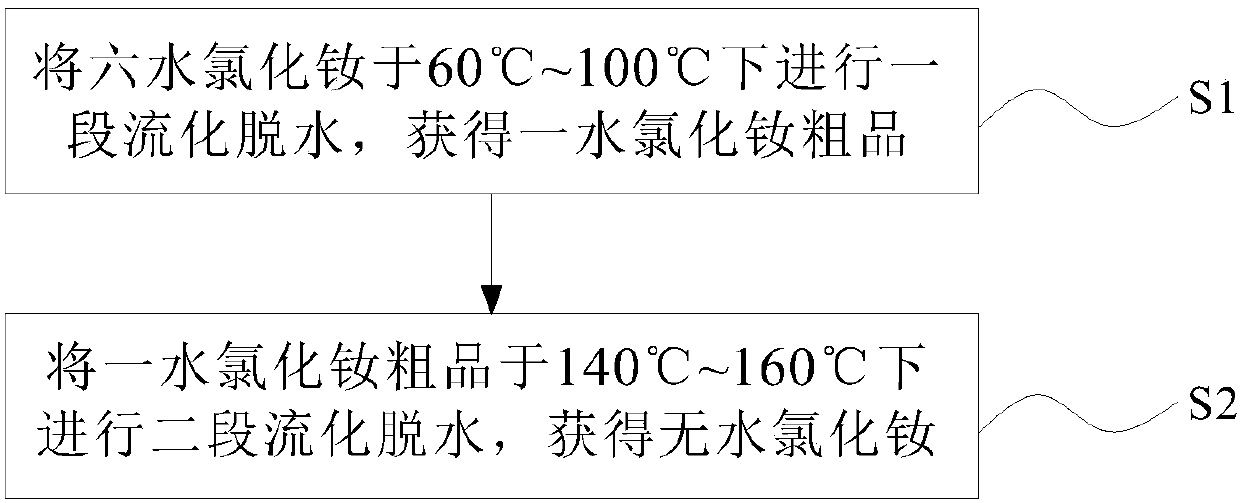

Preparation method of absolute neodymium chloride

InactiveCN107601544AInhibition of hydrolysisReduce pollutionRare earth metal compoundsCalcium Chloride HexahydrateNeodymium chloride

The invention discloses a preparation method of absolute neodymium chloride. The method comprises the following steps: S1) performing primary fluidization and dehydration on neodymium chloride hexahydrate at the temperature of 60-100 DEG C to obtain a neodymium chloride monohydrate crude product; and S2) performing secondary fluidization and dehydration on the neodymium chloride monohydrate crudeproduct at the temperature of 140-160 DEG C to obtain absolute neodymium chloride; wherein, the step of secondary fluidization and dehydration is carried out under hydrogen chloride gas atmosphere. According to the preparation method of absolute neodymium chloride, the neodymium chloride hexahydrate is subjected to segment fluidization and dehydration, hydrogen chloride protective gas atmosphere is provided, the hydrolysis of an intermediate product neodymium chloride monohydrate in a dehydration process to absolute neodymium chloride is effectively inhibited, product purity is greatly increased, the dehydration temperature in the preparation method of the absolute neodymium chloride is low, the preparation cost is low, and the dehydration effect is good.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Method for producing magnesium metal by direct electrolysis of magnesia

The invention relates to a method of making magnesium through electrolyzing magnesia directly, which belongs to the metal material field, characterized in that it uses the magnesia as raw material, uses the neodymium chloride and magnesium chloride as the fused salt electrolyte, wherein the mole percent of neodymium chloride and magnesium chloride is 20~30% and 70~80%. The mixed fused salt has lower fusible point and better conductivity in the range 650~800 Deg.c, in particular that the magnesium has lower dissolvability, and the weight percentage of magnesia dissolvability is 5~10%, the electrolyzing temperature is 720~760 Deg.c, the tank voltage is 4.5~6.5V, and the electric current efficiency can reach 85~90 Deg.c, the direct current consumption of magnesium per kilogram is 11~12.5kwh, the purity of magnesium is above 99.5%. The method is a new highly-effective metallurgical technology with no pollution.

Owner:UNIV OF SCI & TECH BEIJING

Yttrium aluminum garnet powder doped Nd 3<+> ions and its preparation method

InactiveCN102229437AEasy to getSimple preparation processRare earth metal compoundsCalcium Chloride HexahydrateReaction temperature

The invention relates to yttrium aluminum garnet powder doped Nd 3<+> ions and its preparation method. The method of the present invention mainly comprises: burdening reagent containing yttrium: reagent containing aluminum: glucose: cetyl trimethyl ammonium bromide: neodymium chloride hexahydrate according to a mol ratio of 1.5: 5: 3: 0.006: (0.01 - 0.10); mixing and grinding glucose, reagent containing yttrium and reagent containing aluminum under condition of room temperature for 10 minutes, grinding the mixed material and neodymium chloride hexahydrate for 20 minutes, then adding cetyl trimethyl ammonium bromide in the grinded material to grind for 30 minutes; finally drying the grinded mixture at the temperature of 70 DEG C for 2 hours, obtaining a precursor; grinding the precursor for 30 minutes, insulating for 2 hours under the condition of 800 to 1200 DEG C of temperature, preparing the yttrium aluminum garnet powder doped Nd 3<+> ions. The invention has the characteristics of low reaction temperature, simple process, easy control, high yield, less pollution and high dopant amount of Nd 3<+>ions. The prepared powder has good crystallinity with 20 to 120 nm of powder granularity, which has no impure phase.

