Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

102results about How to "Improve defoaming ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water high light wearable intaglio ink and preparing method thereof

The invention relates to a water-base printing ink and its producing method, especially water-base high light friction resistance gravure oil and the producing method thereof. The oil is suitable for packing print in the soft packing field such as food, drink, medicine, health products, chemicals and etc. The water-base high light friction resistance gravure oil is composed of acrylic resin, acrylic emulsion, dye, ethanol, built-up agent, dispersant, deionized water, water-base emulsifying wax, antifoamer, leveling agent. The inventive product completely meets the requirement of the gravure oil, has a reliable quality and can replace the solvent gravure oil, which can be dilute by the tap water of ethanol. The printing device can be washed directly by the tap water. The product has a high concentration, a low viscosity, a good printing adaptability has no harm to the environment and human body. The presswork has a clear pattern, a bright color, a powerful attached fastness, a good water resistance and friction resistance, has no harmful residue after drying and is not easy to fade and shed.

Owner:浙江永在油墨有限公司

Automobile water-based dual-component middle coating excellent in performance and preparation method thereof

The invention discloses an automobile water-based dual-component middle coating excellent in performance and a preparation method thereof. The water-based middle coating is composed of a component A and a component B. The component A is composed of hydroxy acrylic resin, powder syrup, auxiliaries and cosolvent, wherein powder syrup contains deionized water, amine neutralizer, auxiliaries, extender pigment and pigment. The component B is composed of a curing agent, auxiliaries and cosolvent. After being put in according to the formula of the powder syrup of the component A, materials are dispersed at a high speed for 15 min and then enter a grinding machine to be ground till the granularity is smaller than 30 micron, then powder syrup is obtained, and hydroxy acrylic resin, powder syrup, auxiliaries and cosolvent are evenly mixed to obtain the component A. The component A and the component B are mixed in certain proportion, viscosity is adjusted by adding deionized water, and a middle coating film is obtained through spraying construction. By means of the water-based middle coating, the water-based performance of the automobile middle coating is achieved, the VOC content is greatly decreased, and excellent comprehensive performance is achieved.

Owner:GUANGDONG YATU CHEM

Water-based coating

ActiveCN104017445AImprove defoaming abilityWell mixedFireproof paintsAntifouling/underwater paintsExtensibilityWater based

The invention discloses a water-based coating which is characterized by comprising the following components by weight parts: 20-30 parts of water, 20-25 parts of an acrylic emulsion, 0.3-0.5 part of a wetting agent, 0.1-0.3 part of a de-foaming agent, 15-20 parts of titanium dioxide, 10-15 parts of talcum powder, 0.3-0.5 part of a fireproof agent and 0.2-0.4 part of an antibacterial agent. The coating disclosed by the invention is reasonable in composition, low in cost, good in compatibility among the components, environment-friendly, mildew-proof and flame-retardant, and has excellent application values; a natural antibacterial agent and an inorganic antibacterial agent are mixed for use, so that the problems of poor stability due to single use of the natural antibacterial agent or pollution caused by single use of an organic antibacterial agent and high cost due to single use of the inorganic antibacterial agent are solved; due to combined use, the mildew-proof effect is more lasting; the film-forming drying time is short, the hardness is good, and the extensibility and the heat resistance are good.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Automobile water-based two-component epoxy primer with excellent performance and preparation method thereof

