Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1096 results about "Sodium fluosilicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Curing agent for curing marine poor subsoil

ActiveCN102344813ASimple ingredientsCompatibility is reasonableBuilding constructionsOrganic fertilisersSlagSodium silicate

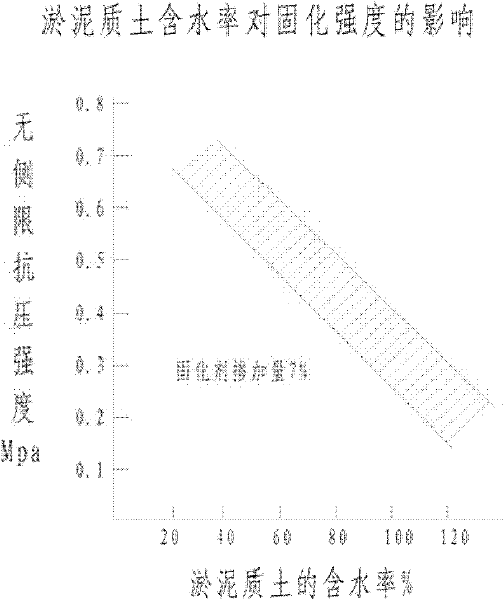

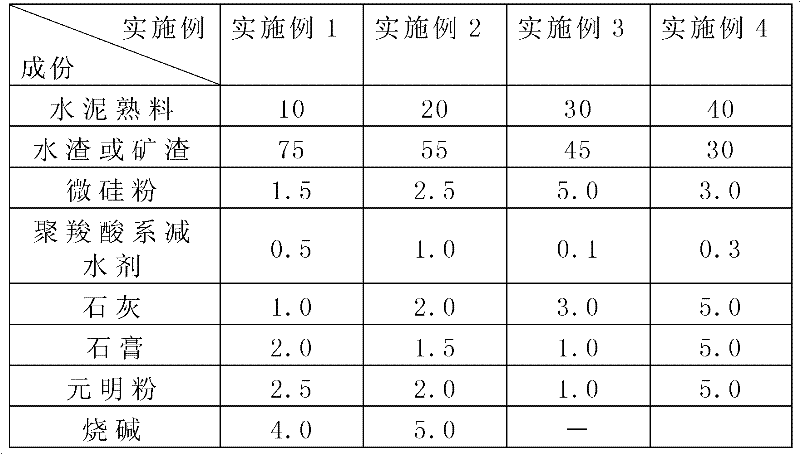

The invention relates to a curing agent for curing marine poor subsoil, which belongs to the technical field of poor subsoil curing. The curing agent for curing the marine poor subsoil is composed by the components of cement clinker, granulating slag or slag, silica fume, polycarboxylic acid type water-reducer, lime, plaster, anhydrous sodium sulphate, caustic soda, sodium silicate and sodium fluosilicate. The adulteration amount of the poor subsoil curing agent is 5%-12% in application, good curing functions can be realized, and the curing agent for curing the marine poor subsoil can be applied in the poor soil curing of building sites, road embankments, roadbeds and ground base layers. The invention has the advantages that: the components of the curing agent are simple, the compatibility is reasonable, the doping amount is less, and the curing effect is good; and during the application process, the construction period is short, the construction cost is low, the induration bearing capacity is high, the induration compression modulus is strong, and the induration permeable resistance is strong.

Owner:徐辰楚 +1

Low-temperature concrete early strength agent

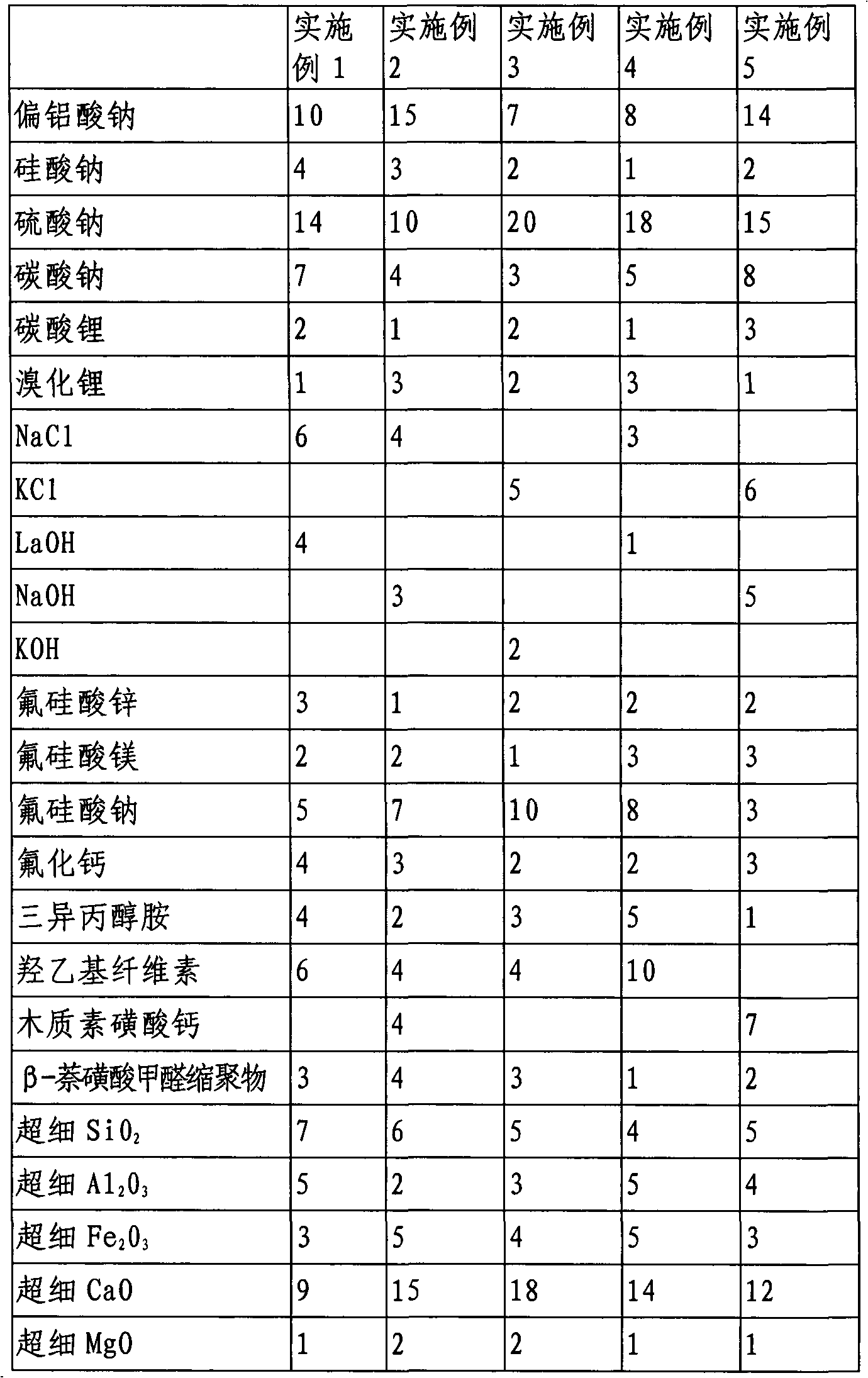

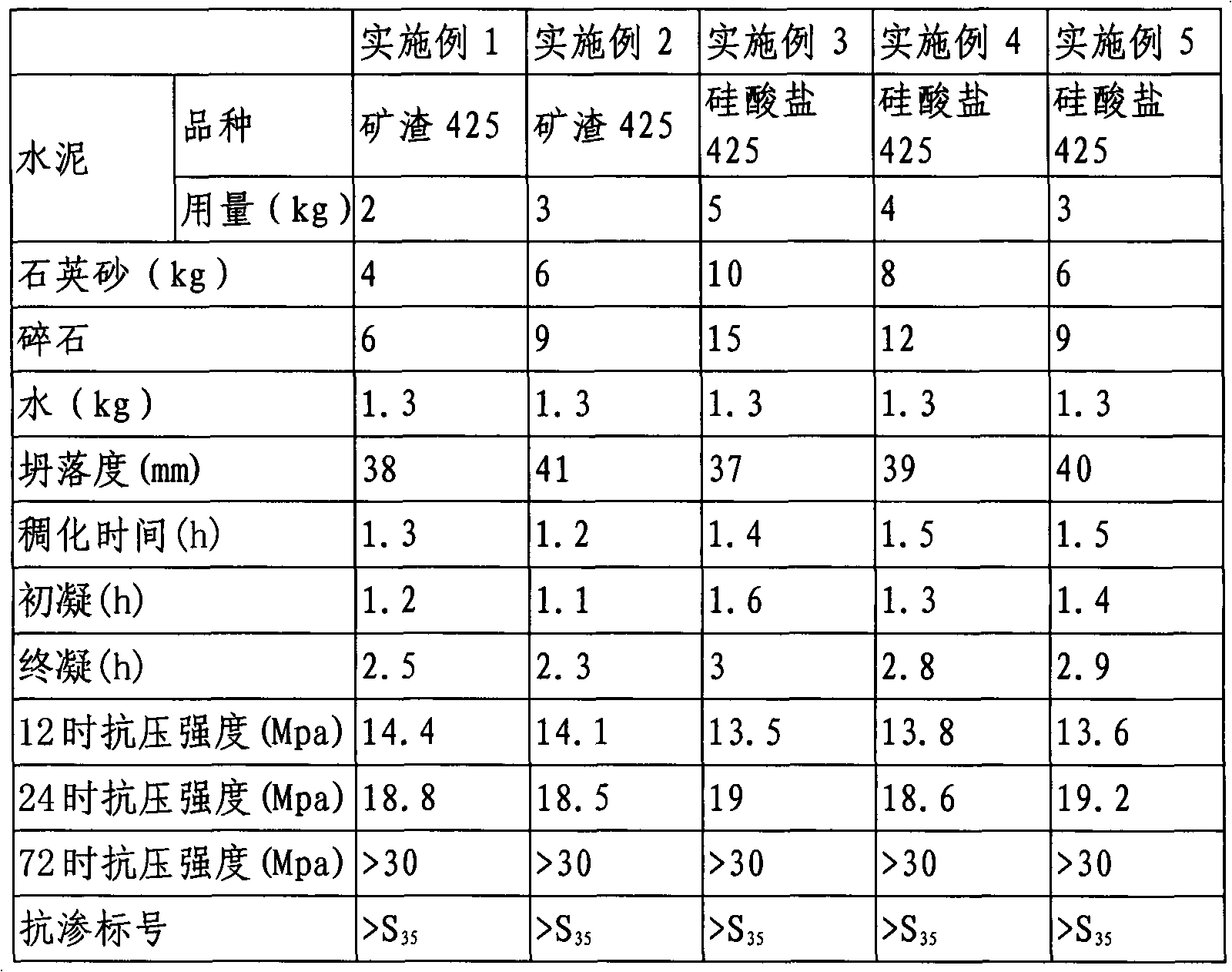

The invention relates to a low-temperature concrete early strength agent, which belongs to cement additives. The early strength agent consists of sodium metaaluminate, sodium silicate, sodium sulfate, sodium carbonate, lithium carbonate, lithium bromide, alkali metal chlorides, alkali metal hydroxides, zinc fluosilicate, magnesium fluosilicate, sodium fluosilicate, calcium fluoride, triisopropanolamine, a filtrate reducer, beta-naphthalene formaldehyde sulfonate polycondensate, ultrafine powder SiO2, ultrafine powder Al2O3, ultrafine powder Fe2O3, ultrafine powder CaO and ultrafine powder MgO. The early strength agent is mainly applied to winter concrete construction or low-temperature environmental emergency projects; when the early strength agent is used, the composition mixture is added into concrete according to 2 to 5 percent of the total weight of cement, water is added and then stirring is performed; and a cement block with the strength of 13.5MPa can be formed in a low-temperature environment at the ambient temperature of approximately 4 DEG C within 12 hours, a cement block with the strength of 18.5MPa can be formed within 24 hours and a cement block with the high strength of 30MPa can be formed within three days.

