Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2328 results about "Fluoride calcium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium fluoride is the inorganic compound of the elements calcium and fluorine with the formula CaF2. It is a white insoluble solid. It occurs as the mineral fluorite (also called fluorspar), which is often deeply coloured owing to impurities.

Free flowing dry back-up insulating material

Disclosed is a free flowing dry back-up material which comprises:from 67 to 96% by weight of fly-ash;from 2 to 15% by weight of a heat sensitive binder such as boric acid;from 2 to 7% by weight of a non-wetting agent such as calcium fluoride;from 0 to 10% by weight of a heat expandable material, viz. a material expandable as a function of the temperature such as vermiculite or graphite; andfrom 0 to 1% by weight of a dust suppressant such as kerosene.This material which is useful in particular in the aluminum industry has the advantages of being water free and free flowing, such avoiding the use of vibrator to position it into a shell. It also has a low density and a low thermal conductivity. Moreover, it is organic free as compared to the existing materials which use an organic binder to ensure a low temperature set; and it sets at a temperature lower than 400° F.

Owner:LES PROD CHIMS INDS DE HAUTE TEMPERATURE PYROTEK

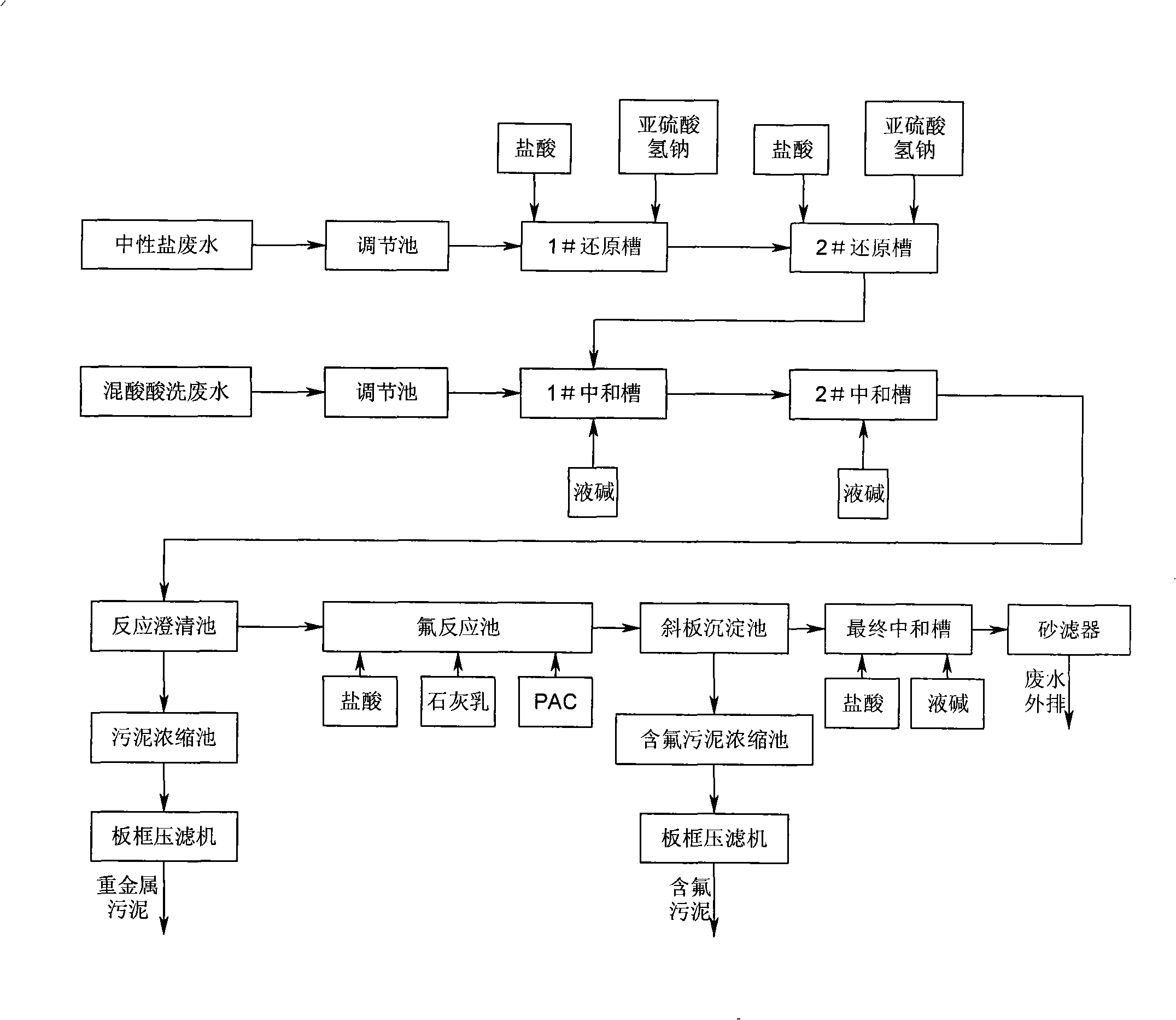

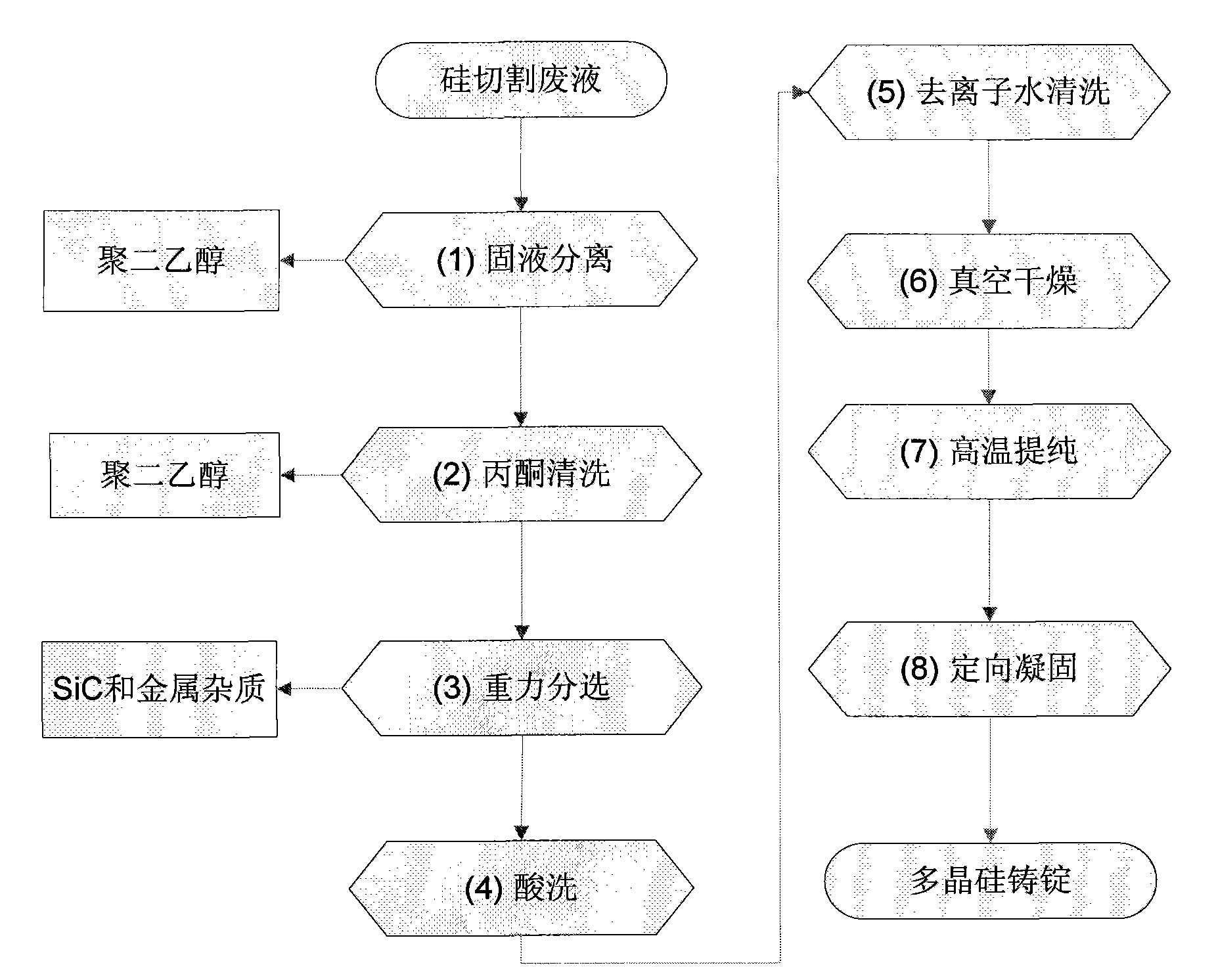

Processing method for stainless steel acid cleaning waste water and liquid

InactiveCN101269889AMeet emission compliance requirementsMeet compliance requirementsSludge treatment by de-watering/drying/thickeningIron oxides/hydroxidesLiquid wasteSludge

The invention relates to a processing method of stainless steel pickling waste liquid, which is characterized in that the processing method includes the steps that: neutral salt wastewater flows into a neutral reduction cell, and mixed acid pickling waste waters flow into a neutralizing tank; reducing agent is added into the neutral reduction cell, and then the reduced wastewater liquid is put into the neutralizing tank and is mixed with the adjusted mixed acid pickling waste waters, and liquid alkali is added into the neutralizing tank; the separated clear waste liquid removes fluorin ions in a settlement tank; neutralizing liquid is added into a final neutralizing tank to cause the pH value of treatment liquid to adjust to be neutralized wastewater liquid which passes through a sand filter to be discharged. The processing method has the advantages that metal ions and fluorin ions are performed the subsection treatment, and neutralizing agent is changed into the liquid alkali from lime cream, the requirement of reaching the standard of the waste liquid emission is not only achieved, but also the mud quantity produced by a mass of lime cream is greatly reduced, heavy metal mud of a retention pond only contains heavy metal compound, the salts of calcium fluoride and calcium sulphate, etc. are separated from the inclined plate settlement tank during the fluoridation stage, thereby the treatment cost is effectively lowered.

Owner:NINGBO BAOXIN STAINLESS STEEL

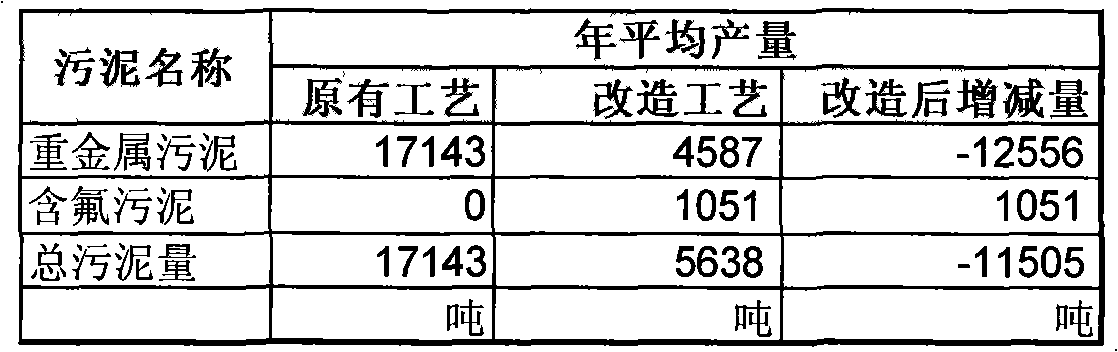

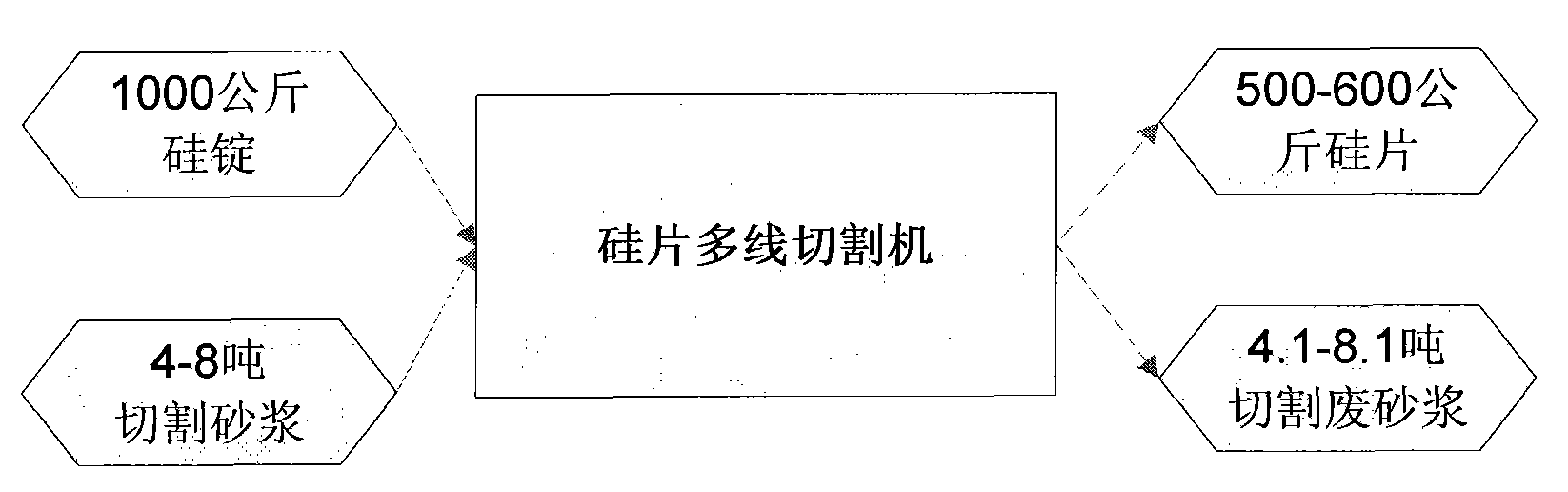

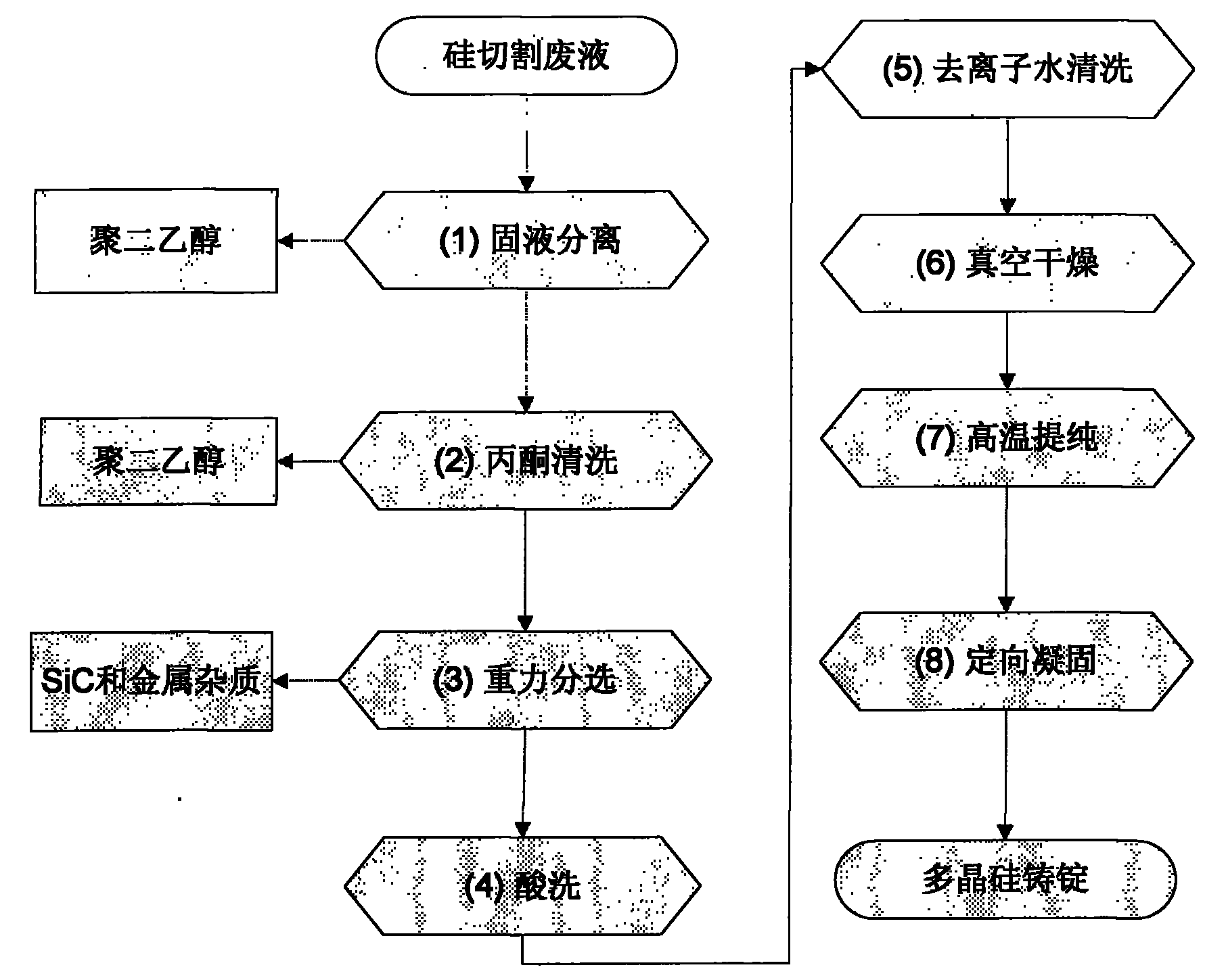

Method for recovering polysilicon ingots, carborundum powder and polyethylene glycol from cutting waste mortar

InactiveCN101792142AHigh yieldMultistage water/sewage treatmentSilicon compoundsPotassiumPolyethylene glycol

The invention discloses a method for recovering polysilicon ingots, carborundum powder and polyethylene glycol from cutting waste mortar. The recovering method comprises the following steps shown as an attached diagram, wherein the high temperature purification comprises the following steps of: mixing the prepared silicon micro powder with a fluxing agent according to the weight ratio of 1: 0.5-5 into lumps, carrying out high temperature treatment in a high temperature vacuum furnace with the treatment temperature range of 1450-1800 DEG C and the treatment time range of 1-10h; and then carrying out directional solidification on melting-state high purity silicon subjected to the high temperature treatment to obtain the polysilicon ingots; wherein the fluxing agent is selected from one or any mixture of silica, alumina, calcium oxide, magnesium oxide, potassium oxide, sodium oxide, calcium fluoride, magnesium fluoride, sodium fluoride, sodium chloride, potassium chloride and calcium chloride. The invention has the advantages that: the yields of carborundum and polyethylene glycol are high and can reach more than 70-80 percent; and the recovered polysilicon ingots reach the purity of 6-7N and completely satisfy of the requirement for preparing silicon slices of silicon solar cell.

