Preparation method of nanometer zinc oxide

A nano-zinc oxide and zinc source technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of inability to prepare special crystal forms and shapes, difficulty in preparing ZnO, strict control conditions, etc. Control, uniform shape, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

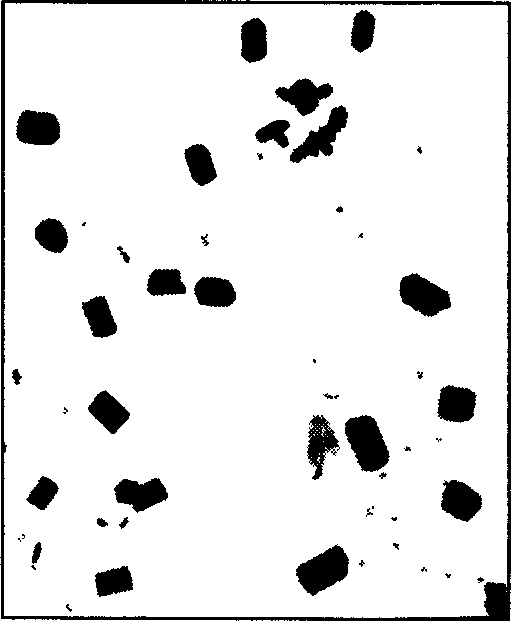

[0034] Embodiment one: a kind of preparation method of nano-zinc oxide former powder, with the ZnSO that concentration is 0.15mol / L 4 ·7H 2 O is a raw material, urea is a precipitant host, and the microwave radiation temperature is maintained at 93° C., and the mol ratio of the reactant zinc sulfate to urea is 1: 2. After the reaction is completed, the precipitate basic zinc carbonate is used respectively Ammonia water with pH=9.0 and absolute ethanol were washed 3 to 4 times respectively, and the precipitate after washing was dried and ball milled in a vacuum dryer to obtain solid basic zinc carbonate powder, which was then roasted at about 380°C for 3 hours, and then ball milled. Nano ZnO powder is obtained.

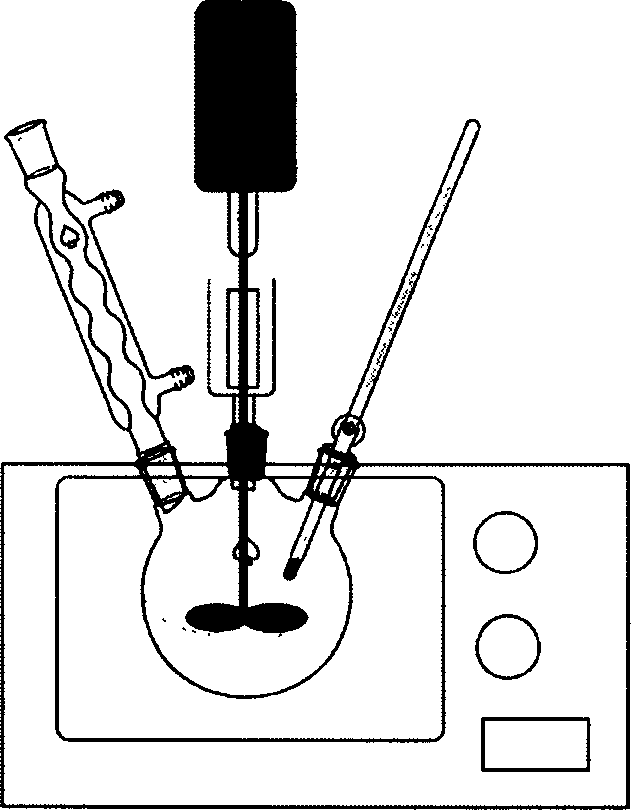

[0035] Its reaction apparatus sees appendix figure 1As shown, the microwave oven is provided with a reaction container with three injection ports, corresponding to the reaction container injection ports, there are three ports on the top of the microwave oven, and the...

Embodiment 2

[0037] Embodiment two: a kind of preparation method of nano zinc oxide former powder, be the ZnSO of 0.2mol / L with concentration 4 ·7H 2 O is the raw material, urea is the precipitant host, and the microwave radiation temperature is maintained at about 90°C. The molar ratio of the reactant zinc sulfate to urea is 1:3. After the reaction is completed, the precipitate basic zinc carbonate is separated Wash with ammonia water of pH=9.0 and absolute ethanol for 3 to 4 times respectively, then dry in a vacuum dryer and ball mill, roast the solid basic zinc carbonate powder at 400°C for 2 hours, and finally ball mill to obtain nano ZnO powder.

[0038] Its reaction apparatus sees appendix Figure 4 As shown, the difference from Embodiment 1 is that the coolant injection port is replaced by a built-in condenser tube. In addition to the common characteristics of the device in Embodiment 1, the cooling effect is good, and the non-thermal effect of microwaves can be effectively used. ...

Embodiment 3

[0039] Embodiment three: a kind of preparation method of nano zinc oxide raw powder, its reaction device sees attached Figure 6 As shown, the container containing the reactant solution is placed outside the microwave oven (see the circular container above the microwave oven), the reactant passes through the water pump, passes through the flow meter, and after the temperature is measured by the thermometer, it is transported to the spiral tube placed in the microwave oven to receive microwave radiation. As shown, the other end of the spiral tube is connected to the cooling tube through the thermometer outside the furnace, and the outlet of the cooling tube is connected to the circular container, and the cooled reactant returns to the circular container to form a cycle. Compared with two devices in embodiment one and two, the average power of microwave radiation during reaction can be known by the flow rate of flowmeter and the display reading of thermometer, and the cooling eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com