Processing method for stainless steel acid cleaning waste water and liquid

A technology for pickling wastewater and treatment methods, which is applied in metallurgical wastewater treatment, neutralized water/sewage treatment, reduced water/sewage treatment, etc. It can solve the problems of large amount of sludge, high treatment cost, and lack of comprehensive utilization value , to achieve the effect of reducing cost and reducing sludge volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

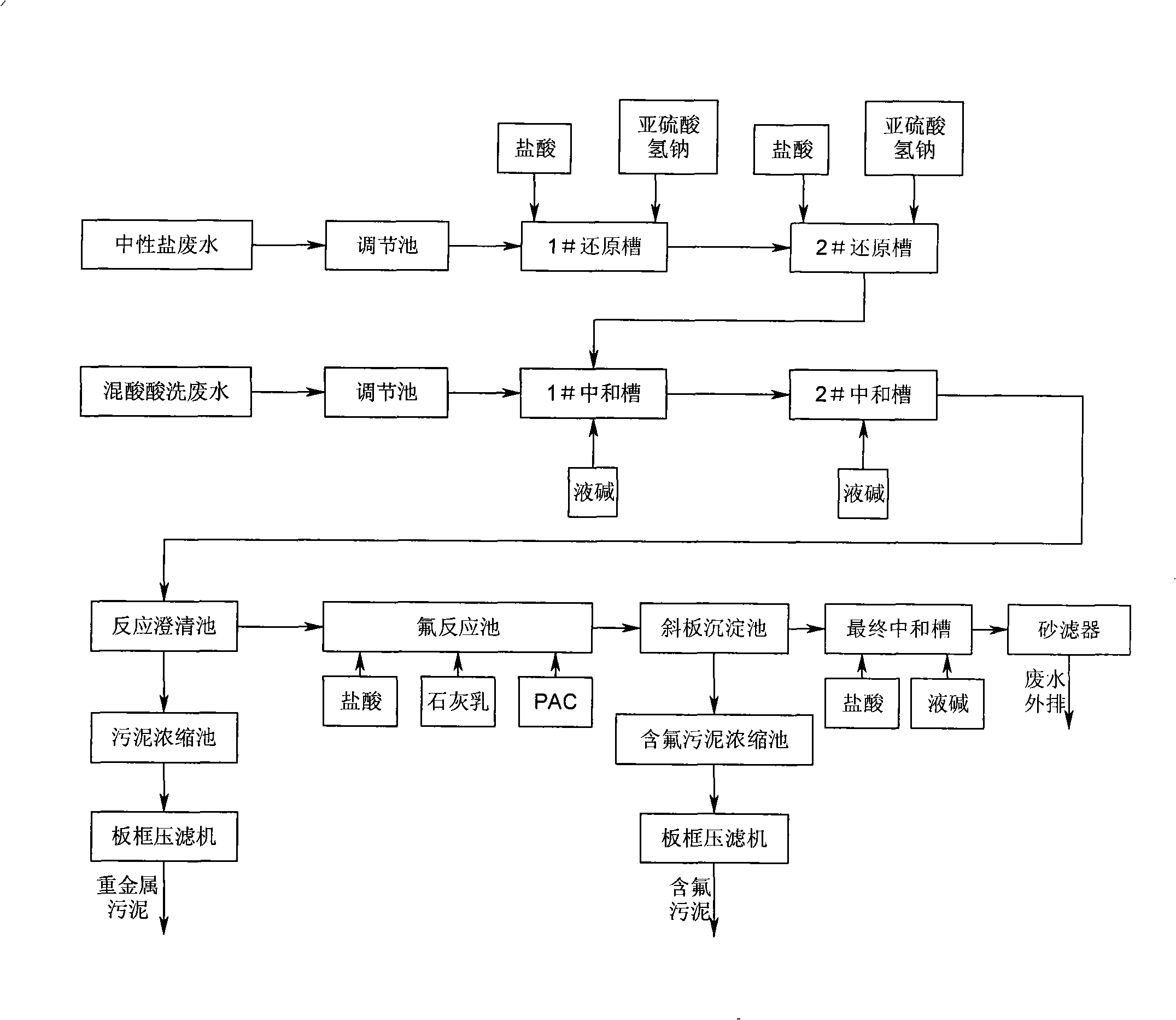

[0016] like figure 1 Shown, the processing method of the stainless steel pickling wastewater liquid of the present embodiment, comprises the following steps successively:

[0017] a. Flow the neutral salt wastewater into the neutral wastewater regulating tank to adjust the water quality, use the capacity of the regulating tank to adjust the concentration and flow peak of the wastewater, and then put the adjusted neutral wastewater into the neutral reduction tank In, the mixed acid pickling wastewater flows into the acid wastewater regulating tank to adjust the water quality; then the adjusted acid wastewater liquid is put into the 1# neutralization tank;

[0018] b. Add hydrochloric acid and ferric sulfite reducing agent in 1# neutral reduction tank, the amount of reducing agent added is controlled by pH value and potential ORP respectively, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com