Owner:唐康宁

Method for treating aluminum electrolysis waste cathode carbon block using acid and alkali combination method

A method for treating aluminum electrolytic waste cathode carbon blocks by an acid and alkali combination method is characterized by comprising the following steps: (1) aluminum electrolytic waste cathode is added to concentrated basic solution for reaction; a filtered solid phase is obtained by filtering and is added to concentrated acid for reaction; and carbon powder is obtained after filtration; (2) filtrates are mixed and dropwise added with the concentrated basic solution, the pH value thereof is adjusted to 9, the obtained mixture is kept standing and filtered to obtain cryolite; (3) the filtrate is added with saturated bleach solution, kept standing and filtered to obtain calcium fluoride; (4) the fourth filtrates is heated, evaporated and crystallized to obtain sodium chloride solid. With the purposes of waste utilization and environmental protection, the method successfully provides the process for treating aluminum electrolytic waste cathode by the acid and alkali method, which causes the waste cathode to not be the conventional waste and pollutant and to become artificial mineral resources. The method solves the problem of waste utilization in aluminum electrolysis industry, improves benefit, and improves the comprehensive level of the aluminum electrolysis industry of China.

Owner:NORTHEASTERN UNIV +1

Lightweight dry refractory

A dry refractory composition having superior insulating value. The dry refractory composition also may have excellent resistance to molten metals and slags. The composition includes filler lightweight material, which may be selected from perlite, vermiculite, expanded shale, expanded fireclay, expanded alumina silica hollow spheres, bubble alumina, sintered porous alumina, alumina spinel insulating aggregate, calcium alumina insulating aggregate, expanded mulllite, cordierite, and anorthite, and matrix material, which may be selected from calcined alumina, fused alumina, sintered magnesia, fused magnesia, silica fume, fused silica, silicon carbide, boron carbide, titanium diboride, zirconium boride, boron nitride, aluminum nitride, silicon nitride, Sialon, titanium oxide, barium sulfate, zircon, a sillimanite group mineral, pyrophyllite, fireclay, carbon, and calcium fluoride. The composition also may include dense refractory aggregate, which may be selected from calcined fireclay, calcined Chamotte, a sillimanite group mineral, calcined bauxite, pyrophyllite, silica, zircon, baddeleyite, cordierite, silicon carbide, sintered alumina, fused alumina, fused silica, sintered mullite, fused mullite, fused zirconia, sintered zirconia mullite, fused zirconia mullite, sintered magnesia, fused magnesia, sintered spinel, and fused spinel refractory grog, a heat activated bonding agent, and a dust suppressant.

Owner:ALLIED MINERAL PROD

Recycling method for treating stainless steel pickling acid pickle and wastewater

ActiveCN104310647AHigh operating costsSimple processWater treatment compoundsWaste water treatment from metallurgical processWash waterLaterite

The invention relates to a recycling method for treating stainless steel pickling acid pickle and wastewater, belonging to the field of treatment of industrial acid pickle and wastewater in iron and steel and metallurgy industries. The acid pickle and wash wastewater generated during stainless steel pickling are collected according to quality and category and the acid pickle is subjected to acid recycling. The acid pickle and wash wastewater are treated through fractional precipitation by adopting lime as a neutralizing agent. Calcium sulfate or calcium fluoride or a mixture of calcium sulfate and calcium fluoride is obtained through precipitation under the acidic condition (the pH value is equal to 3.0+ / -0.5) and can serve as a cement filler or a material for brickmaking or a building material after heavy metal polluted calcium salt is removed. A metal hydroxide is obtained through precipitation under the alkaline condition (the pH value is not more than 9.0) and can serve as a stainless steel smelting raw material as the quality of the product is better than that of the imported laterite-nickel ores in China. The calcium nitrate containing wastewater obtained after the acid pickle is treated is not needed to be discharged or treated and can be recycled. After being treated, the wash wastewater can be reused as production line wash water.

Owner:上海博士高环保科技有限公司

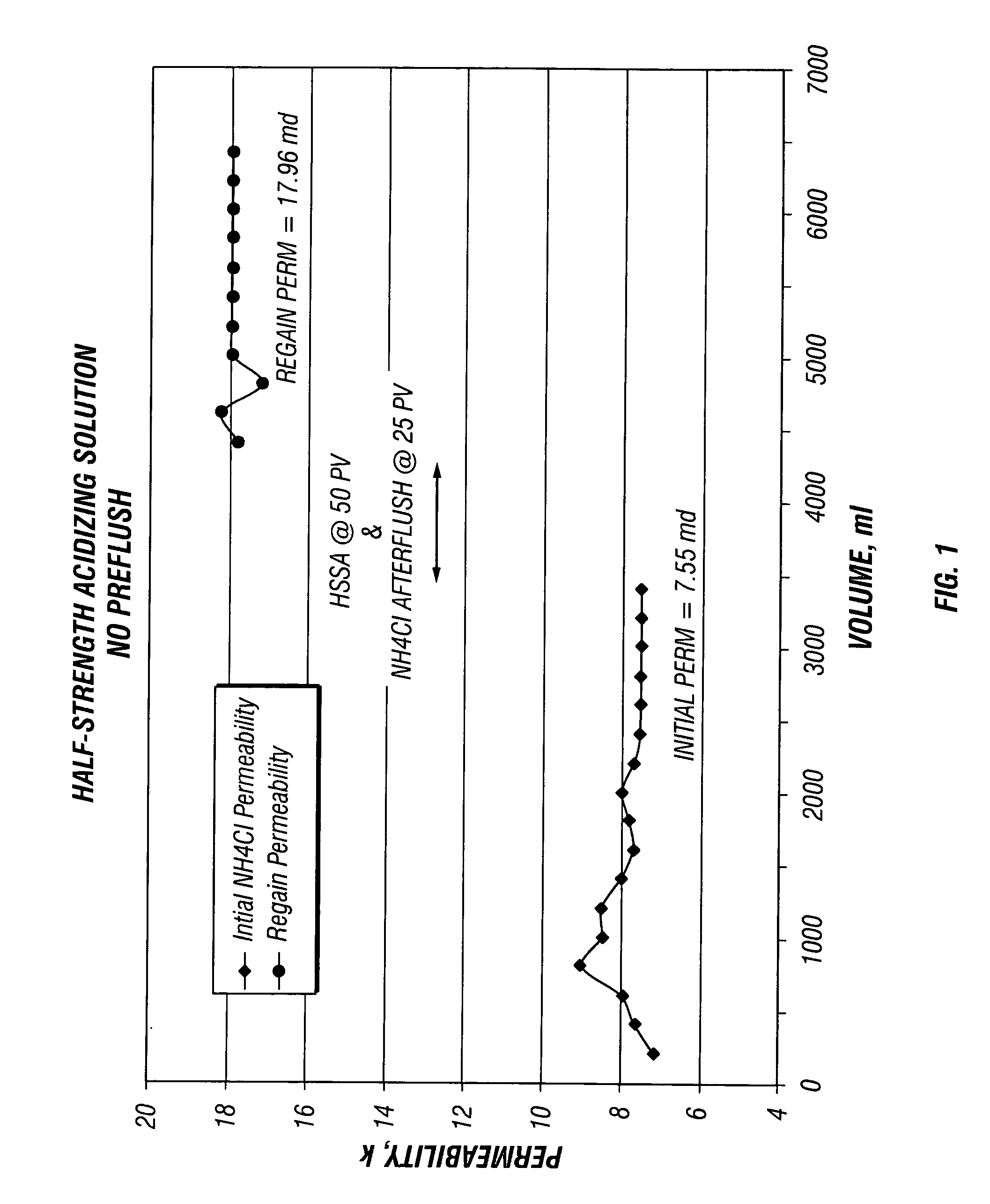

Matrix treatment of damaged sandstone formations using buffered HF-acidizing solutions

InactiveUS20060131022A1Affect productivityRisk minimizationFluid removalFlushingOrganic chemistryFluoride calcium

Sandstone formations of oil and gas and geothermal wells are effectively stimulated when a buffered HF-sandstone acidizing solution is employed without the prior introduction of an acid containing preflush solution. By not using a preflush solution, buffered HF-sandstone acidizing solutions are highly effective in dissolving and removing siliceous material while minimizing the formation of calcium fluoride.