Owner:陈子川

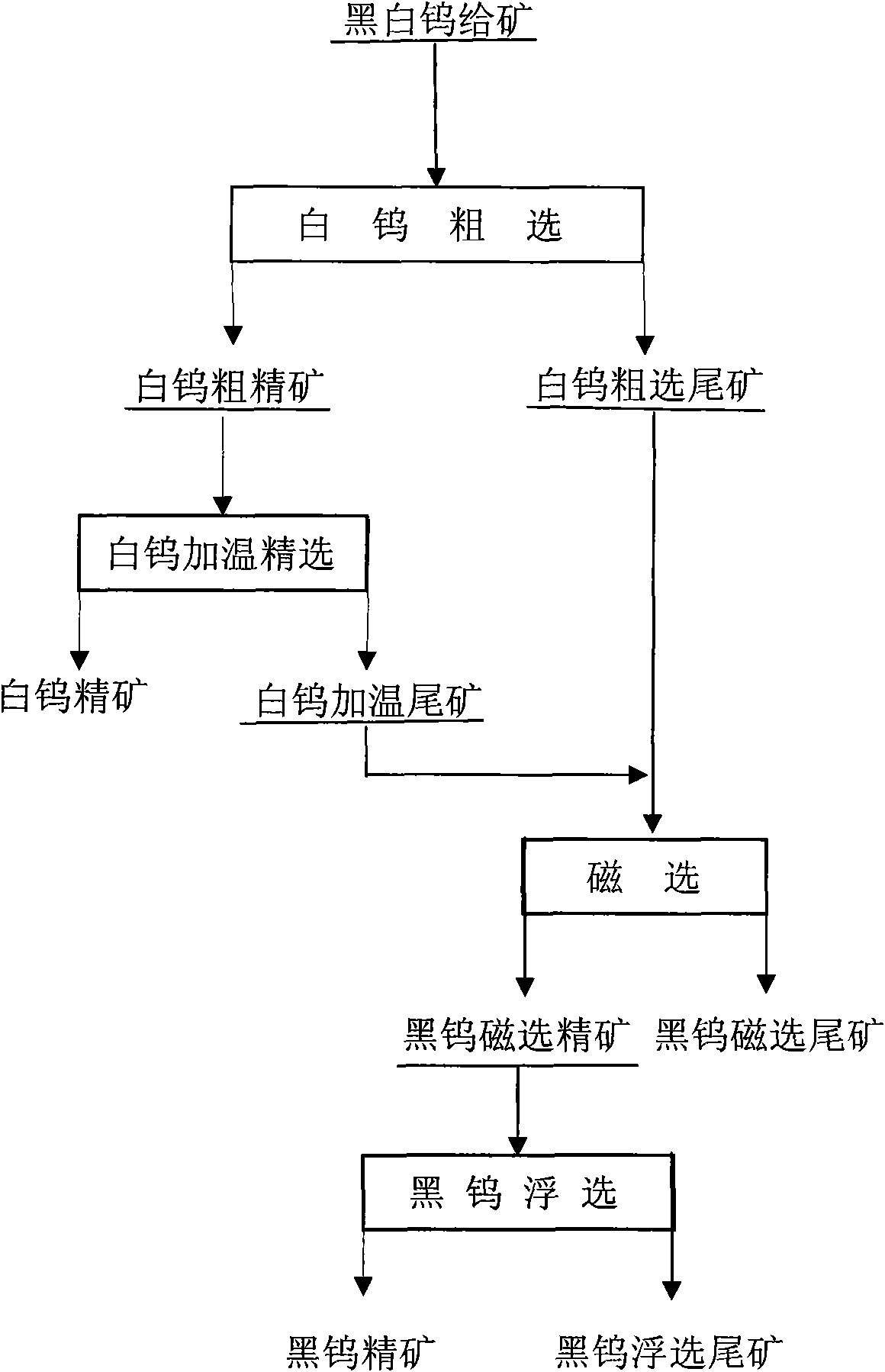

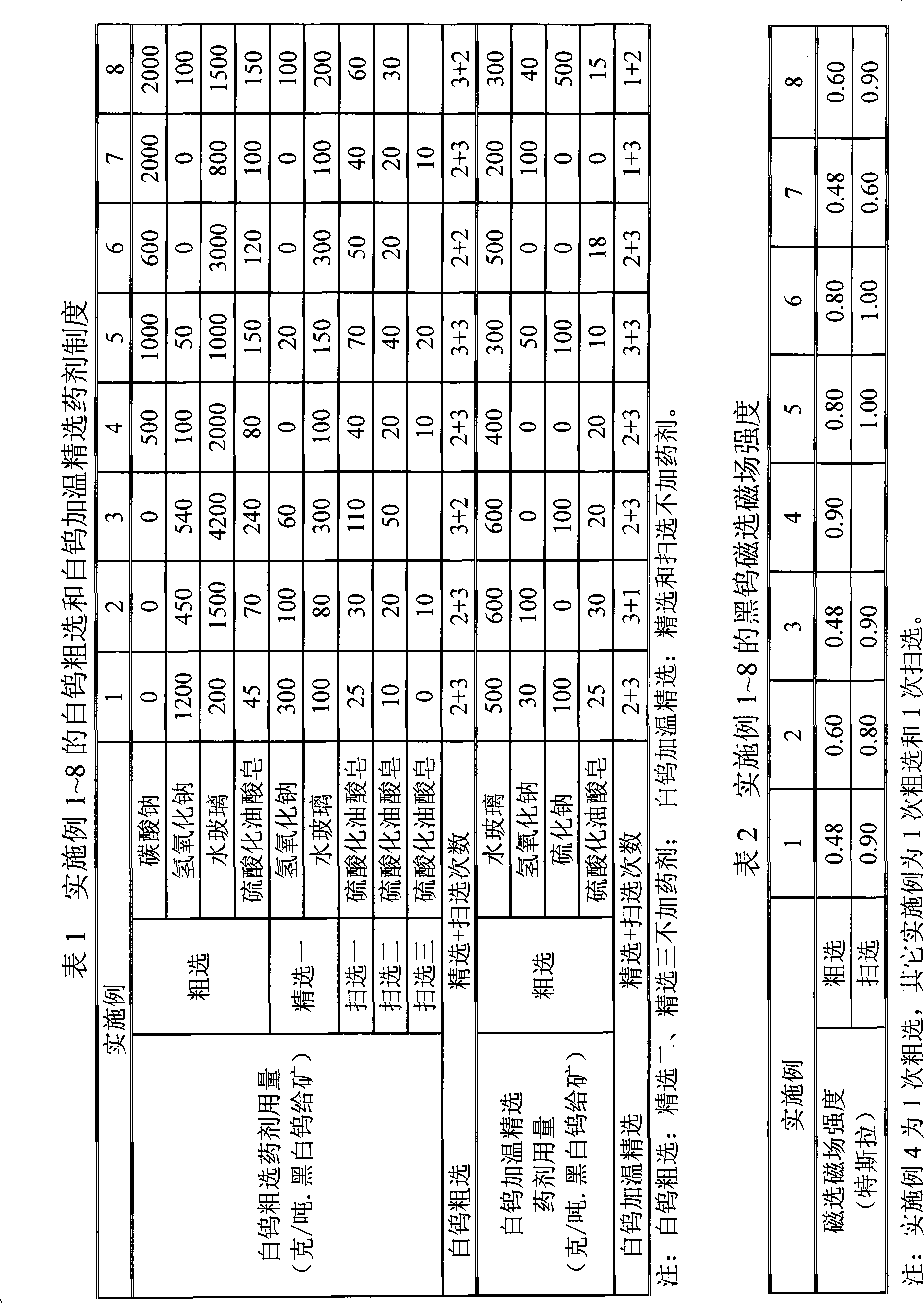

Beneficiation method of black and white tungsten mineral

The invention relates to a beneficiation method of black and white tungsten mineral.The method is characterized in that: black and white tungsten mineral through sulfide floatation and magnetic separation deferrization is added with sodium hydroxide, sodium carbonate, sodium silicate and sulphated nascent soap for white tungsten roughing, so as to obtain white tungsten rough concentrate and white tungsten rougher tailings; the white tungsten rough concentrate is added with sodium silicate, sodium hydroxide, sodium sulfide and sulphated nascent soap for white tungsten warming cleaning, so as to obtain white tungsten concentrate and white tungsten warming tailings; the white tungsten rougher tailings and the white tungsten warming tailings are mixed for magnetic separation, so as to obtain black tungsten magnetic separation concentrate and black tungsten magnetic separation tailings; the black tungsten magnetic separation concentrate is added with sodium carbonate, sodium silicate, aluminum sulfate, lead nitrate, sodium fluosilicate, benzohydroxamic acid, sulphated nascent soap and karaffin oil for black tungsten flotation, so as to obtain black tungsten concentrate and black tungsten flotation tailings. The method of the invention is simple in recovery technology, steady in process, high in tungsten recovery rate and low in reagent cost, the used beneficiation reagent does not pollute the environment, and tailings water can meet emission requirement. The invention is applicable to black and white tungsten mineral with WO3 content of .15-2.0% and black and white tungsten proportion of 1:9 to 9:1.

Owner:广东省资源综合利用研究所

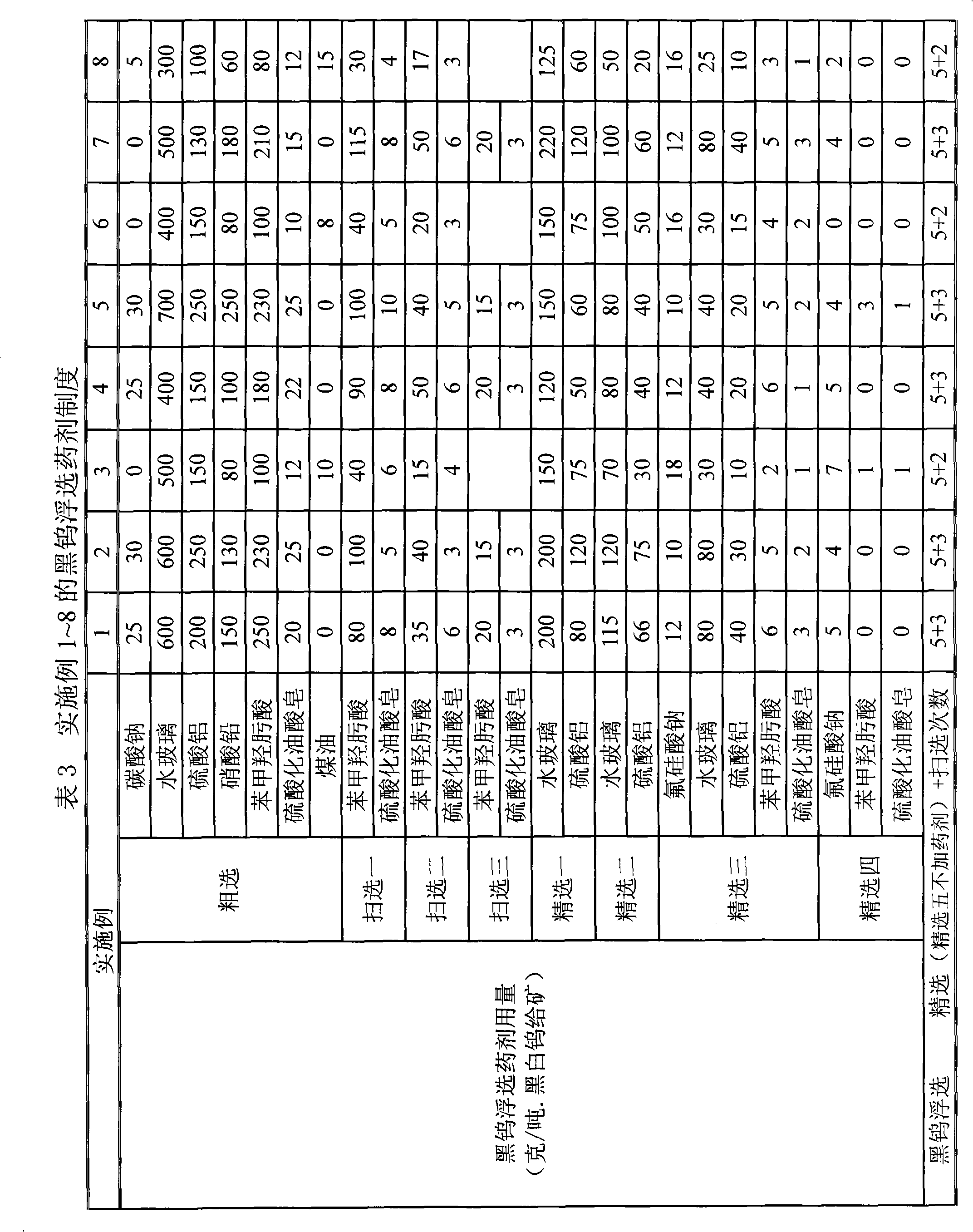

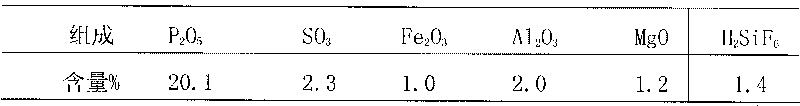

Method for producing industrial and agricultural monoammonium phosphate and magnesium ammonium phosphate with wet-process phosphoric acid

ActiveCN102020256AImprove purification effectTroubleshoot follow-up issuesPhosphatesO-Phosphoric AcidAgricultural engineering

The invention provides a method for producing industrial and agricultural grade monoammonium phosphate and magnesium ammonium phosphate with wet-process phosphoric acid. The wet-process phosphoric acid is taken as a raw material. Sodium fluosilicate, monoammonium phosphate solution, monoammonium phosphate filter cakes and magnesium ammonium phosphate are respectively obtained through defluorination and a three-section substep neutralization process, wherein the monoammonium phosphate solution is concentrated and crystallized to obtain high-quality water soluble industrial monoammonium phosphate, and the monoammonium phosphate filter cakes and the monoammonium phosphate mother solution subjected to repeated crystallization are subjected to size mixed and dried to obtain qualified agricultural monoammonium phosphate. The magnesium ammonium phosphate is a good slow release nitrogenous fertilizer per se. The process has the advantages of little investment of equipment, good adaptability of raw material, low production cost and good product quality. The water soluble industrial monoammonium phosphate with low cost can provide a cheap and good water soluble phosphatic fertilizer for modern facility agriculture.

