Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

120 results about "ROSIN POWDER" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cement concrete air entraining agent and method for preparing same

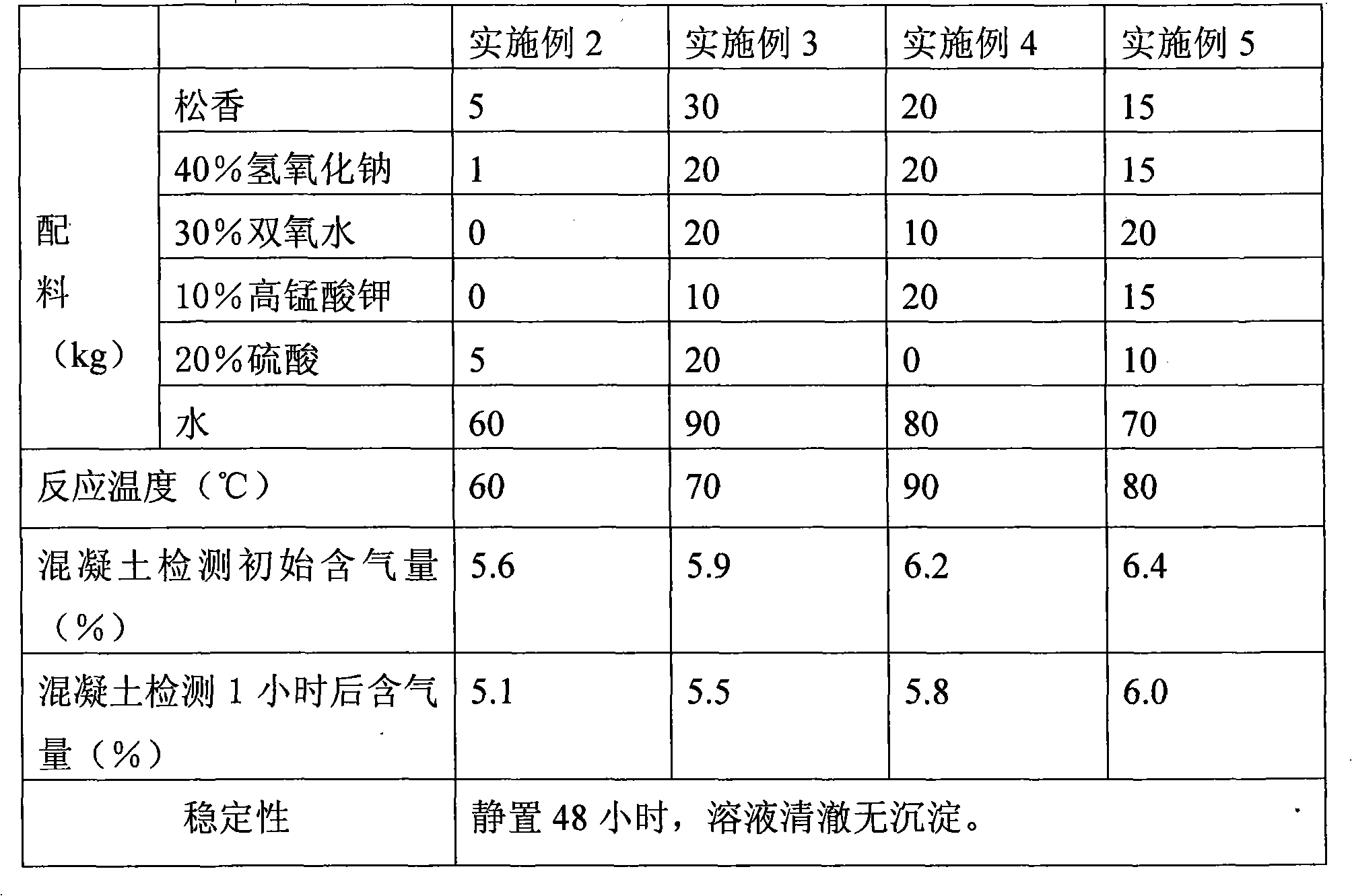

The invention discloses a cement concrete air-entraining agent, which is made from commercial primary, secondary or three-level ordinary rosin powder, commercial industrial-level sodium hydroxide, potassium permanganate, hydrogen peroxide, sulfuric acid and tap water through heated-stirring reaction at 60-90 DEG C; wherein, the weight proportions of the raw materials are as follows: 5-30 weight portions of rosin, 1-20 weight portions of sodium hydroxide solution, 0-20 weight portions of potassium permanganate solution, 0-20 weight portions of hydrogen peroxide solution, 0-20 weight portions of sulfuric acid solution, and 60-90 weight portions of tap water solution. The air-entraining agent disclosed in the invention can be stably preserved for a long time without rosin precipitation; the bubbles caused by the air-entraining agent are exquisite and have good stability, which can be used in cement mortar or concrete and other building materials.

Owner:BEIJING ZHONGYANYI ENG TECH DEV CENT

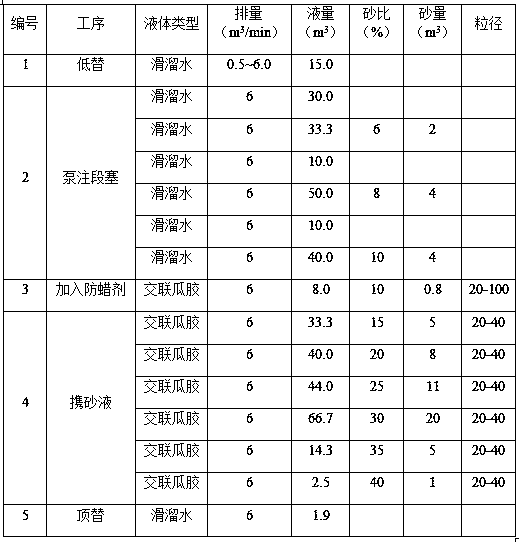

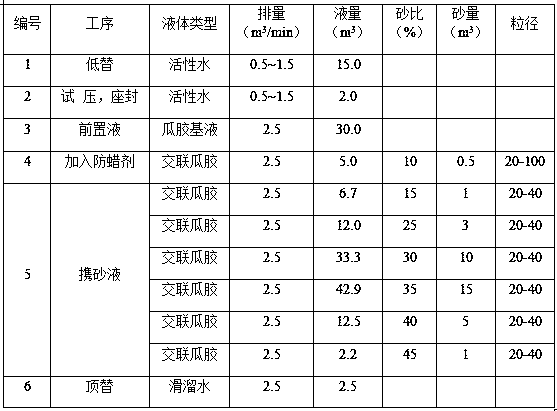

Wax inhibitor added during fracturing construction and preparation method and application thereof

ActiveCN108915637AExpand the scope of actionTo preventCleaning apparatusFluid removalROSIN POWDERSodium stearate

The invention provides a wax inhibitor added during fracturing construction. The wax inhibitor is prepared from the following raw materials in percentage by weight: 10%-20% of sodium stearate, 10%-20%of peregal O-25, 10%-15% of fatty alcohol polyoxyethylene lauryl ether sulfate sodium AES, 5%-10% of sodium dodecyl benzene sulfonate ABS, 0.5%-1% of ethylenediamine traacetic acid, 1%-2% of rosin powder, and the balance of quartz sand. Meanwhile, the invention also provides a preparation method and application of the wax inhibitor. The wax inhibitor provided by the invention does not need separate construction, is added during fracturing construction and can penetrate through the distal end of stratum, so that the action range of the wax inhibitor in the stratum is enlarged, the effective time is long, and the wax inhibitor can be slowly released in the stratum at 30 DEG C for about 2 years; wax inhibition is carried out before crude oil production, so that the source of wax production is directly cut off, and the generation of wax is fundamentally prevented; construction is convenient and construction cost is reduced.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

Method for preparing highly-doped fly ash lightweight heat-insulation bricks, and bricks prepared by same

The invention discloses a method for preparing highly-doped fly ash lightweight heat-insulation bricks. The preparation method comprises: preparing aluminum powder paste, sodium sulfate, sodium abietate, water, fly ash, carbide slag or lime powder and gypsum which are weighed in a ratio by weight into fly ash non-burnt ceramic particles; feeding fly ash, slag or coal gangue, carbide slag or lime powder, desulfurized gypsum or gypsum powder which are weighed in a ratio by weight into a wheel-grinding machine for wheel-grinding and obtaining a mixture; preparing rosin powder, sodium hydroxide, water together with gelatin and water together with triethanolamine which are weighed in a ratio by weight into admixture II; weighing the fly ash non-burnt ceramic particles, the mixture, cement and the admixture II in a ratio by weight and feeding the materials into a stirrer for stirring and adding water while stirring to adjust the water content of the materials to reach 17 to 21 percent; feeding the obtained product into a molding machine to prepare the obtained product into green brick bodies; and obtaining finished products through maintenance. The method has the advantages of low cost and no environmental pollution produced during production, and all standards of the lightweight heat-insulation bricks meet the requirements of national standards.