Owner:BAKER HUGHES INC

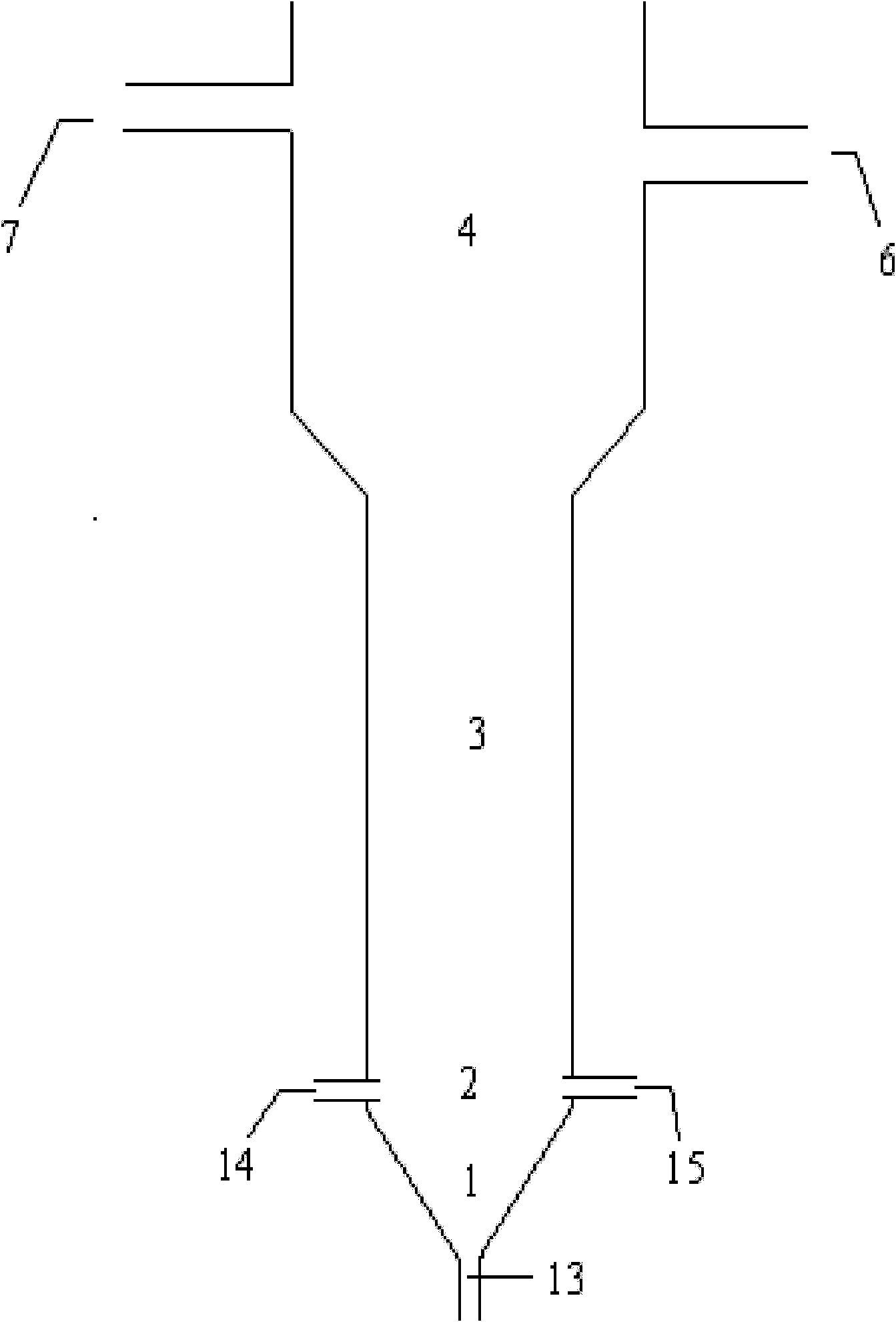

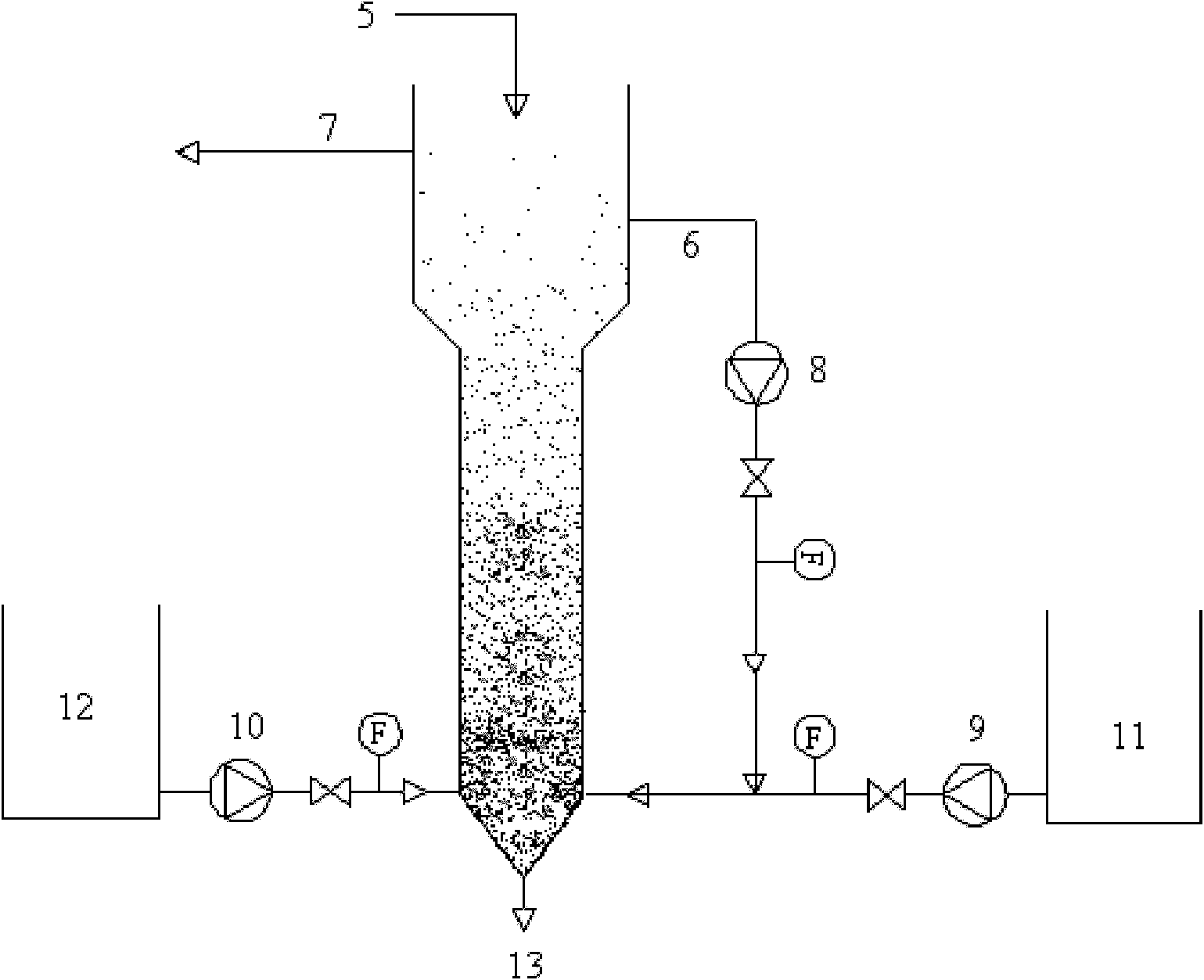

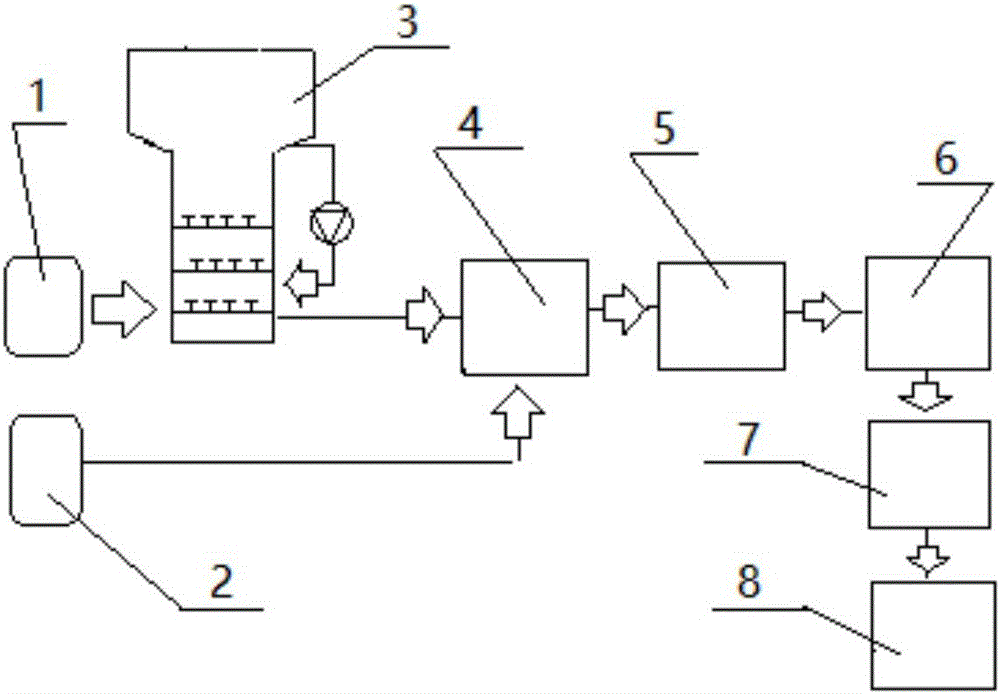

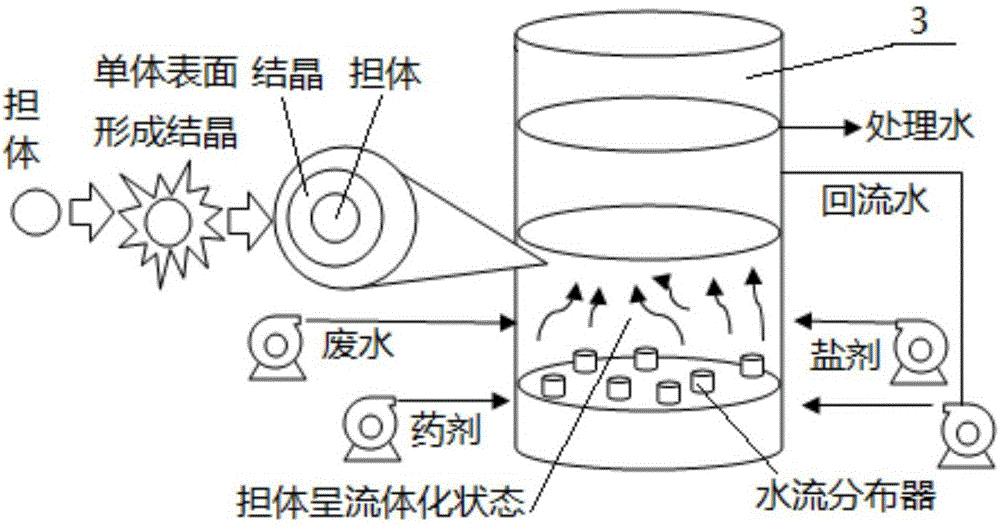

Method and device for treating fluorine-containing waste water

InactiveCN101941752AReduce processing costsHigh purityWater contaminantsCalcium/strontium/barium fluoridesFluidized bedResource recovery

The invention provides a method and a device for treating fluorine-containing waste water. In the method, a solid-liquid fluidized bed is used as a crystal reactor; a certain amount of calcium fluoride seed crystal is added into the reactor; the fluorine-containing waste water and a calcium-containing precipitator are delivered into a treatment device of the solid-liquid fluidized bed in a reacting ratio to ensure that fluorinions are precipitated on the surface of the calcium fluoride seed crystal; the prepared sand-shaped calcium fluoride precipitated slurry after precipitation is reclaimed; and primarily treated water is subjected to flocculent precipitation further to meet the emission standard. By adopting the method, most fluorinions can be precipitated in the crystallization and precipitating process in the fluidized bed, the generated sand-shaped calcium fluoride has low content of water and high content of calcium fluoride and can be used as fluorine resources for recycling; and in the flocculent precipitating process of the primarily treated water, the consumption of the fluorescent is low, and the yield of slurry is low. Therefore, the comprehensive cost for waste watertreatment is low.

Owner:CENT SOUTH UNIV

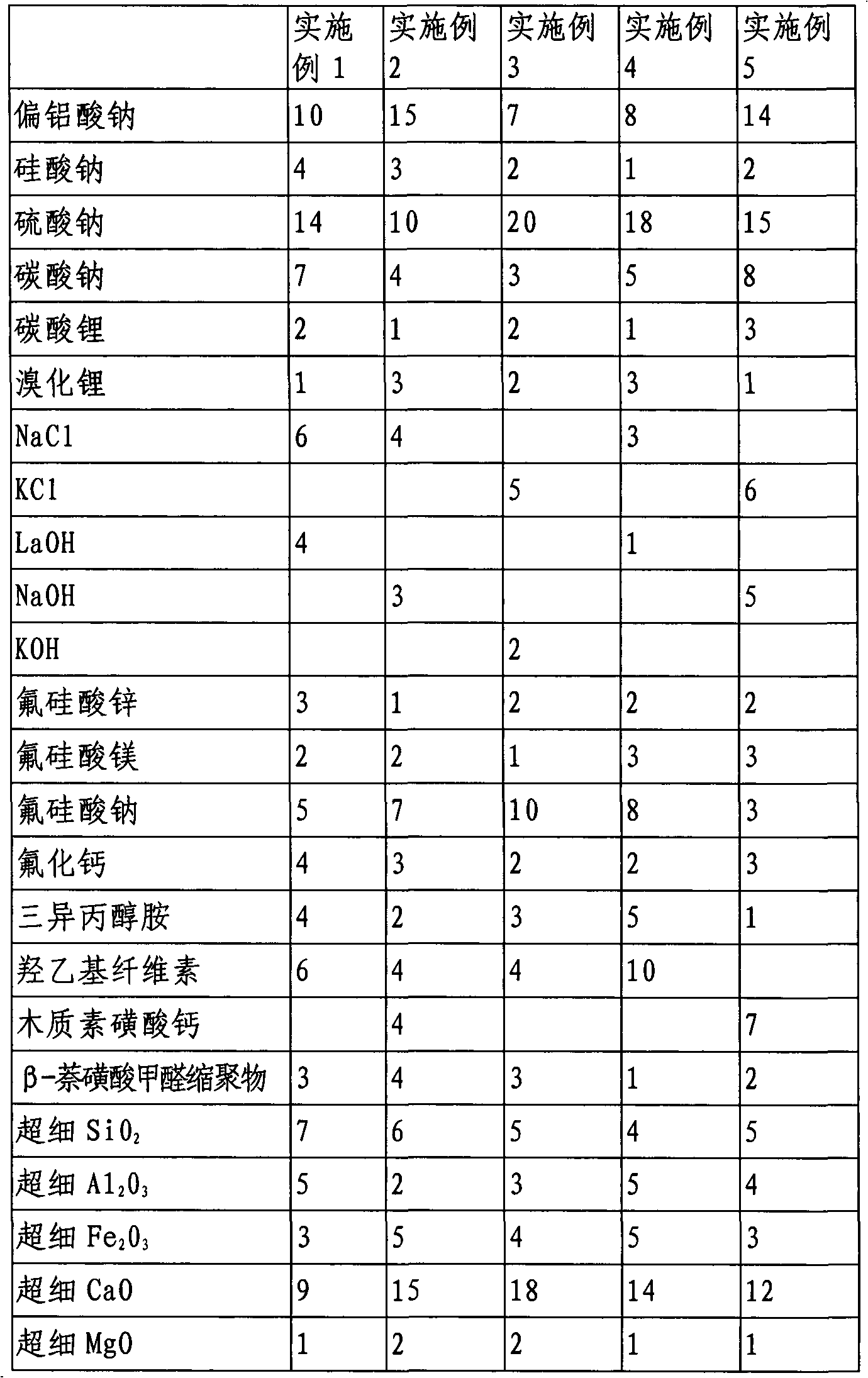

Low-temperature concrete early strength agent

The invention relates to a low-temperature concrete early strength agent, which belongs to cement additives. The early strength agent consists of sodium metaaluminate, sodium silicate, sodium sulfate, sodium carbonate, lithium carbonate, lithium bromide, alkali metal chlorides, alkali metal hydroxides, zinc fluosilicate, magnesium fluosilicate, sodium fluosilicate, calcium fluoride, triisopropanolamine, a filtrate reducer, beta-naphthalene formaldehyde sulfonate polycondensate, ultrafine powder SiO2, ultrafine powder Al2O3, ultrafine powder Fe2O3, ultrafine powder CaO and ultrafine powder MgO. The early strength agent is mainly applied to winter concrete construction or low-temperature environmental emergency projects; when the early strength agent is used, the composition mixture is added into concrete according to 2 to 5 percent of the total weight of cement, water is added and then stirring is performed; and a cement block with the strength of 13.5MPa can be formed in a low-temperature environment at the ambient temperature of approximately 4 DEG C within 12 hours, a cement block with the strength of 18.5MPa can be formed within 24 hours and a cement block with the high strength of 30MPa can be formed within three days.

Owner:陈子川

Thermal spray compositions for abradable seals

Owner:SULZER METCO CANADA INC

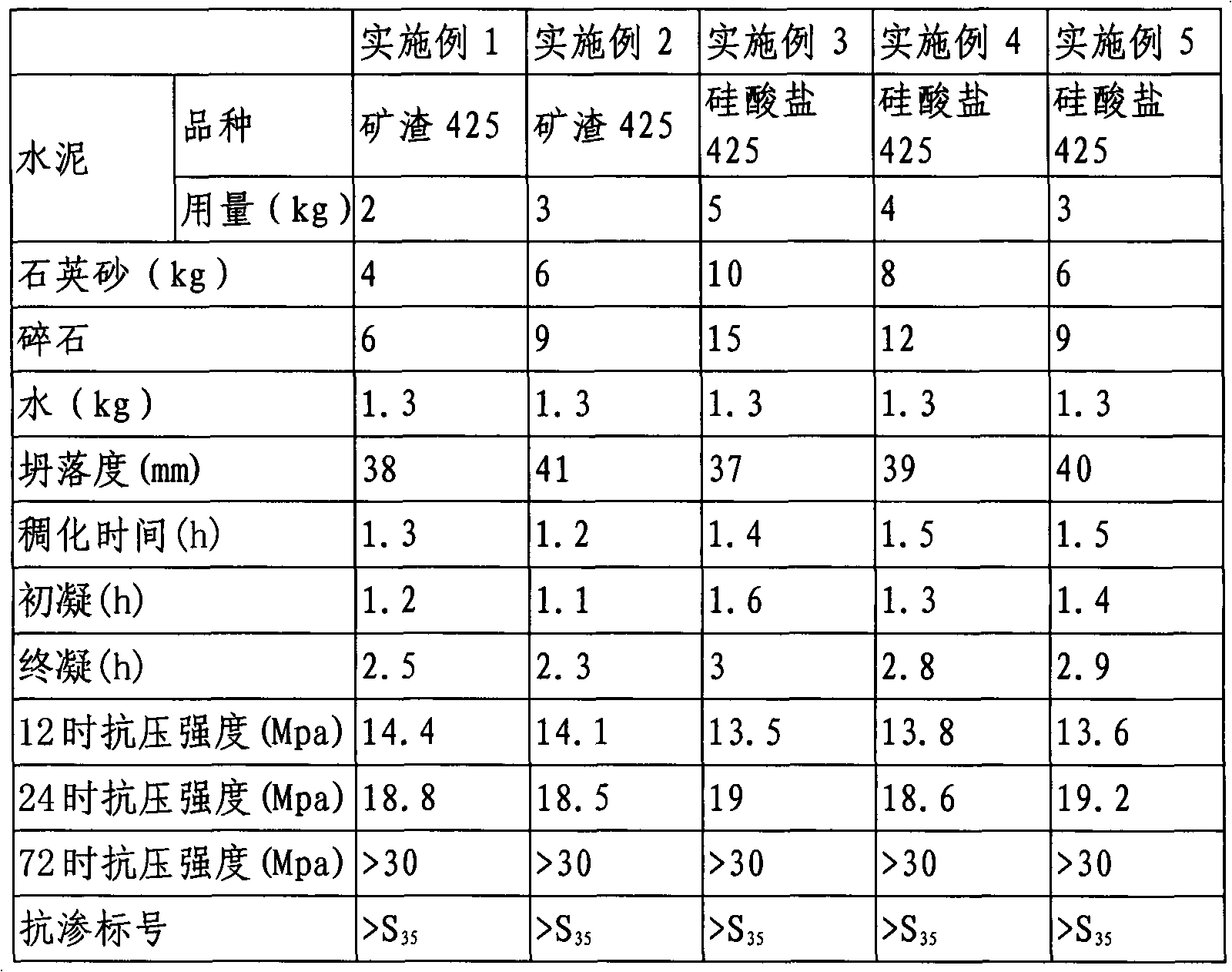

Special cobalt-based metal ceramic alloy powder for optical fiber laser cladding

ActiveCN102650012AHigh hardnessImprove plastic toughnessMetallic material coating processesHigh energyAlloy

The invention discloses special cobalt-based metal ceramic alloy powder for optical fiber laser cladding, which is matched with characteristics of optical fiber laser. The special cobalt-based metal ceramic alloy powder contains the following components by weight percent: 1-2% of carbon, 1-2% of silicon, 2-4% of iron, 1.5-2.5% of nickel, 3-4% of molybdenum, 8-12% of chromium, 3-4% of tungsten, 13-17% of tungsten carbonate, 2-3% of calcium fluoride, 1-2% of silicon nitrate and cobalt for the rest. The metal ceramic alloy powder is specially applied to a cladding process of a high-energy optical fiber laser device, a metal ceramic cladding layer with high hardness, high flexibility and high corrosion resistance can be formed on the surface of a work die of a steel and iron basis material, and the cladding layer is compact in structure, has no defects such as air holes, cracks, shrinkage cavities and the like, and has excellent metallographic performance such as high hardness, high plasticity, flexibility and corrosion resistance, and the like; moreover, the process is convenient and the thermal treatment does not need to be carried out in advance and afterwards. The special cobalt-based metal ceramic alloy powder is particularly suitable for the surface treatment of the die and can greatly prolong the service life of the die.

Owner:CHANGZHOU TIANZHENG IND DEV CO LTD

High-toughness enamel glaze

InactiveCN108658462AImprove toughnessOvercome the defect of porcelain crackLithium oxideSilicon dioxide

The invention discloses high-toughness enamel glaze. The enamel glaze is prepared from the following components in parts by weight: 40-50 parts of silicon dioxide, 15-25 parts of titanium dioxide, 5-15 parts of potassium oxide, 10-20 parts of sodium oxide, 1-5 parts of lithium oxide, 2-4 parts of calcium fluoride, 6-12 parts of vanadium pentoxide, 1-3 parts of tungsten carbide and 5-10 parts of aluminum oxide and zirconium dioxide. According to the enamel glaze, by means of the composition, the toughness of the enamel glaze can be greatly improved, meanwhile, the defect that ceramic cracks arecaused due to collision can be overcome, and therefore, the enamel glaze has a wide application prospect.

Owner:沙冰娟

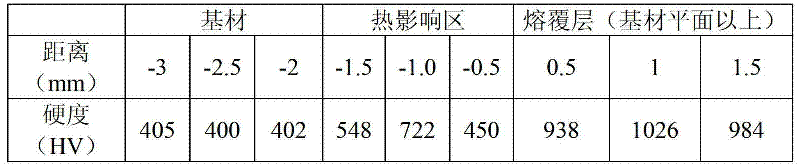

Process for preparing lithium chlorate by lithium extracted from lepidolite

InactiveCN1827527AReduce energy consumptionReduce investmentLithium carbonates/bicarbonatesLithium carbonateSulfate

The invention relates to a method for preparation of lithium carbonate extracting lithium from lithionite. The invention consists of milling, leaching and filtering after modifying by broasting lithonite ore together with the additive findings such as calcium fluoride, calcium sulfate and sodium sulfate at a certain temperature, adding sodium carbonate into the leachate to deposite lithium ion forming the deposition of lithium carbonate, and washing and drying the solid gained by filtering to get the product of lithium carbonate. The filtered mother liquid returns to the circulation to deposit lithium ion. After secondary circulation, we get the mixed salts of potassium sulfate and sodium sulfate as the educts by washing and drying the aforementioned filtered mother liquid. Some of the mixed salts return as findings roasted with lithonite ore for circulation use, while others can be used as raw material for preparation of potassium sulfate.