Owner:WUHAN UNIV OF SCI & TECH

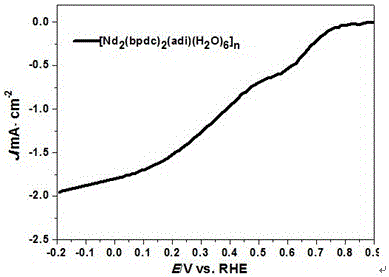

Metal organic framework material containing dipyridyl carboxylic acid and synthesizing method of metal organic framework material

ActiveCN106008990ALow temperature requirementEasy temperature controlOrganic-compounds/hydrides/coordination-complexes catalystsMetal-organic frameworkRoom temperature

The invention provides a metal organic framework material containing dipyridyl carboxylic acid and a synthesizing method of the metal organic framework material, and belongs to the field of organic framework material electro-catalysis materials. The electro-catalysis material has the structural formula shown in the description, wherein L represents the element shown in the description, L1 represents coordinated water, and n represents multiple replication. The amount-of-substance mole ratio of 2,2-bipyridine-3,3-dicarboxylate to adipic acid to neodymium chloride is 2:(2-3):(1-3), 2,2-bipyridine-3,3-dicarboxylate, adipic acid and neodymium chloride are mixed and dissolved with water, stirring is carried out, the pH is regulated to be 4, the mixture is put into a sealed container for a constant temperature reaction at 145 DEG C for 96 h, the temperature is reduced to the room temperature at 1-2 DEG C / h, and purple transparent tabular crystals are obtained. The metal organic framework material containing dipyridyl carboxylic acid and the synthesizing method of the metal organic framework material are simple in synthesizing step, a complex has the ORR activity, and the metal organic framework material can serve as metal organic framework material electro-catalysis materials and has good application prospects.

Owner:BEIJING UNIV OF CHEM TECH

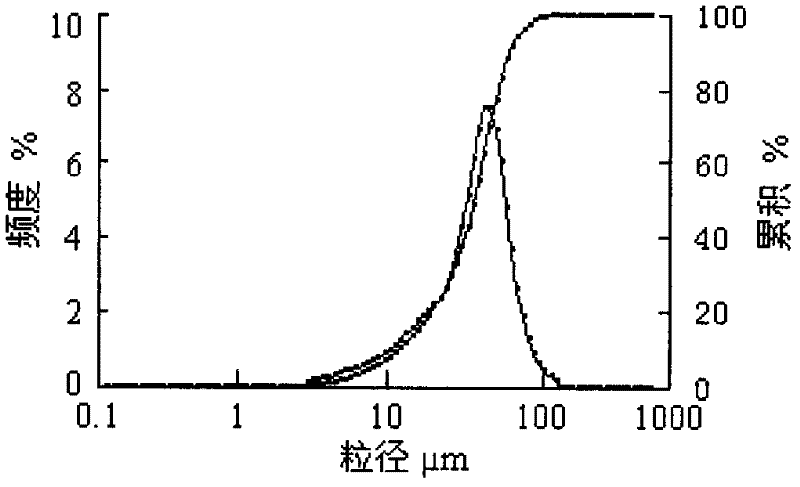

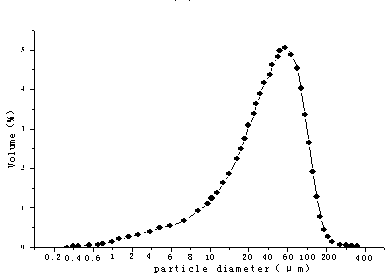

Method for preparing large granular praseodymium neodymium oxide by precipitating ammonium hydrogen carbonate at normal temperature

ActiveCN103738999AIncreased median particle sizeLarge particle sizeRare earth metal compoundsGranularityNeodymium chloride

The invention relates to a method for preparing large granular praseodymium neodymium oxide by precipitating ammonium hydrogen carbonate at normal temperature. The method is characterized by comprising the following steps: adding a praseodymium neodymium chloride solution with a concentration of 0.2-0.8 mol / L into a reactor, and directly adding an ammonium hydrogen carbonate solution with a concentration of 1-3 mol / L into the praseodymium neodymium chloride solution at normal temperature, wherein the molar ratio of praseodymium neodymium chloride to ammonium hydrogen carbonate is 1: (3.2-4); adding the ammonium hydrogen carbonate solution in two steps, firstly adding a part of ammonium hydrogen carbonate solution in the first step, stewing and aging for 10-15 hours, adding the rest ammonium hydrogen carbonate solution until complete precipitation, wherein the pH is 6.2-6.5; aging for 10-15 hours at normal temperature, filtering, washing with hot water, and naturally drying to obtain praseodymium neodymium carbonate precipitate with 8 crystal water, roasting the praseodymium neodymium carbonate precipitate to obtain a large granular praseodymium neodymium oxide product with a median particle diameter of 30-40 microns. The method has the advantages that the stepped aging manner is adopted to increase the median particle diameter of the praseodymium neodymium oxide from 1-2 microns to 30-40 microns, so as to greatly improve the granularity of the praseodymium neodymium oxide, and meanwhile, no heating treatment is needed in the precipitating process, so that the production cost is reduced.