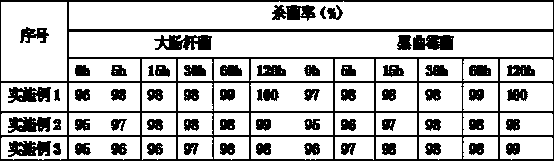

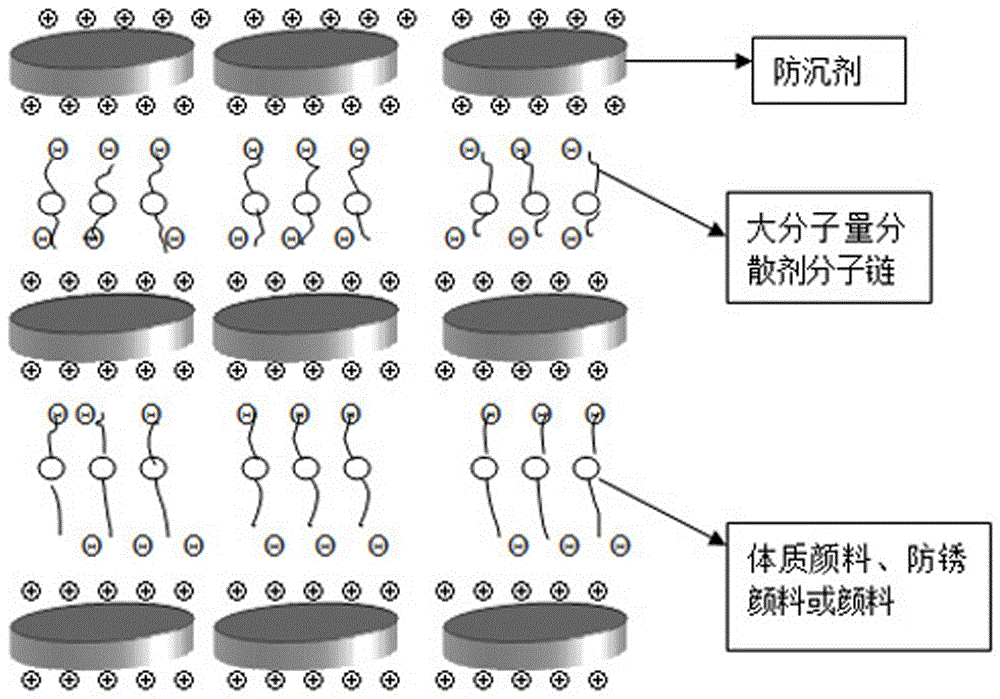

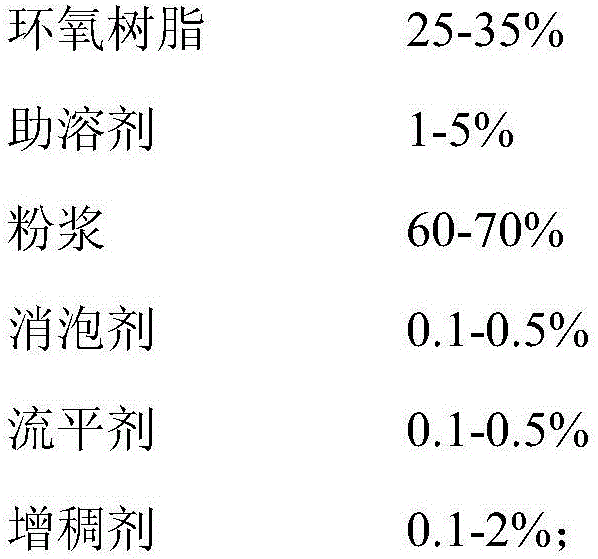

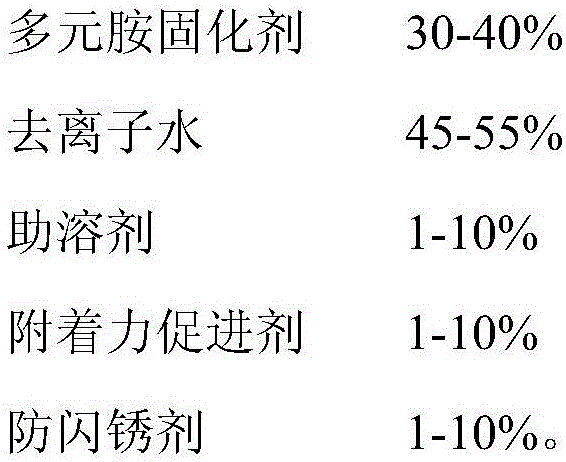

The invention discloses an automobile water-based two-component epoxy primer with excellent performance and a preparation method thereof. The water-based epoxy primer involved in the invention is composed of a component A and a component B. The component A is composed of epoxy resin, a cosolvent, powder slurry and assistants, wherein the powder slurry includes deionized water, additives, extender pigment, anti-rust pigment and pigment. The component B contains a polyamine curing agent, deionized water, a cosolvent and assistants. The preparation method includes: conducting charging according to the powder slurry formula of the component A, then performing high speed dispersion for 15min, then bringing the materials into a sand mill to conduct grinding to fineness of less than 30 micrometers to obtain the powder slurry, mixing epoxy resin, the cosolvent, the powder slurry and the assistants evenly to obtain the component A, mixing the component A with the components B in certain proportion, adding deionized water to adjust viscosity, and carrying out spray coating to obtain an epoxy primer film. The water-based epoxy primer provided by the invention not only realizes aquation of automobile epoxy primer and great reduction of the VOC content, but also has excellent comprehensive performance.