Owner:钟辉

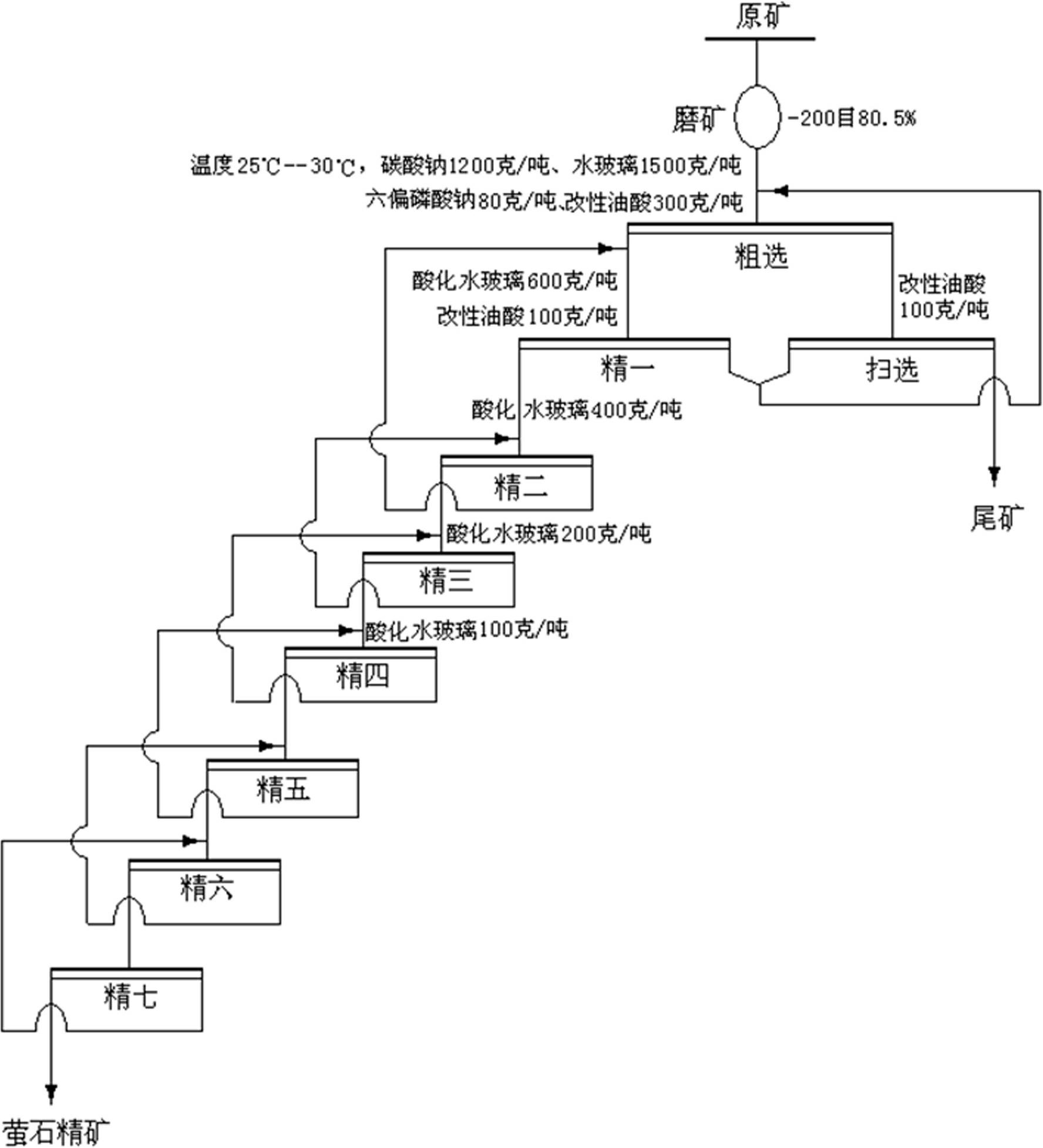

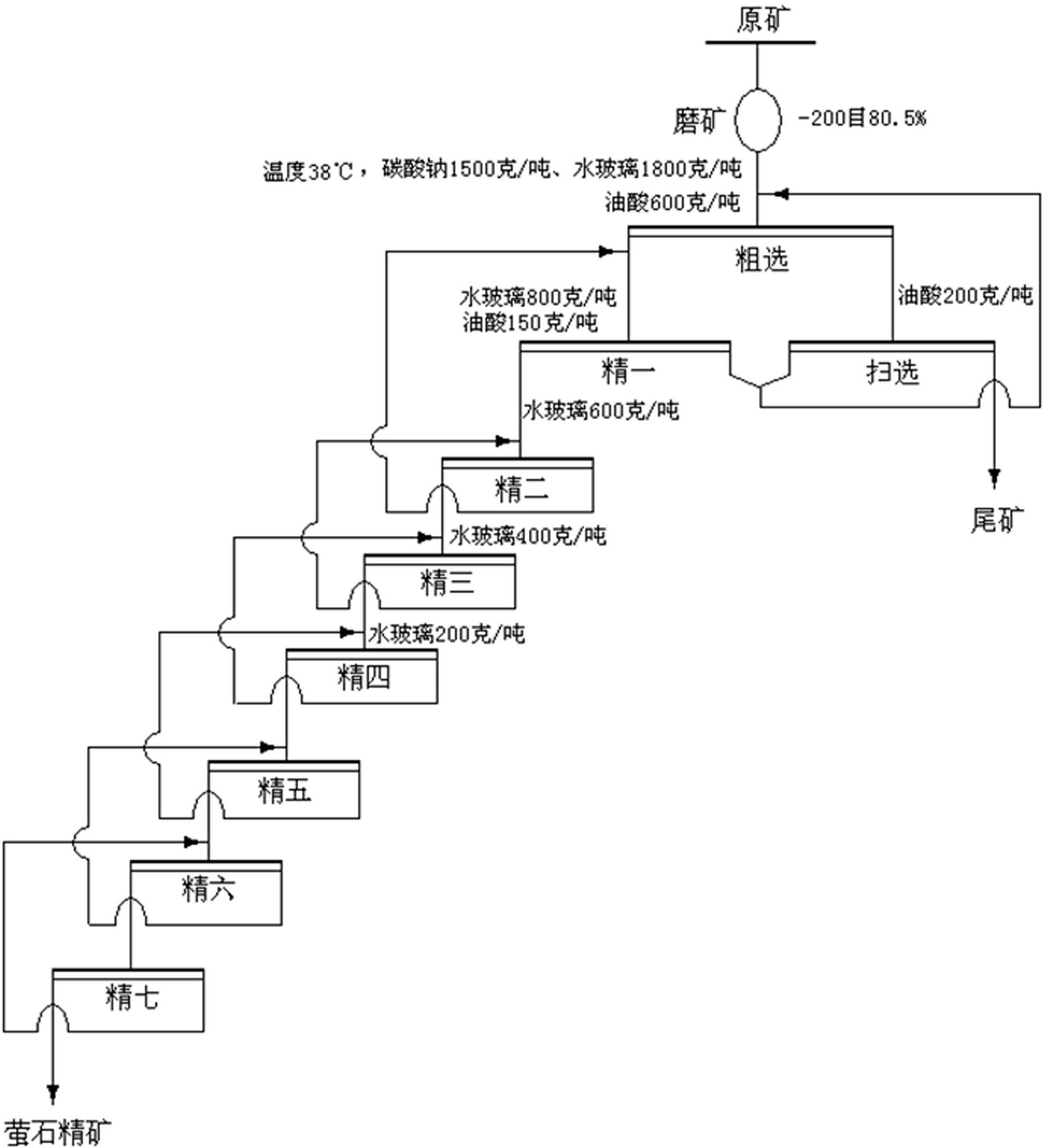

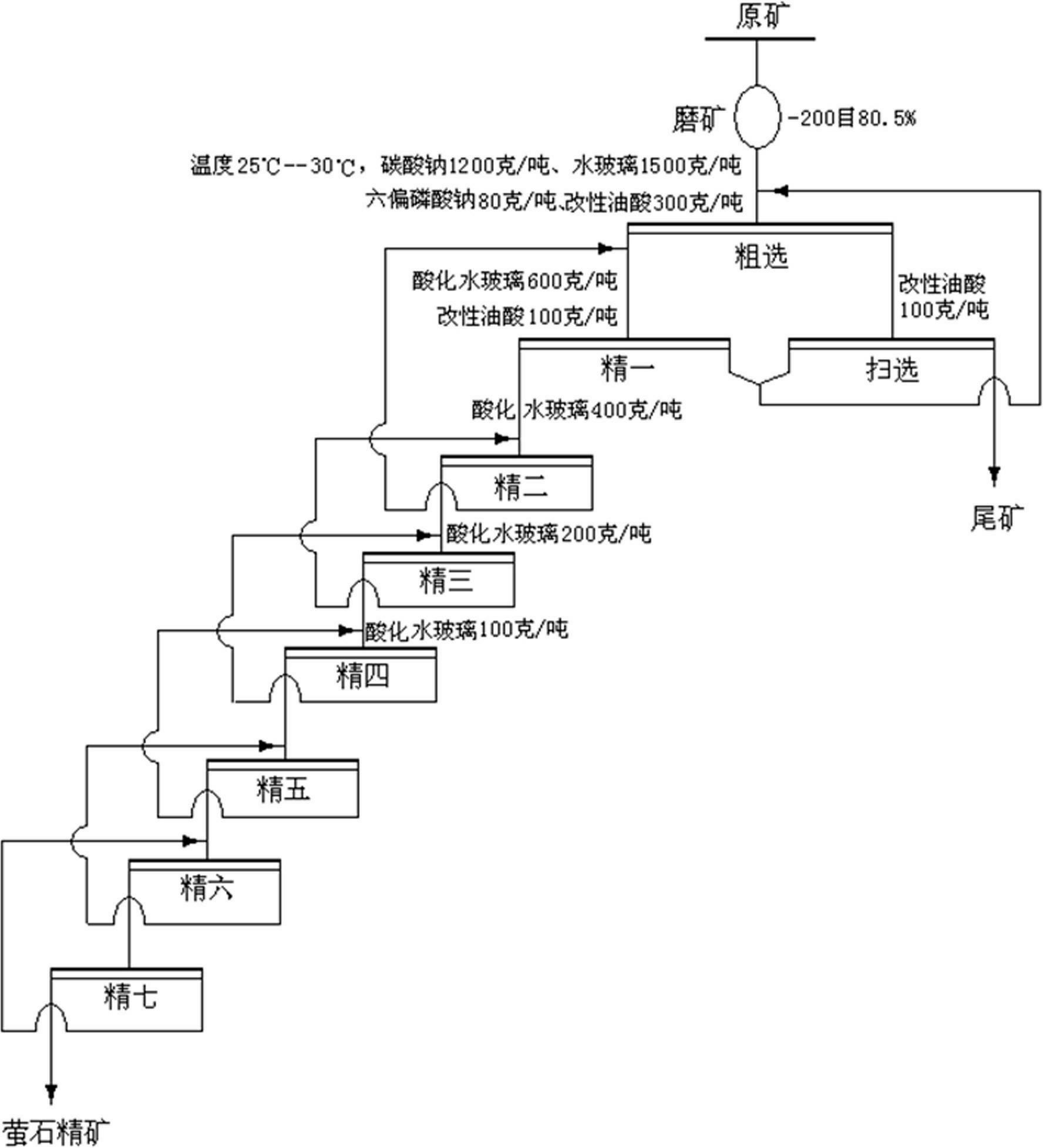

Mineral separation process of complex fluorite difficult to separate

The invention relates to a mineral separation process, in particular to a mineral separation process of complex fluorite difficult to separate. The process includes utilizing sodium hydroxide to treat oleic acid to obtain modified oleic acid, utilizing concentrated sulfuric acid to treat water glass and obtain acidized water glass, conducting ore grinding on fluorite ores according to the prior art, conducting coarse separation under the temperature of 25-30 DEG C, then conducting seven times fine separation on coarse separation foams and adding the acidized water glass into the foams in the first four times of fine separation to prepare fluorite concentrate. The process can improve separation efficiency of calcium fluoride, silica and calcite, improves quality and recycle rate of the fluorite ores, obtains high quality acid grade fluorite ores and resolves the problem of difficulty in separation of complex fluorite flotation, is remarkable in application effect in separation of the complex fluorite difficult to separate, has repeatability, simultaneously reduces requirements of fluorite mineral flotation for ore temperature, reduces energy consumption, reduces usage of collectingagent oleic acid, reduces environment pollution caused by exhaust of a large amount of waste water containing oleic acid and has better economical and social benefits.

