Method for preparing large-particle and flaky praseodymium neodymium oxide

A technology of praseodymium neodymium oxide and large particles, which is applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problem of high production cost, and achieve the effect of uniform particle distribution and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

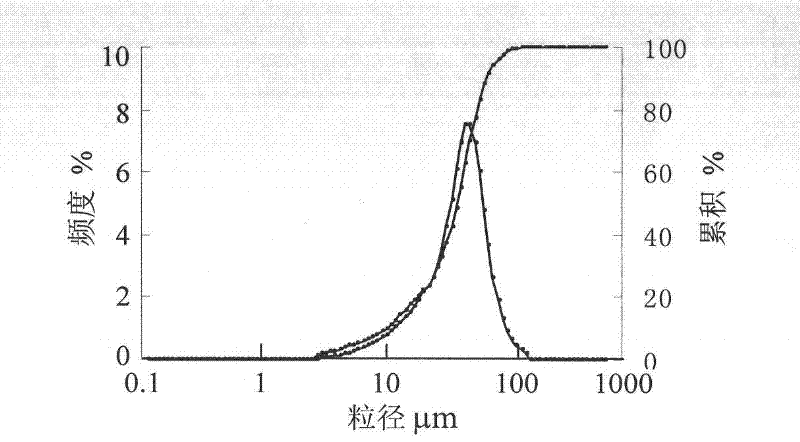

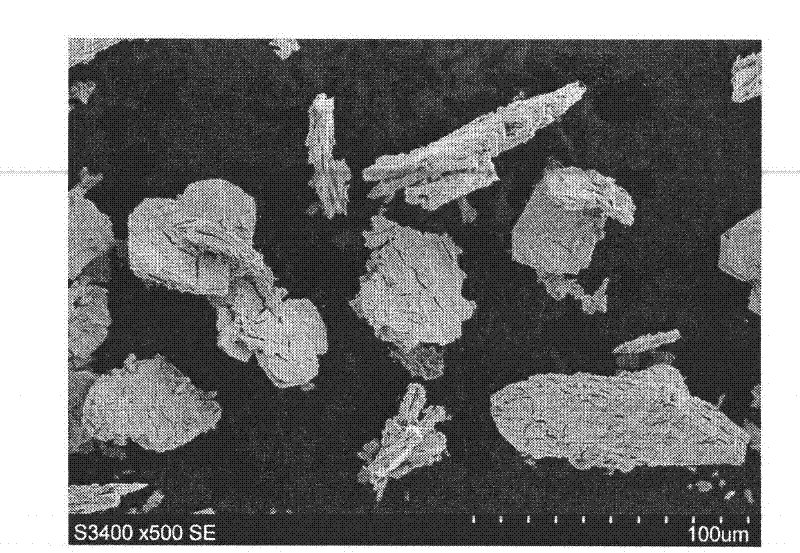

[0011] Add 1000L praseodymium neodymium chloride solution with a concentration of 0.23mol / L in a 3000L reaction tank, heat the praseodymium neodymium chloride solution to 60°C, add 300L ammonium bicarbonate solution with a concentration of 2.5mol / L, and complete the precipitation reaction in 3 hours. Aging for 1 hour, washing, and filtering to obtain a precipitate of praseodymium neodymium carbonate, which was kept in a firing kiln at 1100°C for 4 hours to obtain a product of praseodymium neodymium oxide with a central particle size of 34.32 μm.

Embodiment 2

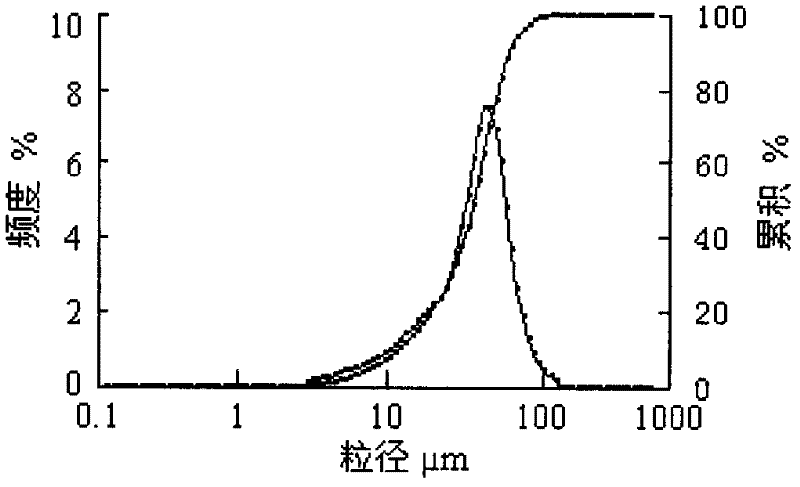

[0013] Add 1000L praseodymium neodymium chloride solution with a concentration of 0.35mol / L into the 3000L reaction tank, heat the praseodymium neodymium chloride solution to 60°C, add 450L ammonium bicarbonate solution with a concentration of 2.5mol / L, the precipitation reaction is completed in 3 hours, and keep warm Aging for 1 hour, washing, and filtering to obtain a precipitate of praseodymium-neodymium carbonate, which was kept in a firing kiln at 1100°C for 4 hours to obtain a product of praseodymium-neodymium oxide with a central particle size of 41.22 μm.

Embodiment 3

[0015] Add 1000L praseodymium neodymium chloride solution with a concentration of 0.18mol / L in a 3000L reaction tank, heat the praseodymium neodymium chloride solution to 60°C, add 240L ammonium bicarbonate solution with a concentration of 2.5mol / L, the precipitation reaction is completed in 3 hours, and keep warm Aging for 1 hour, washing, and filtering to obtain a precipitate of NdPr carbonate, which was kept in a firing kiln at 1100° C. for 4 hours to obtain a NdPr oxide product with a central particle size of 27.06 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com