Owner:GUANGDONG YATU CHEM

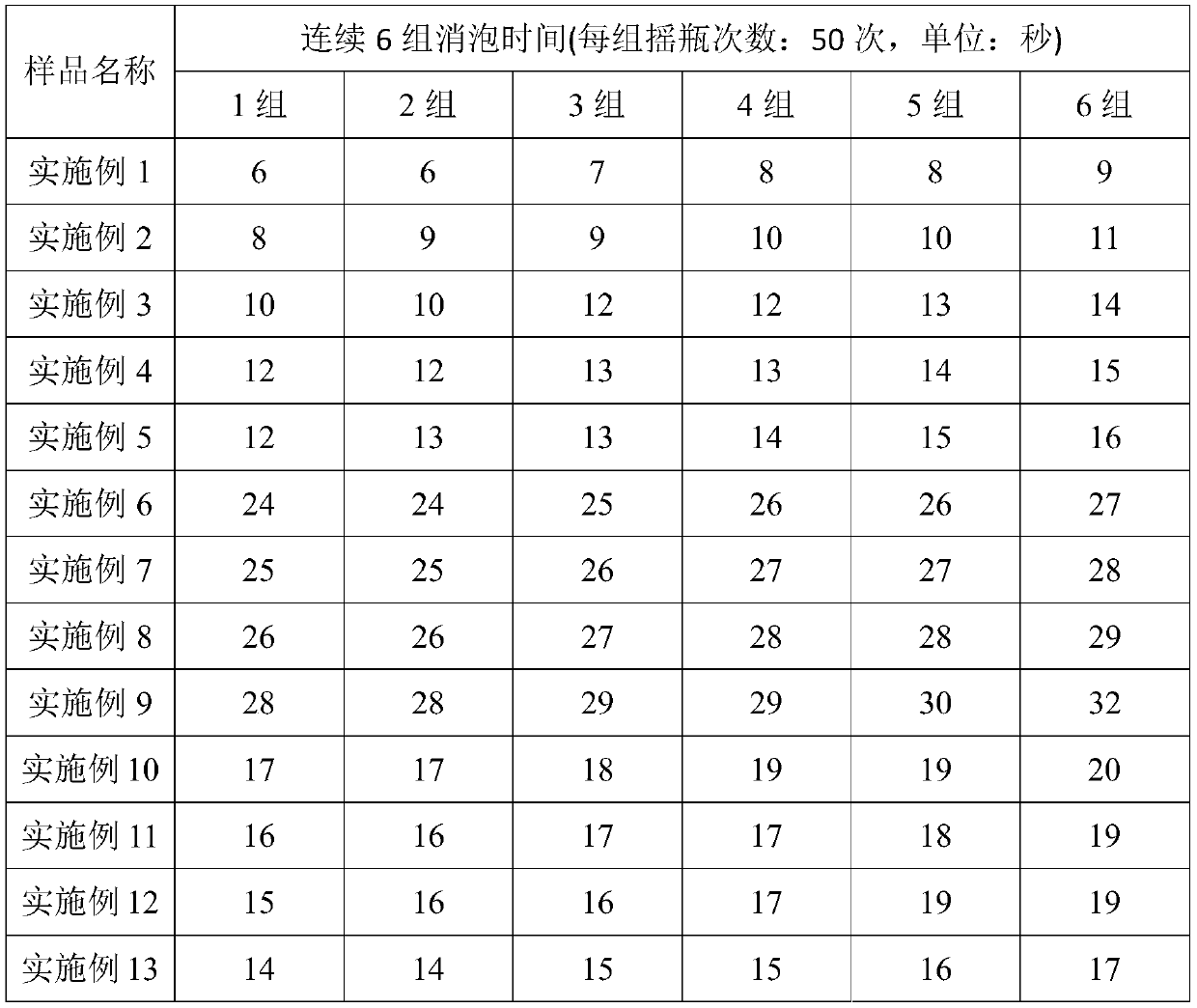

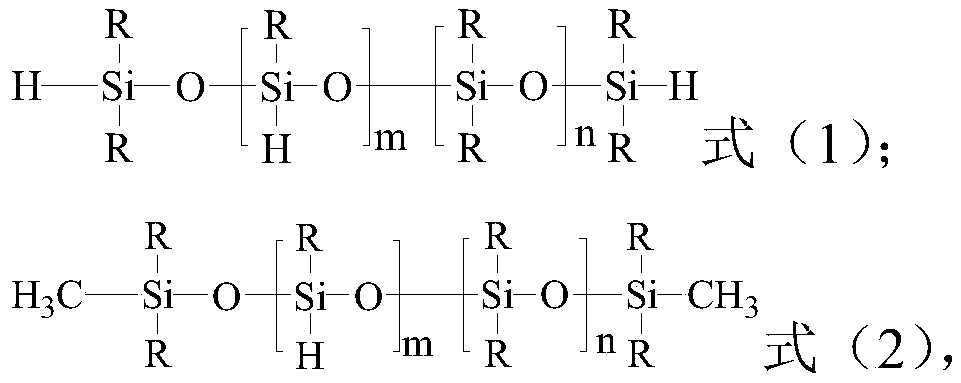

Preparation method of novel polyether modified organic silicon defoamer

InactiveCN111151033AGood defoaming and anti-foaming propertiesGood dispersionFoam dispersion/preventionSide chainDisiloxane

The invention discloses a preparation method of a novel polyether modified organic silicon defoamer, wherein the method comprises the following steps: S1, preparing double-end and side-chain hydrogen-containing silicone oil by using tetramethyldihydrodisiloxane, octamethylcyclotetrasiloxane and tetramethylcyclotetrasiloxane as raw materials and concentrated sulfuric acid as a catalyst; S2, taking5 parts of the double-end and side-chain hydrogen-containing silicone oil and 1 part of allyl polyether as raw materials, and taking 0.15 part of chloroplatinic acid as a catalyst for grafting to obtain double-end and side-chain polyether modified silicone oil; and S3, mixing the double-end and side-chain polyether modified silicone oil, silicon paste and a compound emulsifier, emulsifying, homogenizing, then adding a thickener, stirring and diluting to obtain the novel polyether modified organic silicon defoamer which is high in foam breaking rate, strong in defoaming capacity, short in defoaming time, resistant to acid and alkali at high temperature, strong in stability and simple in process condition.

Owner:GUANGDONG IND TECHN COLLEGE

Quick-setting epoxy grouting mortar suitable for summer first-aid repair construction

The invention discloses a quick-setting epoxy grouting mortar suitable for summer first-aid repair construction. The quick-setting epoxy grouting mortar is formed by mixing of a resin component A, a curing agent component B and a bone powder component C in a mass ratio of 1:(0.2-0.26):(5-7) during use. Specifically, the component A comprises the following components by weight: 100 parts of modified epoxy resin, 1-15 parts of an alcohol ether composite diluent, 1-3 parts of a coupling agent, and 0.5-3 parts of a rheological agent; the component B comprises the following components by weight: 16-23 parts of a modified polyamine curing agent, and 1-3 parts of an accelerator; and the component C comprises the following components by weight: 1-23 parts of dolomite powder, 15-46 parts of bariumsulfate powder, 10-121 parts of cement, 385-588 parts of sea sand, and 0.1-1.5 parts of a defoamer. The quick-setting epoxy grouting mortar provided by the invention has the technical characteristicsof short curing time, high hour strength, and no flash polymerization during high temperature construction, at the same time is non-toxic and harmless, and is simple to prepare, and is widely applicable to concrete structure repair with quick-setting and early strength requirements and construction of installation and anchoring projects, especially suitable for summer repair construction.

Owner:中冶武汉冶金建筑研究院有限公司

Ddelay coking defoaming agent composition and preparation method thereof

ActiveCN103768832AImprove defoaming abilityReduce the amount addedThermal non-catalytic crackingFoam dispersion/preventionAlcoholSolvent

The invention relates to a delay coking defoaming agent composition and a preparation method thereof, the defoaming agent is prepared by compounding fluorine-containing polysiloxane, glycerin type dendritic polyether, high carbon alcohol and a solvent. The preparation method of the defoaming agent is as follows: dispersing the fluorine-containing polysiloxane in the high carbon alcohol, stirring for 1 to 2 hours at 10-30 DEG C, then adding the glycerin type dendritic polyether and the solvent, stirring for 1 to 5 hours at 100-150 DEG C, and cooling to obtain a defoaming agent product. The delay coking defoaming agent has excellent defoaming antifoaming performances at 400-500 DEG C, in a high temperature delay coking process, the delay coking defoaming agent can still maintain good defoaming antifoaming performances and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Defoaming agent

PendingCN110681187AImprove defoaming abilityLong foam suppression timeFoam dispersion/preventionPtru catalystPreservative

The invention relates to the technical field of chemical additives, and specifically discloses a defoaming agent. The defoaming agent is at least prepared from the following preparation raw materials:10 to 30 parts of an organic silicon composition, 1 to 10 parts of hydrogen-containing polysiloxane, 1 to 10 parts of vinyl polysiloxane, 2 to 12 parts of allyl polyether, 0.1 to 2 parts of a catalyst, 5 to 20 parts of an emulsifier, 1 to 5 parts of a thickener, 1 to 5 parts of a preservative and 50 to 90 parts of water. The organic silicon defoaming agent which is high in defoaming speed, long in foam inhibition time, excellent in dispersing performance and outstanding in defoaming durability is prepared through a special formula and process, and what's more important, the defoaming agent prepared through the preparation method is good in product stability, not prone to demulsification and free of oil floating under the conditions of high temperature and strong alkali, and the preparation method is simple and low in cost.