Owner:BAIYIN NONFERROUS GROUP

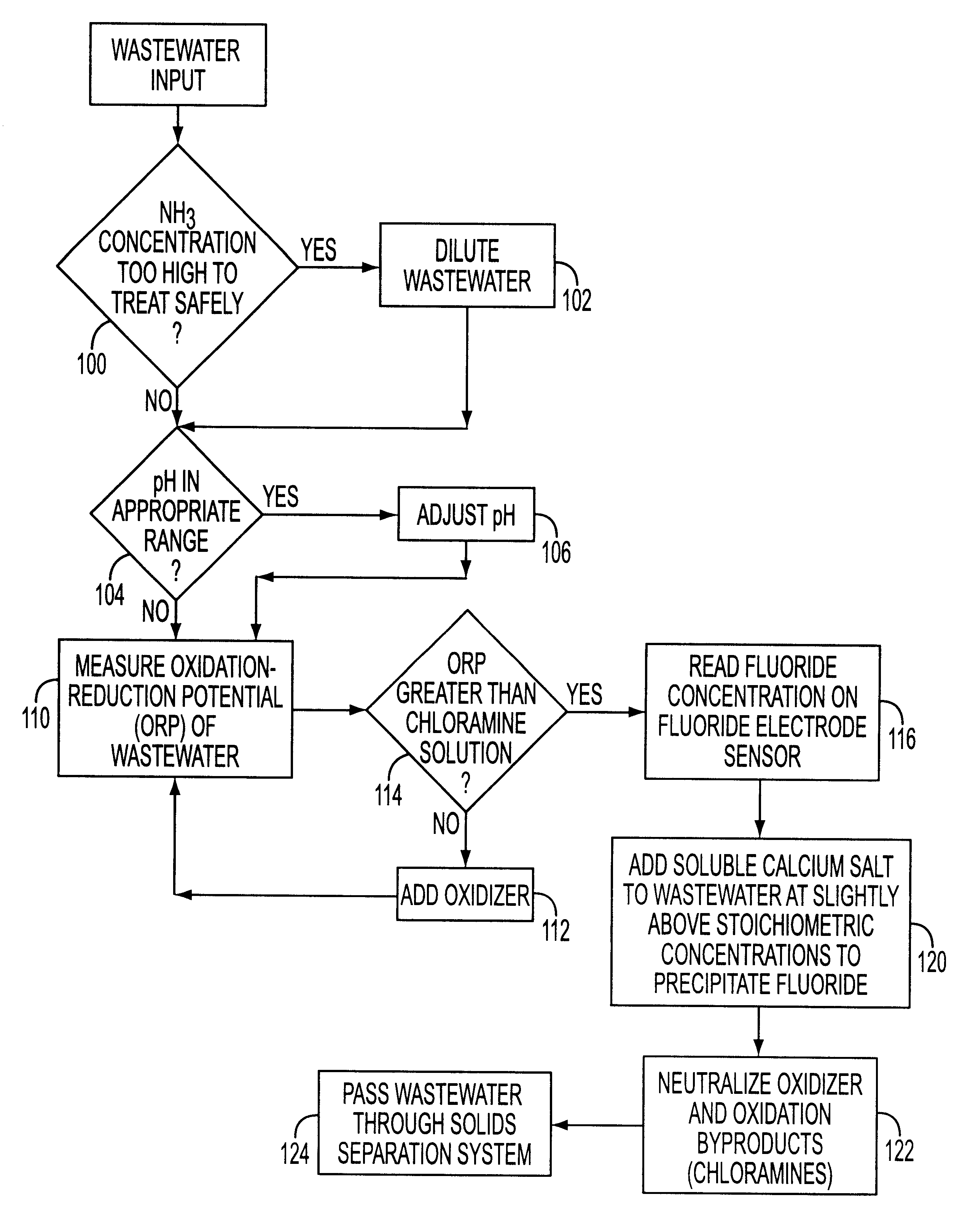

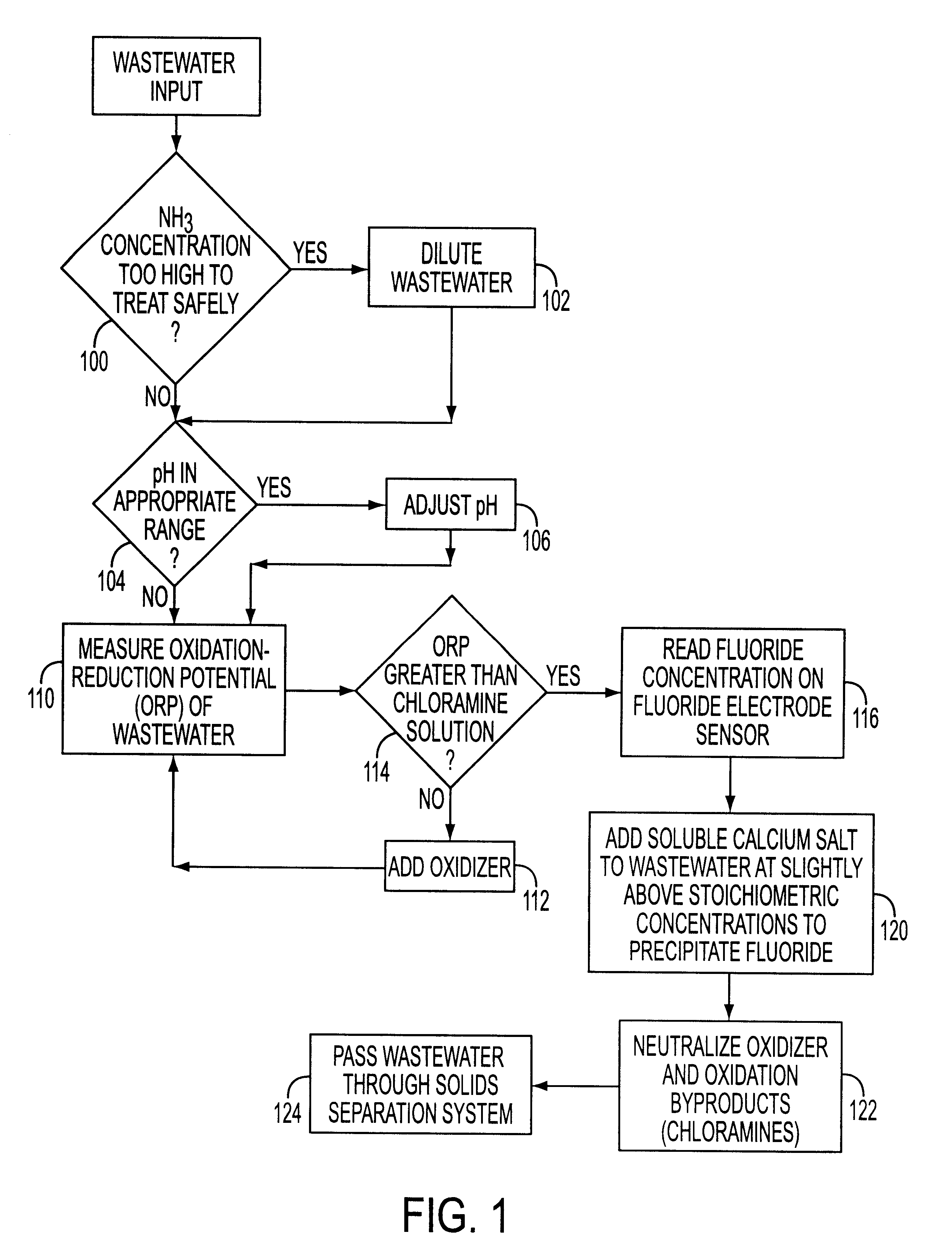

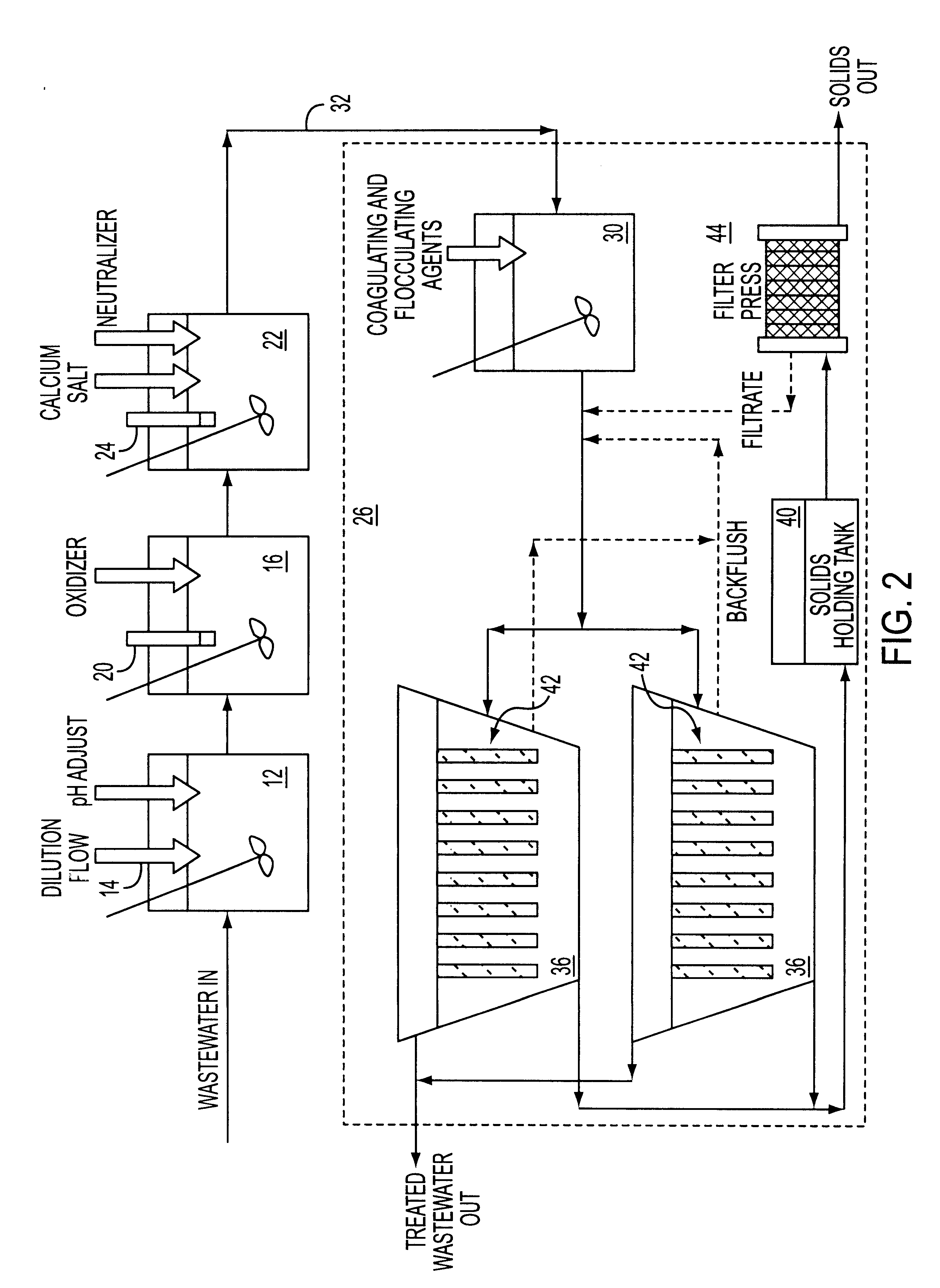

Simultaneous ammonia and fluoride treatment for wastewater

InactiveUS6652758B2Low costLower requirementTreatment involving filtrationSedimentation separationFiltrationWastewater

An improved method of treating wastewater to remove ammonia and fluoride is provided. The method comprises the steps of chemical destruction of ammonia with an oxidizing agent, followed by treatment with calcium salts to precipitate insoluble calcium fluoride, and filtration to remove the precipitate.

Owner:UBS AG STAMFORD BRANCH AS COLLATERAL AGENT

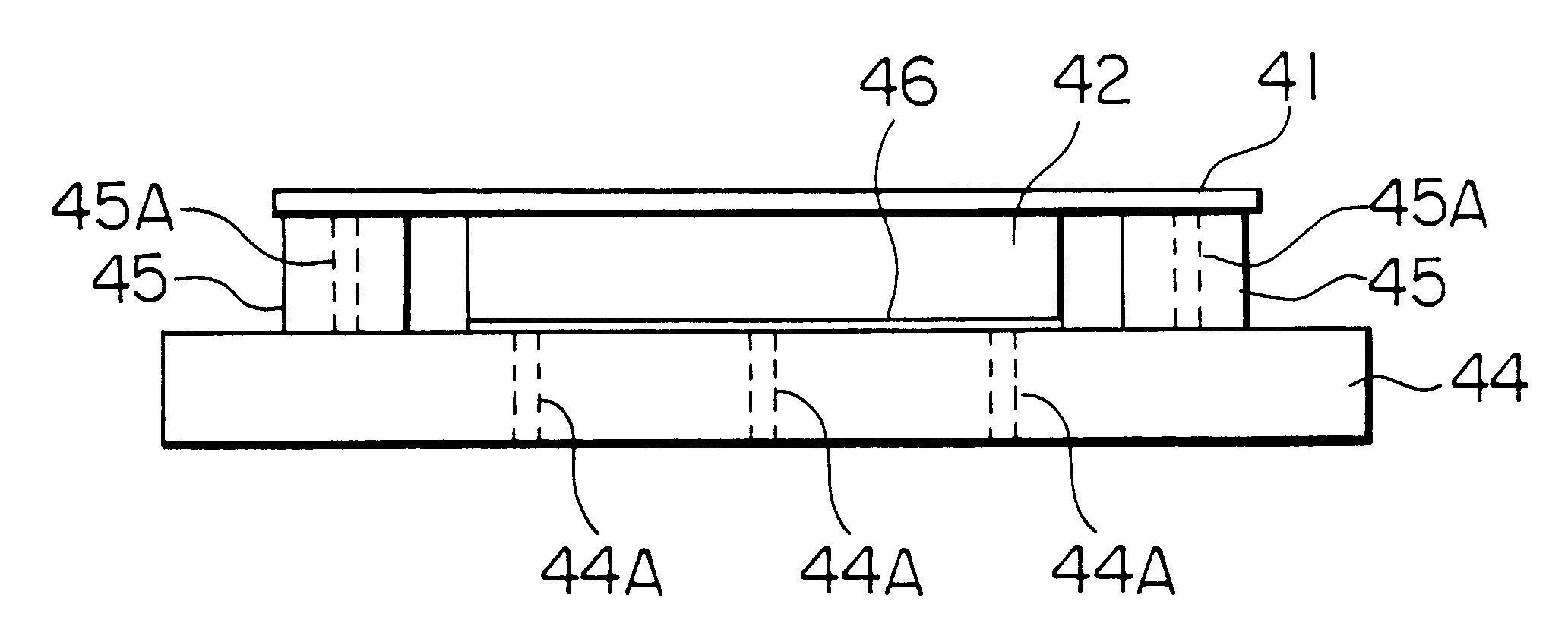

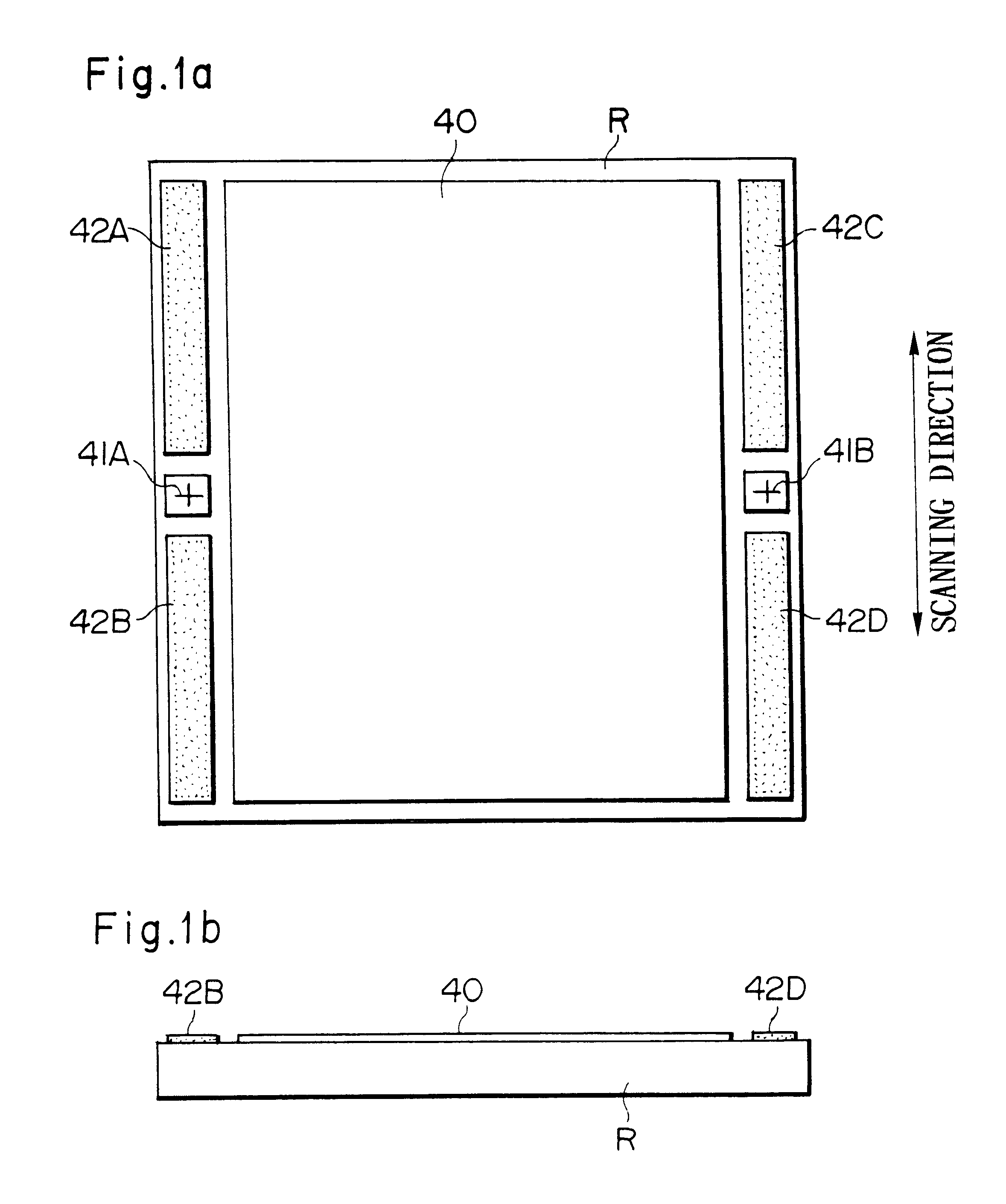

Photomask, aberration correction plate, exposure apparatus, and process of production of microdevice

InactiveUS6653024B1High light transmittanceImproves UV resistancePhotomechanical exposure apparatusMicrolithography exposure apparatusSilicon oxidePhotomask

A photomask including a substrate comprised of fluorite (calcium fluoride (CaF2)) and protective films comprised of chrome (Cr), chromium oxide (Cro), silicon oxide (SiO2 or SiO), etc. and formed at regions, other than the pattern region where the pattern to be transferred is formed, which contact other members when transporting the photomask or using it for exposure.

