Preparation method of large-particle neodymium oxalate

A neodymium oxalate and large particle technology is applied in the field of preparation of large particle neodymium oxalate, which can solve the problems of insufficient particle size of oxides, a large amount of ammonia nitrogen waste water, increase production cost, etc., achieve easy industrial production, reduce production cost, realize The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

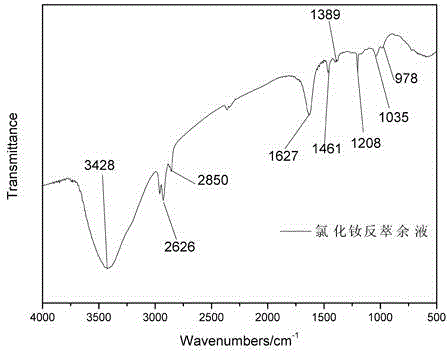

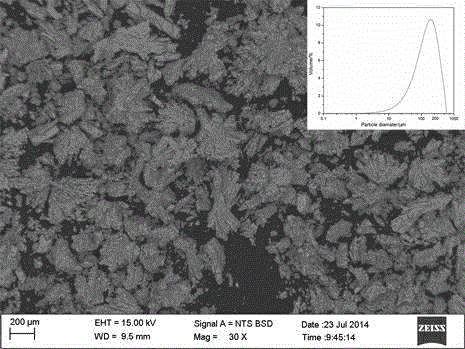

[0028] Example 1: Take 0.1L of neodymium chloride stripping raffinate with a concentration of 0.2 mol / L, heat it to 35°C, and stir at a speed of 400 r / min. -1 and 1035±25cm -1 The absorption peak (the organic phase composition of the following examples is the same), add 3% neodymium oxalate crystal seeds to the feed liquid, the seed crystal center particle size D 50 oxalic acid solution was added dropwise at a rate of 5ml / min to obtain a precipitate of neodymium oxalate, which was aged for 24 hours, filtered, washed, and dried at 80°C to obtain a central particle size D 50 Neodymium oxalate particles with a particle size of 78.63 μm and a normal distribution.

Embodiment 2

[0029] Embodiment 2: Take 0.5L of neodymium chloride stripping raffinate that concentration is 0.12 mol / L, adjust temperature to 15 DEG C, stirring speed is 300 r / min, add 6% neodymium oxalate seed crystal to feed liquid, crystal Kind of central particle size D 50 oxalic acid solution was added dropwise at a rate of 10ml / min to obtain a precipitate of neodymium oxalate, which was aged for 8 hours, filtered, washed, and dried at 100°C to obtain a central particle size D 50 Neodymium oxalate particles with a particle size of 134.65 μm and a normal distribution.

Embodiment 3

[0030] Example 3: Take 0.1L of neodymium chloride stripping raffinate with a concentration of 0.08 mol / L, heat it to 75°C, and stir at a speed of 200 r / min, add 12% neodymium oxalate seed crystals to the feed liquid, and the seed crystals Center particle size D 50 oxalic acid solution was added dropwise at a rate of 8ml / min to obtain a precipitate of neodymium oxalate, which was aged for 32 hours, filtered, washed, and dried at 90°C to obtain a central particle size D 50 Neodymium oxalate particles with normal particle size distribution of 94.65 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com