Owner:SHANGHAI BAOLIJIA NEW MATERIAL CO LTD

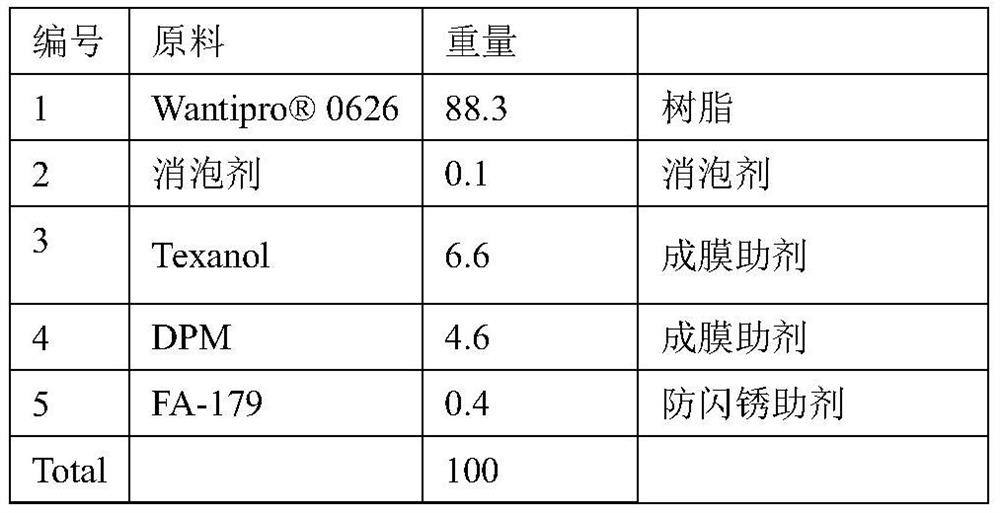

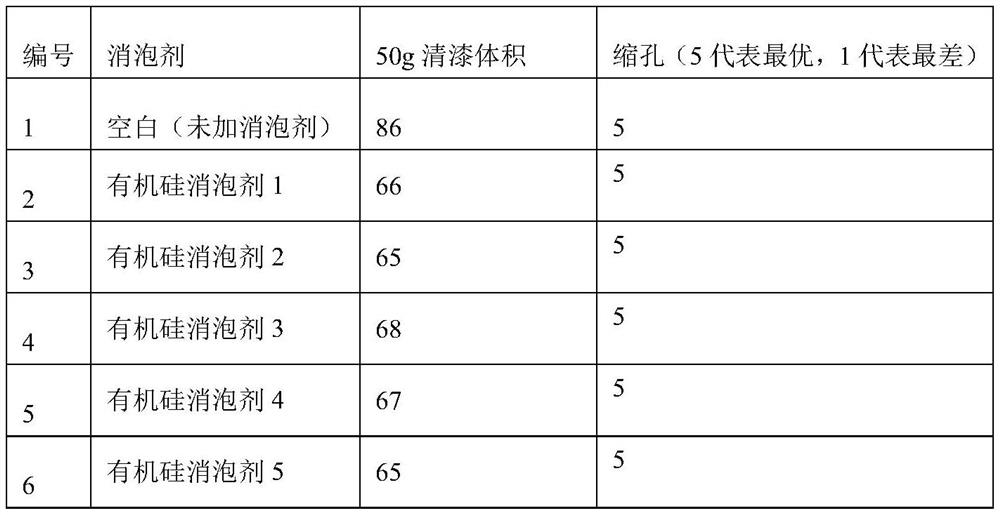

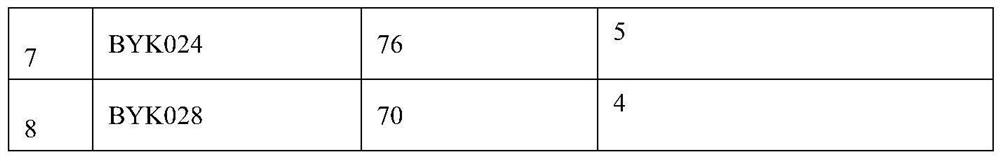

Organic silicon defoaming agent capable of being used for water-based coating material and preparation method thereof

ActiveCN113069796ARaw materials are easy to getSimple processFoam dispersion/preventionEnd-groupEngineering

The invention relates to an organic silicon defoaming agent for a water-based coating material and a preparation method thereof. The preparation method comprises the following steps: (1) synthesizing isomeric alcohol ether terminated allyl polyether; (2) synthesizing end group isomeric alcohol ether terminated polyether modified silicone oil; (3) preparing silicon paste; and (4) preparing the defoaming agent. According to the invention, end group isomeric alcohol ether terminated polyether modified polysiloxane with a symmetrical structure is used, a hydrophilic eo chain segment, a hydrophobic po chain segment and an isomeric macromolecular alkyl alcohol ether group are simultaneously introduced to the end group of a polysiloxane chain, and the hydrophilic and hydrophobic properties of the polymer can be effectively adjusted by controlling the ratio of eo to po, so that better defoaming performance is realized; and the organic silicon defoaming agent disclosed by the invention has the advantages of easily available raw materials, simple process, good stability, capability of effectively eliminating foams of a water-based coating material system, excellent defoaming and foam inhibition performance, difficulty in causing the defects of shrinkage cavities and the like, good wetting performance and capability of saving the use amount of a wetting agent in the water-based coating material.

Owner:WANHUA CHEM GRP CO LTD

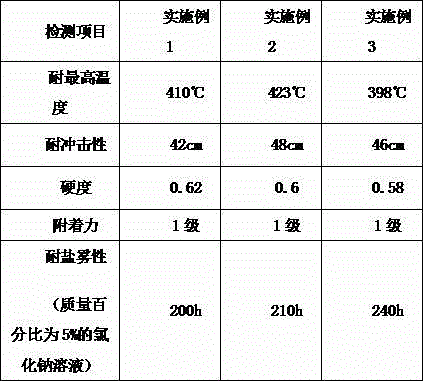

High temperature resistant coating and preparation method thereof

InactiveCN104629559AGood volatilization effectReduce volatilityFireproof paintsAnti-corrosive paintsPtru catalystAcrylic resin

The invention discloses a high temperature resistant coating and a preparation method thereof. The high temperature resistant coating is composed of an A component and a B component, wherein the A component is as follows: 65-68 parts of acrylic resin, 42-45 parts of bisphenol A epoxy resin, 20-25 parts of castor oil, 18-24 parts of mica powder, 12-16 parts of benzyl silicon resin, 20-25 parts of silicone resin, 2-4 parts of defoaming agent, and 45-50 parts of solvent; the B component is as follows: 2-4 parts of rust-inhibiting additive, 10-12 parts of flatting agent, 2-5 parts of catalyst, 8-12 parts of pigment, and 11-13 parts of surfactant. The invention further provides the preparation method of the coating. The coating is not only strong in high temperature resistance and good in fire prevention and corrosion resistance, but also good in adhesion and hard to fall off; the coating is small in surface friction coefficient, friction resistant, various in colors, long in service life, wide in use range, environment-friendly and lowered in cost.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Defoaming active matter, preparation method thereof and defoaming agent

ActiveCN110898467AStrong defoaming abilityThe preparation process is simple and controllableFoam dispersion/preventionDefoamerChemistry