Owner:杜世永

Filtering agent for reducing content of coke tar in tobacco and preparation method thereof

The invention provides a tobacco tar reducing filtering agent and a method for preparing the same, and relates to a tobacco tar filtering material, which is applicable to tobacco manufacture industry and other assortative production industry. The filtering agent is mixed by rosin and active carbon, and the weight proportion of the rosin and the active carbon is 1-2: 0.2-1. The rosin is the Chinese medicine rosin, and the active carbon is the granule active carbon. The method for preparing the tobacco tar reducing filtering agent comprises the following steps: (1) weighting the raw materials namely the rosin and the active carbon in the proportion; (2) taking and grinding the rosin, and screening the rosin ground into powder through a 80 mesh sieve; and (3) mixing the screened rosin powder and the active carbon to prepare the tobacco tar reducing filtering agent. The tobacco tar reducing filtering agent has the advantages of innocuity and strong adsorbing function and can effectively reduce contents of tar and nicotine to really play a role in protecting human body health. The preparing method has the advantages of simpleness, feasibility and low cost and is suitable for marketing.

Owner:成寿林

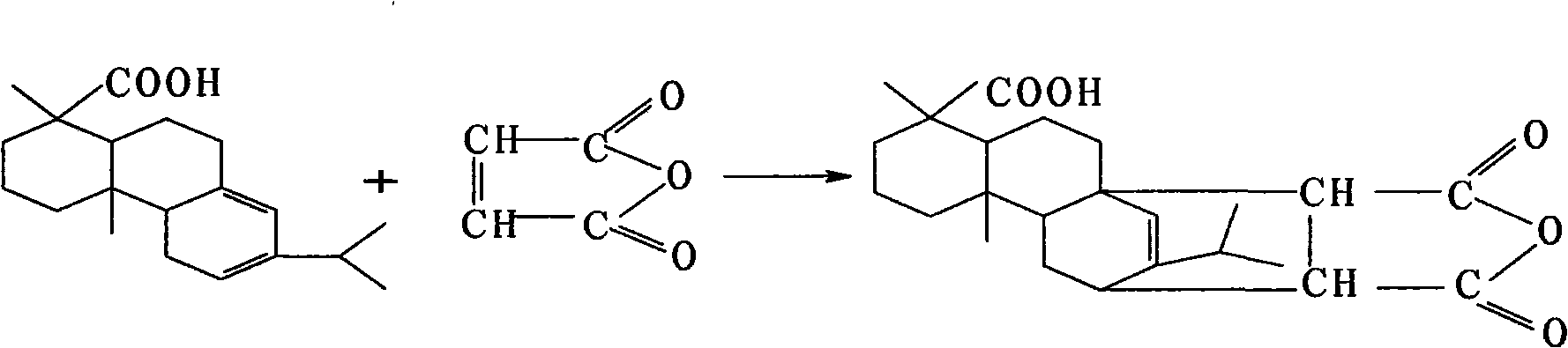

Preparation of maleated rosin polyethenoxy ether diester carboxyl acid natrium surfactant

InactiveCN101254429AStrong degreasing powerImprove water stabilityTransportation and packagingMixingROSIN POWDEREther

A method for producing maleated rosin sodium polyoxyethylene ether carboxylate surfactants is provided. The method includes the following steps: weighing high-quality rosin powder at the ratio given in the formulation, feeding 1 / 4 of the total weight of ground rosin into a four-mouth reactor, heating under incontinuously stirring, further stirring continuously after the powder is dissolved, adding the rest rosin, dissolving at 120-130 DEG C, prolonging the dissolution time, introducing nitrogen gas during the the dissolution process, slowly adding maleic anhydride at the ratio given in the formulation in four times after the rosin is dissolved completely, maintaining the temperature at 190-200 DEG C for 2 hours after the feeding of maleic anhydride is completed, to obtain the maleated rosin; adding the ground maleated rosin at the ratio given in the formulation into another four-mouth reactor, adding a certain amount of water-retaining agent, heating up until boiling, adding dropwise octyl phenol polyoxyethylene ether at the ratio given in the formulation and a small amount of catalysts to the system under stirring, reacting at a maintained temperature at 90 plus or minus 2 DEG C, adding dropwise and slowly the NaOH solution, stirring at a higher speed, reacting at a maintained temperature at 80 plus or minus 2 DEG C for 2 hours, cooling, and discharging.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Montmorillonoid modified waterproof and flame-retardant type biomass plate and preparation method thereof

InactiveCN106752001AImprove mechanical propertiesImprove waterproof performanceROSIN POWDERMelamine phosphate

The invention discloses a montmorillonoid modified waterproof and flame-retardant type biomass plate and a preparation method thereof. The montmorillonoid modified waterproof and flame-retardant type biomass plate is characterized in that rice straws, sulfate wood pulp, carboxyl modified silicone oil, gelatin, nano montmorillonoid, an emulsifier OP-10, liquid paraffin, rosin, polyacrylic acid, melamine phosphate, boric acid, hydrotalcite, pine oil and the like are used as raw materials. The preparation method comprises the following steps: adding the sulfate wood pulp in the rice straws and carrying out fibrillation; adding the carboxyl modified silicone oil to carry out reinforced modification; and adding the pine oil as a foaming agent. Rosin powder is used as a filling agent, and can be used as an adhesive after being melted at high temperature; by nano montmorillonoid modification, the mechanical property and the size stability of the plate are improved remarkably; a micro-capsule waterproof agent is prepared by single cogulation; a melamine phosphate-polypropylene salt-borate flame retardant is prepared, and by the synergistic effect of the melamine phosphate- polypropylene salt-borate flame retardant and the hydrotalcite, the flame-retardant effect is good; and the montmorillonoid modified waterproof and flame-retardant type biomass plate is obtained.

Owner:凤台县双利生物科技有限公司

Process for dyeing wool-cotton worsted fabric with vegetable dye

InactiveCN105970672AImprove diffusion abilityHigh fastnessDyeing processVegetal fibresROSIN POWDERDye absorption

The invention discloses a vegetable dye dyeing process for worsted wool and cotton fabrics, which comprises the steps of ultraviolet radiation treatment, dyeing, color fixing and the like. In the present invention, ultraviolet light is used to irradiate the worsted cotton fabric to oxidize the cystine on the surface of wool fiber scales in the fabric and break the disulfide bond, which helps to improve the dye adsorption of wool fiber and the diffusion capacity of dye in the fiber In addition, the use of rosin powder as a color-fixing agent can improve the color fastness to soaping and rubbing of dyed fabrics. Specifically, rosin powder can be cross-linked on the fiber surface to form a film, and form a coordination bond with the fiber surface group , Improve the binding force between the fiber and the dye molecule.