Owner:NAT ENG RES CENT OF RARE EARTH METALLURGY & FUNCTION MATERIALS

Method for preparing high-purity lanthanum, high-purity cerium and high-purity praseodymium-neodymium

The invention discloses a method for preparing high-purity lanthanum, high-purity cerium and high-purity praseodymium-neodymium. The method is characterized in that a light rare-earth chloride aqueoussolution is taken as feed liquid, and P507 is taken as an extracting agent; and the method consists of three fractional extraction systems, which are separately a La / LaCe / CePrNd / PrNd four-outlet fractional extraction system, a La / Ce full-load two-charge-hole fractional extraction separation system and a Ce / PrNd two-charge-hole fractional extraction separation system. Three fractional extraction separation systems are combined to directly obtain three separated products of 5N-grade lanthanum chloride, 5N-grade cerium chloride and 4N-grade praseodymium-neodymium chloride. The method has the advantages of being high in product purity, high in rare-earth element yield, low in acid and alkaline consumption, short in process flow, low in separating cost, and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

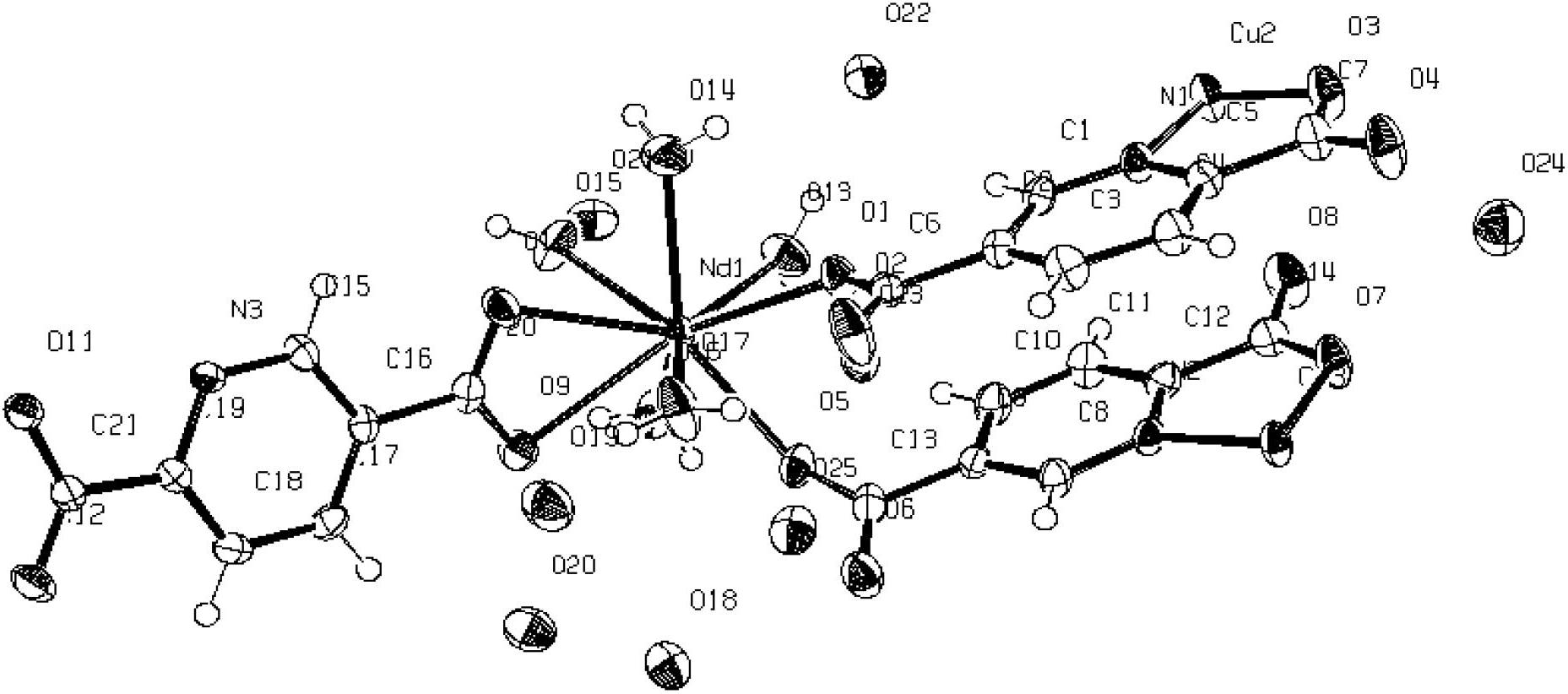

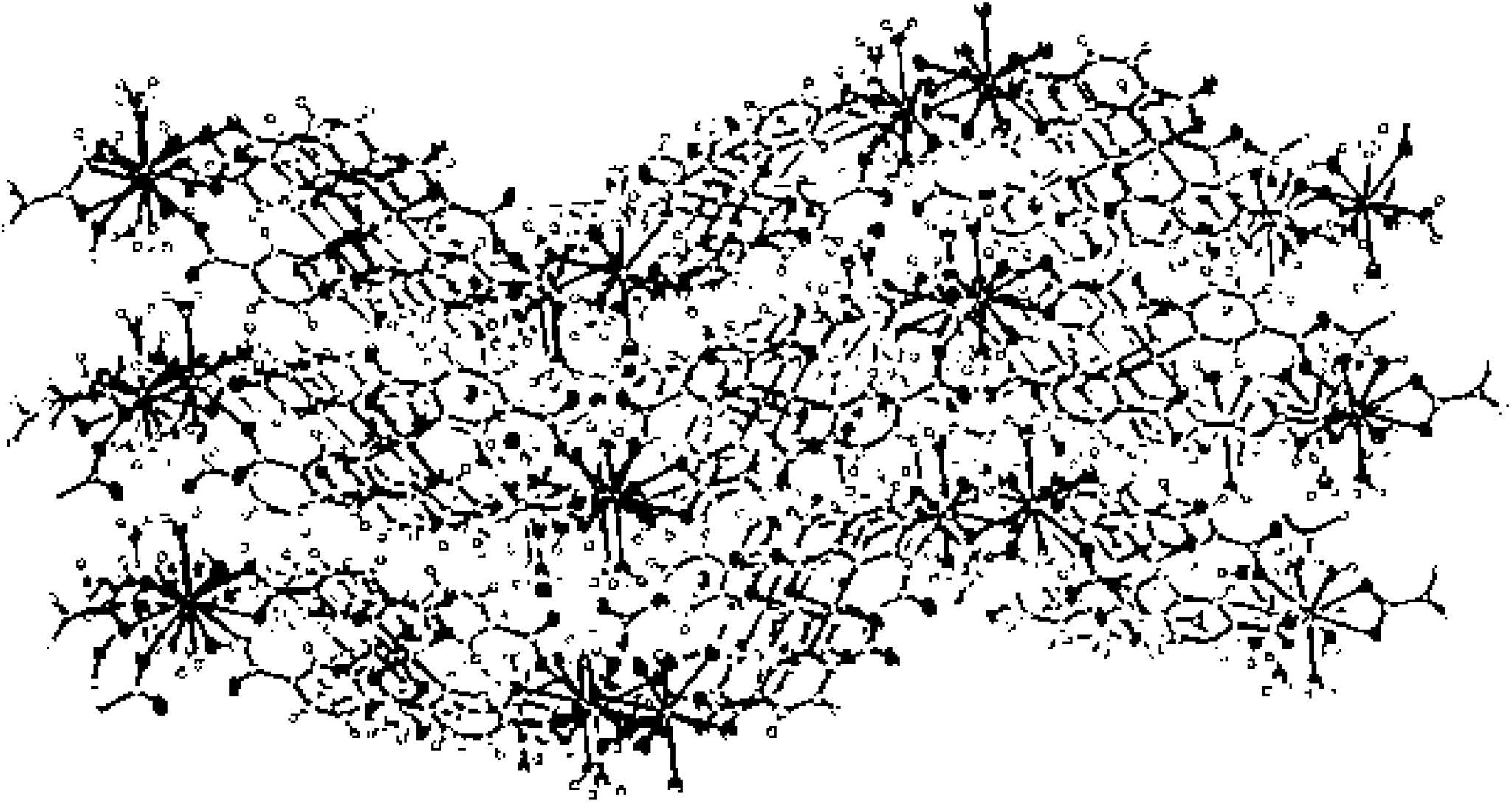

Metal-organic coordination polymer containing neodymium and copper and preparation method

InactiveCN102659852AEasy to manufactureImprove thermal stabilityCopper organic compoundsGroup 3/13 element organic compoundsPolymer scienceNeodymium chloride

