Method for co-depositing magnesium-neodymium mother alloy near room temperature

A technology of co-deposition and room temperature, which is applied in the field of co-deposition of magnesium and neodymium master alloys at near room temperature, can solve problems such as complex synthesis process, existence of competing reactions, and reduction of green characteristics of ionic liquids, so as to shorten the process flow, reduce production costs, and improve operations environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

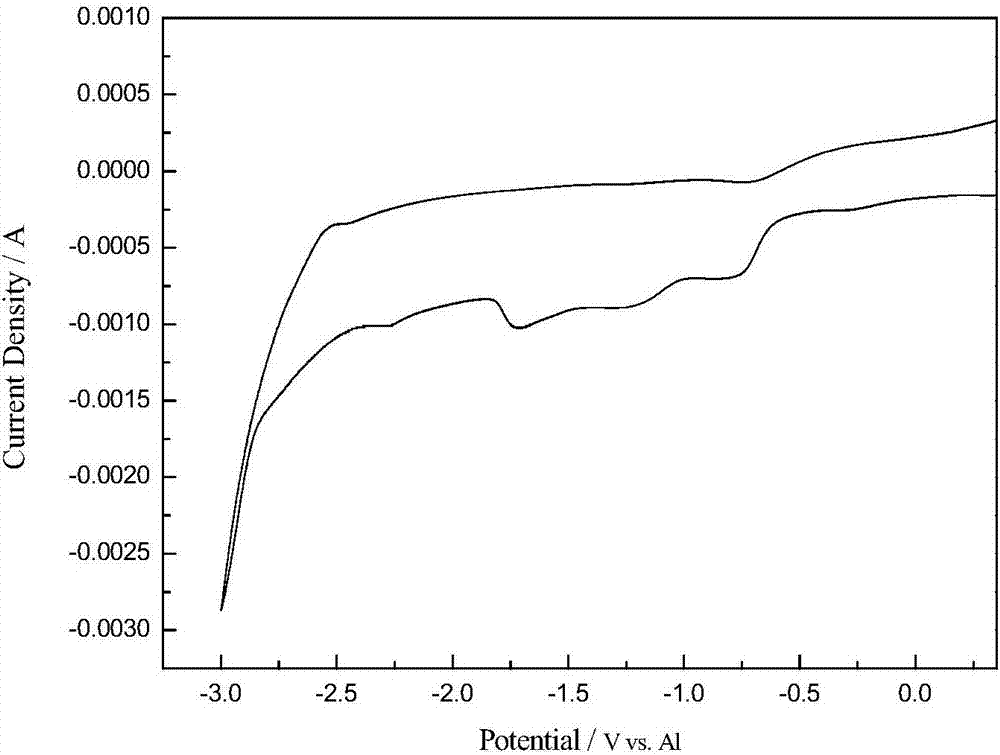

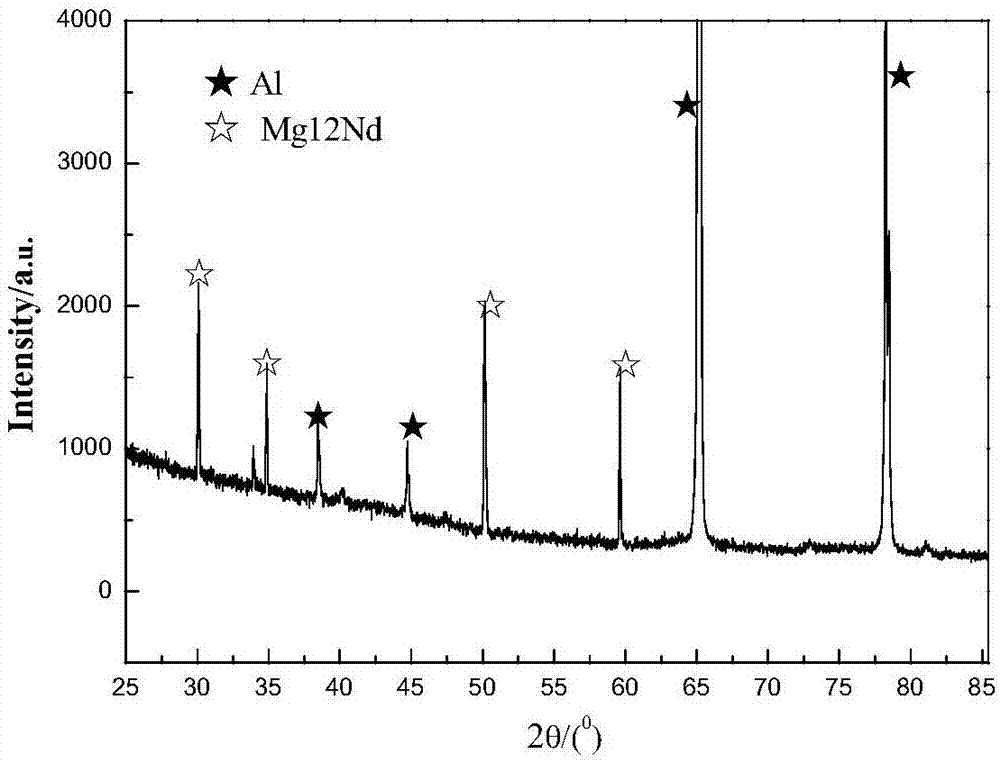

[0067] The raw materials for preparing the electrolyte are lithium chloride, neodymium chloride, magnesium chloride and aluminum chloride vinyl carbonate ionic liquids, wherein the ionic liquids account for 97% of the total mass of the electrolyte, and neodymium chloride and magnesium chloride account for 2% of the total mass of the electrolyte, of which The molar ratio of magnesium chloride to neodymium chloride is 1:1, and lithium chloride accounts for 1% of the total mass of the electrolyte. Continuously feed inert gas into the electrolytic cell to discharge the air and water vapor in it, then add the ionic liquid into the electrolytic cell, then add lithium chloride, neodymium chloride and magnesium chloride, stir and mix in the electrolytic cell to form an electrolyte system, control The electrolyte system is kept at a constant temperature of 50°C. The tungsten rod is used as the anode, the aluminum sheet is used as the cathode, and the electrolysis voltage is -1.8V. Aft...

Embodiment 2

