Ultrathin film material for electronic product and preparation method thereof

An electronic product and ultra-thin film technology, applied in the field of ultra-thin film materials for electronic products and their preparation, can solve problems such as the inability of performance to meet the needs of industrialization, and achieve the effects of being conducive to environmental protection development, avoiding volatilization, and simple and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

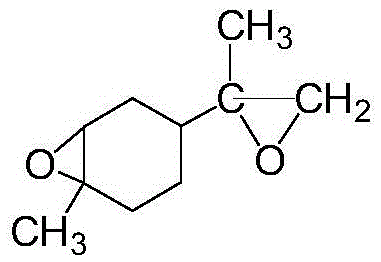

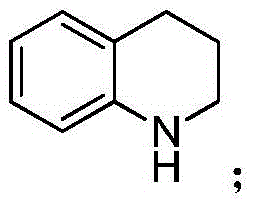

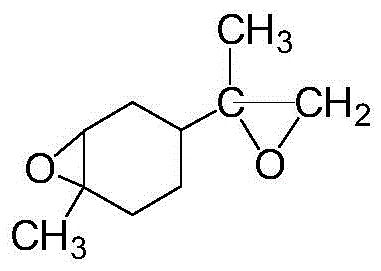

[0024] Add 100g of diisoprene diepoxide into 380g of ethylene glycol, stir at 150°C for 15 minutes, then add 18g of 3-tridecafluorohexylpropene, adjust the temperature to 90°C, and add 10g of 1% superhydrogen Oxidize diisopropyl dicarbonate ethylene glycol solution, stir at 90°C for 8 hours; then remove the solvent by rotary evaporation to obtain fluorine-containing epoxy; add 20g of N-methylphenethylamine to 80g of ethanol, stir and mix for 30 minutes, Then add 2g of ytterbium fluoride and 5g of zirconia, mix for 1 hour, then add 12g of tetrahydroquinoline compound, mix for 2 hours, then add 1.5g of graphite powder; stir at 90°C for 5 minutes to obtain the mixture; then add 30g of fluorine-containing Epoxy, 8g trimethylchlorosilane were added to the mixture, and stirred at 110°C for 25 minutes to obtain a membrane material precursor; a mixed solvent was composed of 10g Tween-20, 100g water and 80g ethanol, and the membrane material precursor was dissolved in A mixed solution ...

Embodiment 2

[0026] Add 100Kg of diisoprene diepoxide into 380Kg of ethylene glycol, stir at 150°C for 15 minutes, then add 18Kg of 3-tridecafluorohexylpropene, adjust the temperature to 90°C, and add 10Kg of 1% supernatant Oxidize diisopropyl dicarbonate ethylene glycol solution, stir at 90°C for 8 hours; then remove the solvent by rotary evaporation to obtain fluorine-containing epoxy; add 20Kg N-methylphenethylamine to 80Kg ethanol, stir and mix for 30 minutes, Then add 2Kg of ytterbium fluoride and 5Kg of zirconia, mix for 1 hour, then add 12Kg of tetrahydroquinoline compound, mix for 2 hours, then add 1.5Kg of graphite powder; stir at 90°C for 5 minutes to obtain the mixture; then add 30Kg of fluorine-containing Epoxy, 8Kg trimethylchlorosilane was added to the mixture, and stirred at 110°C for 25 minutes to obtain a membrane material precursor; 10Kg Tween-20, 100Kg water and 80Kg ethanol were used to form a mixed solvent, and the membrane material precursor was dissolved in A mixed s...

Embodiment 3

[0028] Add 100Kg of diisoprene diepoxide into 380Kg of ethylene glycol, stir at 150°C for 15 minutes, then add 18Kg of 3-tridecafluorohexylpropene, adjust the temperature to 90°C, and add 10Kg of 1% supernatant Oxidize diisopropyl dicarbonate ethylene glycol solution, stir at 90°C for 8 hours; then remove the solvent by rotary evaporation to obtain fluorine-containing epoxy; add 20Kg N-methylphenethylamine to 80Kg ethanol, stir and mix for 30 minutes, Then add 2Kg of ytterbium fluoride and 5Kg of zirconia, mix for 1 hour, then add 12Kg of tetrahydroquinoline compound, mix for 2 hours, then add 1.5Kg of graphite powder; stir at 90°C for 5 minutes to obtain the mixture; then add 30Kg of fluorine-containing Epoxy, 8Kg trimethylchlorosilane was added to the mixture, and stirred at 110°C for 25 minutes to obtain a membrane material precursor; 10Kg Tween-20, 100Kg water and 80Kg ethanol were used to form a mixed solvent, and the membrane material precursor was dissolved in A mixed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com