Nano alumina and its preparation method

A technology of nano-alumina and nano-alumina hydroxide, which is applied in the field of preparation of nano-γ-alumina, can solve the problems of high raw material price, large particle size and unevenness of alumina, and achieve low cost, small dosage, and avoid particle size. The effect of diameter increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

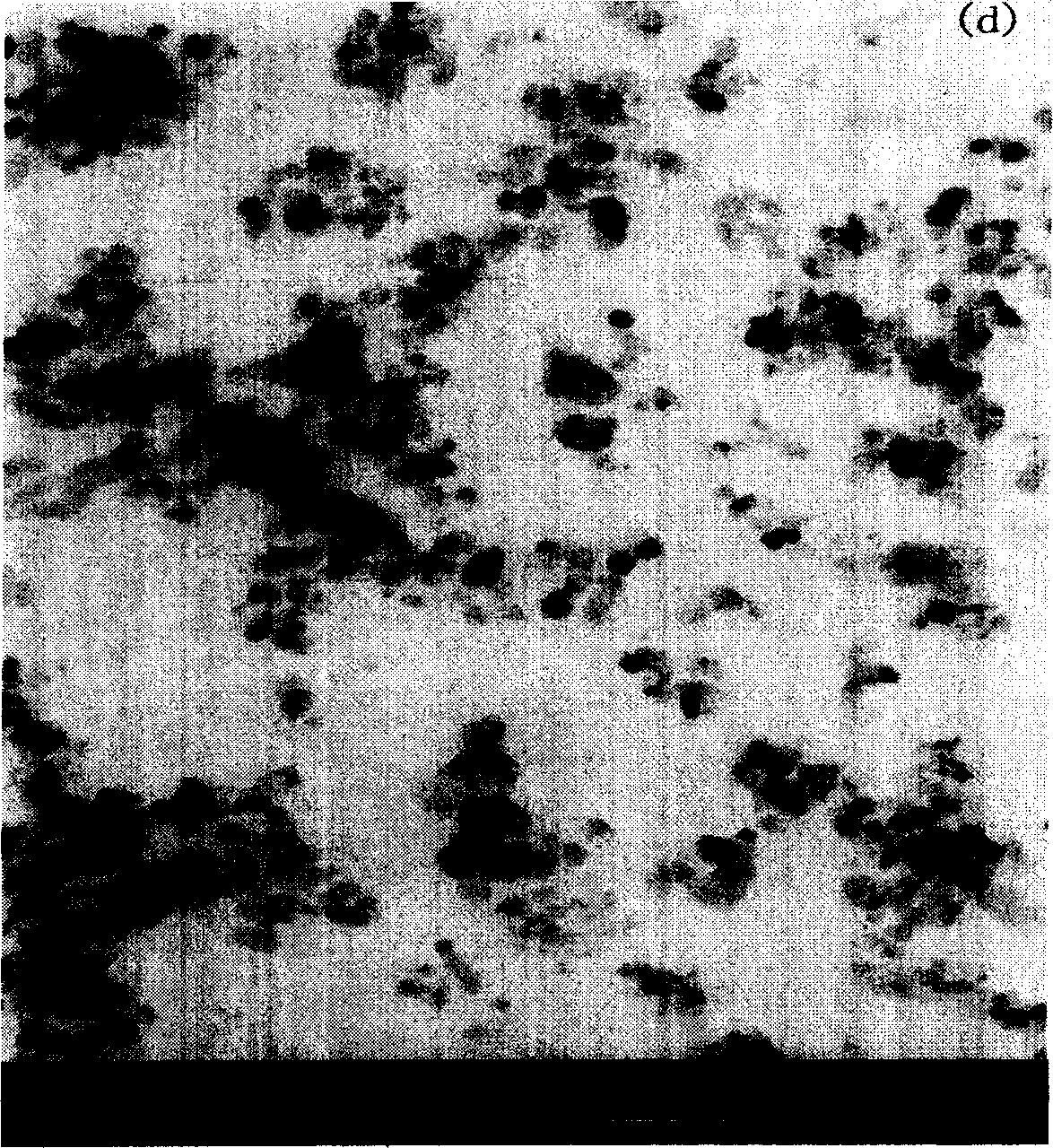

Image

Examples

Example Embodiment

[0047] Example 1

[0048] Mix 50g minus three-line dewaxing oil and 10g SP-80, heat at 80°C to dissolve, and mix uniformly; heat 700g nonahydrate aluminum nitrate to 80°C to melt, slowly add to the above mixture, and mix for 20 minutes to form a uniform super solubilized body. 240 g of saturated ammonia water at 20°C was added dropwise, and aged for 3 hours to obtain nano-aluminum hydroxide gel. The aluminum hydroxide gel was calcined at 550°C for 8 hours to obtain the nano γ-alumina in this embodiment.

Example Embodiment

[0049] Example 2

[0050] Mix 10g minus fourth-line oil, 20g minus first-line oil, 2g minus second-line wax paste, 13g residual oil wax paste, 8g SP-80, 2g OP-4 and 2g M-201, heat at 100°C to dissolve and mix well; mix 820g nine The hydrated aluminum nitrate is heated to 100° C. to melt, slowly added to the above mixture, and mixed for 30 minutes to form a uniform super solubilizing body. In a closed reactor, 123 g of liquid ammonia at 50°C was added to the super sol-enhancing body, and reacted at 180°C for 2 hours to obtain nano aluminum hydroxide gel. The aluminum hydroxide gel is calcined at 600° C. for 8 hours, that is, the nano γ-alumina in this embodiment.

Example Embodiment

[0051] Example 3

[0052] Dissolve and mix 57g of normal three-line oil, 3g of fatty acid monoglyceride, 10g of polyisobutenyl diethylene glycol maleate and 1g of tall oil amide at 100℃; mix and heat 613g of aluminum chloride, 367g of urea and 355g of water Melt at 120°C, slowly add to the above mixture, mix for 20 minutes to form a uniform super solubilizer. The reactor was closed, reacted at 200°C for 4 hours, and aged for 10 hours to obtain nano aluminum hydroxide gel. The aluminum hydroxide gel is calcined at 650° C. for 4 hours, which is the nano γ-alumina in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com