The invention discloses a metal-organic coordination polymer containing neodymium and copper and a preparation method, and belongs to the technical field of metal-organic coordination polymer crystal. The structural unit of the molecular formula of the polymer is [NdCu1.5(pydc)3(H2O)5].7H2O, and the polymer is synthesized by adopting a solvothermal method; 5 mass parts of 2,5-pyridine-dicarboxylic acid, 3 mass parts of neodymium chloride hexahydrate and 2 mass parts of copper bromide are used as raw materials, and 100 to 120 mass parts of deionized water is used as a solvent; and the method comprises the following steps of: regulating the pH to 6-7, and putting into a stainless steel autoclave, wherein the volume ratio of the solution to the autoclave is 6:25; and reacting for 72 to 120 hours at the temperature of between 140 and 170 DEG C, slowly cooling to room temperature within 24 to 48 hours, and thus obtaining the metal-organic coordination polymer crystal. The polymer is high in thermal stability, and has semiconductor property..

Owner:BEIJING UNIV OF CHEM TECH

Method for reducing cerium content in praseodymium neodymium chloride and preparation method of praseodymium neodymium oxide

PendingCN114162846AReduced cerium contentReduce Ce ion contentRare earth metal oxides/hydroxidesRare earth metal compounds preparation/treatmentPhysical chemistryCerium