Owner:昆明隆祥化工有限公司

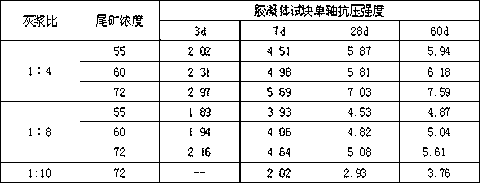

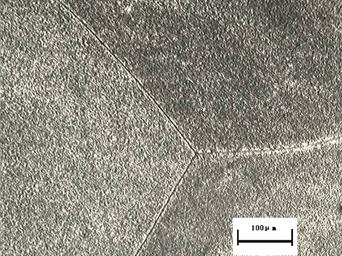

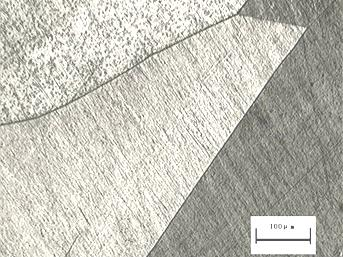

Binding material for filling fine-grain tailings

The invention discloses a binding material for filling fine-grain tailings. The binding material is prepared by milling and mixing the following components in percentage by mass: 15-40% of belite-sulphate aluminum cement, 2-10% of gypsum, 2-8% of quick lime, 40-70% of superfine-grain slag powder, 2-10% of coal ash, 1-6% of activating agent, 0.1-0.5% of activating accelerant, 0.1-0.5% of coagulant, and 0.1-0.5% of water reducer, wherein the activating agent is Na2SiO3, the activating accelerant is sodium fluosilicate, and the coagulant is any one or a mixture of two or more of LiOH, LiCO3 and LiCl; and the water reducer is a naphthalene water reducer or a polycarboxylic acid water reducer. According to the binding material for filling the fine-grain tailings, the problems that -0.074-mm fine-grain tailings and high-silt-content tailings are difficultly solidified and are low in strength after being solidified, and the strength of a filling body can meet a strength requirement on cut and fill of a mine on the filling body by using the binding material; the liquidity of slurry can be improved, and roof-contacting performance of the filling body can be improved; and the water retention capacity can be improved, and the water seepage of the slurry is reduced.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Refuse burning fly ash solidification agent and solidification method of refuse burning fly ash

InactiveCN102173721AReduce leaching toxicityLong-term stabilitySolid waste managementSlagSodium silicate

The invention discloses a refuse burning fly ash solidification agent comprising the following components in percentage by weight: 35%-60% of slag micropowder, 35%-50% of sodium silicate and 5%-20% of sodium fluosilicate. The invention also discloses a solidification method of refuse burning fly ash, comprising the following steps of: weighing the solidification agent in a formula proportion; mixing and solidifying with the refuse burning fly ash to obtain a refuse burning fly ash solidification body; grinding the refuse burning fly ash solidification body into powder; weighing 10%-100% of refuse burning fly ash solidification body powder in the terms of the mass percent of bituminous mixture fillers, and adding to a bituminous mixture to equivalently substitute limestone powder in the bituminous mixture so that the refuse burning fly ash is secondarily solidified in the bituminous mixture. The invention has the advantages of reducing the leaching toxicity of heavy metals contained in the refuse burning fly ash so that the heavy metals have long-time stability, thereby effectively preventing the secondary pollution of an environment.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Method for preparing anti-dazzle glass

The method relates to a method for preparing antiglare glass. The method comprises the following steps that: (1) an etching solution comprises the following compositions in portion by weight according to a formula: 10 to 15 portions of ammonium bifluoride, 20 to 30 portions of ammonium fluoride, 5 to 7.5 portions of calcium fluoride, 10 to 15 portions of barium sulphate, 5 to 7.5 portions of ammonium sulphate, 5 to 10 portions of sodium fluosilicate or 5 to 10 portions of sodium fluoborate, 5 to 10 portions of zinc chloride, 10 to 20 portions of concentrated sulphuric acid and 70 to 100 portions of water; raw materials are weighed, mixed, evenly stirred and matured for 6 to 10 hours at room temperature to prepare the etching solution; (2) the surface of a glass sample is cleaned and dried by absolute ethyl alcohol; (3) one surface of the glass sample which does not need to be etched is covered; and (4) the glass sample is put into the etching solution, marinated, taken out, washed by clean water and dried to produce a finished product of the antiglare glass. The method has simple process and easy operation; the prepared glass sample has the advantages of small particles on the surface and even distribution of the particles, high light transmissivity, good antiglare effect, etc.

Owner:DONGHUA UNIV

Refining agent for copper and copper alloy smelting

A refining agent for copper and copper alloy smelting is characterized in that the components of the refining agent are 5 to 15 percent by weight of calcium fluoride, 1 to 5 percent by weight of silicon dioxide, 1 to 5 percent by weight of titanium dioxide, 2 to 10 percent by weight of sodium fluosilicate, 40 to 60 percent by weight of sodium carbonate and the balance sodium tetraborate; the refining agent materials are weighed according to a formula, uniformly mixed, placed into a drying box and dried under 120 DEG C for an hour, and a metallographic inlaying machine is used for manually pressing the refining agent into the shape of a sheet. The refining agent has the advantages that the refining agent is integrated with the functions of deoxidization, degasification, impurity removal and the like, and has strong adsorbing, dissolving and combination slagging capabilities; the surface tension between the refining agent and metal melt is high, the refining agent can promote molten slag to float up, so that the molten slag can be better separated from molten metal, and thereby the effects of refining, impurity removal and melt purification are achieved; the refining agent has high chemical stability and thermal stability, does not have the corrosion effect on metal and the furnace lining, and cannot chemically react with the molten metal, the refining agent and the molten metal cannot be melted into each other as well, and thereby the original composition and properties of alloy are guaranteed; and the refining agent does not have public hazard, is safe and environment-friendly, is convenient to use, and is cheap.