The invention relates to the technical field of fine chemical preparations, in particular to a defoaming active matter, a preparation method thereof and a defoaming agent. The defoaming active mattercomprises the following raw materials by weight: 40-80 parts of terminal hydroxyl-containing polysiloxane, 2-20 parts of hydrogen-containing polyorganosilicone siloxane, 2-15 parts of filler, 0.5-10 parts of organic silicon resin, 5-20 parts of polyether modified polysiloxane, 5-20 parts of polyfluorosiloxane, 0.01-0.08 part of a basic catalyst and 1-20ppm of a dehydrogenation catalyst. By adopting the above raw materials and controlling the ratio, the prepared defoaming active matter has good affinity with water, then the defoaming active matter can be rapidly dispersed in water, and then canachieve rapid and long-term defoaming. Meanwhile, the defoaming active matter also has good defoaming capacity even if being violently shaken, and can achieve complete defoaming and avoid residual foams.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

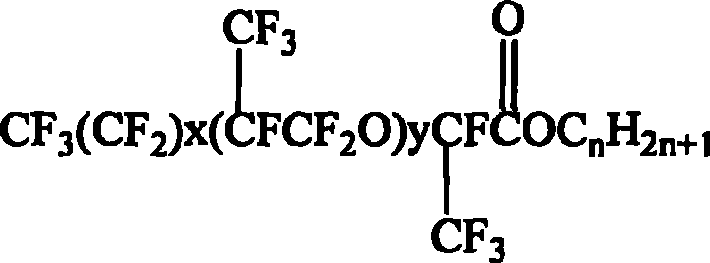

Polyether modified organosilicon, defoamer composition and application thereof

The invention relates to a polyether modified organosilicon, a defoamer composition and application thereof. The structural general formula of the polyether modified organosilicon is shown as the specification. According to the invention, firstly hydrogen-containing silicone oil, allyl polyether (non-hydroxy ended) and allyl glycidyl ether are subjected to hydrosilylation to obtain modified organosilicon containing polyether unit and epoxy group simultaneously, then a substance containing active hydrogen, i.e. a compound containing COOH, OH, SH or NH is employed for reaction with the epoxy group in the above modified organosilicon to generate hydroxyl, and then hydroxyl-containing polyether-modified organosilicon can be obtained. Finally, the hydroxyl-containing polyether-modified organosilicon, hydrophobic fumed silica particles, an emulsifier and deionized water are combined to form a waterborne organosilicon defoamer emulsion. The method adopted by the invention efficiently prepareshydroxyl-containing polyether-modified organosilicon, avoids dehydrogenation side reaction, and the finally formed waterborne defoamer composition has excellent defoaming ability in waterborne paintor waterborne ink.

Owner:AFCONA CHEM HAIMEN

A photoresist developer

InactiveCN1963677AImprove performanceExcellent developabilityPhotosensitive material processingArylAlkalinity

This invention relates to one light resistance image development liquid, which comprises Gemini surface active agent, alkalinity compound and solvent agent, wherein, the surface active agent has the following structure and the R1,R2,R3,R4,R5,R'1,R'2,R'3,R'4,R'5 separately are selected from hydrogen, alkyl, aryl, aralkyl radical, halide; R6 for 2 to 6 methano and n for 6 to 23 integral numbers.

Owner:深圳市合力泰光电有限公司

Alkaline-based developer composition

ActiveCN101178548AAvoid legacyExcellent developabilityPhotosensitive material processingHydrogenUltraviolet

The alkaline developing solution of the present invention is applied to image formation after photosensitive resin is exposed to ultraviolet (UV), and its composition includes (A) pure water, (B) at least one basic compound, (C) content A defoamer less than 500ppm, (D) at least one nonionic surfactant with a total content of 0.05 to 10%; wherein, the structural formula of the nonionic surfactant is: the key point is: in the structural formula of the nonionic surfactant R1 is hydrogen (-H) or methane (-CH3); EO is polyoxyethylene; PO is polyoxypropylene, m and n cannot be zero at the same time, m+n is less than 25, and R2 is Hydrophobic base.

Owner:ECHEM SOLUTIONS

Mildew-proof and bactericidal environmentally friendly coating

InactiveCN108410285AStrong complementarityImprove the bactericidal effectAntifouling/underwater paintsPaints with biocidesEpoxyPyrophyllite

The invention provides a mildew-proof and bactericidal environmental friendly coating. The coating comprises the following components in parts by weight: 25-32 parts of polyvinyl alcohol, 15-18 partsof a polyacrylate emulsifier solution, 8-10 parts of nano attapulgite, 11-13 parts of nano kaolinite, 8-10 parts of pyrophyllite, 12-15 parts of shell powder, 1.2-1.5 parts of zinc oxide, 0.8-1 part of polyacrylamide, 6-8 parts of epoxy resin, 0.7-1.0 part of a mineral oil defoaming agent, 0.5-0.8 part of nano titanium oxide, 10-12 parts of gas cleaning bactericidal powder, 3-5 parts of sepiolitepowder, 0.2-0.3 part of a polyacrylate ammonium salt dispersing agent, 0.1-0.2 part of carboxymethylcellulose, 3-5 part of coconut oil and 50-60 parts of deionized water. The gas cleaning bactericidalpowder is formed by pulverizing dry wormwood, cape jasmine, lemon-scented gum leaves, Eucalyptus Gunnii leaves and lemon-grass according to the mass ratio of 3: 1: 1: 2: 1, and then mixing the foregoing components.

Owner:晋控煤业金宇高岭土山西有限公司

Anti-fall graphene lacquer and preparing method thereof

The invention provides an anti-fall graphene lacquer and a preparing method thereof. The anti-fall graphene lacquer is prepared from, by weight, 20-35 parts of emulsion, 3-5 parts of hydroxyethyl cellulose, 7-12 parts of graphene, 65-80 parts of natural colorful sand, 0.8-1.4 parts of antifoaming agent, 0.5-1.5 parts of adhesion promoter, 0.5-1 part of thickening agent, 5-10 parts of coalescing agent, 1-2 parts of N-aminopropyl-methylethanolamine and 25-45 parts of water. By adding graphene in the composition, hydroxyethyl cellulose is compounded with graphene, the softness and adhesion of thelacquer are improved while the agglomeration problem of graphene is solved, and the compactness of the lacquer coating is improved, so that after the lacquer is used for a long time, the phenomena like stripping and bubbling are not generated.