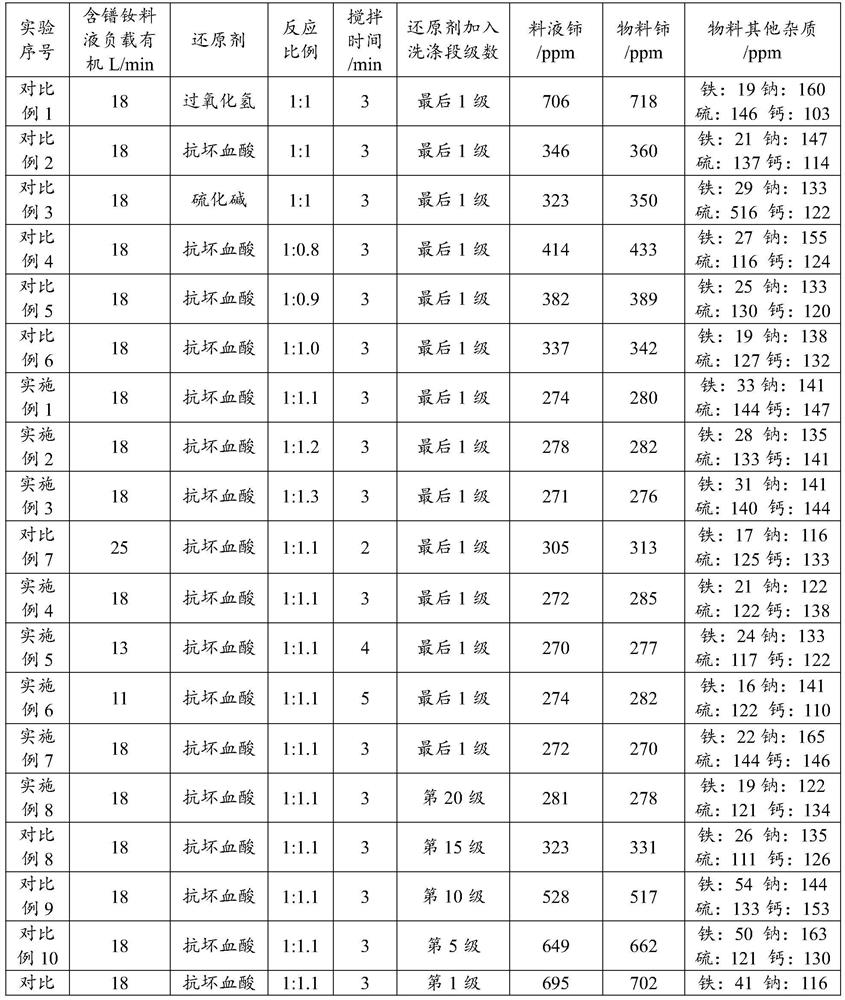

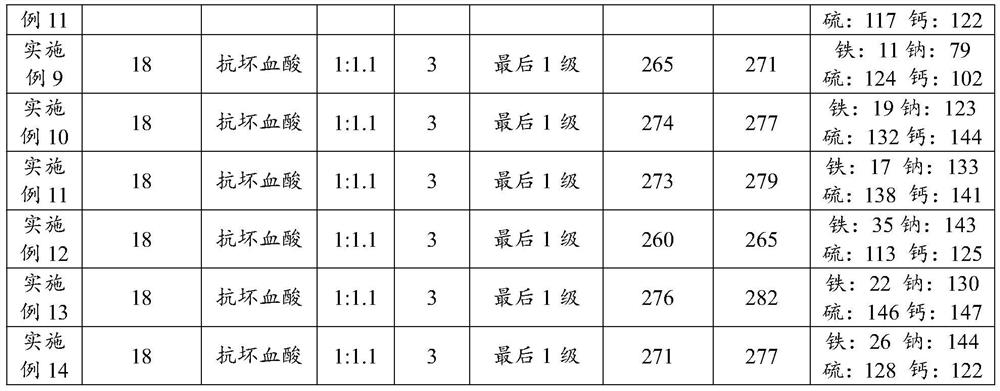

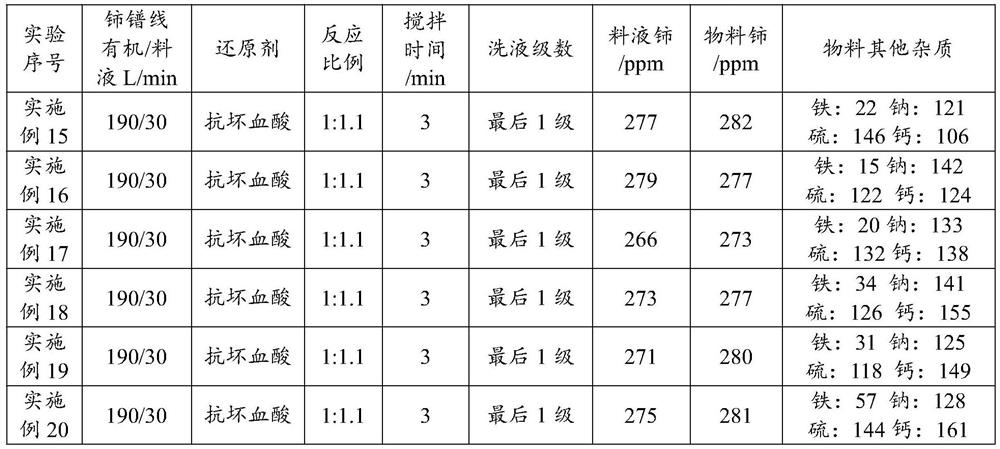

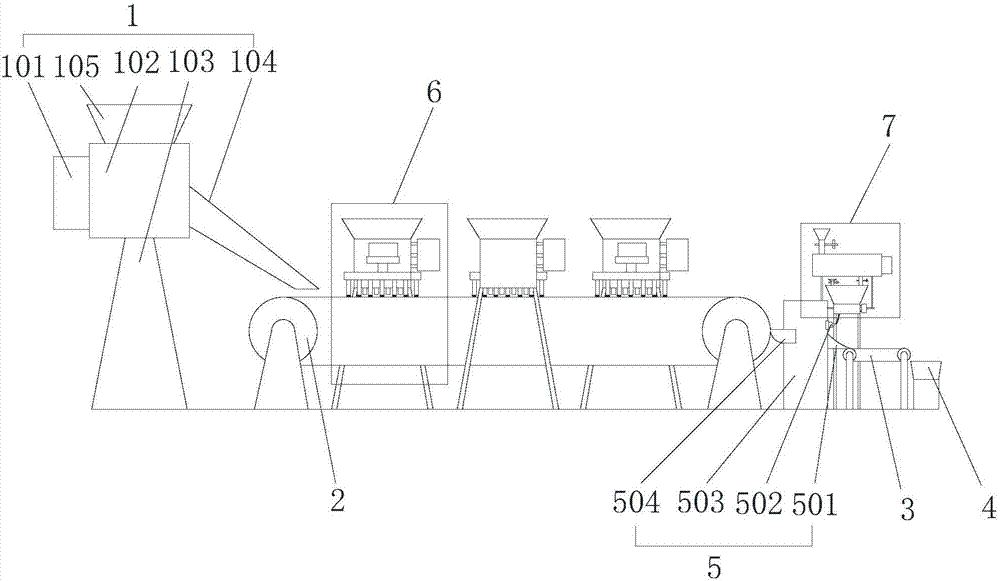

The invention relates to the technical field of praseodymium neodymium oxide preparation, in particular to a method for reducing the content of cerium in praseodymium neodymium chloride and a preparation method of praseodymium neodymium oxide. The method provided by the invention comprises the following steps: carrying out multi-stage countercurrent washing on a praseodymium neodymium chloride organic phase solution and a water phase washing solution, and adding ascorbic acid during at least one stage of the multi-stage countercurrent washing. The purified praseodymium neodymium chloride organic phase solution prepared by the method provided by the invention is low in Ce ion content, so that praseodymium neodymium oxide obtained after the purified praseodymium neodymium chloride organic phase solution is sequentially subjected to multi-stage countercurrent back extraction, precipitation and roasting is low in Ce ion content.

