Method for preparing large granular praseodymium neodymium oxide by precipitating ammonium hydrogen carbonate at normal temperature

A technology of ammonium bicarbonate and praseodymium neodymium oxide, applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problems of easy flying, poor fluidity, energy consumption, etc., and achieve no energy consumption and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

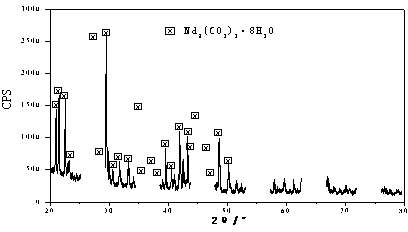

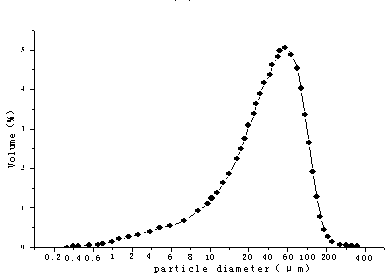

[0015] Add 1L of praseodymium neodymium chloride solution with a concentration of 0.3mol / L into a 4L beaker to prepare 1L of ammonium bicarbonate solution with a concentration of 1mol / L, and add it directly to the praseodymium neodymium chloride solution at room temperature of 25°C The ammonium bicarbonate solution with a concentration of 1mol / L is 25% of the total volume of the ammonium bicarbonate solution, which is added in about 40-60 minutes, left to stand and aged for 10-15 hours, and then the remaining ammonium bicarbonate solution is added until the precipitation is complete, pH=6.2-6.5, and the precipitation The reaction is completed in 4 hours, aged at room temperature for 12 hours, filtered, rinsed with hot water, and dried naturally to obtain a precipitate of praseodymium and neodymium carbonate with 8 crystal waters, and roasting the precipitate of praseodymium and neodymium carbonate to obtain large particles with a median particle size of 35.01 μm Neodymium prase...

Embodiment 2

[0019] Add 1L of praseodymium-neodymium chloride solution with a concentration of 0.59mol / L into a 4L beaker to prepare 1L of ammonium bicarbonate solution with a concentration of 2mol / L. The ammonium bicarbonate solution with a concentration of 2mol / L is 20% of the total volume of the ammonium bicarbonate solution, which is added in about 40-60 minutes, left to stand and aged for 10-15 hours, and then the remaining ammonium bicarbonate solution is added until the precipitation is complete, pH=6.2-6.5, and the precipitation The reaction was completed in 4 hours, aged at room temperature for 12 hours, filtered, rinsed with hot water, and dried naturally to obtain a precipitate of praseodymium and neodymium carbonate with 8 crystal waters, and the precipitation of praseodymium and neodymium carbonate was roasted to obtain large particles with a median particle size of 30.11 μm Neodymium praseodymium oxide products.

Embodiment 3

[0021] Add 1L of praseodymium-neodymium chloride solution with a concentration of 0.71mol / L in a 4L beaker to prepare 1.2L of ammonium bicarbonate solution with a concentration of 2mol / L, and add it directly to the praseodymium-neodymium chloride solution at a room temperature of 15°C. Add 20% of the total volume of the ammonium bicarbonate solution with a concentration of 2mol / L, finish adding in about 40-60 minutes, let stand and age for 10-15 hours, then add the remaining ammonium bicarbonate solution until the precipitation is complete, pH=6.2-6.5, The precipitation reaction is completed in 4 hours, aged at room temperature for 12 hours, filtered, rinsed with hot water, and dried naturally to obtain praseodymium neodymium carbonate precipitates with 8 crystal waters, and the praseodymium neodymium carbonate precipitates are roasted to obtain large particles with a median particle size of 32 μm Neodymium praseodymium oxide products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com