Owner:XIAMEN GULIKE ENERGY SAVING TECH CO LTD

Corrosion-resistant water-borne coating and preparation method thereof

InactiveCN105176269AGood adhesionEasy accessAnti-corrosive paintsEpoxy resin coatingsMeth-Acrylic resin

The invention discloses a corrosion-resistant water-borne coating. The components of the corrosion-resistant water-borne coating include in parts by weight: 40 to 45 parts of acrylic resin, 20 to 23 parts of bisphenol-A epoxy resin, 5 to 8 parts of potassium methylsilanol, 7 to 9 parts of magnesium stearate, 10 to 15 parts of epoxy-modified organic silicone resin, 8 to 12 parts of silicon carbide, 12 to 15 parts of titanium dioxide, 20 to 30 parts of deionized water, 35 to 40 parts of water, 5 to 8 parts of alkyd resin, 15 to 18 parts of talcum powder and 3 to 4 parts of propylene glycol monomethyl ether. Not only is the corrosion resistance of the coating good, but also the adhesion is good, so the coating cannot easily shed; the surface friction coefficient of the coating is small, so the coating can resist abrasion; moreover, colors are diversified; the service life is long, and problems, such as blistering, cracking, whitening and even leafing, cannot take place after the coating is used for a long time; moreover, the coating can be used under harsh environments, so the range of application is wide.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

High temperature resistant defoaming agent and application thereof in delay coking

ActiveCN103768830AReduce surface tensionLow chemical inertnessThermal non-catalytic crackingFoam dispersion/preventionSilazanePolysilazane

The invention relates to a high temperature resistant defoaming agent and application thereof in delay coking, the defoaming agent is prepared by compounding fluorine-containing polysiloxane, hyperbranched polyether, modified nano silica, vinyl-containing polysilazane and a solvent under certain conditions. A preparation method of the defoaming agent is as follows: dispersing required specifications of the fluorine-containing polysiloxane, the hyperbranched polyether and the modified nano silica in the solvent at a constant temperature of 60-100 DEG C, then cooling to room temperature, mixing, simultaneously adding the vinyl-containing polysilazane, and then filtering away non-homogeneous impurities to obtain the defoaming agent finished product. The efficient multi-active-component defoaming agent used in the delay coking process has good defoaming and anti-foaming properties at a high use temperature, also can maintain the high chemical stability, and is not easy to generate low-boiling-point silicon-containing small molecules cyclized compounds, and the adverse influence of the defoaming agent on the subsequent processing process can be avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

Defoaming type polycarboxylate superplasticizer and preparation method thereof

The invention relates to the technical field of concrete admixtures, in particular to a defoaming type polycarboxylate superplasticizer and a preparation method thereof. The defoaming type polycarboxylate superplasticizer is prepared from a first esterification product and hydrogen-containing silicone oil through hydrosilation reaction. The first esterification product is prepared by esterifying a first polymer and grafting the first polymer with an unsaturated polyoxyethylene ether monomer. The first polymer is prepared from an unsaturated polyoxyethylene ether monomer, an acrylate monomer and unsaturated carboxylic acid through a copolymerization reaction. The defoaming type polycarboxylate superplasticizer provided by the invention has the functions of defoaming and foam inhibition while having a high water reducing effect, is high in defoaming capacity and good in stability, and effectively avoids the problem of poor gas content control effect caused by poor compatibility of compounding of the polycarboxylate superplasticizer and the defoaming agent and poor placement stability.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

A kind of preparation method of organosilicon defoamer

ActiveCN103830938BGood lookingSuitable for centrifugal layeringFoam dispersion/preventionEmulsionSurface-active agents

The invention provides a preparation method of an organic silicon defoamer, and relates to the field of a production technology of fine chemical products. The organic silicon defoamer is stable emulsion formed by carrying out emulsification processing on components such as simethicone and a nonionic surface active agent under specified conditions. The prepared organic silicon defoamer has the characteristics of being high in defoaming speed, high in foam inhibition capability, non-toxic, good in adaptability, less in dosage, simple in technology, etc.

Owner:扬州晨化新材料股份有限公司

Vacuum defoaming device and foam removal method adopting device

ActiveCN107551607AImprove defoaming abilityReduce the number of bubblesFoam dispersion/preventionSelf weightEngineering

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Rusty scale growth inhibitor for rusted steel and preparation method thereof

InactiveCN103882418AGrowth inhibitionReduce corrosionMetallic material coating processesGrowth retardantGallic acid ester

The invention discloses a rusty scale growth inhibitor for rusted steel. The rusty scale growth inhibitor is prepared from the following raw materials in parts by weight: 50-100 parts of inorganic acid, 50-100 parts of gallic acid, 10-100 parts of aluminum triphosphate, 10-50 parts of potassium hydrogen tartrate, 30-50 parts of thiourea, 100-300 parts of isoamylol, 10-50 parts of surfactant, 1-50 parts of defoamer, 1-30 parts of thickener and 500-800 parts of water. The inhibitor can infiltrate into the deep part of the rusty scale, acts with active gamma-FeOH, and inhibits transformation to Fe3O4, so as to inhibit growth of an iron scale. In addition, chelate transformation reaction also can be carried out on the existing iron scale, and the iron scale is transformed into an inert protection layer. The inhibitor is broad in demands on the thickness of the rusty scale, does not cause corrosion to a steel base material, and can replace artificial derusting treatment, and the rusted steel base material reacting by the inhibitor can be directly coated with an anticorrosive primer.

Owner:STATE GRID CORP OF CHINA +2

Water high light wearable intaglio ink and preparing method thereof

ActiveCN100575433CStrong color loading capacityFine inkInksOther printing apparatusWater basedHigh concentration

Owner:浙江永在油墨有限公司

Iron ore reverse flotation reagent and application method thereof

ActiveCN108906336AStrong harvesting abilityBalance collection capacityFlotationSodium fluorideReverse flotation

The invention discloses an iron ore reverse flotation reagent and an application method thereof. The iron ore reverse flotation reagent comprises following components including, by weight, 50-60 partsof dodecylamine hydrochloride, 40-50 parts of dodecyl trimethyl ammonium chloride, 10-15 parts of sodium fluoride, 10-15 parts of water glass, 10-15 parts of polyacrylamide, 15-20 parts of sodium tripolyphosphate, 10-20 parts of inhibitor and 3-5 parts of pH adjusting agents. The iron ore reverse flotation reagent has the beneficial effect of being relatively high in separation selectivity for valuable minerals and gangue minerals.