Owner:淄博包钢灵芝稀土高科技股份有限公司

Environment-friendly dielectric material for photo-resistor and preparation method thereof

InactiveCN107935633APhotoconductiveHas a nonlinear optical responseSemiconductor devicesBismuth sulfideDielectric

The invention discloses an environment-friendly photoresistor dielectric material and a preparation method thereof. In parts by weight, the dielectric material includes the following components: 20-40 parts of zinc sulfide, 10-50 parts of bismuth sulfide, and aluminum sulfide. 20-30 parts, 0.1-0.3 parts of lutetium chloride, 0.05-0.15 parts of neodymium chloride, 1-3 parts of copper sulfate solution, and 20-90 parts of ionized water. The application can improve the sensitivity of the photoresistor, and the raw materials used are safe and non-toxic, friendly to humans and the environment, and safe and environmentally friendly.

Owner:SICHUAN QIXING ELECTRONICS

Char-based slow-release compound fertilizer special for cotton and preparation system and method of compound fertilizer

InactiveCN107188721APromote photosynthesisImprove qualityClimate change adaptationAlkali orthophosphate fertiliserNeodymium chlorideEuropium

The invention discloses a char-based slow-release compound fertilizer special for cotton. Raw materials of the fertilizer include urea, a calcium magnesium phosphate fertilizer, a magnesium-potassium sulfate fertilizer, biochar powder, lignin zinc carbonate, disodium octoborate tetrahydrate, manganese chloride, ammonium ferrous sulfate, europium chloride, neodymium chloride and N-phosphorotriamide. The invention further provides a preparation system and method of the compound fertilizer. The preparation method is simple and efficient, and the raw materials are fully mixed and are good in quality. The obtained compound fertilizer is abundant in nutrients, lasting and coordinated in nutrient element release, and high in nutrient utilization efficiency. The fertilizer can improve physical and chemical properties of soil, improve soil fertility, and promote soil microorganism diversity.

Owner:ANHUI SIERTE FERTILIZER IND

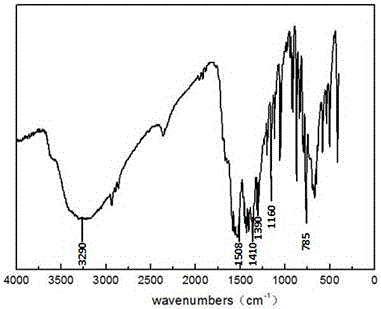

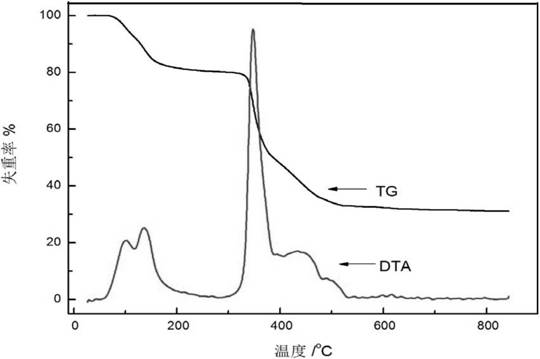

Analysis method for neodymium content in neodymium chloride hydrate

InactiveCN106918528AReduce pollutionNothing producedWeighing by removing componentHypochloriteInterference factor

The invention relates to an analysis method for the neodymium content in neodymium chloride hydrate. The analysis method comprises: (1) carrying out thermogravimetric analysis on a neodymium chloride hydrate sample, wherein X g of a neodymium chloride hydrate sample is weighed, thermogravimetric analysis test is performed, a reaction is performed on the neodymium chloride hydrate to generate neodymium hypochlorite, and after the test is completed, the weight of the remaining material is Y g; and (2) calculating neodymium content in the neodymium chloride hydrate, wherein the neodymium content is Y*73.71% / X. According to the present invention, by using the instrument analysis method, the interference factor is less, and the error is small; and during the testing process, the reagent is not used, such that no waste liquid is produced, and the environmental pollution is low.

Owner:PETROCHINA CO LTD +1

Method for preparing chemical pure neodymium fluoride

InactiveCN101891234AHigh purityLess impuritiesRare earth metal compoundsBarium saltNeodymium chloride

The invention relates to a method for preparing chemical pure neodymium fluoride. The method comprises the following steps of: (1) preparing neodymium chloride, namely, performing a reaction of neodymium oxide and chemical pure hydrochloric acid to obtain solution A; (2) removing impurities of barium and calcium to obtain filtrate B; and (3) adding hydrofluoric acid and oxalic acid into B with continuous stirring to obtain neodymium fluoride deposit and draining. In the preparation method, the neodymium oxide reacts with the hydrochloric acid to generate the neodymium chloride, barium salt and calcium salt are removed by adding the sulfuric acid into a reaction product, so that the neodymium chloride is prepared, and the neodymium chloride reacts with the hydrofluoric acid to synthesize the neodymium fluoride and ammonia gas is introduced to the neodymium fluoride so that optimal chloride ion removing effect is achieved. The preparation method has the advantages of processing steps, advanced synthesis technology, easily-controlled reaction process, good effect and high efficiency. The prepared neodymium fluoride has high purity and low impurity content and can be widely applied in the market.