Owner:JIANGSU SUNSHINE

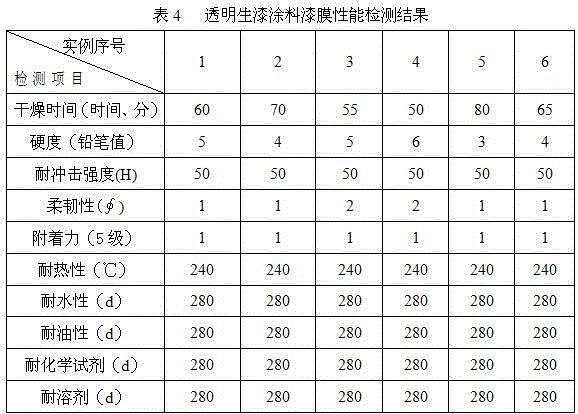

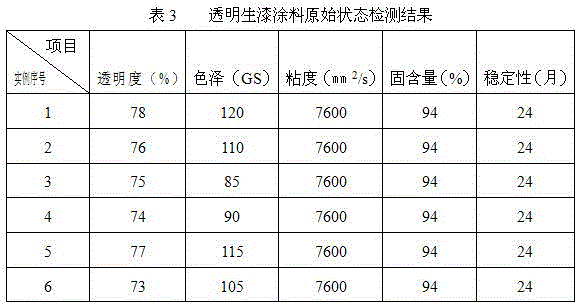

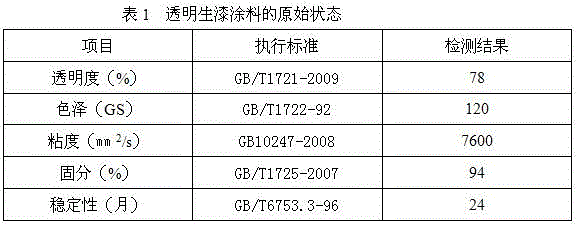

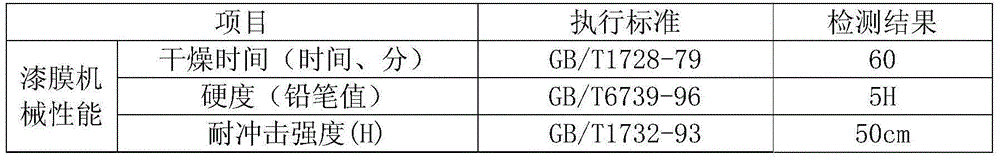

Method for preparing transparent raw lacquer coating

The invention provides a method for preparing a transparent raw lacquer coating. The method comprises the following steps: (1) filtering and removing impurities in raw lacquer, adding the raw lacquer into an oxidation polymerization machine, stirring at normal temperature till the moisture content of the raw lacquer is 6-8 percent, and allowing the raw lacquer liquid to become drawing Newtonian fluid; (2) adding linseed oil subjected to double drift into a polymerization pot, heating to the temperature of 250 DEG C, adding rosin powder, stirring and boiling together, heating to the temperature of 270 DEG C when the rosin is completely fused, preserving the temperature for 10-15 minutes, discharging from the pot when the linseed oil becomes drawing Newtonian fluid, stirring, exhausting, discharging the smoke, and cooling to normal temperature; and (3) kneading the raw lacquer obtained in the step (1) and the linseed oil obtained in the step (2) in a vacuum kneader for 4-5 hours according to a weight ratio of 50:(45-55), thereby obtaining the transparent raw lacquer coating. According to the method disclosed by the invention, filling agents, diluents and driers of metal ions such as manganese, lead, mercury and zirconium are not added, and the method for preparing the transparent raw lacquer coating is green, environmentally friendly and high in quality.

Owner:ZHANGJIAJIE LOUJIANG ECOLOGICAL AGRI DEV CO LTD

High strength silicon carbide deck and production method thereof

The invention relates to a high strength silicon carbide deck and a production method thereof. The high strength silicon carbide deck comprises silicon carbide particles, silicon carbide coarse powder, silicon carbide fine powder, silicon carbide micro-powder, graphene, a composite antioxidant, a composite binder, rosin powder and carbon nanotubes according to mass percentages. Lightweight silica bricks having the advantages of excellent thermal shock resistance, strong oxidation, slag and alkali metal erosion resistance, excellent washing resistance and heat insulation performance, and good high-temperature volume stability can be highly and uniformly dispersed in the deck, promote sintering, make the deck have a uniform microstructure, and improve the strength and the thermal shock resistance of the deck.

Owner:浙江长兴银兴窑业有限公司

Soil conditioner

InactiveCN105273720ANo pollutionRaise the pHAgriculture tools and machinesOrganic fertilisersROSIN POWDERGlutaric acid

The invention relates to a soil conditioner, and relates to the technical field of agricultural fertilizer. The soil conditioner is prepared from the raw materials of, by weight, 300 parts of silicon-calcium powder, 100 parts of agricultural rare earth, 100 parts of maifanite powder, 150 parts of 98% amino acid original powder, 30 parts of rosin powder, 3 parts of oligochitosan, 3 parts of a soil loosening agent, 10 parts of bacillus subtilis, 20 parts of a water retention agent, 1-5 parts of a urease inhibitor, 1 part of a tetramethyl glutaric acid chelating agent, 70-90 parts of ferrous sulfate, 40-60 parts of zinc sulfate, 90-110 parts if magnesium sulfate, and 40-60 parts of borax. With the soil conditioner provided by the invention, pesticide dose can be greatly reduced, and pesticide residue pollution can be reduced. While crop yield is increased, the soil is turned healthier. As a result of experiments, the soil conditioner has effective functions of breaking soil compaction, regulating acid-base balance, reducing soil salt damage, retaining water and fertilizer, resisting drought and waterlogging, loosening soil and ventilating, and supplementing medium-trace elements and biological bacteria. The soil conditioner is a green ecological functional fertilizer worth promoting.

Owner:解永红

Blending method of transparent raw lacquer coating

The invention belongs to the field of chemical modification treatment of coatings, particularly relates to a transparent raw lacquer coating and aims to provide a high-quality light-color transparent raw lacquer coating on account of the improvement on the shortcomings of the raw lacquer coating in the prior art. A blending method of the transparent raw lacquer coating comprises the following steps: pre-treating the raw lacquer; filtering and removing impurities of the raw lacquer, stirring the raw lacquer till the raw lacquer can be drawn into 5-8cm newtonian fluid; pre-treating linseed oil; adding 50 parts of linseed oil after being leached twice into a polymerization pot for heating, adding rosin powder, stirring and decocting the linseed oil and the rosin powder together, adding the raw lacquer and the linseed oil which are subjected to pretreatment into a vacuum kneading machine according to a weight ratio of 50 to 50, and kneading for 4-5 hours to obtain the transparent raw lacquer coating.

Owner:湖北宝石花工艺品有限公司

Carbon fiber reinforced and modified waterproof anti-flaming type biomass plate and preparation method thereof

The invention discloses a carbon fiber reinforced and modified waterproof anti-flaming type biomass plate and a preparation method thereof. The preparation method is characterized by using rice straw, sulfate wood pulp, carboxyl modified silicone oil, gelatin, nano montmorillonite, an emulsifying agent OP-10, liquid paraffin, rosin, polyacrylic acid, melamine polyphosphate, boric acid, hydrotalcite, a titanate coupling agent, carbon fiber, furan resin, pine oil and the like as raw materials. According to the carbon fiber reinforced and modified waterproof anti-flaming type biomass plate and the preparation method of the carbon fiber reinforced and modified waterproof anti-flaming type biomass plate, disclosed by the invention, devillicating and brooming are carried out by adding the sulfate wood pulp in the rice straw, reinforcement and modification treatment is carried out by adding the carboxyl modified silicone oil, and a foaming agent-pine oil is added; rosin powder is used as a filling agent and can be used as an adhesive after high-temperature melting; the mechanical performance and the size stability of the carbon fiber reinforced and modified waterproof anti-flaming type biomass plate are remarkably increased through modification treatment of the nano montmorillonite; a microcapsule waterproof agent is prepared by adopting a simple coacervation method; a melamine polyphosphate-polyacrylate-borate anti-flaming agent is prepared and is in synergistic effect with the hydrotalcite, so that the anti-flaming effect is better; the carbon fiber reinforced and modified waterproof anti-flaming type biomass plate is obtained.

