High energy density nickel cobalt lithium manganese oxide positive electrode material and preparation method thereof

A technology of nickel-cobalt lithium manganese oxide and positive electrode materials, which is applied in the direction of positive electrodes, battery electrodes, active material electrodes, etc., can solve the problems of poor structural stability and electrical properties, and achieve improved compaction density, increased median particle size, The effect of increasing energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0089] The second aspect of the present invention provides a method for preparing a nickel-cobalt lithium manganese oxide positive electrode material, comprising the following steps:

[0090] 1) Nickel salt, cobalt salt, and manganese salt are formulated into a mixed salt solution according to the molar ratio of Ni:Co:Mn=x:y:(1-x-y); the precipitant, complexing agent, dispersant, and additive a are respectively formulated as a solution;

[0091] 2) Pass the mixed salt solution, the precipitant solution, the complexing agent solution, the dispersant solution, and the additive a solution into the reaction kettle at the same time and respectively, under an inert atmosphere, carry out the first reaction, and continue to stir for aging, Obtain a solid-liquid mixture;

[0092] 3) press-filtering the solid-liquid mixture, washing the filter cake to neutrality, and drying to obtain a precursor of nickel-cobalt-lithium-manganese-oxide cathode material;

[0093] 4) Mixing the nickel-c...

Embodiment 1

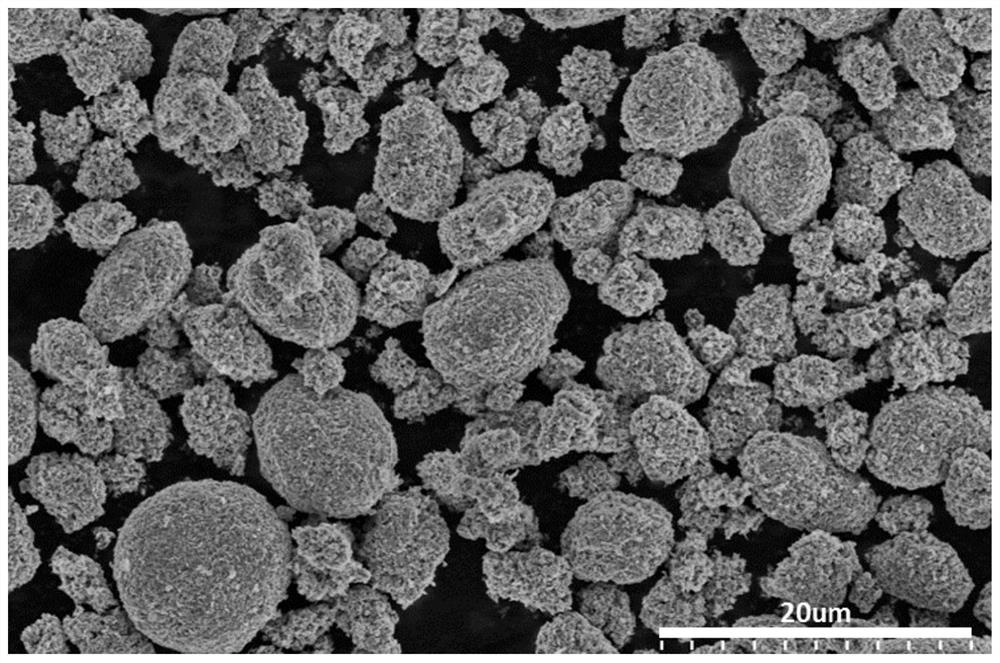

[0177] Prepare 2.0mol / L nickel-cobalt-manganese sulfate mixed solution (molar ratio Ni:Co:Mn=50:20:30), 2.5mol / L NaOH solution, 3mol / L ammonia water, 10g / L PEG1000 dispersant Aqueous solution, the above-mentioned several solutions are passed into the reaction kettle under nitrogen protection atmosphere in a co-current manner, the stirring speed is 250rpm, the reaction temperature is kept at 60°C, and the reaction pH value is 12.0. After the reaction is completed, it is aged for 12 hours, and then press-filtered, washed, dried at 110° C., and sieved to obtain a small-particle 50 / 20 / 30 nickel-cobalt lithium manganate cathode material precursor. SEM results such as figure 1 As shown, the particle structure of the precursor is loose, and there are many gaps on the particle surface.