Owner:TIANJIN CHEM REAGENT RES INST

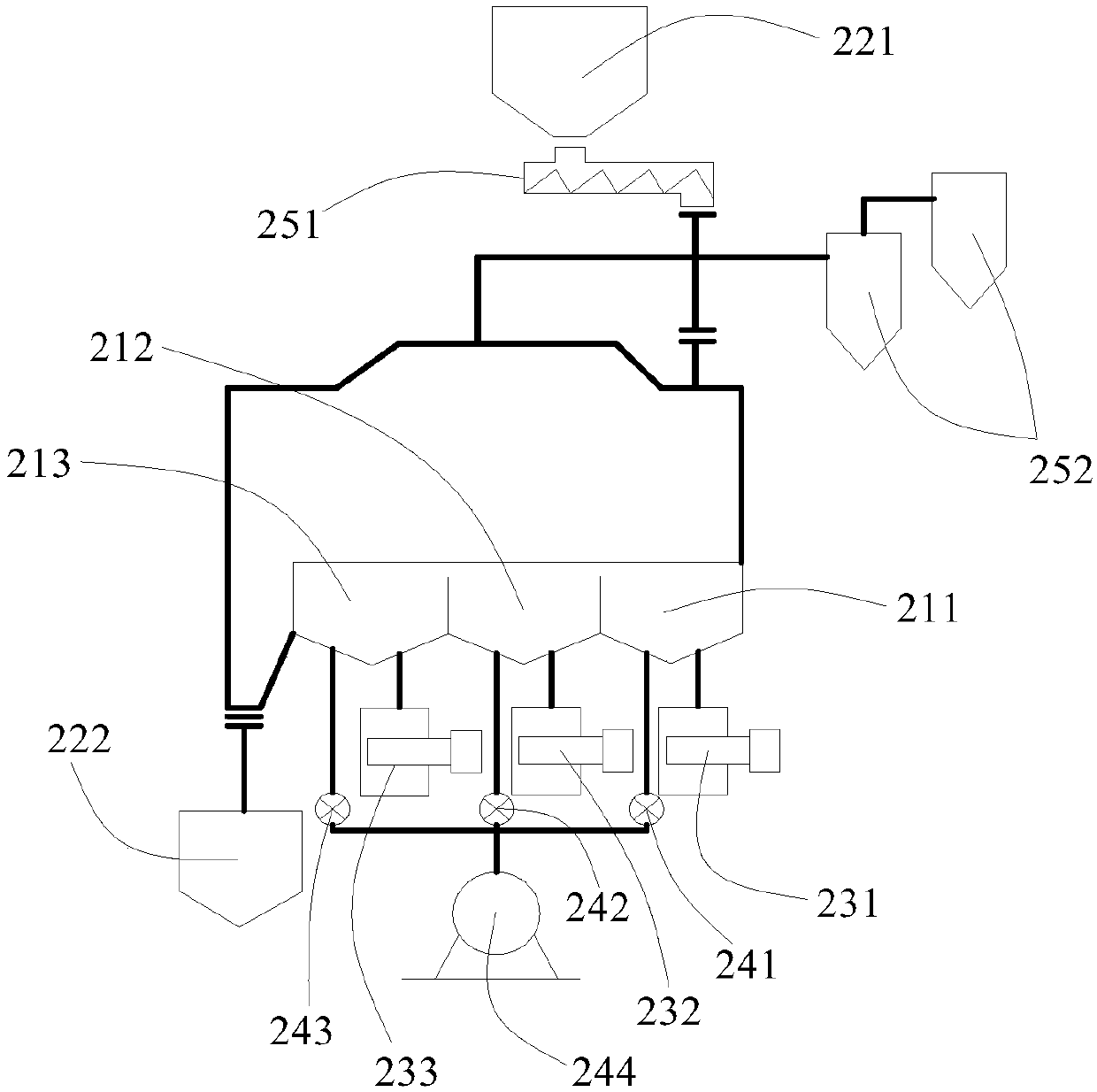

Anhydrous neodymium chloride preparation method

InactiveCN110092404AReduce the content of oxychlorideGood water solubilityRare earth metal chloridesSolubilityFiltration

The invention discloses an anhydrous neodymium chloride preparation method, which comprises: stabilizer adding, pH value adjusting, impurity removal through filtering, microfiltration, evaporation concentration, cooling crystallization, centrifugal dehydration, preliminary drying dehydration, medium dehydration and complete dehydration to prepare the anhydrous neodymium chloride. According to thepresent invention, the preparation method is simple and reasonable; through the multiple filtrations and the multiple dehydrations, the oxychloride content in the anhydrous neodymium chloride can be effectively reduced so as to improve the water solubility of the anhydrous neodymium chloride and reduce the non-rare earth impurities in the product; by adding the two stabilizers, the prepared anhydrous neodymium chloride has high stability; and the preparation method has low requirements on the equipment, has high operability, and is suitable for good social promotion application.