[0069] The raw materials for preparing the electrolyte are lithium chloride, neodymium chloride, magnesium chloride and aluminum chloride propylene carbonate ionic liquid, wherein the ionic liquid accounts for 96% of the total mass of the electrolyte, neodymium chloride and magnesium chloride account for 3% of the total mass, and the magnesium chloride The molar ratio to neodymium chloride is 1:1, and lithium chloride accounts for 1% of the total mass of the electrolyte. Continuously feed inert gas into the electrolytic cell to discharge the air and water vapor in it, then add the ionic liquid into the electrolytic cell, then add lithium chloride, neodymium chloride and magnesium chloride, stir and mix in the electrolytic cell to form an electrolyte system, control The electrolyte system is kept at a constant temperature of 60°C. The graphite rod is used as the anode, the aluminum sheet is used as the cathode, and the electrolysis voltage is -1.8V. After 45 minutes of electro...

Embodiment 3

[0071] Prepare the electrolyte raw materials as neodymium chloride, magnesium chloride and aluminum chloride butylene carbonate ionic liquid, wherein the ionic liquid accounts for 95% of the total mass of the electrolyte, neodymium chloride and magnesium chloride account for 4% of the total mass, and wherein magnesium chloride and chloride The molar ratio of neodymium is 1:1, and lithium chloride accounts for 1% of the total mass of the electrolyte. Continuously feed inert gas into the electrolytic cell to discharge the air and water vapor in it, then add the ionic liquid into the electrolytic cell, then add lithium chloride, neodymium chloride and magnesium chloride, stir and mix in the electrolytic cell to form an electrolyte system, control The electrolyte system is kept at a constant temperature of 70°C. The graphite rod is used as the anode, the aluminum sheet is used as the cathode, and the electrolysis voltage is -1.8V. After 45 minutes of electrolysis, carry out a fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com