Defoaming active matter, preparation method thereof and defoaming agent

An active substance and defoaming technology, which is applied in the field of defoaming agents and defoaming active substances, can solve the problems of foam occupying space, operation fluctuation, and affecting reaction speed, etc., to achieve controllable preparation process, good defoaming ability, and avoid residue Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] Further, the embodiment of the present invention also provides a preparation method of an antifoaming active substance, comprising:

[0067] Mix and react polyorganosiloxane containing terminal hydroxyl group, polyorganosiloxane containing hydrogen, filler, silicone resin, polyether modified polysiloxane, polyfluorosiloxane basic catalyst and dehydrogenation catalyst The antifoam active is formed.

[0068] Specifically, the polyorganosiloxane containing terminal hydroxyl groups, the hydrogen-containing polyorganosiloxane and the dehydrogenation catalyst are subjected to a dehydrogenation polymerization reaction to obtain a 3D network polysiloxane with a micro-crosslinked structure; The micro-crosslinked structure is a three-dimensional network structure. Then, it further undergoes random copolymerization reaction with organic silicon resin, polyether modified polysiloxane, polyfluorosiloxane and filler to obtain defoaming active material.

[0069] Specifically, the po...

Embodiment 1

[0074]This embodiment provides a defoaming active substance, the raw materials of which include 60g polyorganosiloxane containing terminal hydroxyl group, 5g hydrogen-containing polyorganosiloxane, 10g fine filler, 3g silicone resin, 10g polyether modified polysilicon Oxane, 12g polyfluorosiloxane, 0.05g basic catalyst and 10ppm dehydrogenation catalyst.

[0075] The structural formula of hydroxyl-terminated polysiloxane is:

[0076]

[0077] Among them, the R group is -CH 3 , n=100.

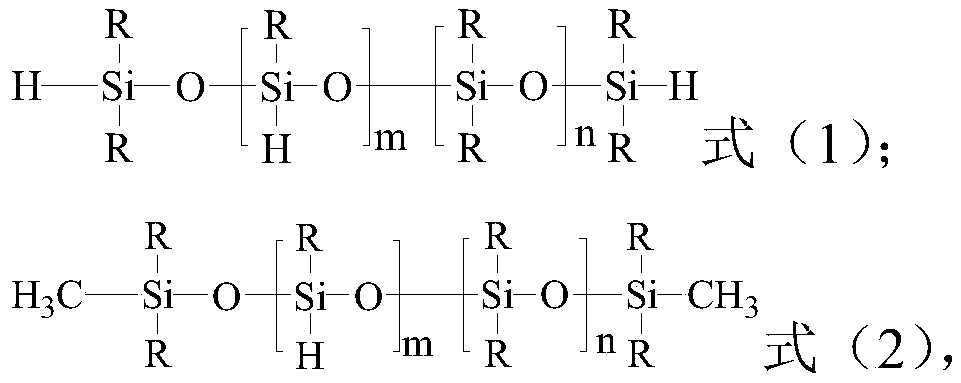

[0078] The structural formula of hydrogen-containing polyorganosiloxane is as follows:

[0079]

[0080] Among them: R group is -CH 3 , n=28.

[0081] The structural formula of polyfluorosiloxane:

[0082]

[0083] Among them: R group is -CH 3 , n=80.

[0084] Among them, the hydroxyl-terminated polyorganosiloxane is a hydroxyl silicone oil with a dynamic viscosity of 200 mPa s; the hydrogen-containing polyorganosiloxane is a methyl hydrogen-containing silicone oil with a dynamic...

Embodiment 2

[0091] This embodiment provides an antifoaming active substance, the raw materials of which include 50g polyorganosiloxane containing terminal hydroxyl group, 2g hydrogen-containing polyorganosiloxane, 5g fine filler, 5g silicone resin, 18g polyether modified polysilicon Oxane, 20g polyfluorosiloxane, 0.01g basic catalyst and 20ppm dehydrogenation catalyst.

[0092] The structural formula of hydroxyl-terminated polysiloxane is:

[0093]

[0094] Among them, the R group is -CH 3 , n=190.

[0095] The structural formula of hydrogen-containing polyorganosiloxane is as follows:

[0096]

[0097] Among them: R group is -CH 3 , n=60.

[0098] The structural formula of polyfluorosiloxane:

[0099]

[0100] Among them: R group is -CH 3 , n=260.

[0101] Among them, the hydroxyl-terminated polyorganosiloxane is a hydroxyl silicone oil with a dynamic viscosity of 500 mPa s; the hydrogen-containing polyorganosiloxane is a methyl hydrogen-containing silicone oil with a dyn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com