Owner:凤台县双利生物科技有限公司

Concrete air entraining agent

The invention belongs to the technical field of concrete admixture, and in particular relates to a concrete air entraining agent which is prepared from the following raw materials in parts by weight: 40-60 parts of rosin powder, 10-18 parts of sodium hydroxide, 6-16 parts of sulfuric acid, 8-18 parts of glycol, 5-13 parts of bisphenol A, 7-15 parts of pentaerythritol and 90-130 parts of water. When being used in concrete, the concrete air entraining agent is stable in bubble, appropriate in size, uniform in distribution, capable of increasing strength of concrete, and capable of improving peaceability of concrete.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

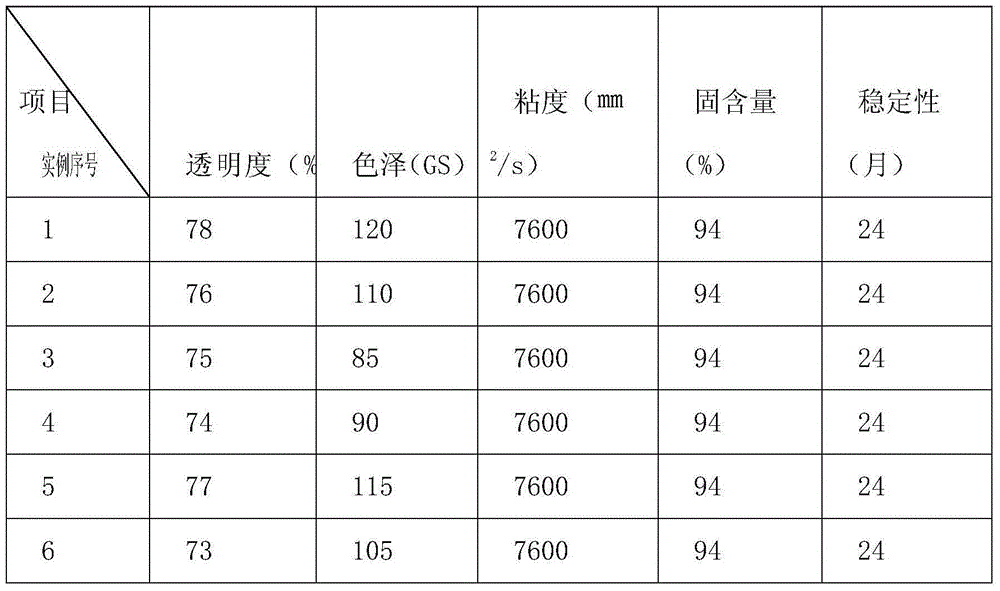

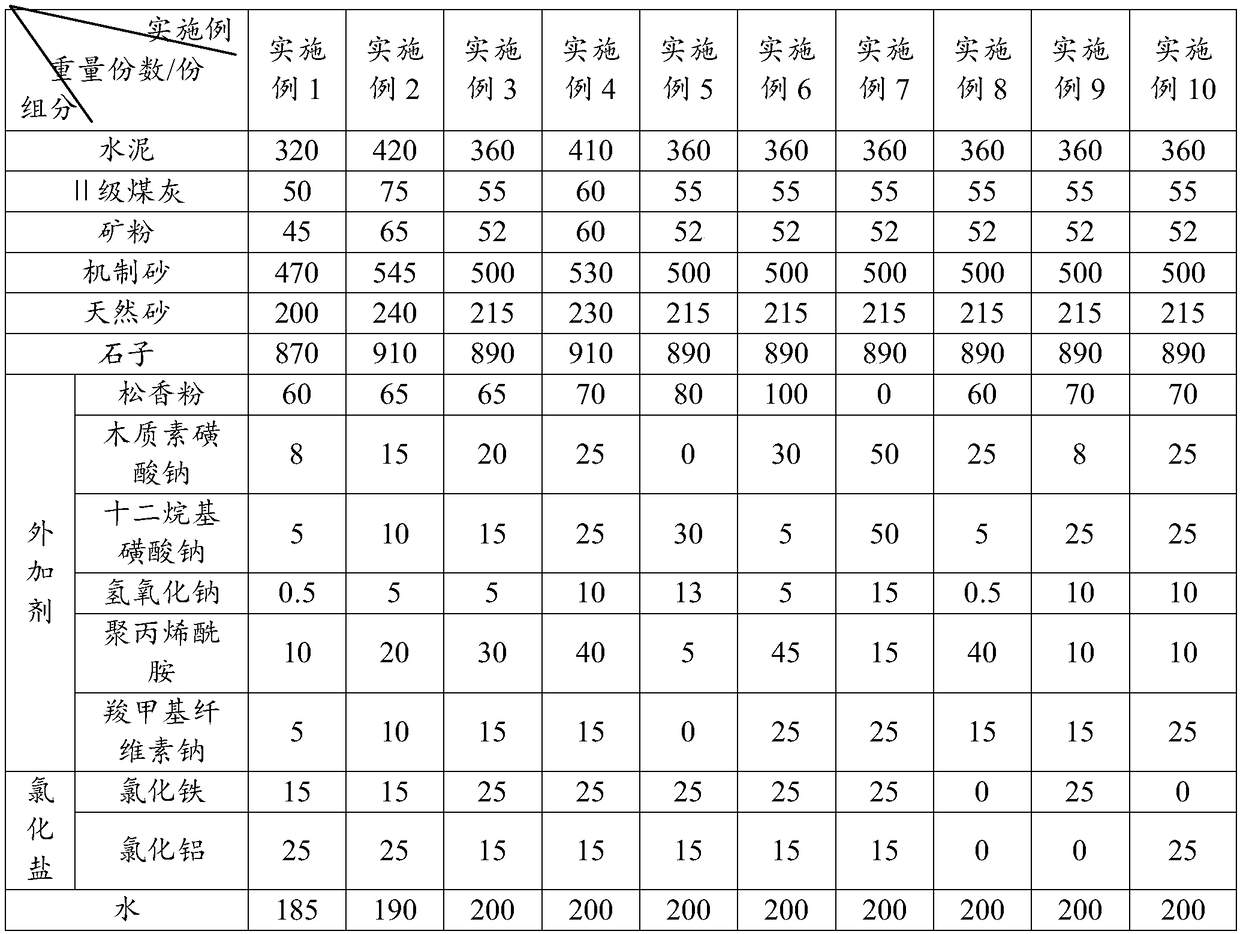

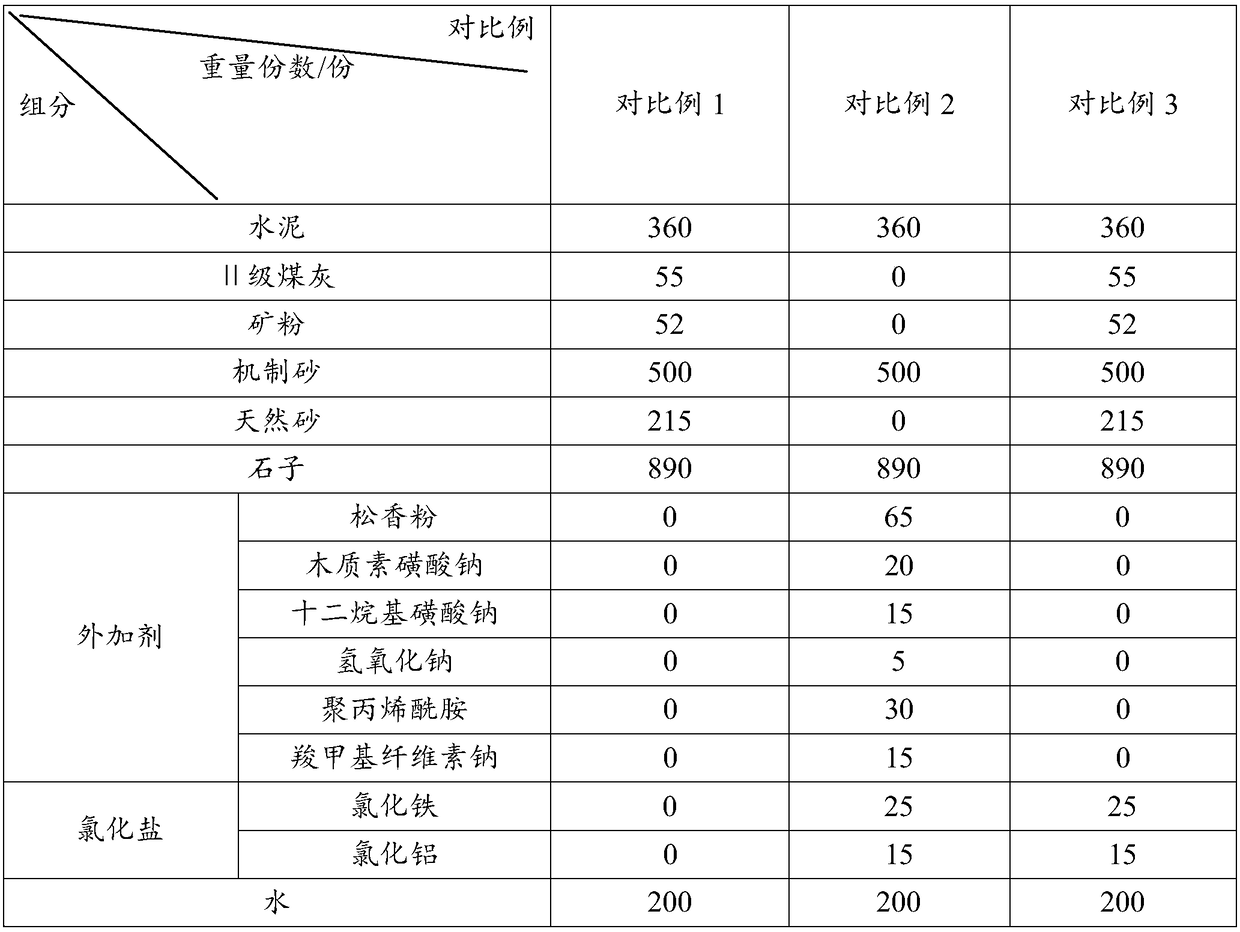

Concrete, and preparation method thereof

The invention discloses a concrete, and a preparation method thereof, and belongs to the field of building material. The concrete comprises, by weight, 320 to 420 parts of cement, 50 to 75 parts of IIgrade fly ash, 45 to 65 parts of ore powder, 470 to 545 parts of machine-made sand, 200 to 240 parts of natural sand, 870 to 910 parts of cobblestone, 128.5 to 210 parts of an additive, and 185 to 200 parts of water; the additive comprises at least four ingredients selected from rosin powder, sodium lignosulfonate, sodium dodecanesulphonate, sodium hdroxide, polyacrylamide, and carboxymethylcellulose sodium. The concrete is capable of avoiding concrete layering, separation, and water segregation, and the concrete compressive strength is increased effectively.

Owner:杭州金鼎实业有限公司

Pumpkin planting method with effect of improving soil acidity

InactiveCN109588223ALow costSave resourcesAnimal corpse fertilisersBioloigcal waste fertilisersROSIN POWDEREdible oil

The invention discloses a pumpkin planting method with an effect of improving soil acidity. The method comprises specific steps as follows: plant ash, rosin powder and waste edible oil are mixed in aweight ratio being 1:1:1, and a saponification liquid is formed; the saponification liquid and water are blended in a ratio being 1:200 for soaking seeds, and sterilization and disinfection are performed; the disinfected seeds are aired and then sowing and germination accelerating are started; after germination accelerating, the seeds can be sown on a seedbed and earthed when 50% of the seeds emerge; field planting treatment is performed; watering management is performed; reasonable fertilization is performed. With the adoption of the technical scheme, acidity of soil can be effectively improved, land pollution is reduced, and yields of other staple food grains and other crops planted by crop rotation in the later period are further increased.