Owner:蒋盼盼

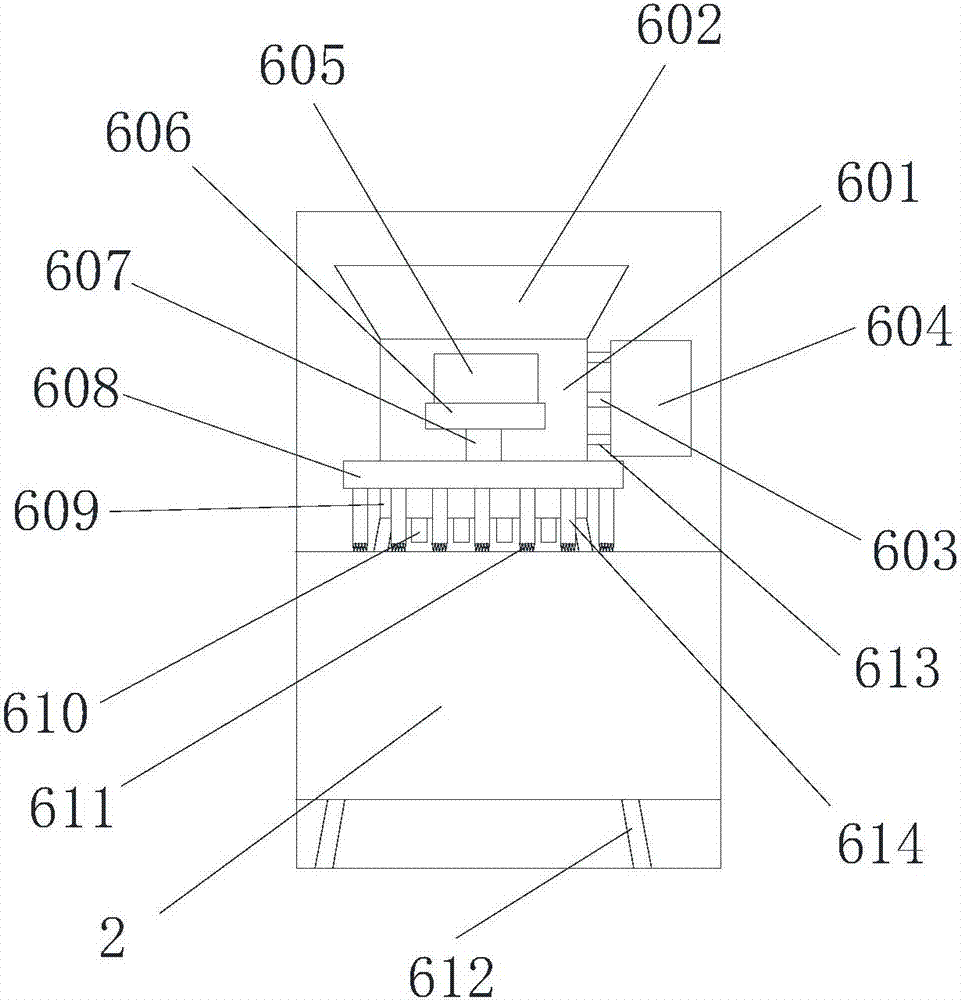

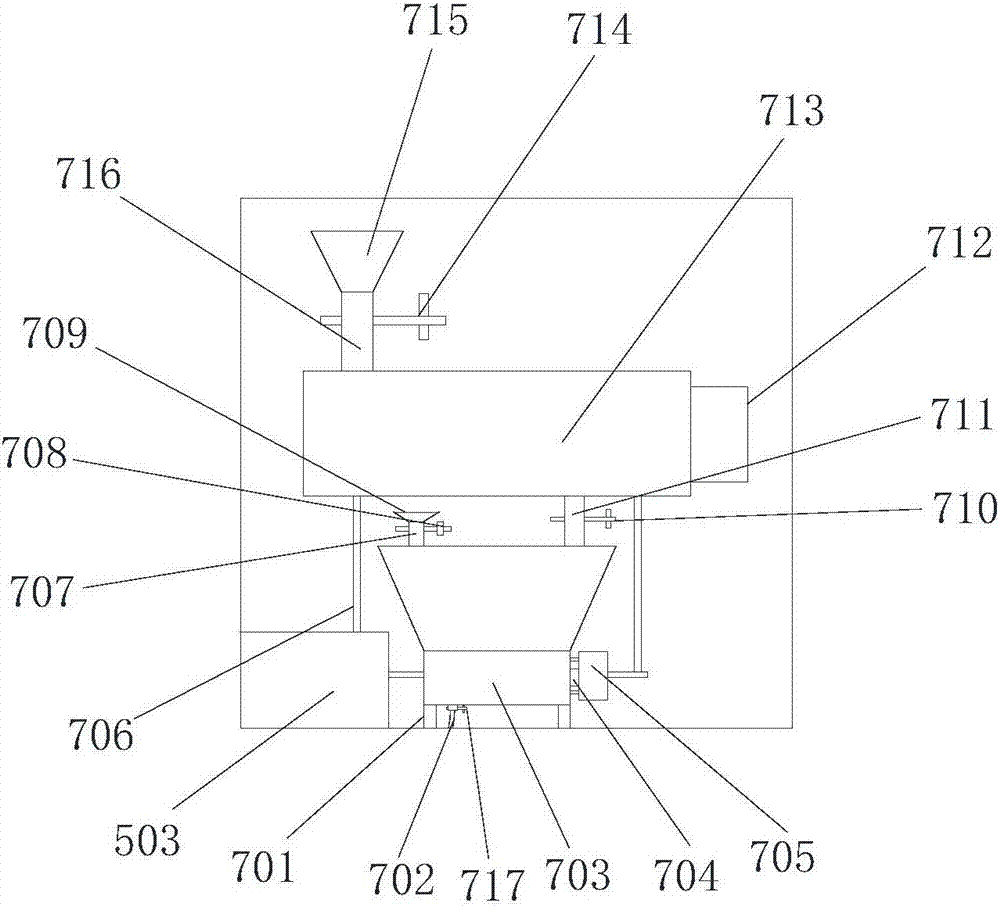

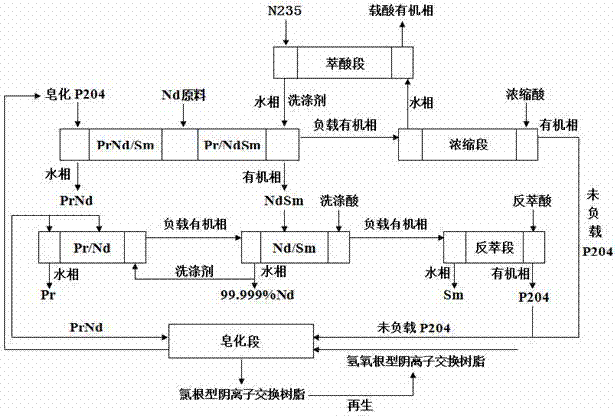

A kind of p204 extraction and separation method for preparing 5n neodymium

InactiveCN105936977BReduce consumptionHigh purityProcess efficiency improvementNon solventIon exchange

Owner:NANCHANG HANGKONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com