[0178] test result D. 50 5.7 μm, D max is 15.1μm, and the specific surface area is 11.9m 2 / g, bulk density AD is 0.90g / cm 3 , the tap density TD is 1.70g / cm 3 .

[0179] Gained nickel-cobalt l...

Embodiment 2

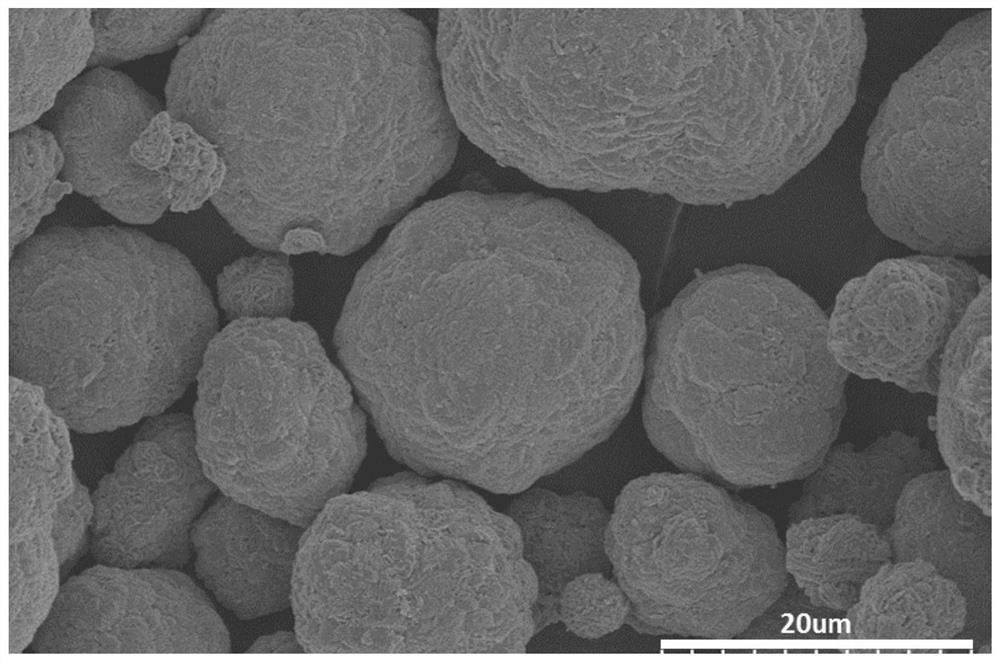

[0183]Prepare 1.5mol / L nickel-cobalt-manganese nitrate mixed solution (molar ratio Ni:Co:Mn=65:15:20), 6mol / L NaOH solution, 4mol / L ammonia water, 15g / L polyvinyl alcohol Dispersant aqueous solution, 0.2mol / L Y 2 (SO 4 ) 3 Solution, the above-mentioned several solutions are passed into the reactor in a parallel flow mode, control [n(Ni)+n(Co)+n(Mn)]: n(Y)=0.001, keep the reaction temperature at 50°C, The pH value is 12.5, the stirring speed is 200rpm, it is precipitated under the protective atmosphere of argon, aged for 16h, then washed, filtered, dried at 120°C, sintered at 500°C for 2h, and sieved to obtain large particles 65 / 15 / 20 Type nickel cobalt lithium manganese oxide cathode material precursor; SEM results are as follows image 3 As shown, the particle structure of the precursor is relatively loose, and there are gaps on the particle surface.

[0184] Test the D of the precursor 50 18.6 μm, D max is 45.3μm, and the specific surface area is 43.0m 2 / g, bulk dens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com