Owner:NANCHANG UNIV

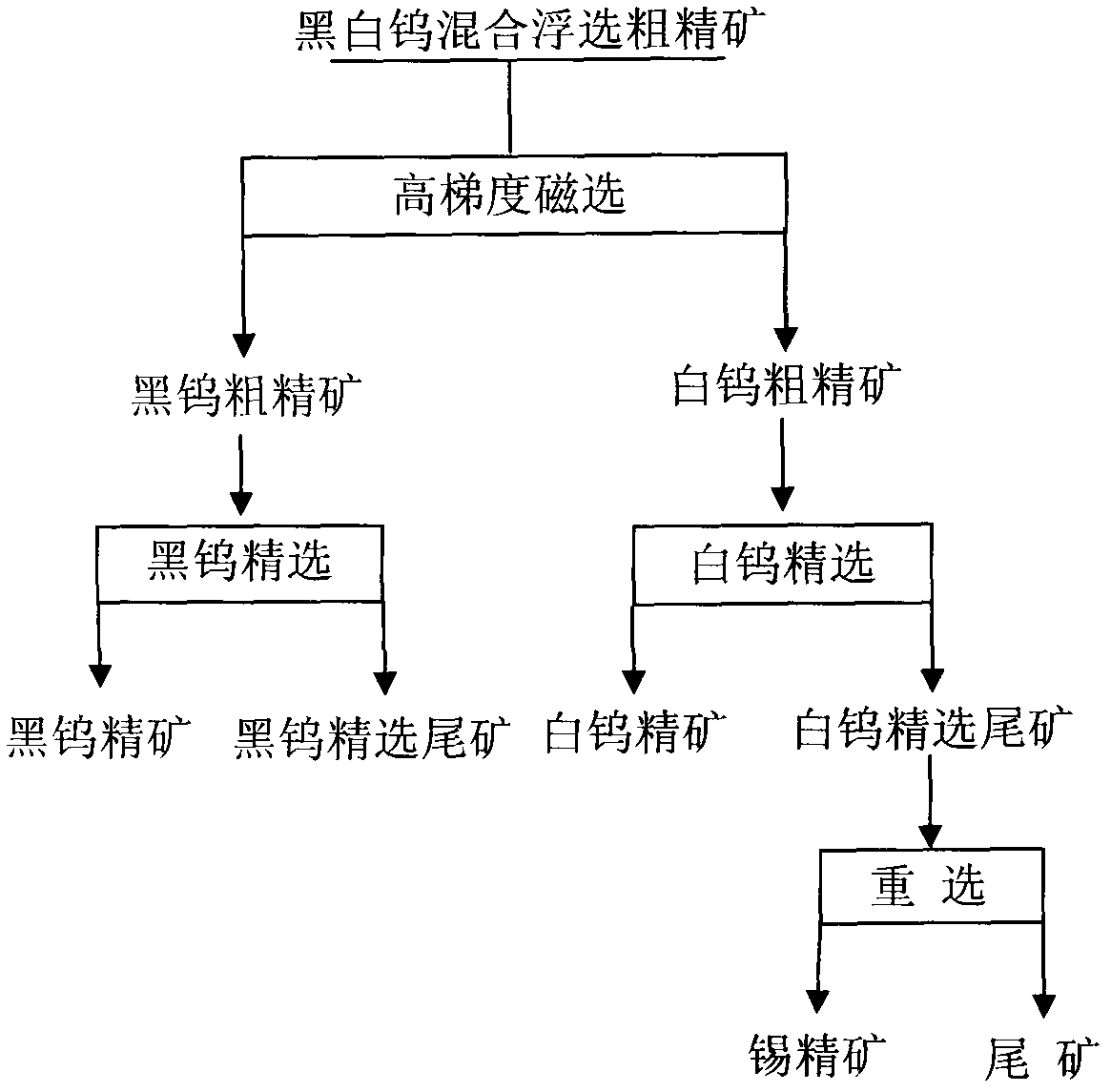

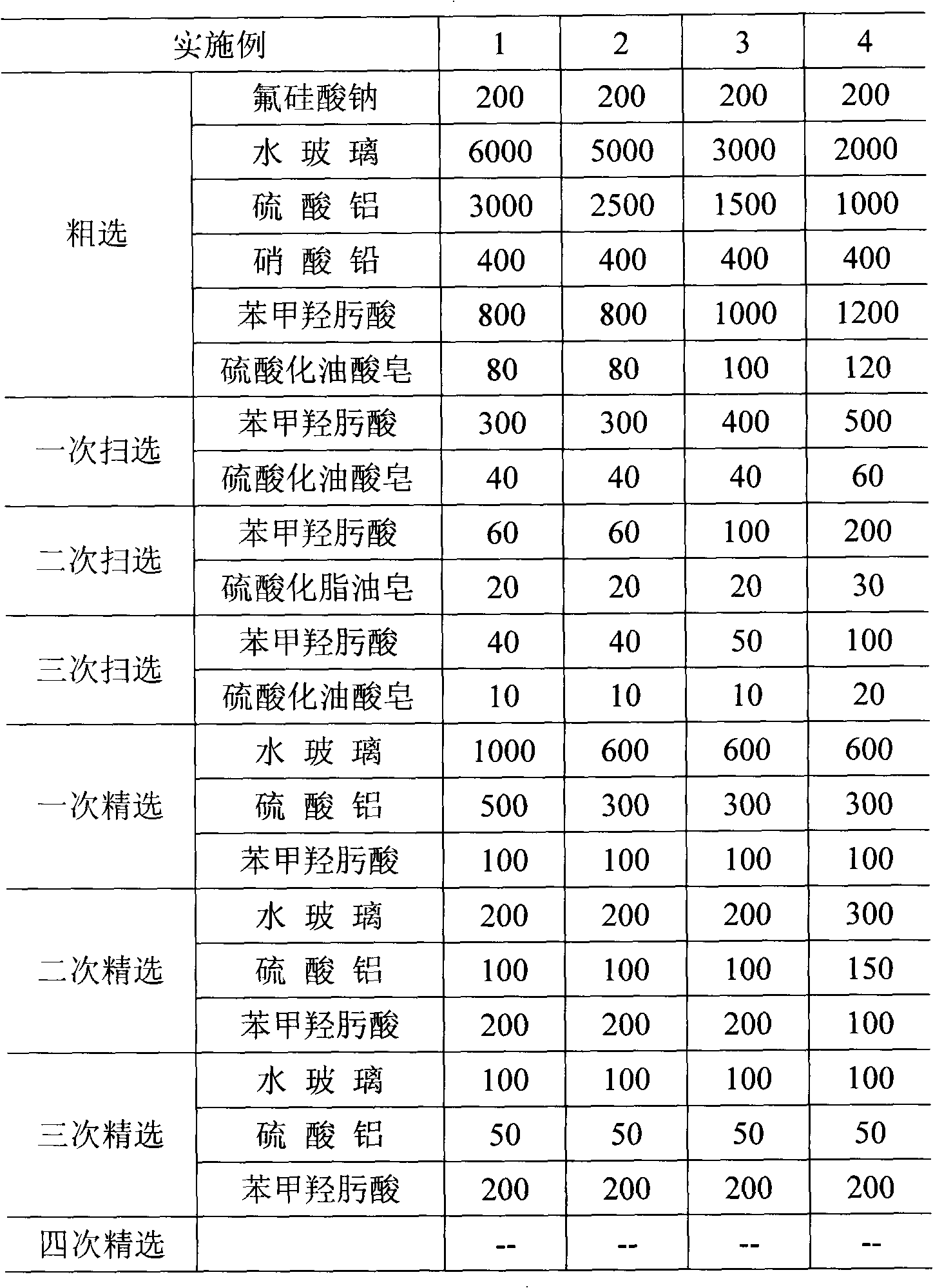

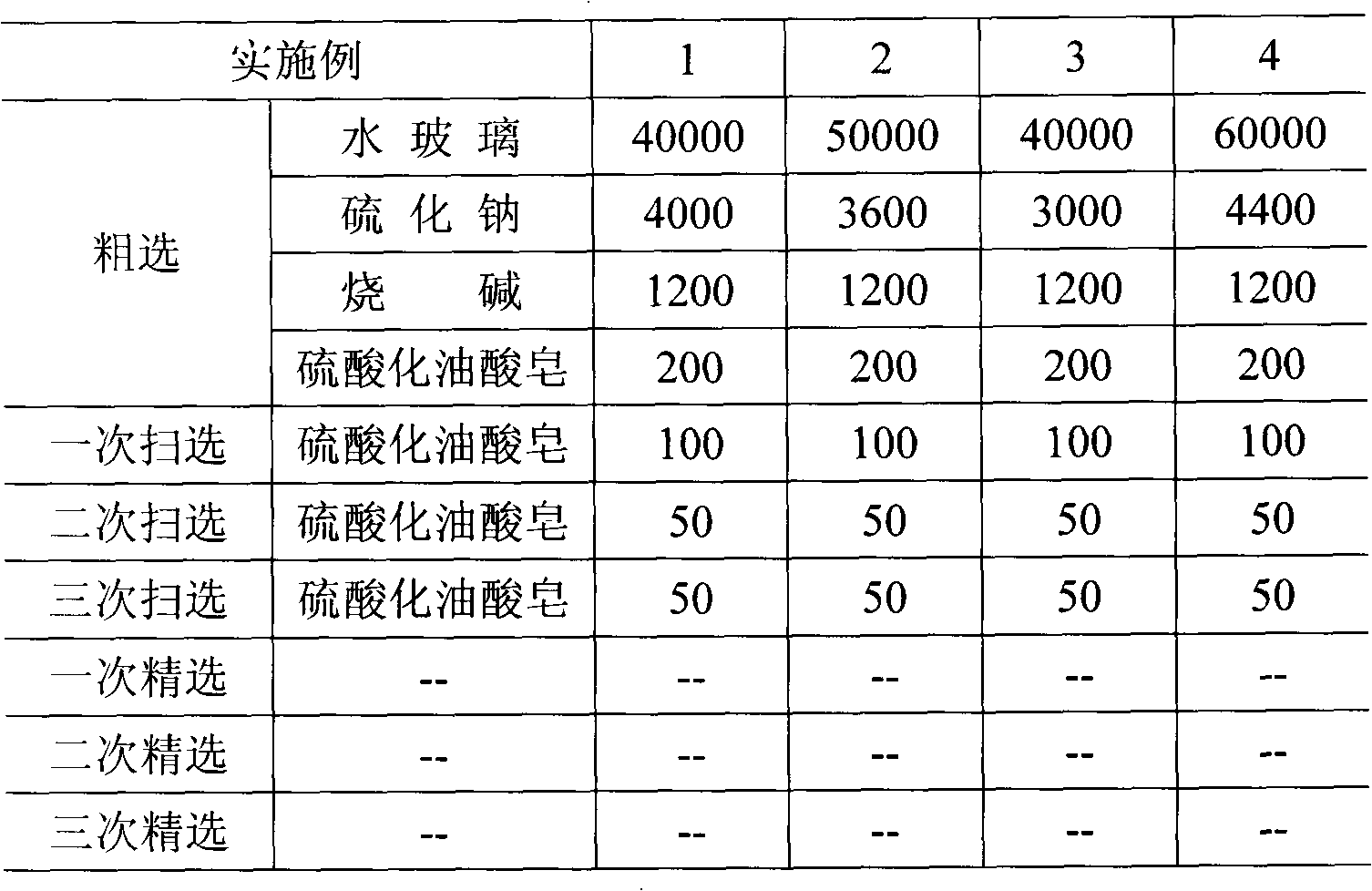

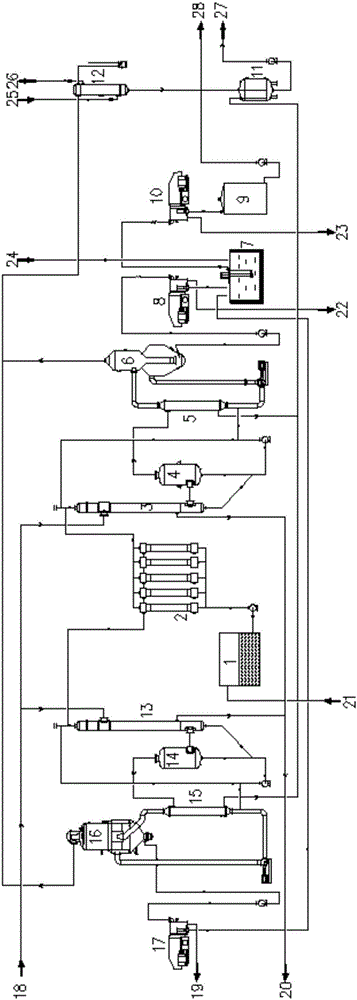

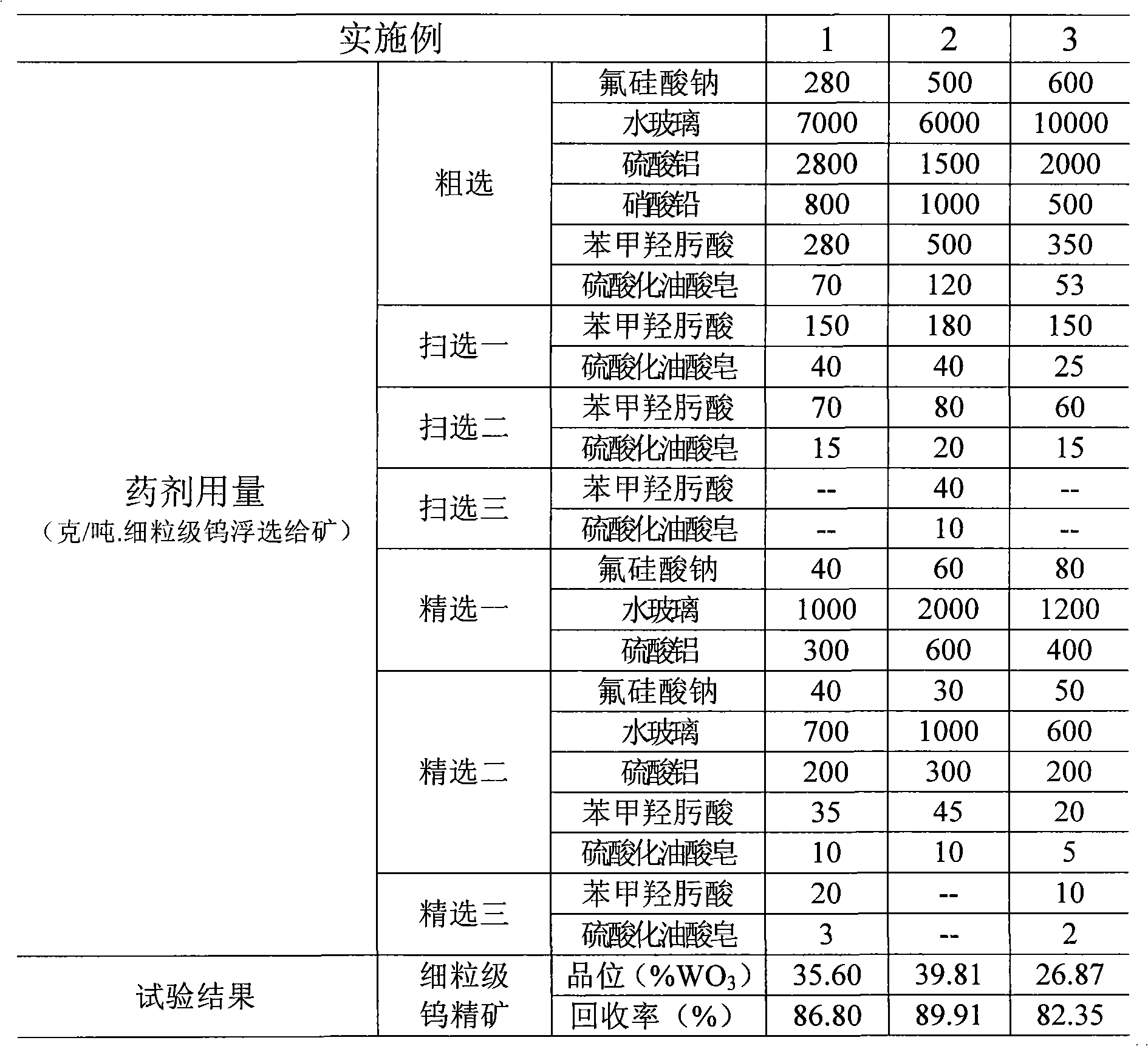

Method for separating black and white tungsten bulk flotation rough concentrates

ActiveCN102211053AHigh recovery rateReduce mutual interferenceGlass recyclingWet separationLead nitrateFatty acid

The invention relates to a method for separating black and white tungsten bulk flotation rough concentrates. The method is characterized in that a black tungsten rough concentrate and a white tungsten rough concentrate are obtained by virtue of high-gradient magnetic separation, roughing or roughing and scavenging; black tungsten concentrates and black tungsten cleaner tailings are obtained via carrying out once roughing, three-time scavenging and four-time concentrating on the black tungsten rough concentrate by utilizing sodium fluosilicate, sodium silicate, aluminum sulfate, lead nitrate, benzohydroxamic acid and sulfated nascent soap; white tungsten concentrates and white tungsten cleaner tailings are obtained via carrying out once roughing, three-time scavenging and three-time concentrating on the white tungsten rough concentrate after the white tungsten rough concentrate is heated up and stirred by utilizing sulfated fatty acid soap, sodium silicate, caustic soda and sodium sulfide; cassiterites in the white tungsten cleaner tailings are recovered by a table concentrator. The method related by the invention has the advantages of small mutual interference of black tungsten ore and white tungsten ore in the black and white tungsten bulk flotation rough concentrates, high recovery ratio of black tungsten ore and high and stable quality of the black tungsten ore; and the method is suitable for the black and white tungsten bulk flotation rough concentrates containing 5-40% of WO3.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI +1

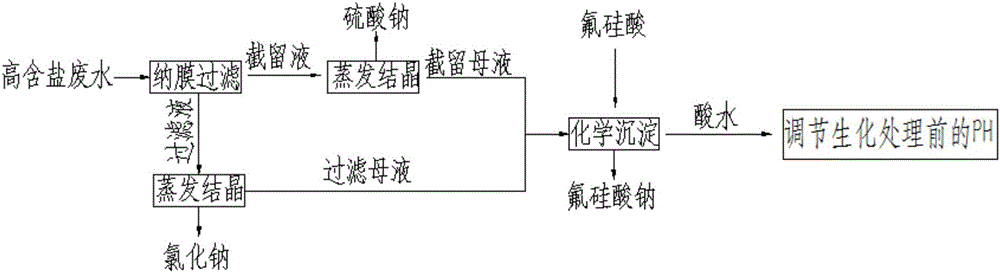

Recycling method for high-salinity wastewater containing sodium chloride and sodium sulfate

InactiveCN105110536AReduce processing costsRealize resource utilizationWater/sewage treatment by centrifugal separationWater contaminantsAcid waterWastewater

The invention discloses a recycling method for high-salinity wastewater containing sodium chloride and sodium sulfate and belongs to the field of wastewater treatment. The method comprises: filtering wastewater through a nanofiltration membrane; performing evaporative crystallization on filtrate through the nanofiltration membrane to obtain sodium chloride and filtered mother liquor; performing evaporative crystallization on retained liquor which does not pass through the nanofiltration membrane to obtain sodium sulfate and retained mother liquor; mixing the filtered mother liquor with the retained mother liquor to obtain a mixture and adding fluosilicic acid into the mixture; and stirring sufficiently the mixture to obtain sodium fluosilicate by filtering. Filtered acid water is used in pH value adjustment of a system before biochemical treatment.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

Water based detergent for oil dirty

InactiveCN101003769AImprove rust resistanceImprove defoaming abilityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsWater basedSodium metasilicate

This invention discloses a waterborne detergent for cleaning oil stains. The detergent is composed of: oleic acid 2-10%, ethanolamine 10-20%, surfactant 10-20%, sodium metasilicate 5-10%, sodium carbonate 5-10%, sodium fluosilicate 2-4%, defoamer 0.05-0.1%, and water. The detergent has good anti-rust performance on a variety of metals and alloys, and is suitable for cleaning oil stains on metals and alloys. The detergent has good effect on oil stains of machine tools, hardware, household range hoods, and especially dark red fused-ring aromatic hydrocarbon stains in oil-refinery apparatus.

Owner:JIANGSU UNIV OF SCI & TECH

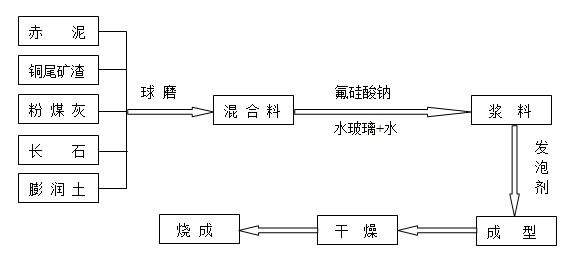

Foamed ceramic insulation board and preparation method thereof

The invention belongs to the technical field of building materials and particularly relates to a foamed ceramic insulation board and a preparation method thereof. The technical scheme provided by the invention is that the foamed ceramic insulation board comprises the following components in parts by weight: 100 parts of mixture, 4-15 parts of sodium fluosilicate, 50-100 parts of sodium silicate, 5-40 parts of water and 5-25 parts of foaming agent. According to the foamed ceramic insulation board, industrial waste can account for 70-85 percent. The solid waste is largely utilized, and inorganic materials are completely utilized, therefore, the national class-A non-combustible standard can be reached.