Owner:黄志鹏

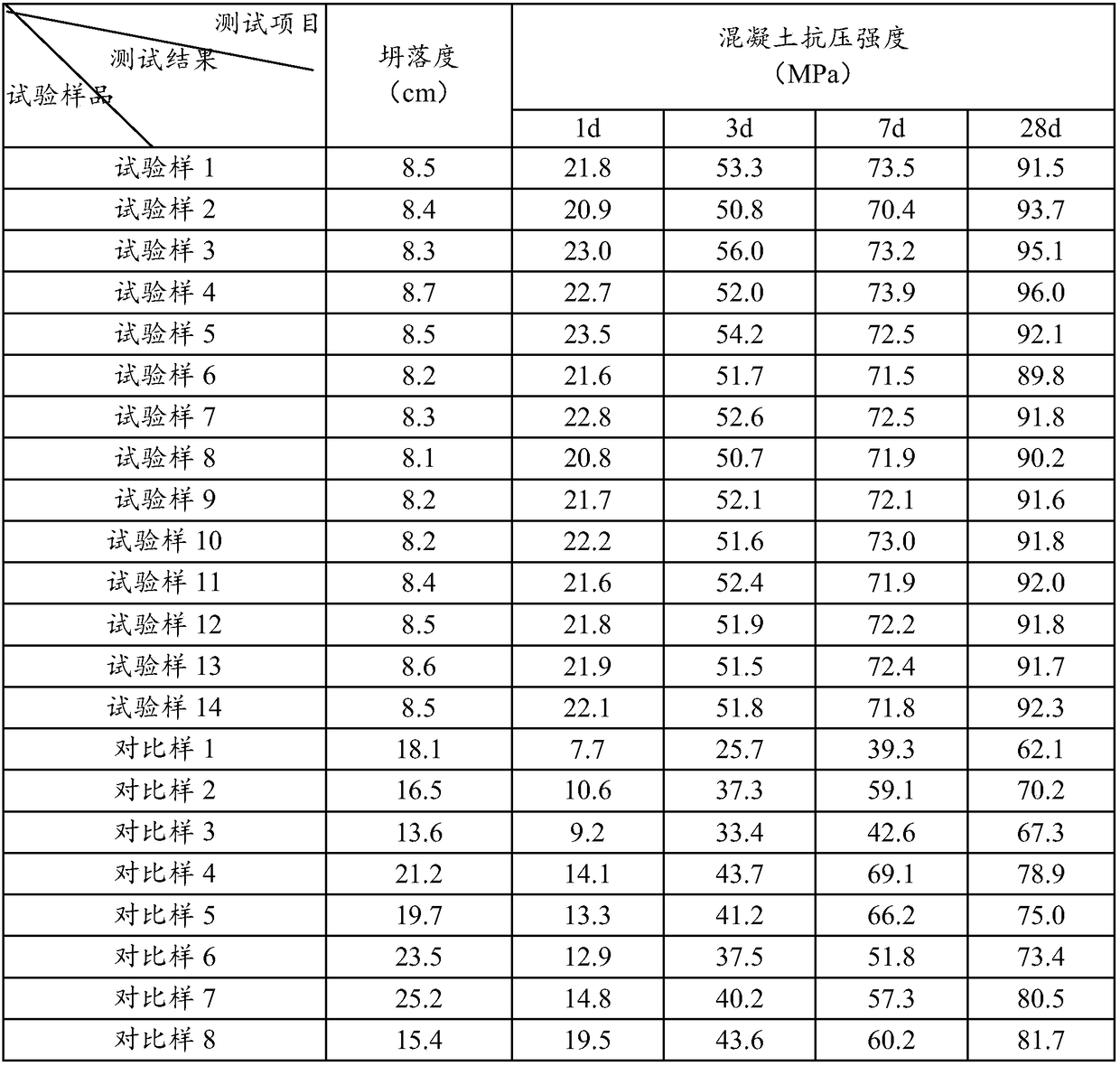

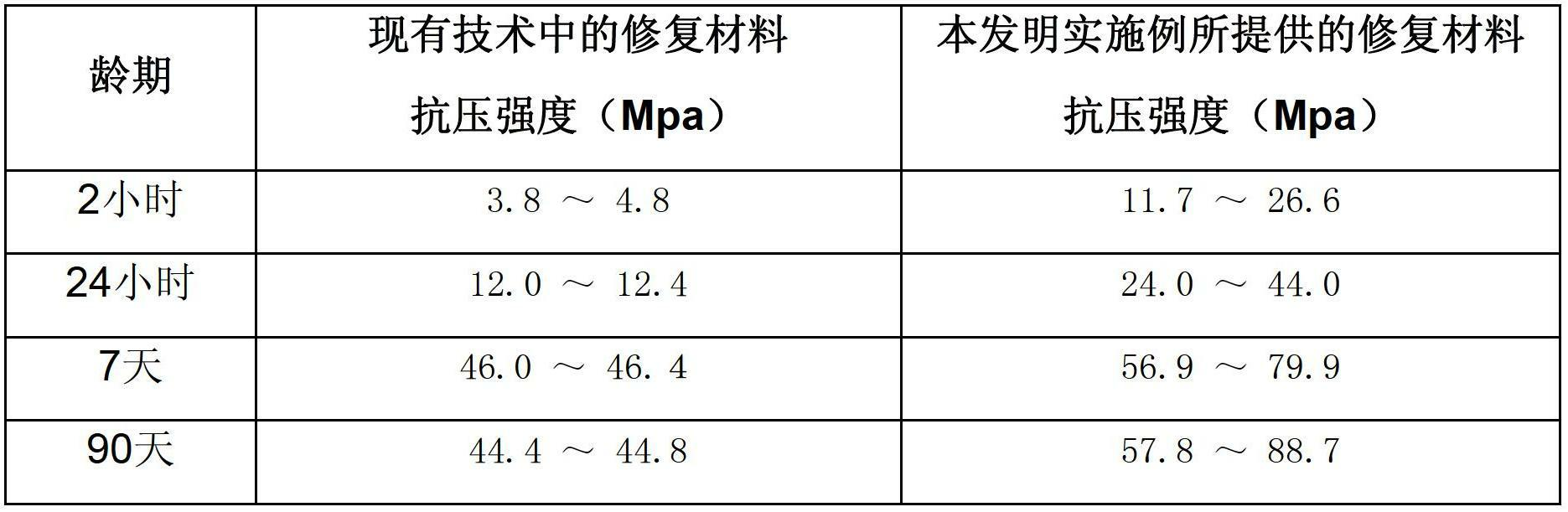

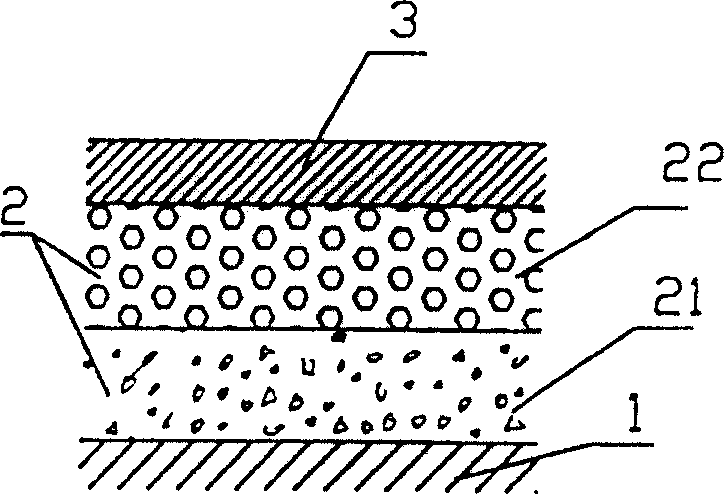

Repairing material of cement concrete structure and preparation method for same

The invention relates to a repairing material of a cement concrete structure and a preparation method for the same, wherein the repairing material comprises the following components: alkaline residue composite calcinates, lithium hydroxide, sodium fluorosilicate, polycarboxylic water reducer, lithium carbonate, calcium aluminate, borax, sodium chlorate, calcium sulphate, rosin powder, magnesium oxide and silica; and the ratio of the mass of each component to a total mass is as follows: the alkaline residue composite calcinates: 50-70 parts, the lithium hydroxide: 0.2-0.6 part, the sodium fluorosilicate: 0.1-0.6 part, the polycarboxylic water reducer: 0.1-0.5 part, the lithium carbonate: 2-7 parts, the calcium aluminate: 8-18 parts, the borax: 0.03-0.5 part, the sodium chlorate: 0.1-1 part, the calcium sulphate: 5-15 part, the rosin powder: 0.03-0.1 part, the magnesium oxide: 0.1-0.5 part, and the silica: 5-12 parts. According to the embodiment of the invention, alkaline residue is effectively utilized, thus lightening environmental pollution; and moreover, the cost of raw materials is decreased and the cost performance of product is improved while the quality of product is improved.

Owner:BEIJING HUAXIA PIONEERING NEW MATERIAL

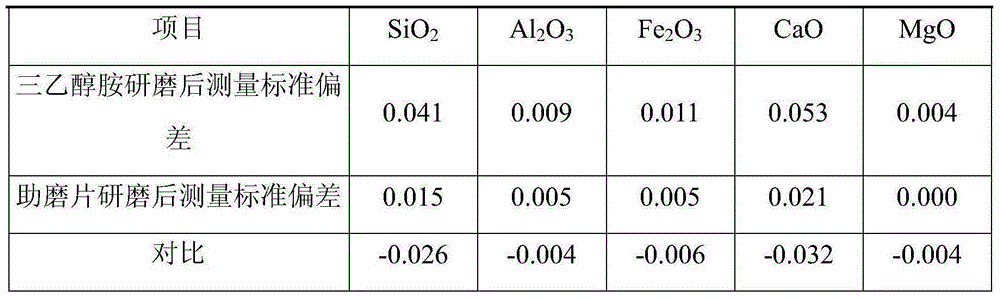

Grinding aid sheet for fluorescence analysis and preparation method thereof

The invention belongs to the field of fluorescence analysis, and particularly relates to a grinding aid sheet for fluorescence analysis and a preparation method thereof. The invention aims to solve the technical problem that the inaccurate addition amount of the grinding aid can easily cause deviation of the analytic result and is not beneficial to controlling the production quality. In order to solve the technical problem, the invention provides a grinding aid sheet for fluorescence analysis, which is prepared from the following raw materials in percentage by mass: 5-30% of rosin powder, 30-60% of starch, 5-30% of polyvinylpyrrolidone, 5-30% of methyl cellulose and 3-20% of zinc stearate. The grinding aid sheet provided by the invention is beneficial to enhancing the work efficiency, lowering the labor intensity and enhancing the data accuracy, and has promotion actions on enhancing the production quality control level.

Owner:SICHUAN ESHENG CEMENT GROUP

Building heat-insulating foam material and preparation method thereof

The invention discloses a building heat-insulating foam material. The foam material is prepared from, by weight, 5-7 parts of potassium titanate whiskers, 130-150 parts of styrene, 5-7 parts of an initiator, 6-8 parts of zinc diricinoleate, 20-30 parts of an organic filler emulsion, 10-12 parts of a foaming agent, 2-4 parts of rosin powder, 1-2 parts of melamine and 0.8-1 part of polyethylene glycol fatty acid ester. The styrene used as a monomer is mixed with an alcohol ester solution, the obtained solution is polymerized under the action of the initiator, and the obtained polymer is mixed with the rosin powder and the foaming agent to realize foaming, so the foaming effect is effectively improved, thereby the foam material has low thermal conductivity, good heat insulation property and excellent comprehensive performances.