Owner:山西亚鑫能源集团有限公司

Defoaming agent

InactiveCN107130432AReduce surface tensionImprove surface activityFibre treatmentSolventChemical stability

The invention relates to a defoaming agent, in particular to a defoaming agent for textile. The defoaming agent is prepared from the following components in parts by weight: 10 to 20 parts of silicone grease, 15 to 25 parts of polyether, 3 to 6 parts of sodium lauryl sulfate, 20 to 30 parts of aliphatic hydrocarbon, 2 to 5 parts of sodium chloride, 1 to 3 parts of cosolvent, and 130 to 180 parts of deionized water. The defoaming agent has the characteristics that the silicone grease, an emulsifier, a thickener and the like are mixed with a proper amount of water to be mechanically emulsified; the surface tension is small, the surface activity is high, the defoaming ability is strong, the usage amount is small, and the cost is low; most of air bubble mediums can be defoamed; the heat stability is better, and the defoaming agent can be used in the broad temperature range; the chemical stability is better, the reaction with other matters is difficult, the defoaming agent can be used in acid, alkaline and salt solutions, and the damage to product quality is avoided; the defoaming agent can be applied to defoam in the dyeing, refining and sizing process of textile industry.

Owner:王蒙

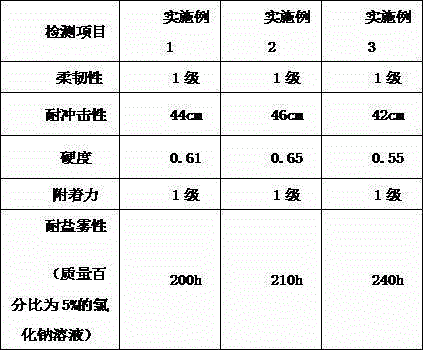

Anti-oxidation emulsion and anti-oxidation waterborne coating varnish prepared from same

ActiveCN107033288AImprove defoaming abilityStrong anti-foaming abilityPaper coatingCorrosion-inhibiting/anti-oxidant agent additionCardboardHot stamping

The invention relates to the technical field of coating varnish, in particular to anti-oxidation emulsion and anti-oxidation waterborne coating varnish prepared from the same. The anti-oxidation emulsion is prepared from raw materials in percentage by weight as follows: 30%-50% of an acrylic resin solution with neutral pH, 29%-41% of mixed monomers, 0.5%-1% of an emulsifier, 0.3%-0.8% of an initiator, 0.01%-0.05% of an oxidizing agent, 0.01%-0.05% of a reducing agent and 10%-25% of deionized water, and the sum of the raw materials in percentage by mass is 100%. According to the anti-oxidation emulsion, possibly existing acid-base substances can be reduced, the probability of oxidation is reduced, and hot stamping foil is not prone to oxidation; the anti-oxidation waterborne coating varnish prepared from the anti-oxidation emulsion contains no organic solvents, is low in content of VOCs (volatile organic chemicals) or free of VOCs, is environment-friendly, non-toxic and anti-oxidation, and is suitable for surface lustering of substrates, prone to hot stamping oxidation, of black cardboards, blackened paper, coated black paper and the like.

Owner:GUANGDONG YINGKE GRP CO LTD

Petroleum natural gas pipeline corrosion inhibitor prepared by waste grease and method thereof

The invention relates to a petroleum and natural gas pipe corrosion inhibitor prepared by use of waste greases and a method for preparing the petroleum and natural gas pipe corrosion inhibitor. Main raw materials of the petroleum and natural gas pipe corrosion inhibitor come from recycling of the waste greases. The preparation method comprises the following steps that: the waste greases are purified and classified; the greases are degraded through immobilized lipases so as to generate fatty acids; the fatty acids generate animation reaction with cyclohexylamines and ethoxyl ethylene diamines; the petroleum and natural gas pipe corrosion inhibitor is prepared by adoption of the purified greases as carriers and addition by mass percent of 0.5 to 1.5 percent of animation reaction products, 0.1 to 0.3 percent of pyridine oxalates, 0.1 to 0.3 percent of cyclohexylamines, 0.05 to 0.15 percent of AMP96, 0.3 to 0.8 percent of silane coupling agents, 0.05 to 0.15 percent of defoaming stabilizers and 0.3 to 0.8 percent of mildew inhibitors. The corrosion inhibitor has good multiphase inhibition performance on petroleum and natural gas metal pipes and realizes recycling of the waste greases by adoption of the latest environment-friendly and energy conservation technology.