Owner:NIKON CORP

Bismuth vanadate pigments comprising at least one metal fluoride coating

InactiveUS6423131B1Inorganic pigment treatmentSynthetic resin layered productsBismuth vanadatePrinting ink

Owner:BASF AG

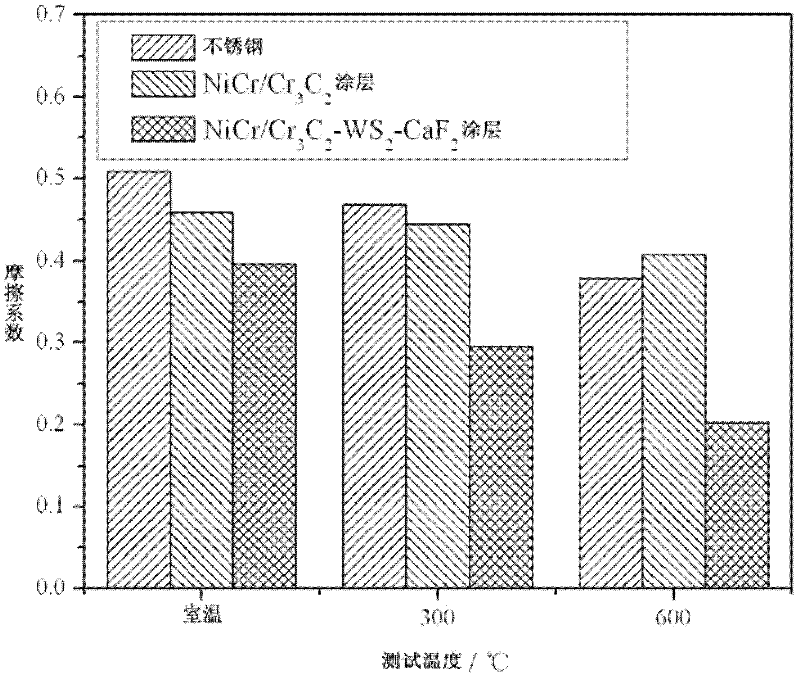

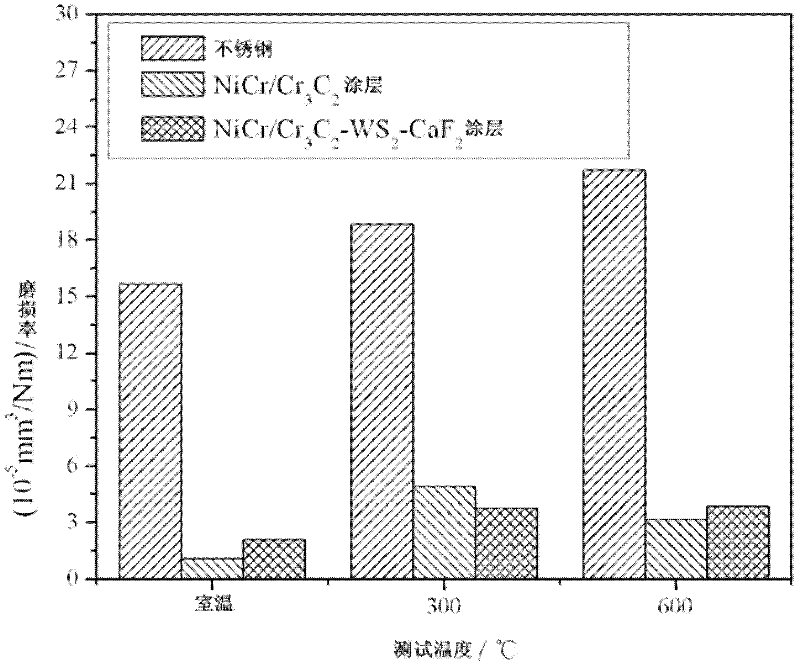

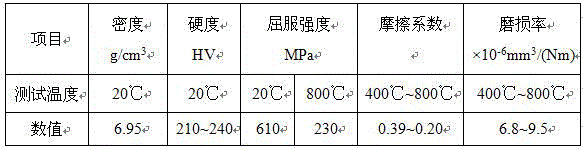

Self-lubricating solid composite material and preparation method of self-lubricating solid coating

ActiveCN102363853AImprove wear resistanceReduce coefficient of frictionMetallic material coating processesMelting tankChromium carbide

The invention provides a self-lubricating solid composite material, which comprises 15-30 wt% of nickel-chromium alloy, 40-60 wt% of chromium carbide, 10-20 wt% of tungsten disulfide and 10-20 wt% of calcium fluoride. The invention also provides a preparation method of a self-lubricating solid coating. By a laser cladding method, the self-lubricating solid coating is formed on a matrix material. The self-lubricating solid composite material can be firstly coated on the matrix material and forms a coating by laser cladding; and also the matrix material can be firstly irradiated by a laser beam to form a molten pool, and then the self-lubricating solid composite material is sent into the molten pool and is continuously irradiated to form the coating. The prepared self-lubricating solid coating has excellent wear resistance and good lubrication performance within the temperature range of room temperature to 600 DEG C, and can satisfy the usage requirement under severe working conditions.

Owner:SUZHOU UNIV

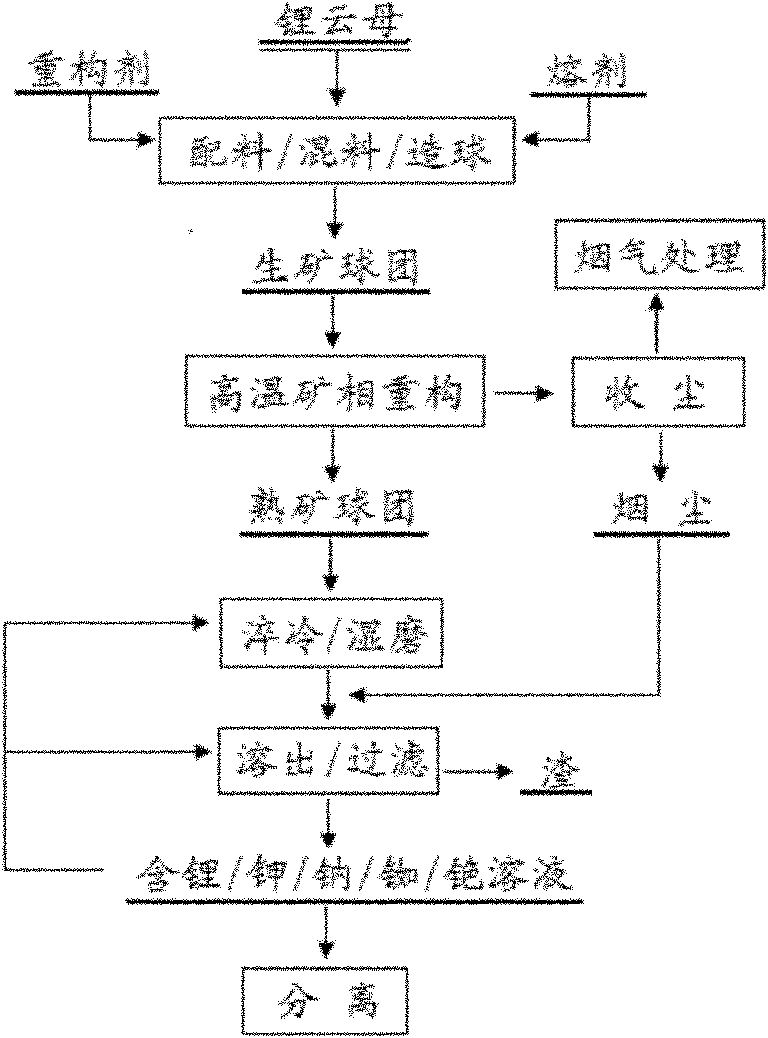

Method for extracting lithium and other alkali metal elements from lepidolite mineral

InactiveCN101974678AEfficient extractionEasy to optimizeProcess efficiency improvementRubidiumPotassium

The invention discloses a high-temperature mineral phase reconstruction method for extracting lithium and other alkali metal elements from lepidolite mineral, comprising the following steps: mixing raw materials, pelletizing, calcining at high temperature, water quenching, ball milling, dissolving out, producing compounds and the like. The invention teaks raw mineral component composition to design target reconstruction mineral and composition to obtain the purpose of optimizing processes, lowering energy consumption and cost of treatment process and efficiently extracting lithium, potassium, rubidium, caesium and the like. Silicon and aluminum in lepidolite can enter anorthite type mineral phase (CaO.Al2O3.2SiO2, (Ca, Na)O. (Al, Si)2O3.2SiO2) and calcium ash quarry phase (CaO.SiO2) after mineral phase reconstruction, and do not dissolve in water and aqueous solution. After mineral phase reconstruction reaction, fluorine in lepidolite enters calcium fluoride mineral phase and does not dissolve in water and aqueous solution. Lithium and other alkali metal elements in lepidolite enter salt (chloride, sulfate) or alkali (hydroxide) phase of lithium and other alkali metal elements after mineral phase reconstruction reaction and can be dissolved in water and aqueous solution.

Owner:CENT SOUTH UNIV

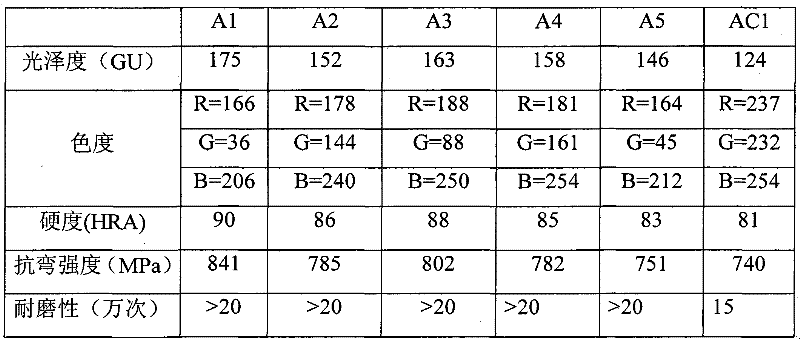

A kind of zirconia ceramic and its preparation method

The invention, belonging to the technical field of zirconia ceramic, discloses a zirconia ceramic and a preparation method thereof. The ceramic comprises matrix, sintering aid, neodymium oxide and additive, wherein, the matrix is yttria stabilized zirconia, the additive is selected from one or more of zinc oxide, barium carbonate and calcium fluoride, and the diffraction peak of the XRD appears when the 2 theta is 34.8-36.2 degrees. The zirconia ceramic has stable and beautiful purple. The preparation method comprises the following steps: adding neodymium oxide particles in a diethanolamine solution for soaking, then carrying out solid-liquid separation; carrying out ball mill mixing of the matrix, processed neodymium oxide particles, sintering aid and additive, then carrying out die forming and high temperature sintering. The preparation method provided by the present invention is simple and easy, and is suitable for large-scale industrial production.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

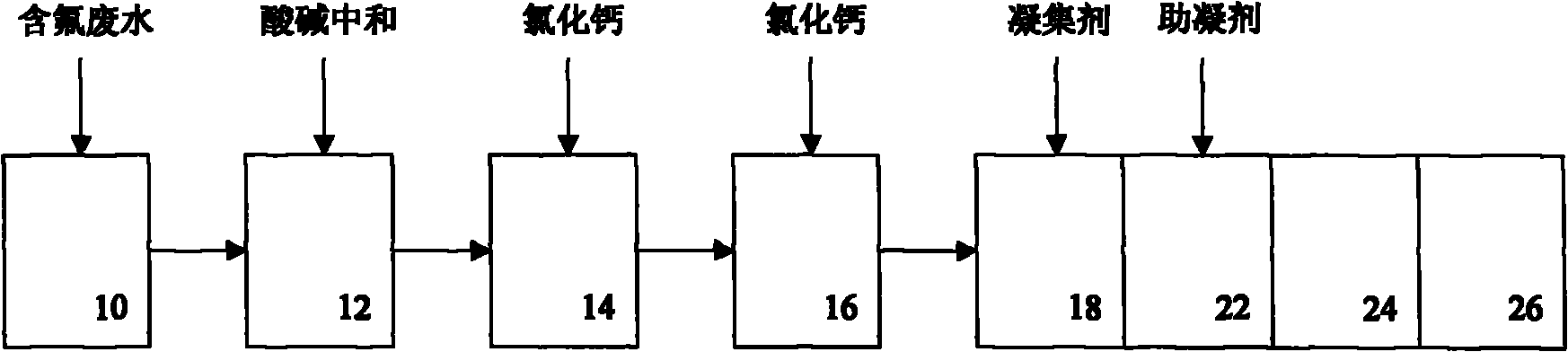

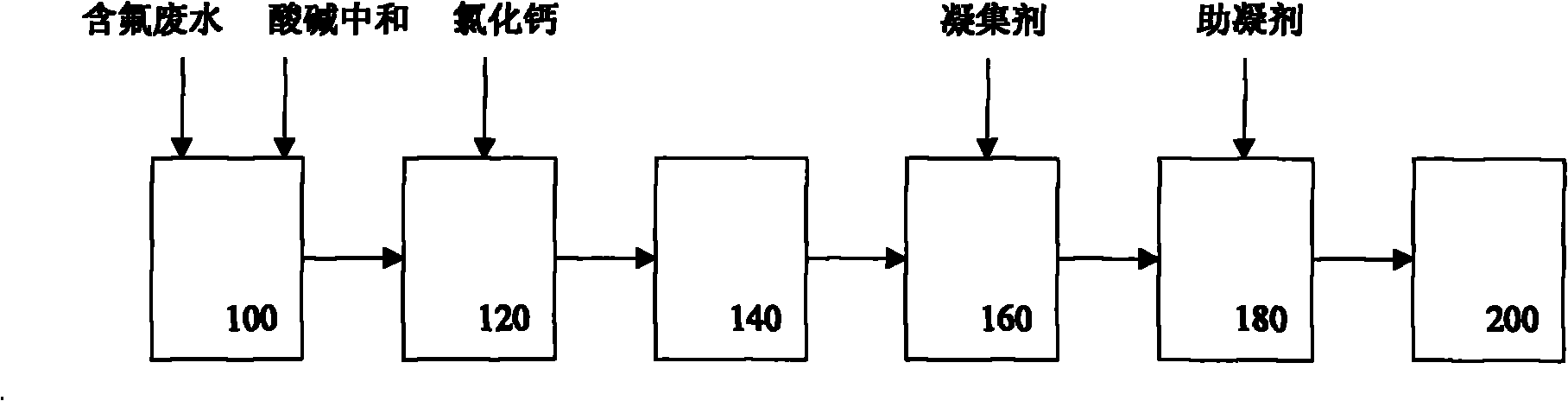

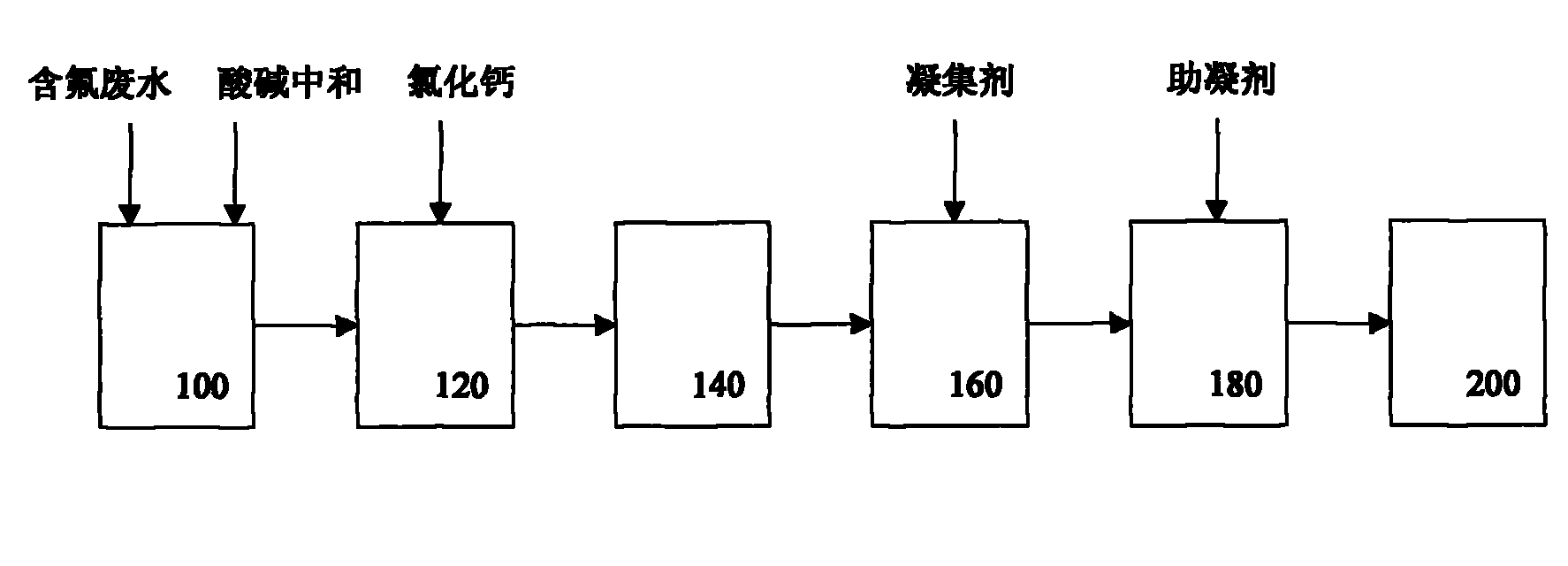

Fluorine-containing wastewater treatment method

InactiveCN102050531AReduce consumptionGood processing effectWater contaminantsMultistage water/sewage treatmentFlocculationWastewater

The invention provides a fluorine-containing wastewater treatment method, which comprises the following steps of: detecting pH value of the fluorine-containing wastewater; adjusting the adding amount of alkali or acid solution according to the pH value detection result to control the pH value of the fluorine-containing wastewater; detecting fluorine ion concentration of the fluorine-containing wastewater, and determining the adding amount of a calcium salt according to the result; delivering the fluorine-containing wastewater to a first reaction tank and a second reaction tank in turn, stirring the wastewater and performing full mixing reaction; delivering the treated wastewater to a third reaction tank, stirring the wastewater, adding coagulant into the wastewater to generate flocculation reaction to realize solid-liquid separation, and separating calcium fluoride from the wastewater; delivering the treated wastewater to a fourth reaction tank, stirring the wastewater, and adding coagulant aid to improve the settling effect; and finally, delivering the treated wastewater into a settling tank, discharging clear solution, and filter-pressing silt into mud cakes. The fluorine-containing wastewater treatment method provided by the invention has ideal treatment effect, meanwhile saves the consumption of chemicals, and reduces the treatment cost.