Owner:SUZHOU JUHUIBANG NEW MATERIAL TECH CO LTD

Liquid curing agent for making road and its production process

InactiveCN1707027AReduce thicknessReduce capillary water absorptionRoadwaysOrganic fertilisersROSIN POWDERIon exchange

The present invention relates to highway construction technology, and is especially one kind of liquid curing agent for making road and its production process. The liquid curing agent consists of sodium hydroxide, sulfuric acid, phenol, rosin powder and soft water in certain proportion. The production process includes mixing rosin powder and phenol and heating in some container, adding solution of sodium hydroxide and heating to near 100 deg.c for 2 hr, and storing the mixture inside storing container while the mixture is still hot. During construction, the liquid curing agent is mixed with water repellent agent in the weight ratio of 1-2 to 8-9, and the mixture is then mixed with soil, sand and stone. The liquid curing agent is combined with soil to produce ion exchange reaction, and this can reduce or eliminate water film attached to soil, coagulate soil grains, reduce capillary effect and raise the water resisting and antifreezing performance of road bed.

Owner:张杞 +1

Thermally conductive and insulating aluminum base compound radiating material for LED

The invention relates to a radiating material of a lamp and particularly relates to a thermally conductive and insulating aluminum base compound radiating material for an LED and a production method of the radiating material. The radiating material is prepared from the following raw materials in parts by weight: 70-72 parts of aluminum, 12-15 parts of aluminum nitride, 1-3 parts of fibrolite, 2-3 parts of chlorite, 2-4 parts of sodium castor oil sulfonate, 8-10 parts of polyacrylate, 12-15 parts of kaolin, 10-11 parts of zinc oxide, 1-3 parts of trisodium phosphate, 3-4 parts of rosin powder, 1-2 parts of sodium citrate and 4-5 parts of an auxiliary. The radiating material provided by the invention integrates the advantages of components such as aluminum, aluminum nitride and kaolin and has both good thermal conductive and insulating performances. Soaked by a mixed dilute solution sodium citrate and trisodium phosphate, the radiating material is more easily compatible with metal powder. Components such as polyacrylate, rosin powder and the auxiliary can assist formation, improve the sintering effect of a blank and shorten the sintering time. The radiating material is compact in structure, insulative and safe, high in thermal conductivity coefficient, good in mechanical property and durable, and can effectively protect the LED lamp, so that the service life of the lamp is greatly prolonged.