Owner:CHENGDU DUZHIJIE SCI & TECH

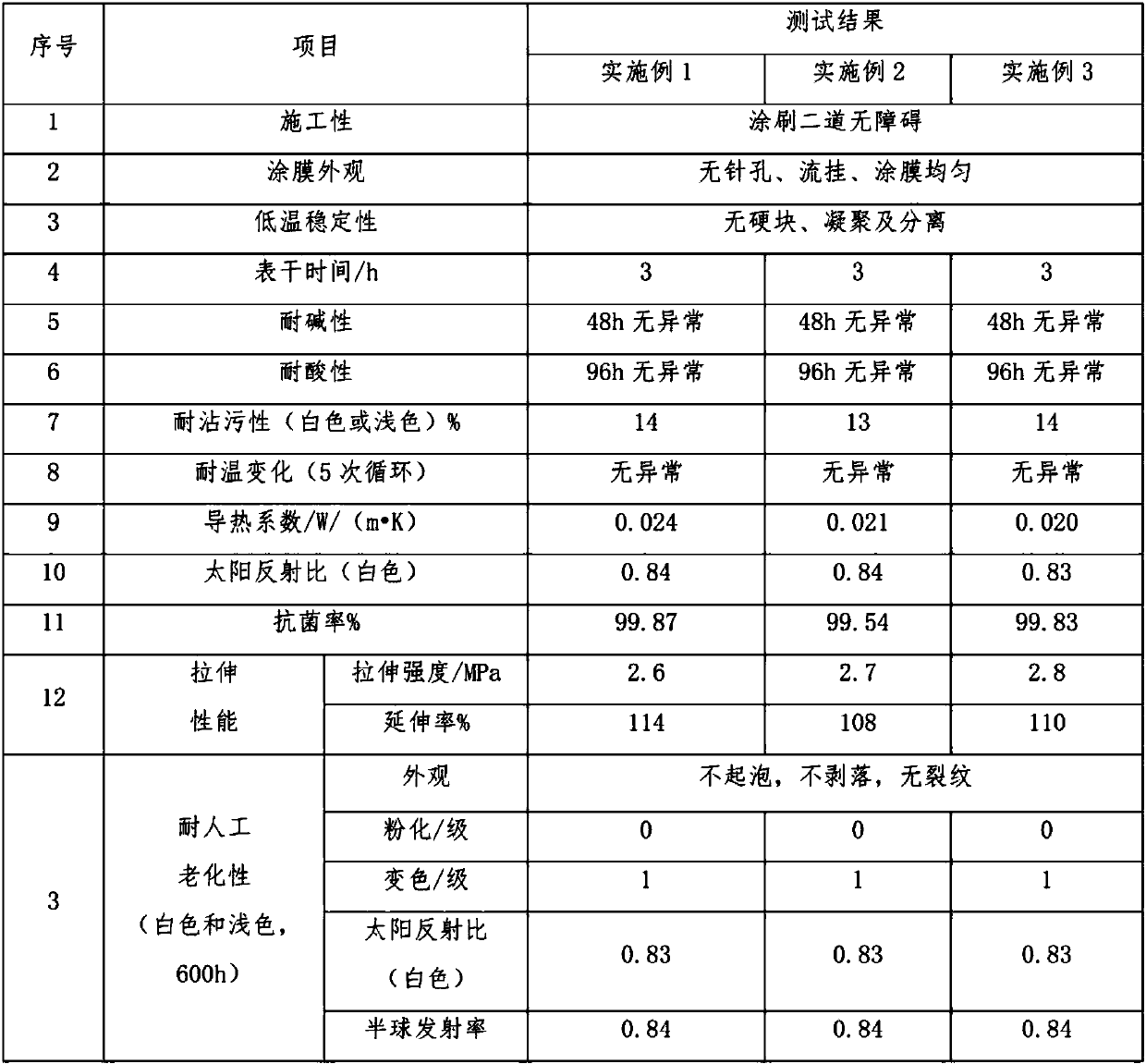

Aqueous nano hollow glass bead heat-preservation thermal-insulating coating and preparation method thereof

InactiveCN110218491AShort surface drying timeImprove anti-agingAntifouling/underwater paintsPaints with biocidesDrying timeSodium salt

The invention discloses an aqueous nano hollow glass bead heat-preservation thermal-insulating coating and a preparation method thereof. The aqueous nano hollow glass bead heat-preservation thermal-insulating coating consists of the following components in parts by weight: 10.5-20 parts of deionized water, 0.8-1 part of hydroxyethyl cellulose, 40-45 parts of a pure acrylic emulsion, 0.6-0.8 part of a 5040 sodium salt dispersant, 0.2-0.3 part of a wetting agent, 15-20 parts of nano titanium dioxide, 5-10 parts of a calcium carbonate pigment filler, 0.15-0.2 part of an AMP-95 multifunctional aid, 5-8 parts of a texanol film formation aid, 1.5-2 parts of an ethylene glycol anti-freezing agent, 0.2-0.3 part of a fungicide, 0.2-0.3 part of an anti-mold agent, 0.2-0.4 part of a 681F defoaming agent, 0.5-1.2 parts of a thickening agent and 20-25 parts of hollow glass beads. The aqueous nano hollow glass bead heat-preservation thermal-insulating coating disclosed by the invention has the advantages of being short in surface drying time, excellent in anti-aging property, low in heat conduction coefficient, good in heat-preservation thermal-insulating property, excellent in tension resistance, and the like.

Owner:重庆多仑建材有限公司

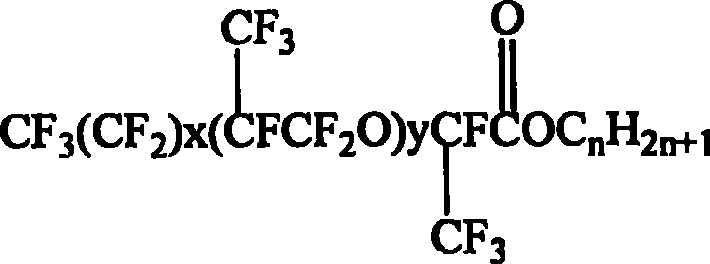

Synthesis of hexafluoropropylene oxide oligomer type fluorocarbon surfactant and use thereof

InactiveCN101380556AImprove solubilityImprove defoaming abilityTransportation and packagingMixingTextile printerCarbon number

The invention relates to a synthetic method of novel oil-soluble fluorocarbon surfactant with hexafluoropropylene oxide oligomer type and the application thereof. The invention is characterized in that the structure of the series of the novel fluorocarbon surfactant is characterized in that: a. a hydrocarbon chain segment with excellent oil-solubility is adopted as an oil-wet end and the hexafluoropropylene oxide oligomer is adopted as a fluorine chain segment; b. the fluorine chain segment also contains oxygen atom, thus improving the flexibility and dispersion capacity of the fluorocarbon surfactant; c. the length of the hydrocarbon chain segment in molecule is adjustable and the carbon number thereof is in the range of 8 to 18; d. the molecule contains an ester group. The synthetic method of the surfactant is simple and convenient and is applicable to industrial production; the surfactant has good surface activity in organic solvent, can reduce the surface tension of the organic solvent remarkably, can still keep very high surface activity in strong acid or strong alkali, is a good surfactant and can be used in the industries of electroplating industry, textile printing, petroleum, coatings and inks, and the like.

Owner:张永明 +2

Soybean milk defoamer and preparation method thereof

InactiveCN103330003AIncrease nutritionHas physiological health effectsMilk substitutesFood scienceGlycerolCarbon chain

The invention relates to a soybean milk defoamer and a preparation method thereof. The preparation method of the soybean milk defoamer comprises the steps that phospholipase A1, phospholipase A2 and phospholipase D are utilized to carry out enzymolysis ester bond on granulesten and soybean oil, so that the mixture which has the main compositions of phospholipid, glycerol, fatty acid with different carbon chain lengths, and soybean oil is formed, and the oleophylic and defoaming capabilities are reinforced, the HLB (hydrophile-lipophile balance) value is within the range of 2.4-2.8, the efficient and rapid defoaming effect is realized, and the use level of the defoamer is reduced due to the strong defoaming capability. As the soybean milk defoamer is a natural product and reaches the food security level, the use level is not strictly limited, and the use level reaching the defoaming effect is recommended; the phospholipid has the physiological health care efficacy, and the nutrition of the soybean milk is increased with the adoption of the soybean milk defoamer; and the soybean milk defoamer can be hermetically contained in a container for storage at the temperature of 4 DEG C below zero, and the use method of the soybean milk defoamer is as simple as that of a chemical defoamer.

Owner:袁怀波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com