Owner:UNIV OF JINAN

Polymer microsphere insulation heat-proof dry-powder paint

InactiveCN101250343AImprove thermal insulation performanceImprove thermal insulationFireproof paintsPowdery paintsHollow fibreFiber

Polymer microsphere thermal insulation dry powder paint is formed by raw material with following parts by weight of 20-40 water glass powder, 8-15 pore closed expansive perlite, 3-15 hollow glass or ceramic micro-bead, 10-30 polymer phase-change microsphere, 2-5 hollow fiber, 3-5 sodium fluosilicate, 5-10 emulsion powder and 5-10 water-proof anti-permeability addition agent, which shares the common characteristics of thermal resistance type and thermal capacity type materials, and has prominent weatherability and extremely excellent strain resistance. Hollow fiber provides excellent thermal insulation property, and largely increases the properties of pull-resistance, cracking resistance and breaking resistance at large amplitude. An excellent barrier layer is formed through the mutual gradation of hollow glass or ceramic micro-bead, hollow fiber and polymer microsphere and the like according to particle size, thereby largely increasing thermal insulating property. Dry powder supply is employed, which largely reduce transportation cost and storage cost, and is convenient for storing and transporting and construction.

Owner:金小刚

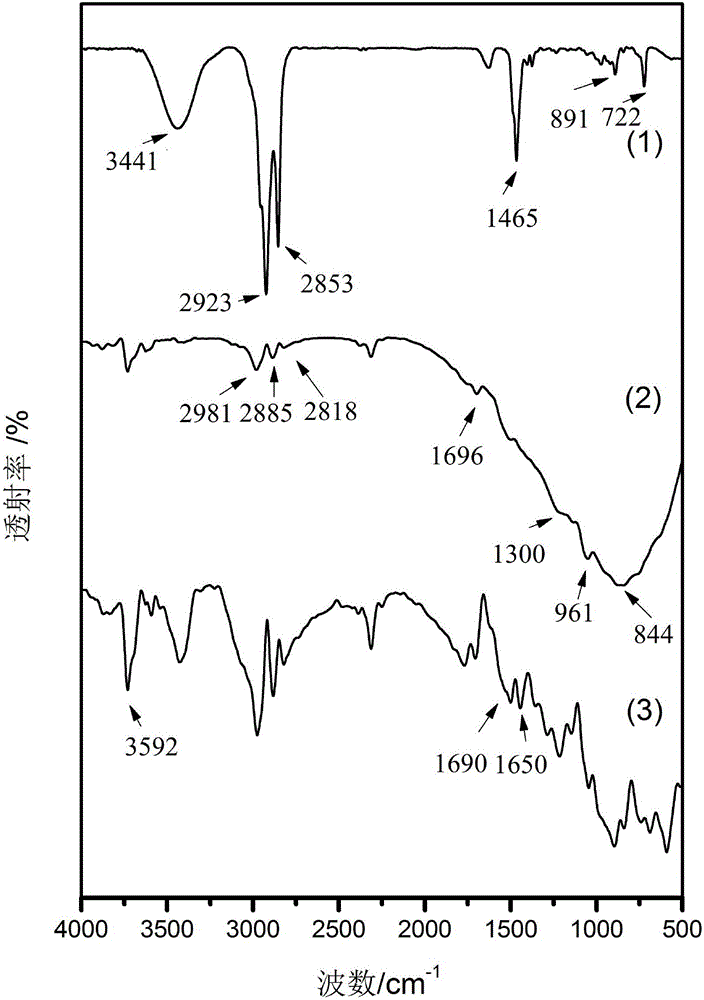

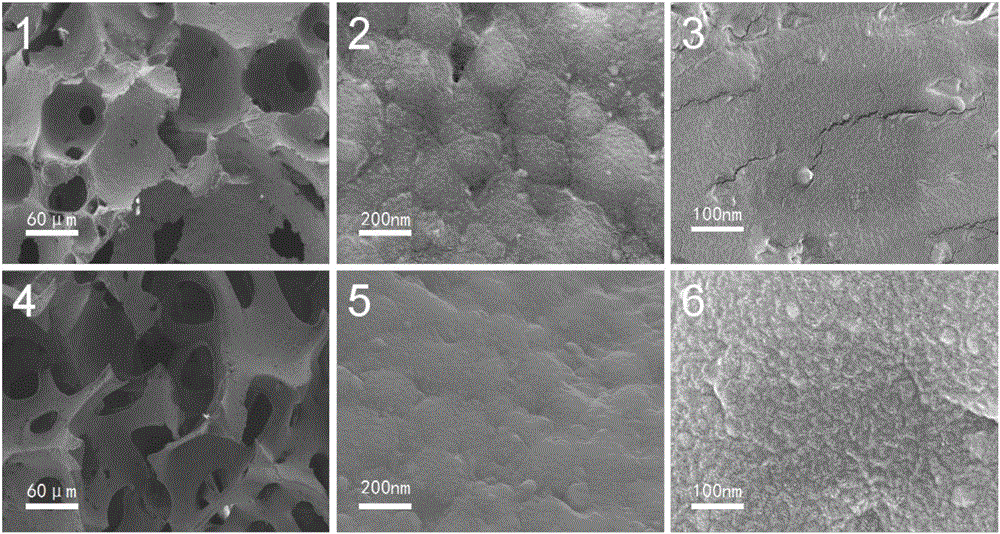

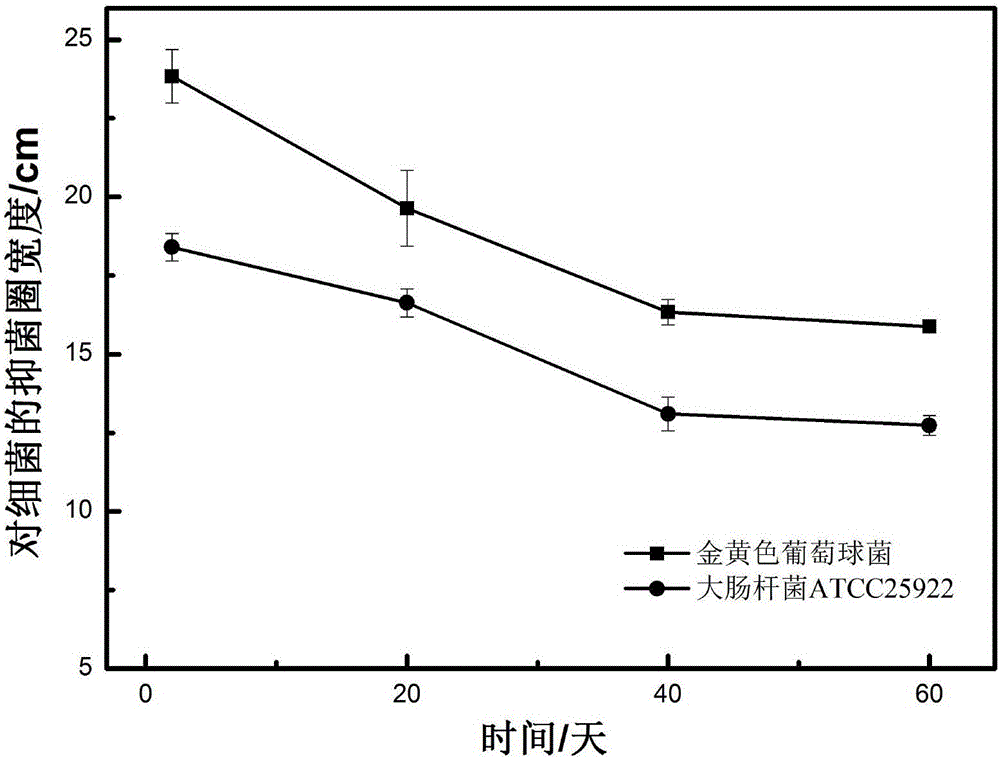

Antibacterial natural latex product based on quaternary ammonium salt antibacterial agent and preparation technology of antibacterial natural latex product

The invention discloses an antibacterial natural latex product based on a quaternary ammonium salt antibacterial agent and a preparation technology of the antibacterial natural latex product, and belongs to the technical field of latex materials. The antibacterial natural latex product is prepared from the following components by weight: 90 to 100 parts of natural latex, 1 to 9 parts of sulfur, 1 to 5 parts of a vulcanization accelerator, 1.5 to 2 parts of an anti-aging agent, 1 to 6 parts of zinc oxide, 0.5 to 2 parts of sodium fluosilicate, 1 to 3 parts of potassium castorate, 0.1 to 2 parts of potassium oleate, 0.5 to 1 part of potassium permanganate and 0.1 to 3 parts of the quaternary ammonium salt antibacterial agent. The antibacterial natural latex product is based on the antibacterial characteristic of a low-concentration quaternary ammonium salt compound. The adopted quaternary ammonium salt compound has the advantage of stable performance, and the compound is tightly combined with latex polymer molecules and cannot permeate the skin of people or an animal by changing the physicochemical property of material surface. The latex product prepared in the invention has the advantages of high antibacterial property, hygiene, high practicability and the like, and has a broad market prospect.

Owner:江苏金世缘乳胶制品股份有限公司 +1

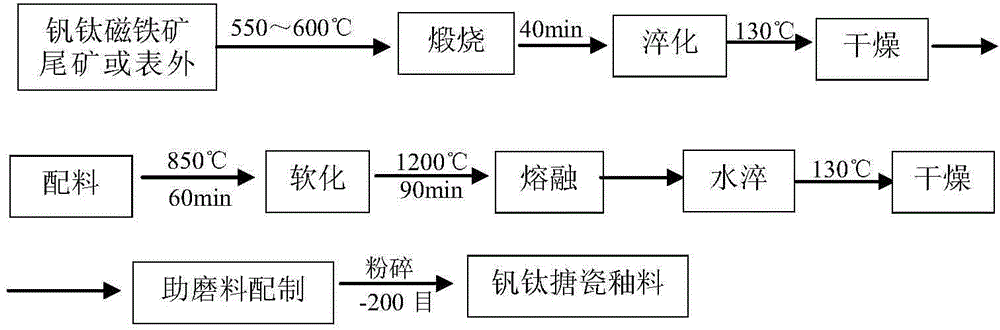

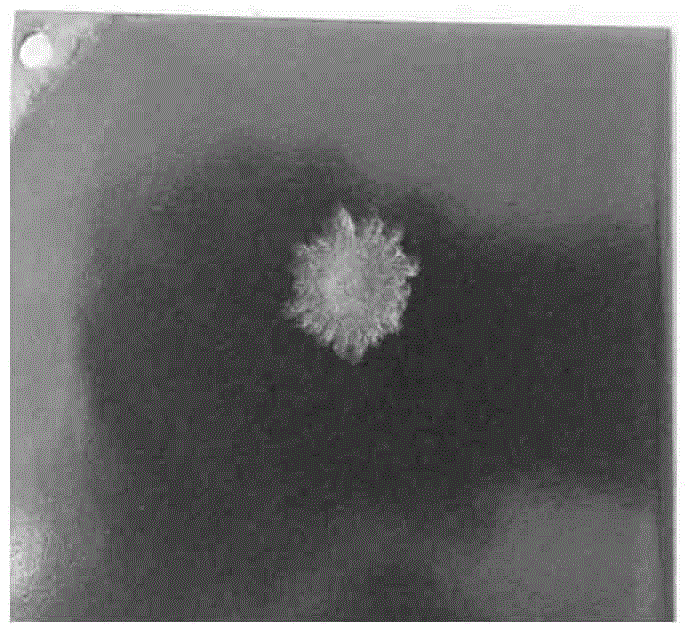

Vanadium-titanium enamel glaze material, and preparation method thereof

The invention belongs to the technical field of enamel material, and specifically relates to a vanadium-titanium enamel glaze material, and a preparation method thereof. The preparation method is used for solving technical problems that cost of a conventional vanadium-titanium enamel glaze material is high, glossiness of enamel glaze obtained via sintering is not high enough, fishscaling is observed, and acid and alkali resistance is not high enough. The vanadium-titanium enamel glaze material is prepared from, by mass, 22 to 28 parts of pretreated vanadium-titanium magnetite titanium separation tailing or vanadium-titanium boundary ore, 20 to 22 parts of feldspar powder, 5 to 8 parts of quartz sand, 24 to 26 parts of borax, 1.5 to 2 parts of sodium nitrate, 3.5 to 5.5 parts of lithium carbonate, 5 to 7 parts of fluorite powder, 0.1 to 0.3 part of sodium fluosilicate, 3 to 5 parts of cryolite, 2 to 4 parts of limestone, 3 to 4 parts of cobalt nitrate, 1 to 2 parts of nickel nitrate, 2 to 3 parts of sodium vanadate, and 1 to 2 parts of antimony oxide. Firm combination of the vanadium-titanium enamel glaze material with carbon steel billet can be realized; acid and alkali resistance is higher than that stipulated by national standard; and the vanadium-titanium enamel glaze material can be used for a plurality of matrixes such as hot-rolled carbon steel and cast iron.