Owner:YANYANG LAMP SET TIANCHANG CITY

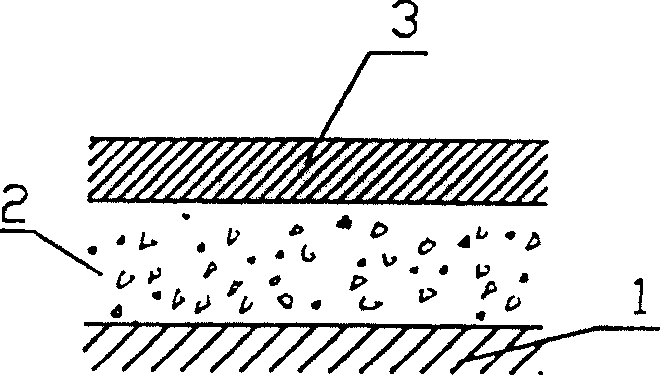

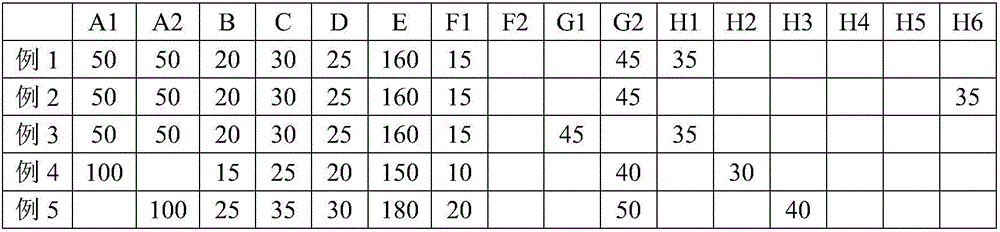

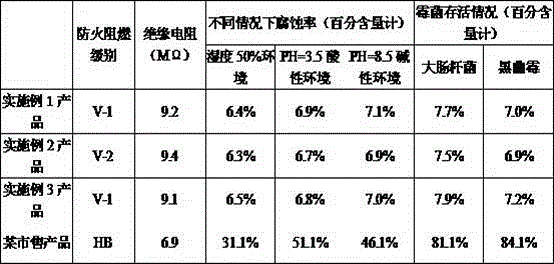

Lvyuan regulating herbal plaster

InactiveCN106075231AReduce excitabilityActivate the immune systemCosmetic preparationsInorganic active ingredientsROSIN POWDERTO-18

The invention discloses a Lvyuan regulating herbal plaster which is prepared from the following components in parts by weight: 100 parts of jade powder, 15 to 25 parts of tourmaline powder, 25 to 35 parts of ceramic powder, 20 to 30 parts of rosin powder, 150 to 180 parts of Vaseline, 10 to 20 parts of essential oil, 40 to 50 parts of beewax and 30 to 40 parts of traditional Chinese herb mixtures. The traditional Chinese herb mixtures consist of the following substances in parts by weight: 6 to 14 parts of almonds, 4 to 12 parts of bulbus fritillariae cirrhosae, 4 to 12 parts of radix adenophorae, 1 to 8 parts of herba schizonepetae, 8 to 16 parts of radix platycodi, 4 to 12 parts of radix stemonae, 1 to 8 parts of flos farfarae, 2 to 10 parts of cortex mori radicis, 8 to 16 parts of snakegourd fruits, 4 to 12 parts of radix asteris, 6 to 14 parts of colla corii asini, 8 to 16 parts of herba epimedii, 12 to 20 parts of herba cistanche, 2 to 10 parts of semen cuscutae, 18 to 26 parts of sesames, 14 to 22 parts of millets, 6 to 14 parts of cornu cervi, 12 to 20 parts of bark of eucommia, 10 to 18 parts of lotus seeds, 5 to 13 parts of fructus viticis and 14 to 22 parts of radix polygoni multiflori.

Owner:郑州五行舒体科技有限公司

Short cycle hot press inorganic adhesive, preparation method and application thereof

ActiveCN108485535AImprove curing speedReduce brittlenessNon-macromolecular adhesive additivesMacromolecular adhesive additivesROSIN POWDERAdhesive

The invention discloses a short cycle hot press inorganic adhesive, which comprises the following components by weight: 40-60 parts of aluminum tripolyphosphate, 60-80 parts of sodium silicate, 10-15parts of phosphoric acid, 3-8 parts of a wetting agent, 6-8 parts of a toughening agent, 5-8 parts of rosin powder, 10-20 parts of bisphenol A cyanate ester resin, and 20-50 parts of water. The invention also provides a preparation method and application of the short cycle hot press inorganic adhesive. The inorganic adhesive contains the pre-locking agent bisphenol A cyanate ester resin and the initial adhesive rosin. When the inorganic adhesive is used for artificial boards, the hot press time is shorter, and the hot press time can be shortened by 50% or more. In addition, the artificial boards prepared with the inorganic adhesive have no emission of free formaldehyde or other toxic gases.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

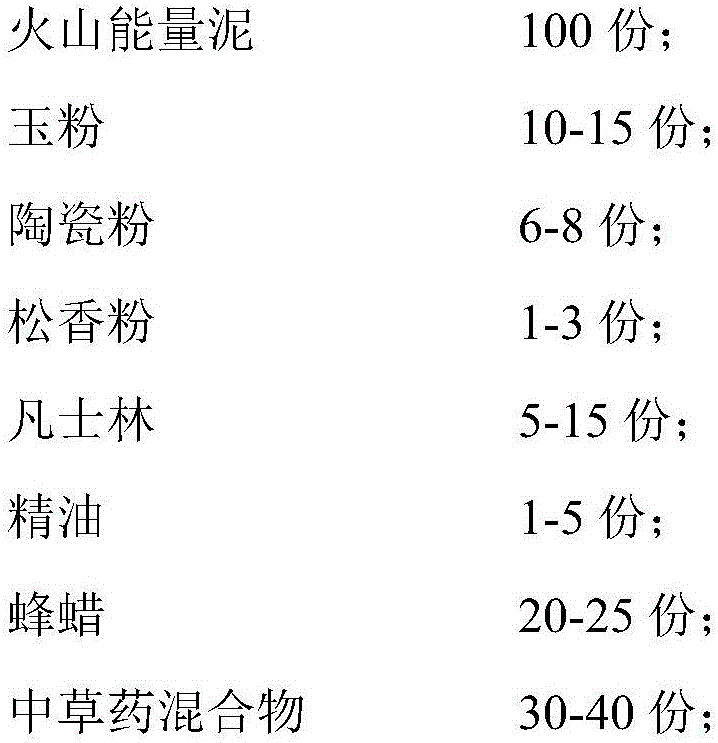

Lvtou purifying herbal patch

Luto purifying herbal membrane, in parts by weight, at least includes the following components: 100 parts of volcanic energy, 10-15 parts of jade powder, 6-8 parts of ceramic powder; 1-3 parts of rosin powder; 5-15 parts of petroleum jelly; essential oil 1-5 parts; 20-25 parts of beeswax; 30-40 parts of Chinese herbal medicine mixture; each substance in the Chinese herbal medicine mixture and the parts by weight in the Chinese herbal medicine mixture are: 1-8 parts of black trigonum, 1-8 parts of curcuma , Qingpi 2‑10 parts, Citrus aurantium 2‑10 parts, Atractylodes macrocephala 1‑8 parts, Ophiopogon japonicus 4‑12 parts, Hawthorn 12‑16 parts, Malt 6‑14 parts, Gu Ya 1‑8 parts, Chinese yam 12‑20 parts Codonopsis 16‑24 parts, Rehmannia glutinosa 14‑22 parts, Rhubarb 12‑20 parts, Magnolia officinalis 8‑16 parts, Three needles 10‑18 parts, Aster 14‑22 parts, Huaijiao 18‑26 parts, Chuanbei 1‑8 parts, 2‑10 parts of Dendrobium, 4‑12 parts of Mint, 6‑14 parts of Baibu.