Owner:SEMICON MFG INT (SHANGHAI) CORP

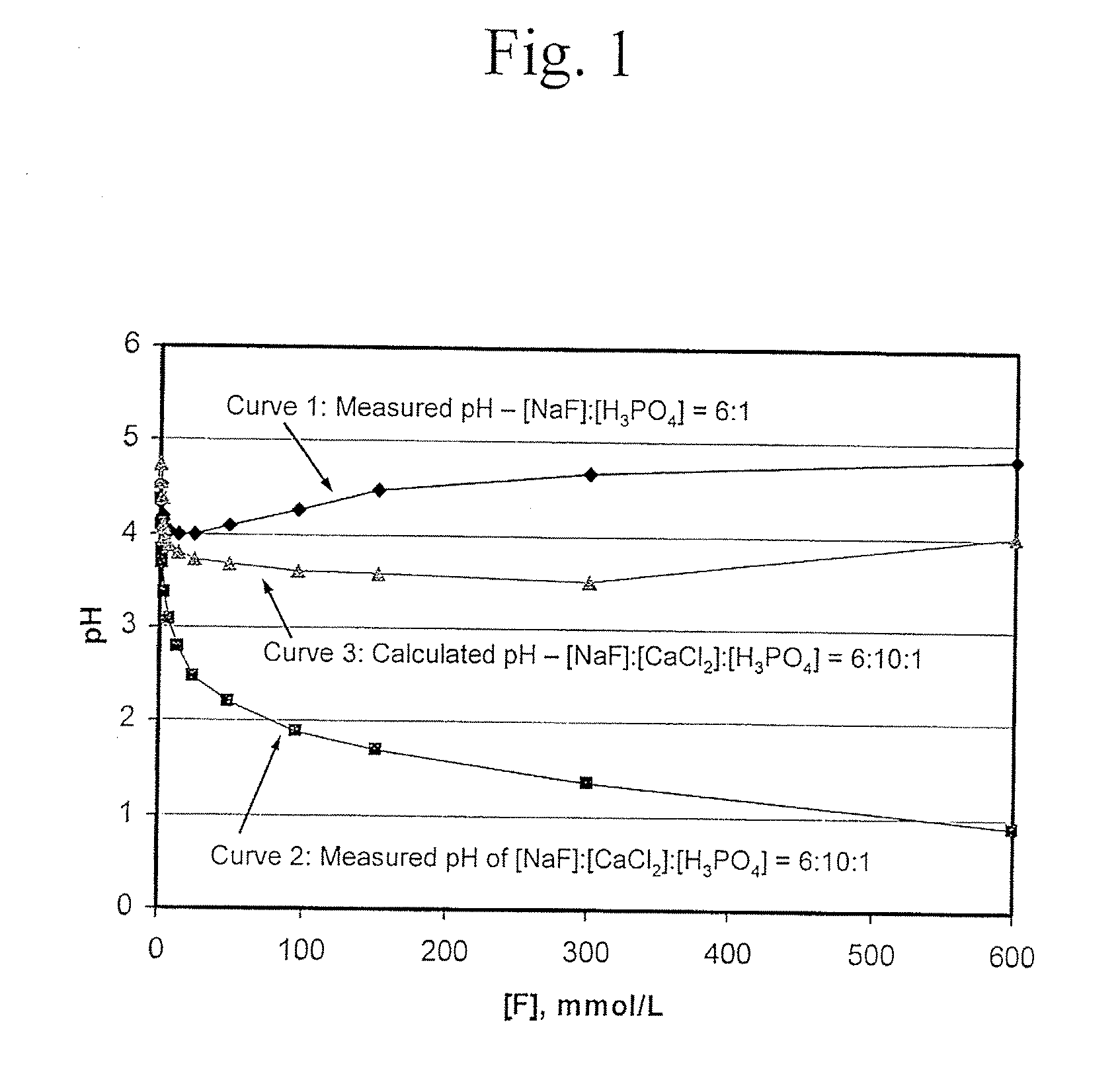

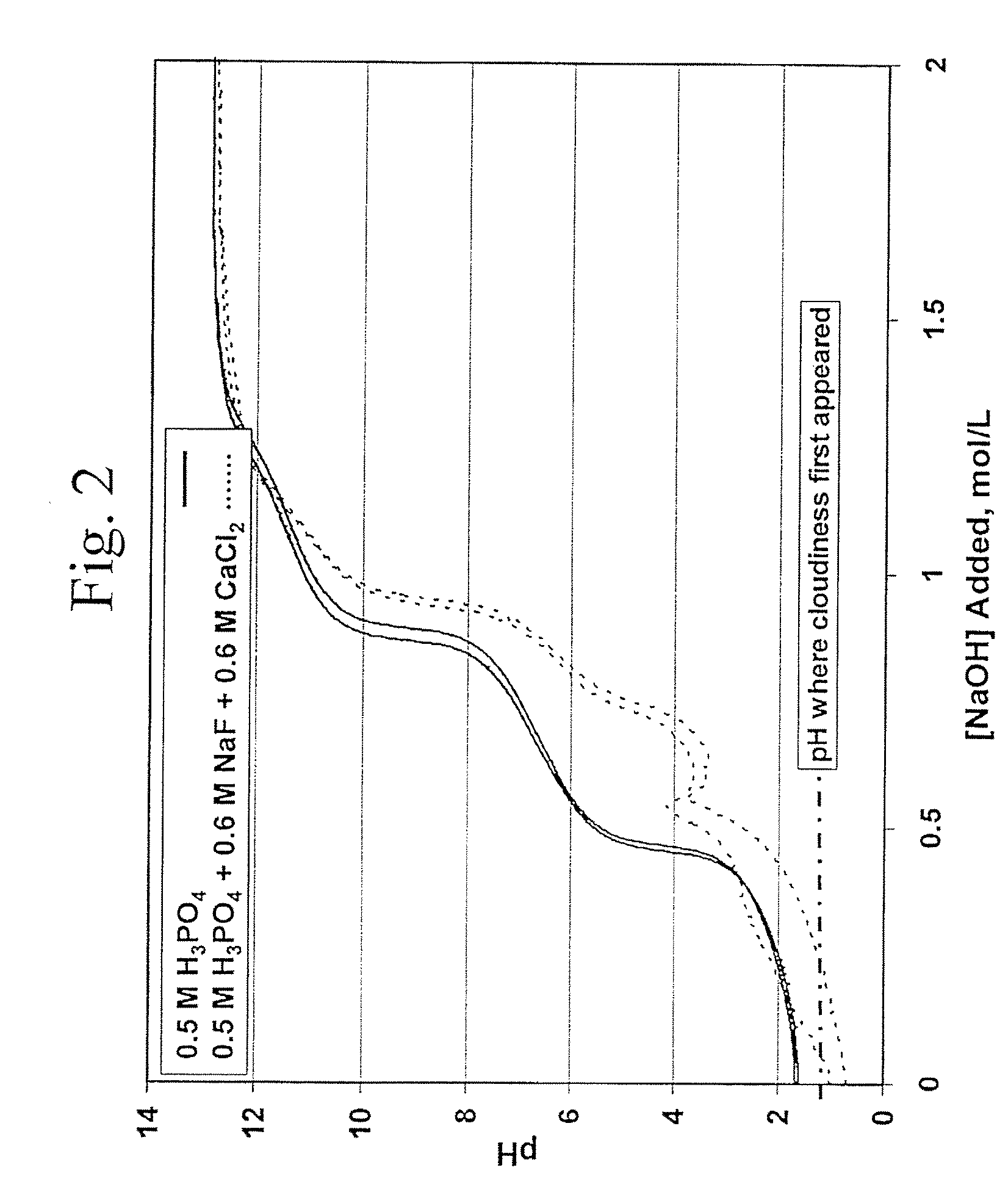

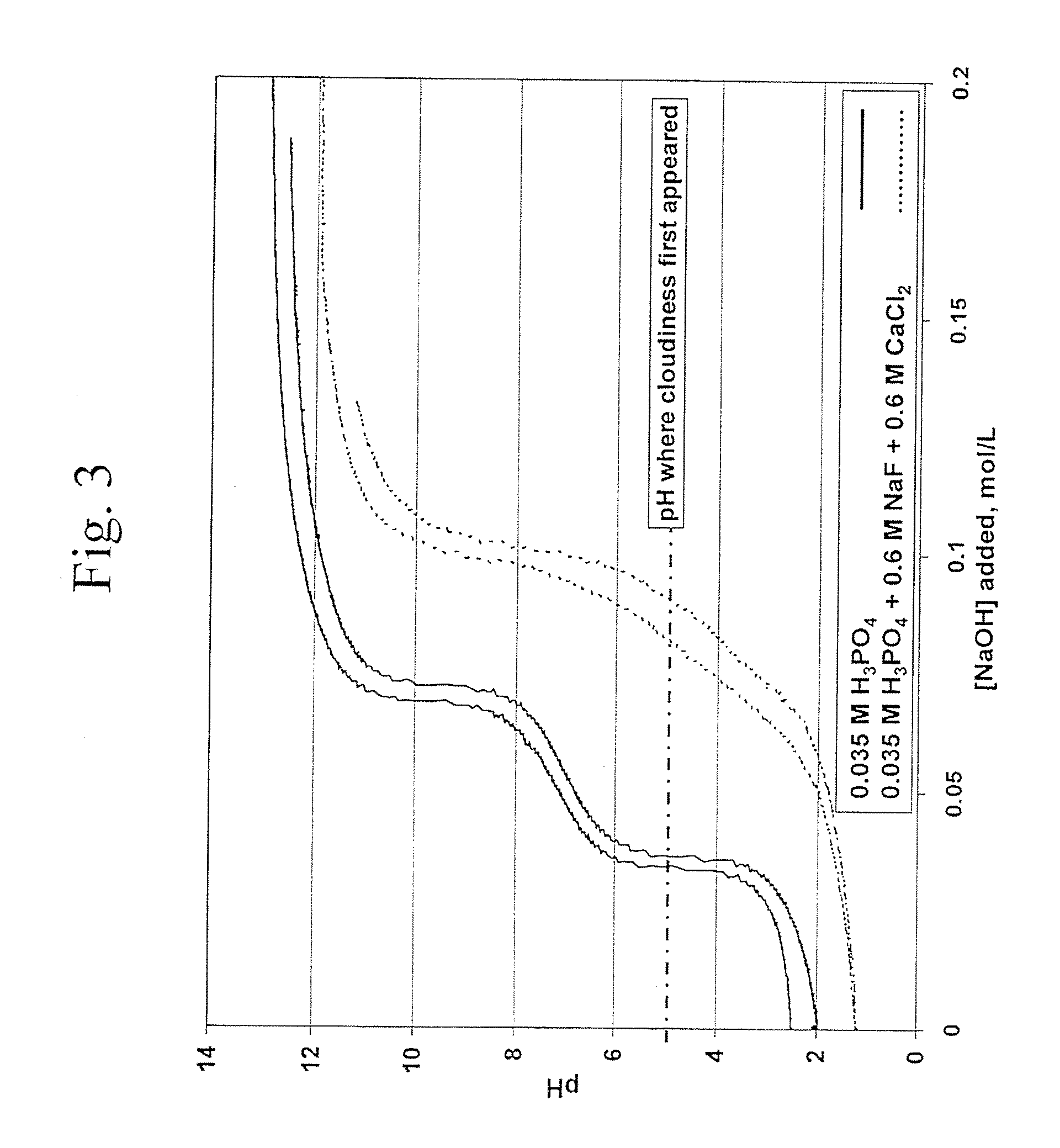

Fluoride-Calcium Compositions, Dental Products, and Methods for Providing Dental Fluoride

ActiveUS20070098652A1AmountReduce the amount requiredCosmetic preparationsToilet preparationsPhosphateDental Product

Disclosed are dental compositions and methods. In accordance with one embodiment, a dental composition includes calcium, fluorine, which is generally present in the form of fluoride, and phosphate or another stabilizing anion. The composition is stable as against precipitation of calcium fluoride during transport and storage, but is unstable against the precipitation of calcium fluoride in the oral cavity of a human. In many embodiments, the amount of fluoride may be less than the amount of fluoride used in a comparable composition intended for a similar purpose. A dental method comprises applying the composition to the oral cavity of a patient, whereupon calcium fluoride precipitates from the composition.

Owner:ADA FOUND

A treating method of waste cathode charcoal blocks

InactiveCN106166560ARealize harmless treatmentEliminate pollutionSolid waste disposalSolid fuelsElectrolysisSlag

A treating method of waste cathode charcoal blocks is provided. The waste cathode charcoal blocks are from electrolytic tank heavy maintenance slag of an electrolytic aluminium factory. The method includes treating the electrolytic tank heavy maintenance slag to obtain powdered waste cathode charcoal blocks, subjecting the powdered waste cathode charcoal blocks to water leaching to obtain a leachate and cathode charcoal blocks after leaching, performing solid liquid separation after the leachate and a fluorine removal agent are subjected to a curing reaction, returning the filtrate to the leaching step for circulated use, and stacking filter cakes or adopting the filter cakes as a raw material for preparing calcium fluoride. The method adopts a manner of a plurality of times of leaching, thus achieving innocent treatment of the waste cathode charcoal blocks. The filtrate and the filter cakes after leachate treatment can be reused, and the cathode charcoal blocks after leaching can be adopted as fuel for producing alumina. The method overcomes a series of problems caused by stacking of a large amount of the waste cathode charcoal blocks, achieves efficient utilization of the waste cathode charcoal blocks, and is obvious in economic benefit and suitable for industrial production.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

Refining agent for smelting aluminum alloy and preparation method of refining agent

InactiveCN102181757AIncrease surface tensionImprove working environmentPotassium nitrateWorking environment

The invention relates to an aluminum smelting purifying agent, in particular to a refining agent for smelting an aluminum alloy and applied to purification treatment in a smelting furnace in the process of aluminum and aluminum alloy smelting, and a preparation method of the refining agent. The refining agent is prepared from the following raw materials in part by weight: 26 to 34 parts of sodium nitrate (NaNO3), 30 to 40 parts of potassium nitrate (KNO3), 15 to 22 parts of sodium aluminofluoride (Na3AlF6), 4 to 6 parts of calcium fluoride (CaF2), 6 to 12 parts of graphite (C), and 2 to 4 parts of sodium carbonate (Na2CO3). The preparation method of the refining agent comprises the following steps of: putting the raw materials of the sodium nitrate, the potassium nitrate, the sodium aluminofluoride, the calcium fluoride, the graphite and the sodium carbonate into a drying type rotary composite stirrer; stirring the raw materials for 60 to 90 minutes at 150 to 250 DEG C; and finally, preparing a powdery refining agent finished product. The refining agent has strong refining capability, has an obvious function in improving the quality of aluminum industry products, is low in cost and less in used amount, significantly saves the cost, improves the working environment of workers, and causes less environmental pollution.

Owner:湖南德利亨新材料科技股份有限公司

Method for preparing anti-dazzle glass

The method relates to a method for preparing antiglare glass. The method comprises the following steps that: (1) an etching solution comprises the following compositions in portion by weight according to a formula: 10 to 15 portions of ammonium bifluoride, 20 to 30 portions of ammonium fluoride, 5 to 7.5 portions of calcium fluoride, 10 to 15 portions of barium sulphate, 5 to 7.5 portions of ammonium sulphate, 5 to 10 portions of sodium fluosilicate or 5 to 10 portions of sodium fluoborate, 5 to 10 portions of zinc chloride, 10 to 20 portions of concentrated sulphuric acid and 70 to 100 portions of water; raw materials are weighed, mixed, evenly stirred and matured for 6 to 10 hours at room temperature to prepare the etching solution; (2) the surface of a glass sample is cleaned and dried by absolute ethyl alcohol; (3) one surface of the glass sample which does not need to be etched is covered; and (4) the glass sample is put into the etching solution, marinated, taken out, washed by clean water and dried to produce a finished product of the antiglare glass. The method has simple process and easy operation; the prepared glass sample has the advantages of small particles on the surface and even distribution of the particles, high light transmissivity, good antiglare effect, etc.

Owner:DONGHUA UNIV

High-entropy alloy self-lubricating composite material and preparation method thereof

ActiveCN105908049AGood self-lubricating performanceGood mechanical propertiesHigh entropy alloysRoom temperature

The invention discloses a high-entropy alloy self-lubricating composite material. According to the high-entropy alloy self-lubricating composite material, four-element high-entropy alloy CoCrFeNi serves as a matrix, and silver, graphite, molybdenum disulfide, calcium fluoride, barium fluoride and cerium oxide serve as a lubrication phase; the silver element content is 2%-15%, the sum of the content of the graphite and the content of the molybdenum disulfide is 5%-10%, and the content of the graphite is equal to that of the molybdenum disulfide; the sum of the content of the calcium fluoride and the content of the barium fluoride is 5%-10%, and the ratio of the content of the calcium fluoride to the content of the barium fluoride is 4:6; the content of the cerium oxide is 3%-8%; the balance is the four-element high-entropy alloy CoCrFeNi; and all the contents are expressed by mass percent. The invention further discloses a preparation method of the composite material. The composite material provided by the invention has good self-lubricating performance and meanwhile has excellent strength and toughness within the wide temperature region (the room temperature to 800 DEG C).