Owner:PANZHIHUA UNIV

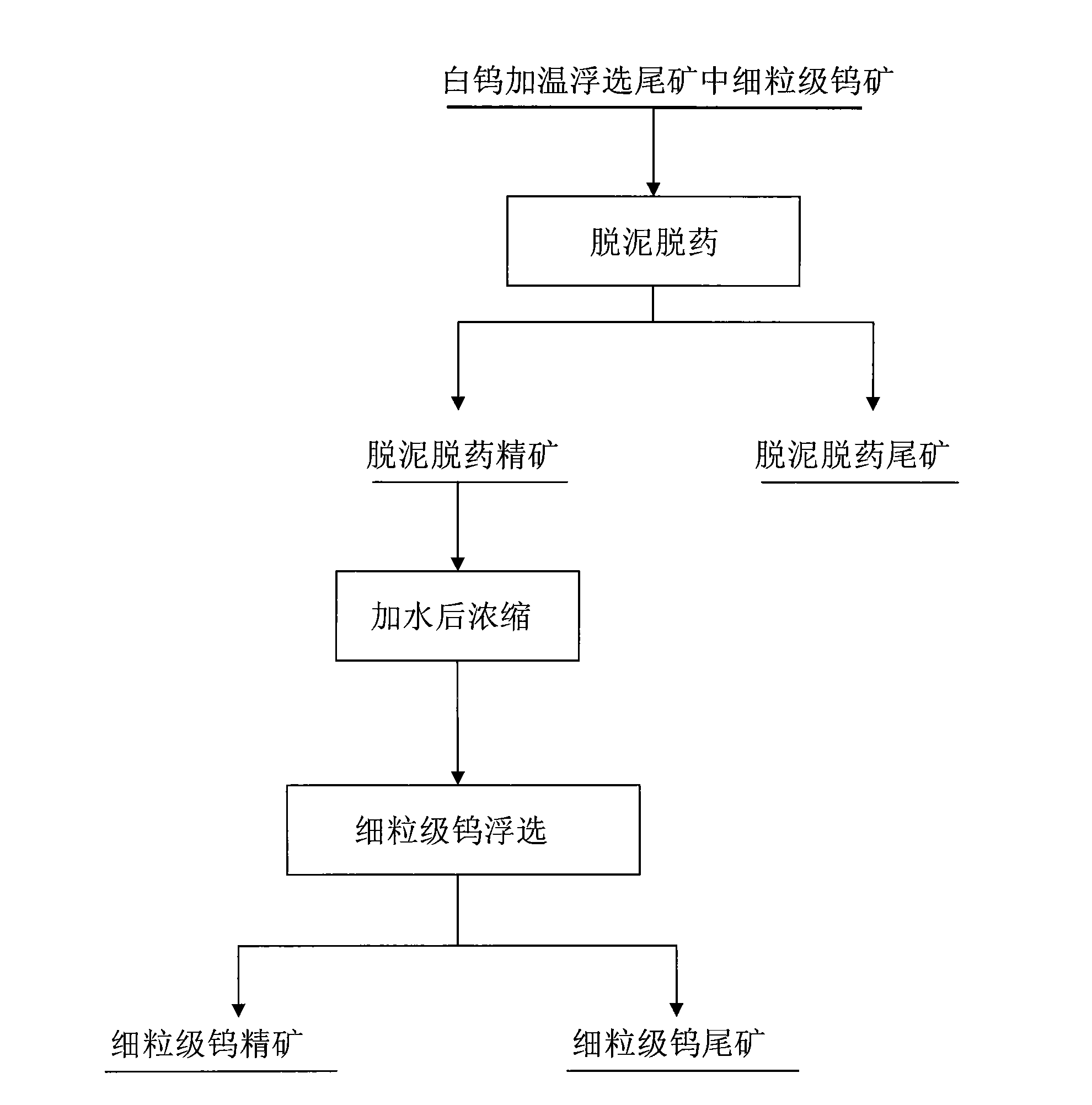

Benefication method for concentrating fine tungsten ore in tailings by warming scheelite

InactiveCN101579653ASimple recycling processThe beneficiation process is stableFlotationWet separationLead nitrateSoluble glass

The invention discloses a benefication method for concentrating fine tungsten ore in tailings by warming scheelite, which is characterized by comprising the following steps in turn: performing desliming and reagent removal; condensing concentrate after desliming and reagent removal, which is added with water, into 26 to 44 percent of pulp density, and controlling the pH of pulp at about 8.5; performing floatation on the fine tungsten ore; adding regulators of sodium fluosilicate, soluble glass, aluminium sulphate and lead nitrate; and adding collecting agents of benzohydroxamic acid and sulfated oleate soap, and performing rough concentration, concentration and scavenging to obtain the fine tungsten ore concentration and fine tungsten tailings. The method has simple recovery process flow, stable benefication process, high tungsten recovery rate, and low cost of reagents; the used benefication reagents do not pollute environment; and tailing water can meet the emission requirement. The method is suitable for the fine tungsten ore, of which the WO3 content is 0.95 to 5.10 percent, the ratio of peanut ore to the scheelite is between 1:9 to 9:1, and the occupancy rate of WO3 metal smaller than 30 microns is more than or equal to 60 percent, and which is subjected to concentration of the tailings by warming the scheelite and then reconcentration of the tailings by a shaker.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

Sintered flux for two phase stainless steel

InactiveCN102039498AWelding specifications are stableEasy to remove slagWelding/cutting media/materialsSoldering mediaSlag (welding)SS - Stainless steel

The invention discloses a sintered flux for two phase stainless steel. The sintered flux comprises the dry powder components by weight percent: 24-32% of MgO, 12-23% of CaF2, 12-18% of ZrO2, 10-15% of Al2O3, 9-14% of SiO2, 2-10% of CaO, 1-3% of rare earth fluoride, 0.5-2% of sodium fluosilicate, 0.5-2% of chromium oxide green, 0.5-2% of deoxidier, 2-8% of alloying agent, and the balance chromium metal, wherein the deoxidier is Si-Fe in which the content of Si is not less than 70%, and the alloying agent contains 1.5-2.5% of ferromolybdenum in which the content of molybdenum is not less than 50%. The sintered flux disclosed by the invention is matched with ER2209 solder wires, is suitable for the welding and overlaying of two phase stainless steel containing 22% of Cr; the welding is ruled and stable, the slag detachability is excellent, and the weld pass is even in width, moderate in pile height, smooth in transition; the defects of gas pits, intermediate crystallization lines, slag bonding and the like are overcome; and the flux has high content of deposited metal ferrite, excellent mechanical property and corrosion resisting property.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Marbled glass ceramics directly employing fusion blast furnace slag and preparation method of marbled glass ceramics

ActiveCN106587634AImprove mechanical propertiesImprove the decorative effectCharging furnaceGlass productionSlagPotassium carbonate

The invention discloses marbled glass ceramics directly employing fusion blast furnace slag and a preparation method of the marbled glass ceramics. The marbled glass ceramics comprises the following raw materials, by mass, 55-75 parts of blast furnace slag flux and 25-45 parts of auxiliary material flux; and auxiliary materials comprise the following components, by mass, 8.5-19.5 parts of quartz sand, 0.5-5.5 parts of limestone, 1-5 parts of sodium carbonate, 2-5 parts of potassium carbonate, 1-4 parts of zinc oxide, 1-4 parts of ammonium di-hydrogen phosphate, 1-2 parts of spodumene, 2.5-5 parts of sodium fluosilicate, 0.5-1.5 parts of sodium fluoroaluminate and 0.5-1 part of borax. The preparation method is characterized in that through controlling the mixed melting temperature and time of the blast furnace slag flux and the auxiliary material flux, a flux mixture is obtained; through forming, annealing and microcrystallization heat treatment, the marbled glass ceramics is obtained. The molten blast furnace slag and the auxiliary materials are mixed in a flux form and the flux mixture having certain micro-inhomogeneity is obtained accurately, then with the combination of subsequent forming and heat treatment technologies and the like, the marbled glass ceramics is obtained, so that the technology is easy to implement, and the influence of uncertainty on a product in a mixing process is reduced.

Owner:WUHAN UNIV OF TECH

Surface treating agent of recycled aggregate and preparation method thereof

InactiveCN102674730ALow water absorptionImprove water absorptionSolid waste managementCalcium silicateCalcium hydroxide

The invention discloses a surface treating agent of recycled aggregate. The surface treating agent is mainly prepared by the following raw materials by weight: 0.5-1.5% of polyvinyl alcohol, 4-10% of sodium silicate, 0.5-3% of urea, 0.2-1% of sodium fluosilicate and 88-93.8% of water. The surface treating agent has the advantages of being capable of improving surface state of the recycled aggregate and remarkably reducing water absorption rate of the recycled aggregate by utilizing the polyvinyl alcohol, sodium silicate and sodium fluosilicate which are good in film formation performance, utilizing sodium silicate and sodium fluosilicate solution to fill holes and micro cracks of the recycled aggregate and obviously improving strength of the recycled aggregate accordingly. In addition, when the recycled aggregate is processed and used for preparing concrete, the film-shaped sodium silicate and sodium fluosilicate on the surface of the recycled aggregate and cement are hydrated to be subjected to calcium hydroxide reaction to produce calcium silicate and calcium fluosilicate which are capable of remarkably improving strength of a concrete transition area and improving bounding performance between the aggregate and cement stone.

Owner:JIANGSU MINGHE GRP

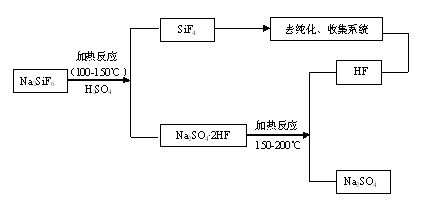

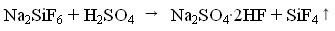

Method for preparing silicon tetrafluoride and anhydrous hydrogen fluoride from sodium fluosilicate acidified by sulfuric acid

InactiveCN101948114ATake advantage ofEfficient use ofFluorine/hydrogen-fluorideHalogenated silanesChemical industryHydrogen fluoride

The invention provides a method for preparing silicon tetrafluoride and anhydrous hydrogen fluoride from sodium fluosilicate acidified by sulfuric acid, which relates to the technical field of fluorine chemical industry, in particular to a method for preparing silicon tetrafluoride gas and anhydrous hydrogen fluoride gas by reaction of sodium fluosilicate and sulfuric acid. The method of the invention comprises the following steps: (a) stirring sodium fluosilicate and excessive sulfuric acid at the temperature lower than 150 DEG C for reacting to obtain silicon tetrafluoride gas, wherein hydrogen fluoride remains in solid residues; (b) dedusting, cooling, drying, refining and compressing the silicon tetrafluoride gas generated in the step (a) to obtain high-purity silicon tetrafluoride gas; (c) continuously heating to 200 DEG C to enable the hydrogen fluoride gas to escape; and (d) dedusting, cooling, drying, refining and compressing the hydrogen fluoride gas escaping in the step (c) to obtain the anhydrous hydrogen fluoride (AHF) gas. The invention enables the specific fluorine and silicon resources of phosphate fertilizer enterprises to be fully and efficiently utilized.

Owner:YUNNAN CHEM RES INST

Method for recycling phosphorus and fluoride in sewage residue of phosphorus fertilizer plant

InactiveCN102502552AImprove use valueEffective way to usePhosphatesAlkali orthophosphate fertiliserO-Phosphoric AcidAgricultural engineering

The invention discloses a method for recycling phosphorus and fluoride in the sewage residue of a phosphorus fertilizer plant. According to the method, the sewage residue is decomposed by using sulfuric acid, the phosphorus and the fluoride in the sewage residue are extracted, calcium sulfate dihydrate crystal or calcium sulfate hemihydrate crystal and diluted phosphoric acid solution are generated, diluted phosphoric acid and phosphogypsum which is the by-product are obtained through solid-liquid separation, the diluted phosphoric acid is concentrated into concentrated phosphoric acid, the escaped fluorine containing gas is recycled in the process of concentrating the phosphoric acid and making acid and produced into the fluoride such as the fluosilicic acid and the like, or defluorination agent is added into the diluted phosphoric acid to recycle fluoride resources in the form of the fluoride such as the sodium fluosilicate and the like, and the obtained concentrated phosphoric acid can be used to prepare other phosphate products such as the ammonium phosphate and the like by using the traditional method. The method can be used to effectively recycle the phosphorus and fluoride resources in the sewage residue of the phosphorus fertilizer plant so that the waste materials can be changed into the valuable materials and the recycling value of the phosphorus and fluoride resources in the sewage residue of the phosphorus fertilizer plant can be improved. The method has good economic benefit and environment protection significance.

Owner:WENGFU (GRP) CO LTD

High-chromium-manganese austenitic steel alkalescent full-position gas-protection flux-cored wire

InactiveCN101428376AImprove ductilityReduce splashWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

The invention discloses a high chromium and manganese type austenite steel alkali full-position gas shielded flux-cored wire, which comprises a 0Cr17 stainless steel band sheath and flux cored, wherein, the flux cored is prepared by mixing the following components by the weight percentages: 4-10 percent of rutile, 1-5 percent of feldspar, 0.5-2 percent of sodium carbonate, 8-15 percent of fluorspar, 0.5-1.5 percent of sodium fluosilicate, 40-68 percent of manganese powder or low carbon ferromanganese, 1.5-20 percent of chromium powder, 0-15 percent of nickel powder, 2-4 percent of graphite, 0-15 percent of molybdenum powder or ferromolybdenum, 0.5-4.5 percent of ferrosilicon and iron powder in balancing amount. The invention has the advantages that the ductility of the welding wire is good, the diameter is small, the small-scale welding can be conducted, the impurity content is low, and the hot cracking resistance is good; meanwhile, the splashing degree of the welding wire is low, the welding mold is good, the slag detachability is good, the excellent processing property such as the full-position welding can be conducted, and the production efficiency of the welding is high.

Owner:TIANJIN SAINTEAGLE WELDING CO LTD

Method for producing defluorinated sulfenyl nitrogen-phosphorus-potassium compound fertilizer

InactiveCN101717290AIncrease profitSave resourcesFertilizer mixturesChemical industryPhosphoric acid

The invention relates to a method for producing defluorinated sulfenyl nitrogen-phosphorus-potassium compound fertilizer, which belongs to the technical field of production in the chemical industry. The method comprises the following steps of: firstly, adding soluble sylvite (or sodium salt) into fluosilicic acid in wet phosphoric acid to generate potassium fluosilicate (or sodium fluosilicate) precipitate, wherein after separating the potassium fluosilicate (or sodium fluosilicate) precipitate, the potassium fluosilicate (or sodium fluosilicate) precipitate is used as byproduct; then mixing the defluorinated wet phosphoric acid with converted potassium bisulfate at low temperature, carrying out neutralization reaction on mixed acid and gas ammonia; and granulating, drying, sieving, cooling and packing the neutralized slurry to prepare the defluorinated sulfenyl nitrogen-phosphorus-potassium compound fertilizer. The invention is mainly used for producing chemical fertilizers.

