Polycarboxylic acid water reducing agent as well as preparation method and application thereof

A technology of water reducing agent and polycarboxylic acid, which is applied in the field of polycarboxylic acid water reducing agent and its preparation, can solve the problems of low strength and high air content in concrete, and achieve low volatility, outstanding defoaming ability and excellent performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

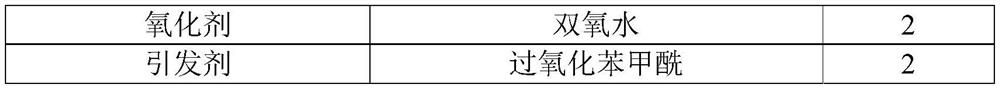

[0040] This embodiment provides a polycarboxylate water reducer, the raw materials for the preparation of the polycarboxylate water reducer include the following components in parts by weight:

[0041]

[0042]

[0043] The preparation method of described polycarboxylate water reducer comprises the following steps:

[0044] (1) Mix methacrylic acid, methyl methacrylate, polyethylene glycol and hydrogen peroxide, and carry out an esterification reaction at 65° C. for 5 hours to obtain a prepolymer;

[0045](2) Mix the prepolymer obtained in step (1), vinyltriethoxysilane and benzoyl peroxide, and carry out a free radical polymerization reaction at 85° C. for 3 hours to obtain the polycarboxylic acid water-reducing agent.

Embodiment 2

[0047] This embodiment provides a polycarboxylate water reducer, the raw materials for the preparation of the polycarboxylate water reducer include the following components in parts by weight:

[0048]

[0049] The preparation method of described polycarboxylate water reducer comprises the following steps:

[0050] (1) Mix methacrylic acid, methyl methacrylate, polyethylene glycol and hydrogen peroxide, and carry out an esterification reaction at 65° C. for 5 hours to obtain a prepolymer;

[0051] (2) Mix the prepolymer obtained in step (1), vinyltrimethoxysilane and benzoyl peroxide, and carry out a free radical polymerization reaction at 85° C. for 3 hours to obtain the polycarboxylate water reducer .

Embodiment 3

[0053] This embodiment provides a polycarboxylate water reducer, the raw materials for the preparation of the polycarboxylate water reducer include the following components in parts by weight:

[0054]

[0055]

[0056] The preparation method of described polycarboxylate water reducer comprises the following steps:

[0057] (1) Mix methacrylic acid, hydroxyethyl acrylate, polyethylene glycol and hydrogen peroxide, and carry out an esterification reaction at 55° C. for 5 hours to obtain a prepolymer;

[0058] (2) Mix the prepolymer obtained in step (1), vinyltrimethoxysilane and azobisisobutyronitrile, and carry out a free radical polymerization reaction at 75°C for 3h to obtain the polycarboxylate water-reduced agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com