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

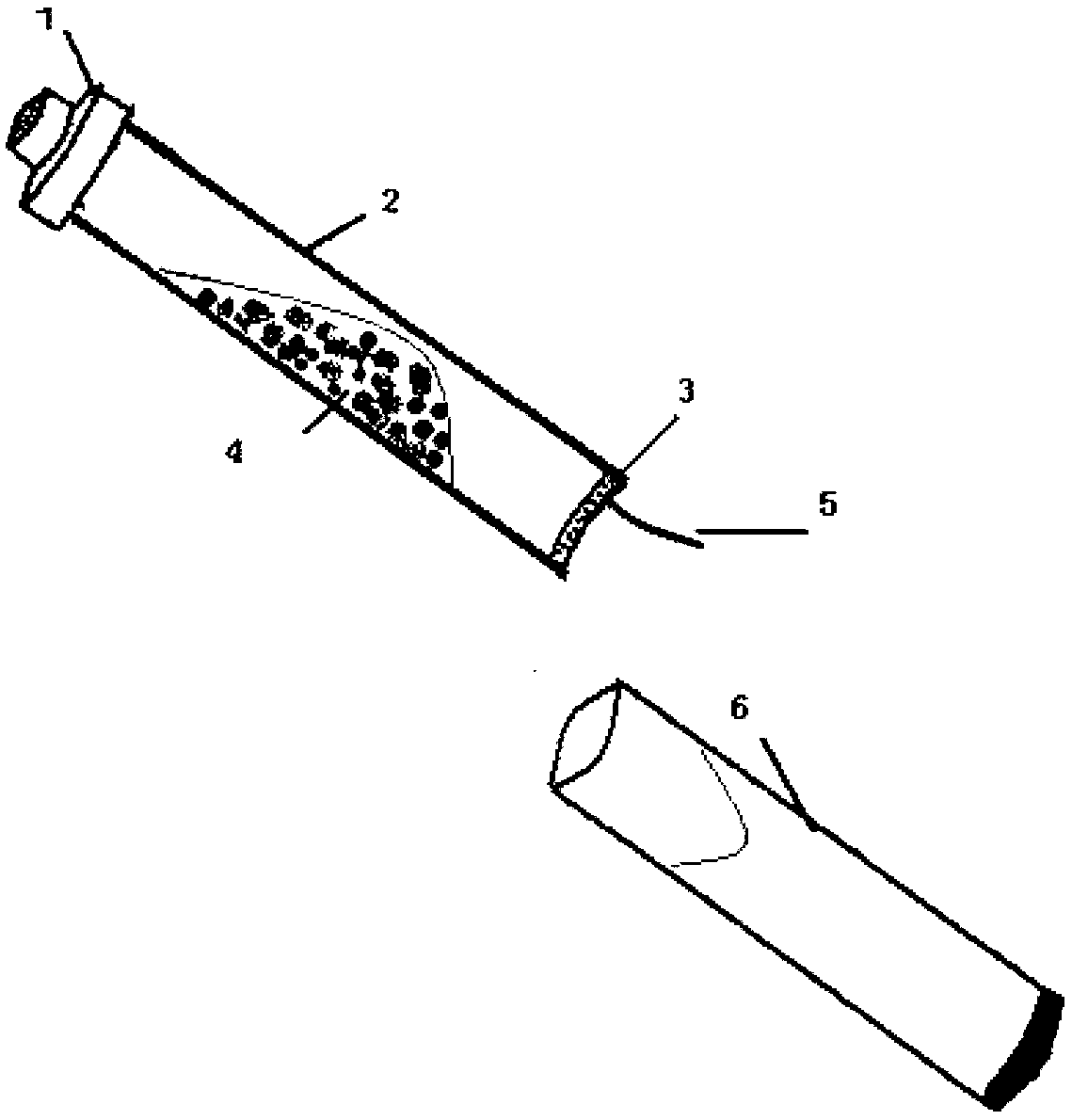

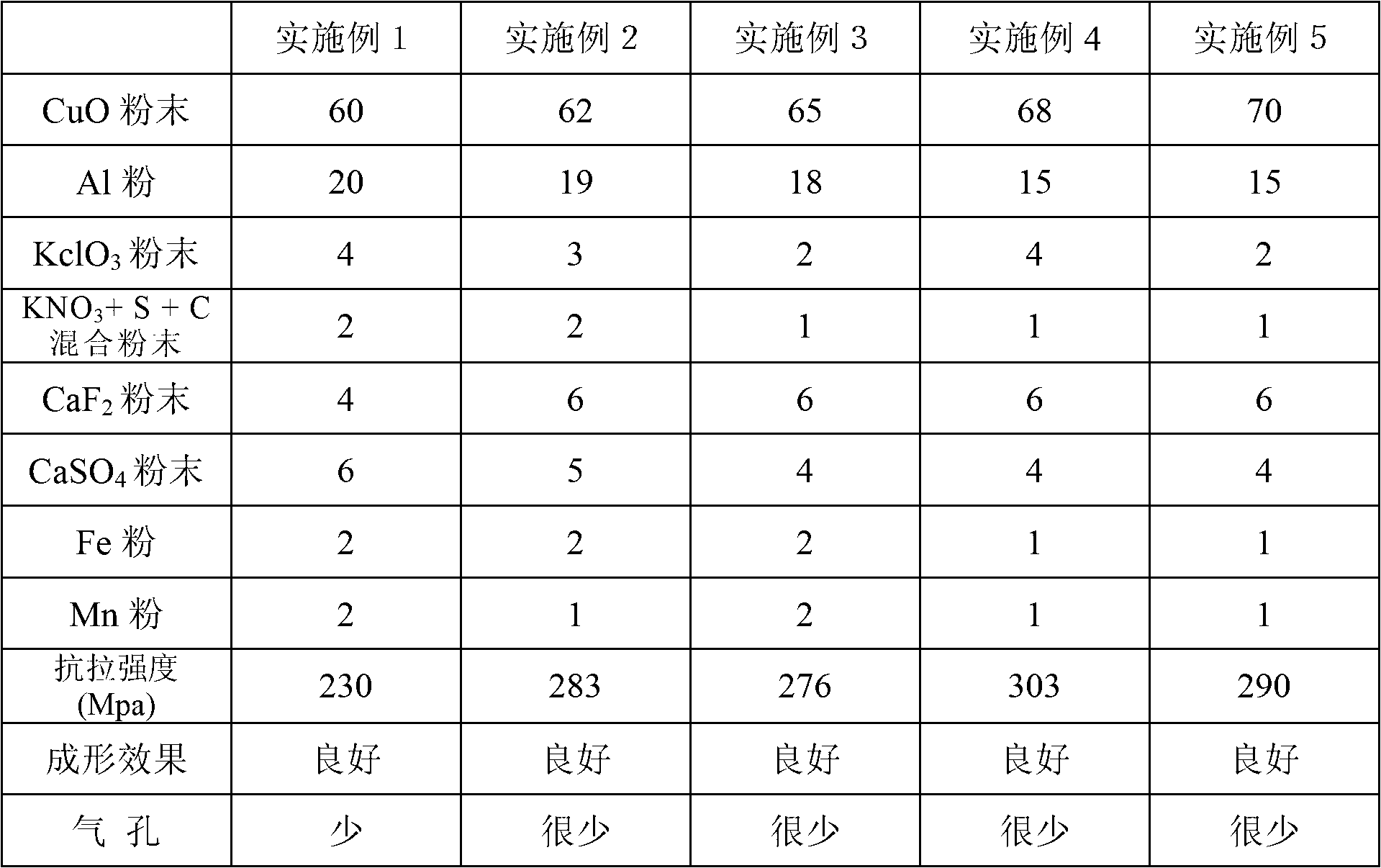

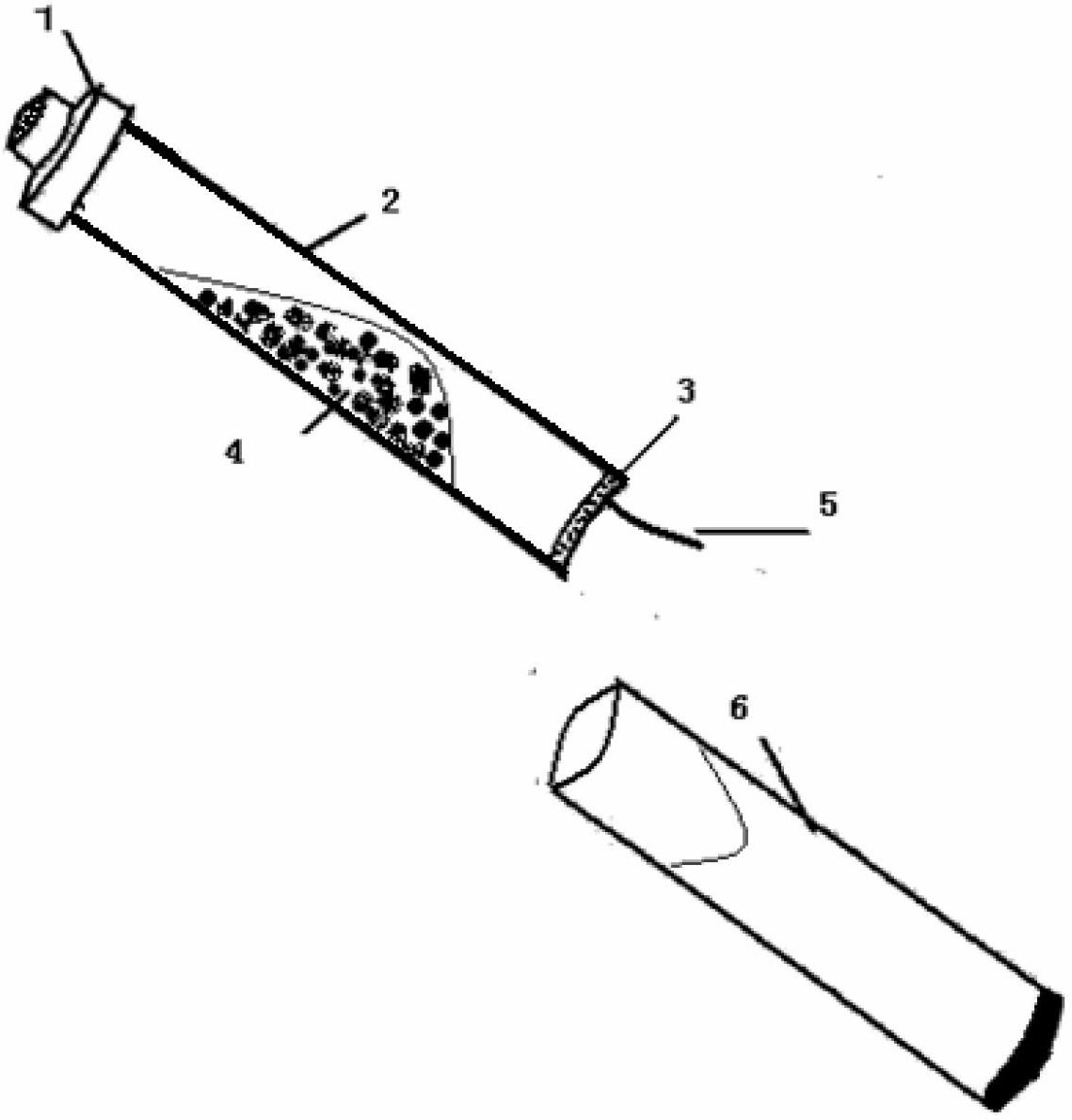

Simple electroless welding pen and preparation method of electroless welding pen

InactiveCN102699521AEasy to makeThe welding operation is simple, fast and safeWelding/cutting media/materialsSoldering mediaSlagManganese

The invention discloses a simple electroless welding pen, which comprises a cartridge, welding flux and a lead. The welding flux is thermite; the simple electroless welding pen comprises the raw material constituents by weight percent: 60-70% of CuO (cupric oxide) powder, 15-20% of Al (aluminum) powder, 2-4% of KClO3 (potassium chlorate), 1-2% of KNO3 (potassium nitrate)+S (sulfur)+C (carbon) mixed powder, 4-6% of CaF2 (calcium fluoride) powder, 4-6% of CaSO4 (calcium sulfate) powder, 1-2% of Fe (Ferrum) powder and 1-2% of Mn (manganese) powder; and the mixed powder is KNO3, S and C freely mixed. According to the method disclosed by the invention, the problems of inexhaustive slag separation and more welding line defects in the welding lines in the prior art are solved without any welding device and power supply. The preparation method has the advantages of simple preparation process and simple, fast and safe welding operation, and is particularly suitable for field emergency operation.

Owner:TIANJIN UNIV

Composition for caries prevention

InactiveUS20050089481A1Excellent composition for preventionInhibition is effectiveCosmetic preparationsImpression capsCementum cariesPhosphopeptide

To obtain a composition for caries prevention, which has effects for efficiently suppressing demineralization and promoting remineralization and stability in keeping for a long time, 0.01 to 10% by weight of sodium carboxymethylcellulose having the etherification degree of 0.7 to 1.0 is used in a composition blended with a casein phosphopeptide-amorphous calcium phosphate complex (CPP-ACP) and / or a casein phosphopeptide-amorphous calcium fluoride phosphate complex (CPP-ACFP), a sodium carboxymethylcellulose, a viscosity regulator and water.

Owner:GC CORP

Formulation of anti-dazzle glass product etching liquid and etching technique

The invention relates to a formula of etching liquid of anti-dazzle glassware and an etching process. Raw materials of the formula proportion by weight comprise: ammonium fluoride holding 17-24 parts or ammonium hydrogen fluoride holding 8.5-12 parts, ammonium sulfate holding 2.5-3 parts, potassium sulfate holding 2.5-3 parts, calcium fluoride holding 2.5-3 parts, sulfuric acid holding 8-12.5 parts or hydrochloric acid holding 24-37.5 parts and water holding 60-75 parts. The process comprises: (1) weighing the raw materials according to the formula of the etching liquid, then mixing, uniformly stirring and ageing to formulate the etching liquid, (2) rinsing and drying pre-etched glass by organic solvent mixed by glycerol, (3) shielding one face of the rinsed glass needing not be etched and (4) immersing the glass in the formulated etching liquid for soak, then taking out the glassware and preparing anti-dazzle glass finished products after washing by clear-water and drying. The invention has the advantages of simple process, easy operation, labor saving, subtle granular surface of the prepared glassware, high penetration rate, good anti-glare effect, durable service and the like.

Owner:DONGHUA UNIV

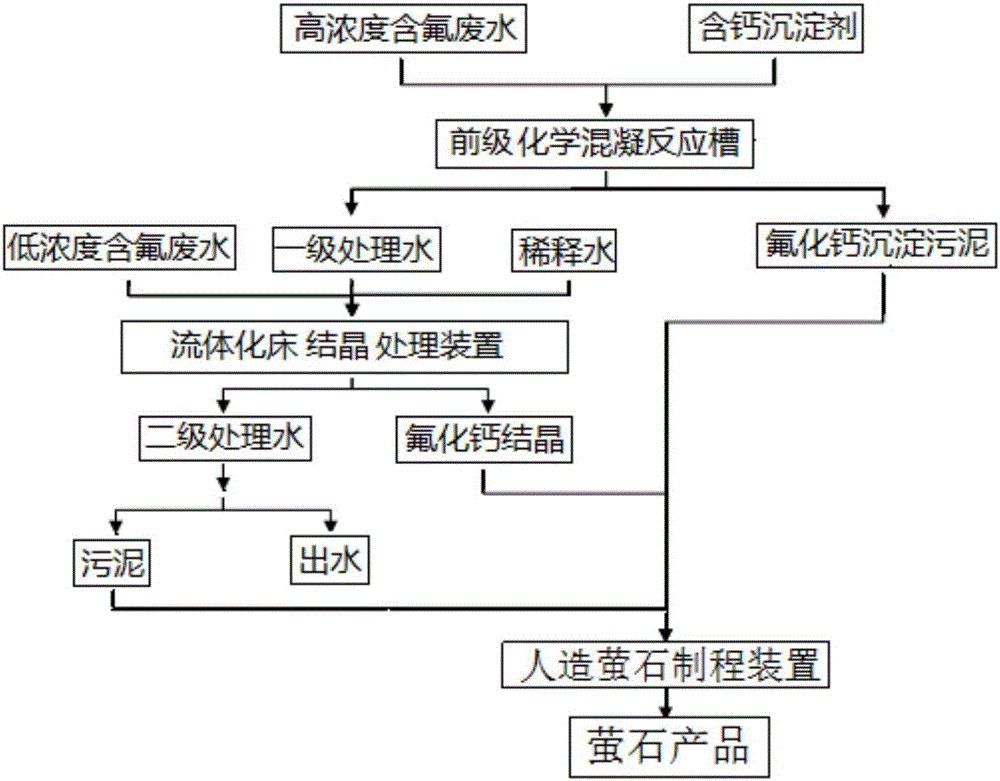

Process for preparing high-purity artificial fluorite by recovering fluoride-containing wastewater

ActiveCN105905933ASolve pollutionAvoid wastingCalcium/strontium/barium fluoridesWater contaminantsHigh concentrationPollution

According to a process for preparing high-purity artificial fluorite by recovering fluoride-containing wastewater, a fluidized bed serves as a crystallization treatment device, fluoride components in wastewater are efficiently extracted in a supporter crystallization mode, a high-purity calcium fluoride artificial fluorite product is prepared, fluoride-containing wastewater can be treated to reach the standard, no secondary pollution exists, the problems of land occupation and environment pollution of bottom mud produced during treatment of industrial fluoride-containing wastewater are solved, fluoride resources in the bottom mud are effectively used, circulation is short, operation is simple, implementation is easy, fluoride pollution and fluoride resource waste are reduced, and process efficiency is high; good balance can be achieved between making emission not exceed the standard and controlling wastewater treatment cost. Produced calcium fluoride crystals are suitable for preparing artificial fluorite to serve as the substitute of natural fluorite, calcium fluoride crystals produced in the technological process are low in water content, fluoride-containing waste reducing or resourceful using aim is effectively achieved, and the process is an environment-friendly method for treating high-concentration fluoride-containing wastewater and is wide in industrial application prospects.

Owner:KUNSHAN YANGCHENG LANGU ENVIRONMENTAL INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com