Aluminum alloy surface titanium plating treatment method

A technology of aluminum alloy surface and treatment method, applied in the field of aluminum surface treatment, can solve the problems of high temperature, high melting point, difficult to form high-quality titanium film, etc., to achieve the effect of good electroplating effect, enhanced performance and guaranteed activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with embodiment, the present invention will be further described. The following description is by way of example, but the protection scope of the present invention should not be limited thereto.

[0052] The titanium plating treatment method on the aluminum alloy surface of the present embodiment, its treatment process is as follows:

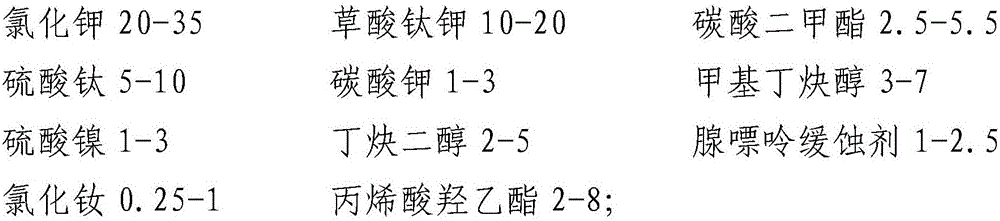

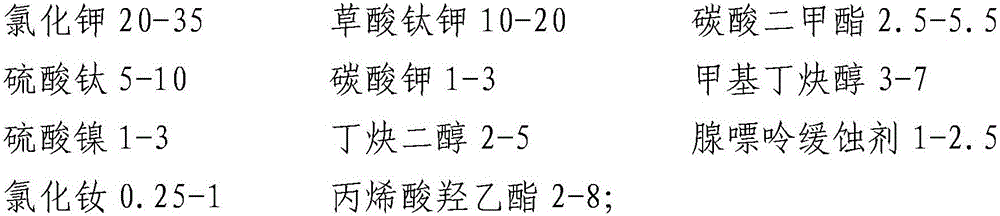

[0053] (1) Preparation of each liquid:

[0054] (1) Preparation of alkaline mixed aqueous solution:

[0055] Potassium hydroxide, sodium silicate, dodecylphenol vinyl ether and sodium pyrophosphate were respectively taken, according to potassium hydroxide 45g / L, sodium silicate 7g / L, dodecylphenol vinyl ether 12g / L, pyrophosphoric acid The concentration ratio of sodium is 7g / L, and it is evenly mixed with clean water to form an alkaline mixed aqueous solution.

[0056] (2) Preparation of acidic mixed aqueous solution:

[0057] Take hydrochloric acid, oxalic acid, and myristyl phenol vinyl ether respectively, and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com