Owner:SHANDONG HONGRI ACRON CHEM

Boron-chromium-rare-earth co-seeping agent and its low-temperature co-seeping process below eutectoid line

InactiveCN101265563AReduce distortionReduce brittlenessSolid state diffusion coatingHigh carbonRare earth

The invention relates to a boron-chrome-rare earth permeating agent and the low-temperature permeating process under the eutectoid line thereof. The permeating agent contains the components at weight ratio as follows: high carbon ferrochrome 6.1-6.2, rare earth chloride 5-6, sodium fluosilicate 15.5-16, calcium silicon 11-11.5, borax 23-23.5, graphite 35-35.5, carbamide 1.8-2, and ammonium chloride 1-1.05. The permeating process includes the workpiece shot blasting, the boxing and the boron-chrome-rare earth permeating step. In the boron-chrome-rare earth permeating step, after being sealed by double-deck water glass mud, a box is dried at 90-110 DEG C, and then is heated to 600-680 DEG C for getting into a heating furnace; when achieving the temperature, the timing heat preservation is carried out for 4-4.5 hours; after discharging, the air cooling process is carried out. The boron-chrome-rare earth permeating agent and the low-temperature permeating process under the eutectoid line have the advantages of little deformation of the workpiece, deep permeating layer of the workpiece, little brittleness of the permeating layer, good abrasion resistance of the workpiece, high hardness, low cost, saving energy, obtaining single Fe2B permeating layer, and so on.

Owner:SHANDONG JIANZHU UNIV

Fiber-reinforced fireproof insulation board and preparation process thereof

InactiveCN103979918AOvercome defectsAvoid defectsSolid waste managementClimate change adaptationCalcium formateFire retardant

The invention discloses a fiber-reinforced fireproof insulation board. The fiber-reinforced fireproof insulation board is prepared from the raw materials in parts by weight: 80-100 parts of fly ash, 30-50 parts of expanded perlite, 10-20 parts of ceramsite, 10-20 parts of plant fiber, 5-10 parts of floating bead, 5-8 parts of meerschaum, 3-5 parts of sodium fluosilicate, 3-5 parts of calcium formate, 3-5 parts of flame retardant, 0.1-0.5 part of oleic triisopropanolamine and 0.1-0.3 part of glycol dimethyl ether. According to the fiber-reinforced fireproof insulation board, industrial production wastes are adopted as main raw materials, so that the production cost is reduced; through the organic combination and generated synergism of the fly ash, lightweight aggregate and additives, the defects in the existing building insulation boards can be effectively overcome.

Owner:秦菊霞

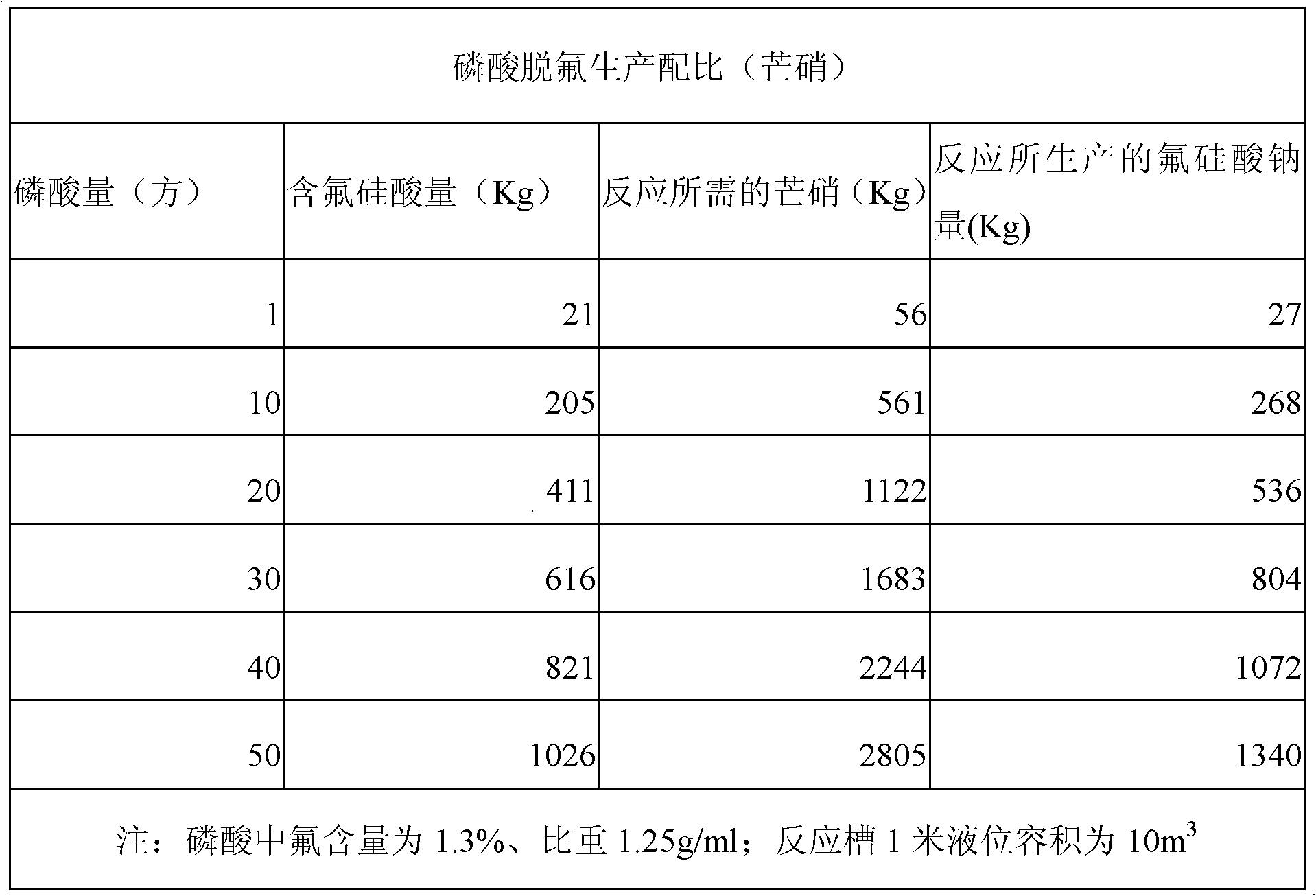

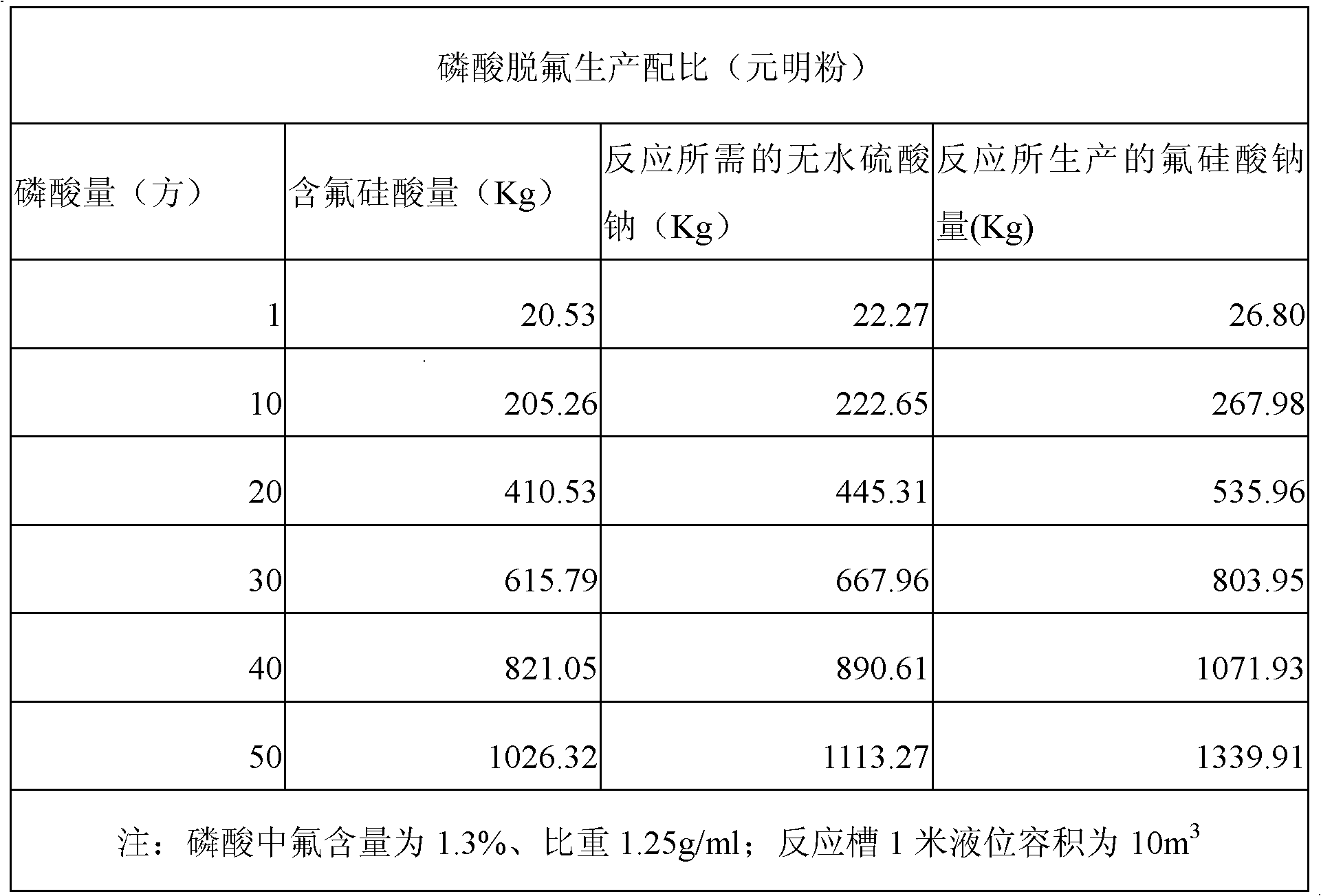

Production method of sodium fluosilicate

InactiveCN102153091AQuality improvementReduce or eliminate hazardsSilicon halogen compoundsPhosphoric acidEconomic benefits

The invention relates to a production method of sodium fluosilicate. The method comprises the following steps: adding a phosphoric acid purification device to purify the phosphoric acid produced in a phosphoric acid workshop; injecting the purified phosphoric acid in a filtrate receiver, injecting in a reaction tank by using a variable frequency pump; injecting fluorine-removing agent in the reaction tank at a ratio according to the fluorine content of phosphoric acid, reacting by utilizing the stirring action of the reaction tank; injecting the obtained mixture in a settling tank by using a pump after the reaction in the reaction tank, centrifuging the settled precipitate, and drying to obtain a sodium fluosilicate product and obtain the defluorinated phosphoric acid on the upper layer. In the method, after wet-process phosphoric acid is purified, fluorine-removing agent is used to remove about 2% of fluorine in phosphoric acid and form insoluble fluosilicate, and the fluosilicate is precipitated, washed, separated and dried to obtain a sodium fluosilicate product, thus the rational utilization of resource can be realized and the economic benefit of the enterprise can be increased. By adopting the method, fluorine resource can be fully recycled in the production process of compound fertilizer, high quality fluorine-free compound fertilizer can be produced and the damages to soil can be reduced or eliminated.

Owner:山东聊城鲁西化工第四化肥有限公司

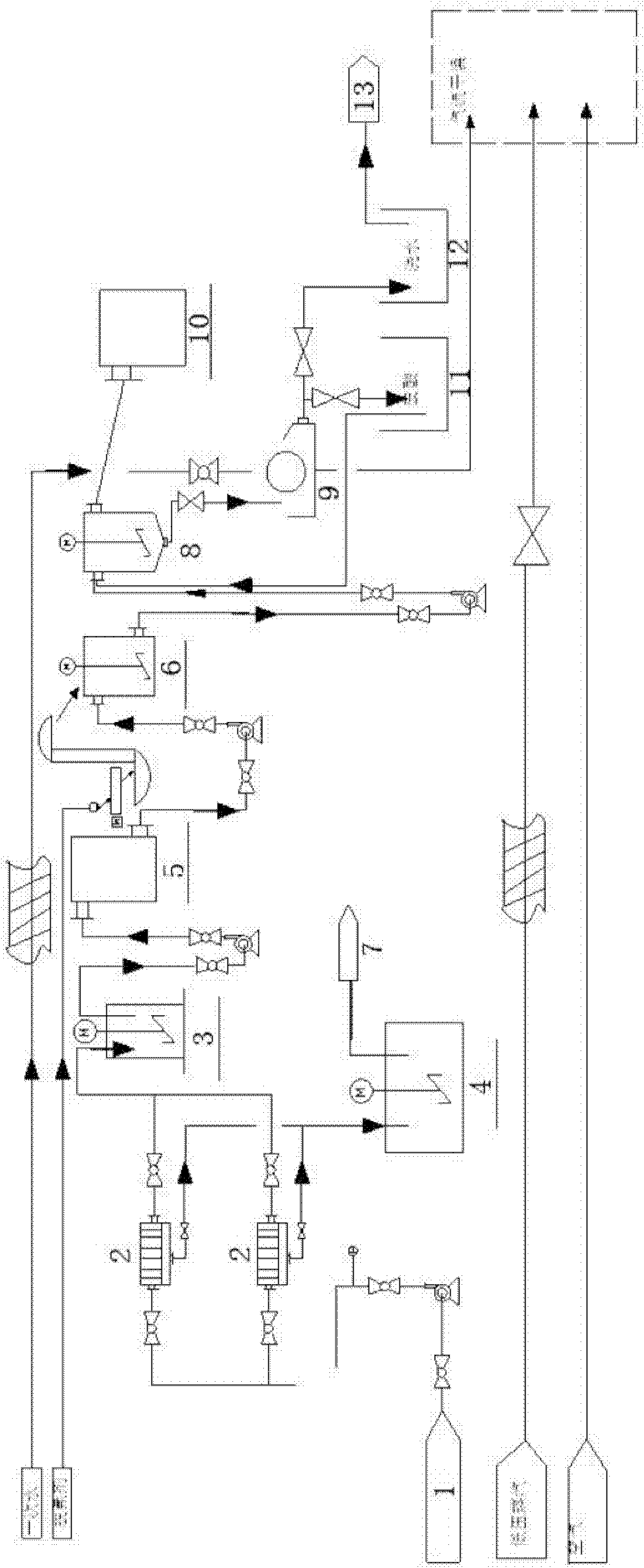

Method for preparing silicon tetrafluoride through pyrolysis of sodium fluosilicate in rotary reaction furnace

ActiveCN101698482AAct as a diluentImprove liquidityHalogenated silanesWastewaterSilicon tetrafluoride

The invention provides a process for preparing silicon tetrafluoride through pyrolysis of sodium fluosilicate in a rotary reaction furnace, which comprises the steps of: performing drying and heat treatment on the sodium fluosilicate at a temperature of between 200 and 300 DEG C in a calciner to remove the moisture in the sodium fluosilicate, and maintaining a negative pressure in the calciner, wherein the negative pressure value is controlled to between 10 and 30mmH2O; and sending the dried sodium fluosilicate into the rotary reaction furnace for the pyrolysis at a temperature of between 500 and 900 DEG C (material temperature) for 1 to 2 hours, and obtaining the silicon tetrafluoride and sodium fluoride after the pyrolysis. The generated silicon tetrafluoride gas is dedusted, cooled, dried, compressed and collected to form high-purity silicon tetrafluoride gas. The process has the advantages of single reactant and no discharge of waste gas, waste water and waste residue, and belongs to an environmentally-friendly comprehensive utilization project.

Owner:西安三瑞实业有限公司 +1

High brightness wear resistant domestic ceramic product

The invention relates to domestic ceramic products, and particularly relates to a high brightness wear resistant domestic ceramic product and a preparation technology thereof. The ceramic product is prepared from the following raw materials in parts by weight: 40-45 parts of kaolin, 32-35 parts of clay, 23-25 parts of potassium feldspar, 10-12 parts of quartz sand, 3-4 parts of barite, 10-15 parts of talcum powder, 1-2 parts of glucose powder, 2-3 parts of sodium silicate, 3-4 parts of sodium fluosilicate, and 5-6 parts of additive. Due to the utilization of raw materials such as the quartz sand, the barite and the talcum powder, the hardness and strength of the blank are improved, the blank does not change the color in firing at high temperature, the whiteness of the finished product is improved, the finished product has smooth surface, good gloss, and good lubricity, is wear resistant, is non-toxic and harmless, is attractive in appearance and practical, and can meet daily use requirement.

Owner:安徽省含山瓷业股份有限公司

Curing agent for curing/stabilizing silt (sludge) and soft foundation, and application thereof

ActiveCN102584165AEasy to prepareGood curing effectStream regulationSoil preservationCarrageenanAluminium hydroxide

The invention relates to a curing agent for curing / stabilizing silt (sludge) and soft foundation, and the application thereof. The curing agent comprises 5-10 parts of cement clinker, 10-20 parts of aluminium hydroxide, 10-15 parts of quick lime, 1-5 parts of anhydrous gypsum, 50-60 parts of special rock ballast powder, 5-10 parts of sodium silicate, 0.1-3 parts of sodium fluosilicate, 1-3 parts of anionic polyacrylamide, 0.5-1.5 parts of sodium dodecyl benzene sulfonate and 0.3-1.0 part of carrageenan concentration powder; and the curing agent prepared by the components has the pH value of 8-9 and the particle size of 0.005-0.15mm. 5-10% of curing agent is evenly mixed with silt (sludge), and after treatment, the compression strength reaches 0.2-0.4Mpa and the compression strength of seven days reaches 0.9-1.85Mpa, so that the curing agent has the characteristics of excellent waterproof property, water stability and hydraulicity, and can be widely applied to the curing process for a sea reclamation intertidal zone, the curing process for the sludge generated by riverway dredging, the curing and stabilizing treatment for the sludge generated in a sewage treatment plant, the strengthening for the soil of a road soft foundation layer, and the leakage-proof treatment for a mud layer at the bottom of water in a river and a lake.

Owner:TIANJIN BLUE SKY ENVIRONMENT POLYTRON TECH INC

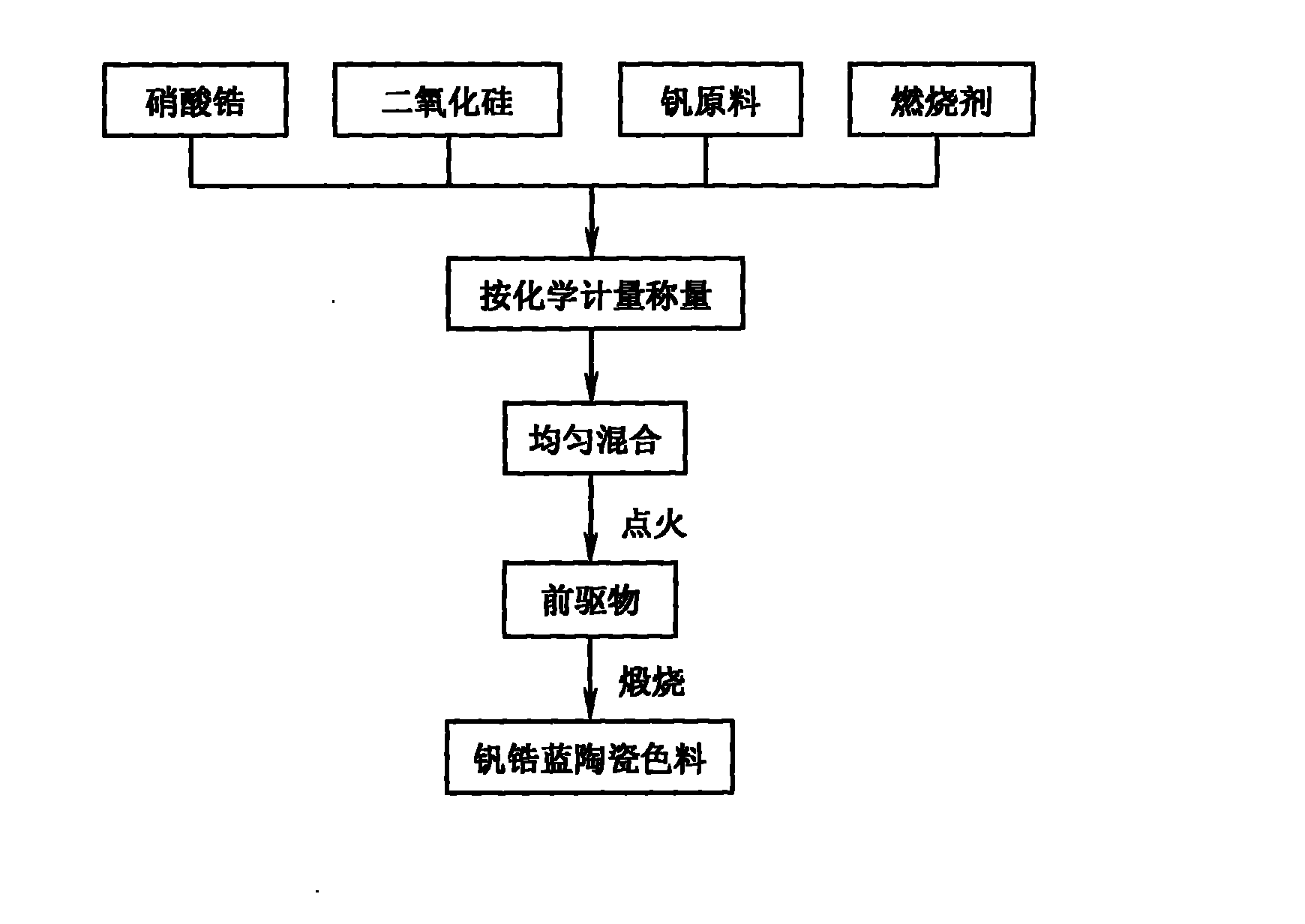

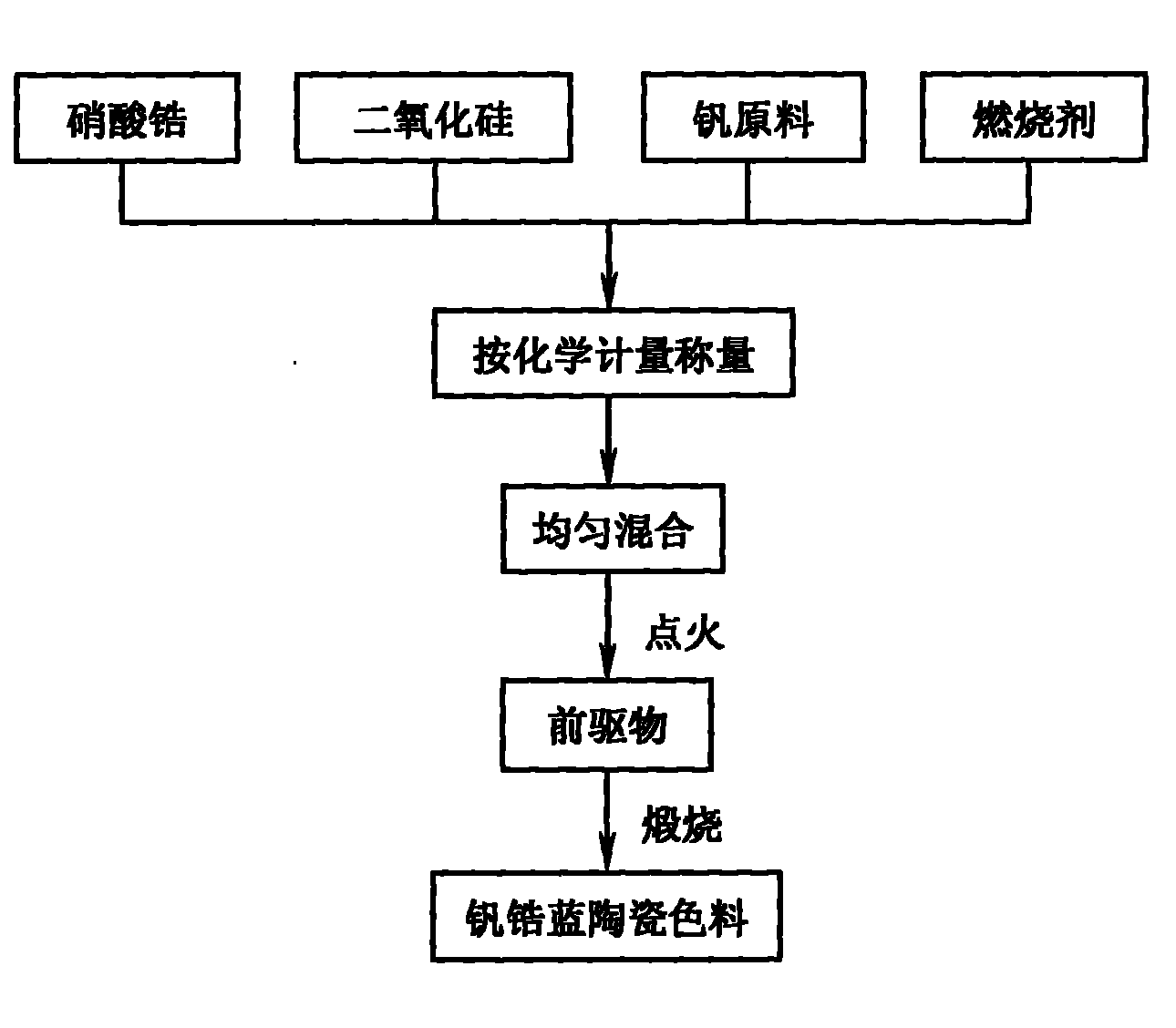

Method for preparing zircon-vanadium blue ceramic pigment

InactiveCN102050640ALow equipment requirementsSimple production processAmmonium metavanadateSilicon dioxide

The invention discloses a method for preparing a zircon-vanadium blue ceramic pigment, and belongs to the technical field of fine ceramics. In the method, zirconium nitrate and silicon dioxide are respectively taken as a vanadium raw material and a silicon raw material, ammonium acetate and the like are taken as organic incendiary agents, vanadium pentoxide, ammonium metavanadate and the like aretaken as zircon raw materials, sodium chloride, sodium fluoride and sodium fluosilicate are taken as a composite mineralizer, and the zircon-vanadium blue ceramic pigment is prepared by combustion synthesis and calcining technology. The method has the advantages that: the production process is simple, the equipment requirement is low, and the method is suitable for industrial production. The prepared zircon-vanadium blue ceramic pigment has narrow size distribution and stable color.

Owner:佛山市华南精细陶瓷技术研究开发中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com