Owner:郑州五行舒体科技有限公司

Art design packaging film material

InactiveCN106519713AExcellent flame retardantGood acid and alkali resistanceFlexible coversWrappersROSIN POWDERChromium trioxide

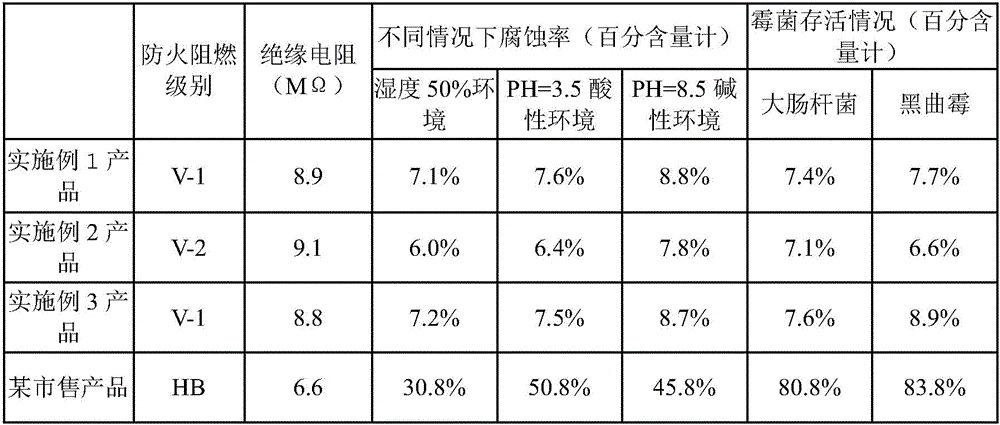

The present invention relates to an art design packaging film material, which comprises rosin pentaerythritol ester, an ethylene-vinyl acetate copolymer, an epichlorohydrin rubber, isobutyl propionate, epichlorohydrin, butyl acetate, glyceryl monostearate, diethanolamine, dimethyl fumarate, bromohexadecane, imidazoline, ammonium fluorosilicate, diantimony trioxide powder, chromium trioxide powder, quick lime powder, limestone powder, asbestos fiber, graphite fiber, disodium octaborate tetrahydrate, rosin powder, hexabromocyclododecane, triphenyl phosphate, sodium stannate, trichloroethyl phosphate, sodium methylenebisnaphthalenesulphonate, tert-butyl peroxybenzoate, benzoyl peroxide, oxidized polyethylene, polyvinyl formal-acetal, and n-oxydiethylidene-2-benzothiazole sulfamide. The product of the present invention has advantages of excellent fire retardation, excellent acid resistance, excellent alkali resistance, excellent anti-mildew property, excellent antibacterial property, and product performance improving.

Owner:安陆市万众创新智能科技有限公司

Air entraining agent for concrete

InactiveCN106116221AThe effect of adding air-entraining agent cannot be achievedImprove workabilityROSIN POWDERPolyvinyl alcohol

The invention belongs to the technical field of concrete admixtures, and particularly relates to a concrete air-entraining agent, which is made of the following raw materials in parts by weight: 25-45 parts of rosin powder, 15-35 parts of potassium hydroxide, 5-15 parts of sulfuric acid, and 20 parts of melamine ~30 parts, 5~15 parts of polyvinyl alcohol, 10~20 parts of glutaconic acid, 80~160 parts of water. The concrete air-entraining agent of the present invention is added to concrete with reasonable bubble structure, uniform distribution, stable bubble size and appropriate size, significantly improves the workability and durability of cement, has good compoundability with other admixtures, and has strong adaptability to concrete .

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Building finishing and furniture article timber binder

InactiveCN106010397AExcellent flame retardantGood acid and alkali resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesROSIN POWDERBoron carbide

The invention relates to a wood adhesive for building decoration and furniture, which is composed of the following components: phenolic resin, fluorosilicone resin, hydrogenated rosin, carbo resin, isobutyl propionate, methylaniline, butyl acetate, stearin Acid glyceride, polyhexamethylene guanidine hydrochloride, methyl p-hydroxybenzoate, vanillin, nano-zirconium phosphate silver-loaded antibacterial agent, vanadium trioxide powder, boron trioxide powder, molybdenum trioxide powder, Limestone powder, graphite fiber, rosin powder, carbon black, boron carbide powder, dibasic lead stearate, tri(butoxyethyl) phosphate, hexabromobenzene, sodium stannate, ethylene bisstearate Amide, aminoethylpiperazine, oleic acid amide, p-benzoquinone dioxime, 4,4'-diaminobiphenyl, polytrimethylene adipate. The product of the invention has comparatively superior properties of flame retardancy, acid and alkali resistance, anti-mildew and antibacterial performance, and improves product performance.

Owner:李红玉

New technology for preparing high-performance waterproof fiberboard with semipermeable membrane technology enhancing enzymolysis degree

InactiveCN104149152AEasy to solveGuaranteed to be environmentally friendlyFlat articlesDomestic articlesROSIN POWDERFiber

The invention relates to a technology. According to the technology, multiple biological enzyme programs are used for processing crop waste straw, a semipermeable membrane technology is used for solving the problem that hydrolysates inhibit the enzymolysis degree, and a high-performance waterproof fiberboard is produced. The technology is characterized in that the crop waste straw is loosened through a loosening machine, the laccase and hemicellulase programs are added for hydrolysis, the hydrolysis process is conducted in a system with a semipermeable membrane capable of filtering out medium and small size molecules, after hydrolysis is completely conducted, processed straw fibers and the medium and small size molecules filtered out by the semipermeable membrane are mixed again, moisture is evaporated, drying is conducted until the water content reaches 1-5 percent, about 3 percent of rosin powder is added to be evenly stirred and put into a die to be laid and packaged, and the rosin powder is pressed under the designated temperature, pressure intensity and time. Raw materials are sufficient, the price is low, materials are cheap, a chemical adhesive waterproof agent does not need to be added on the manufactured fiberboard, cost of the board is reduced, the manufacturing technology is environmentally friendly and free of pollution, and the obtained fiberboard is good in mechanical property, good in waterproof performance, high in finished product qualification rate and not prone to deformation.

Owner:HUBEI UNIV +1

Cleaner composition for cleaning surface of rubber and preparation method thereof

InactiveCN104004606AEasy to cleanAvoid harmOrganic non-surface-active detergent compositionsNon-surface-active detergent solventsROSIN POWDERAlcohol

The invention discloses a cleaner composition for cleaning the surface of rubber and a preparation method thereof. The composition contains C2-C4 alcohol, C5-C9 acetate, rosin powder and soluble carbonate. The preparation method comprises the step of mixing C2-C4 alcohol, C5-C9 acetate, rosin powder and soluble carbonate. The cleaner composition disclosed by invention has excellent cleaning capacity and is environmental-friendly simultaneously.

Owner:WUHU FENGXUE RUBBER

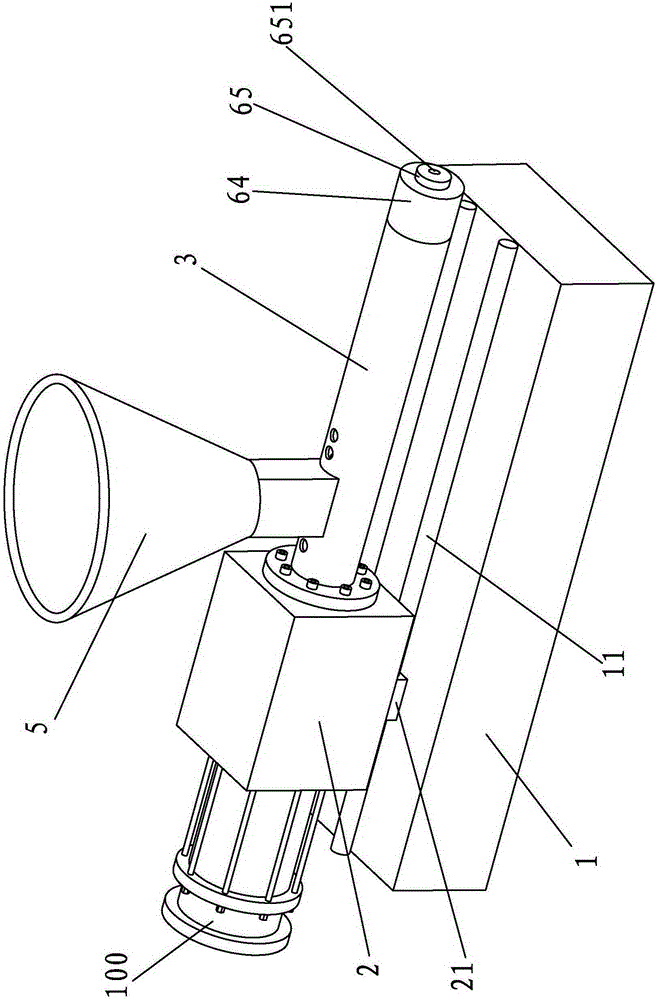

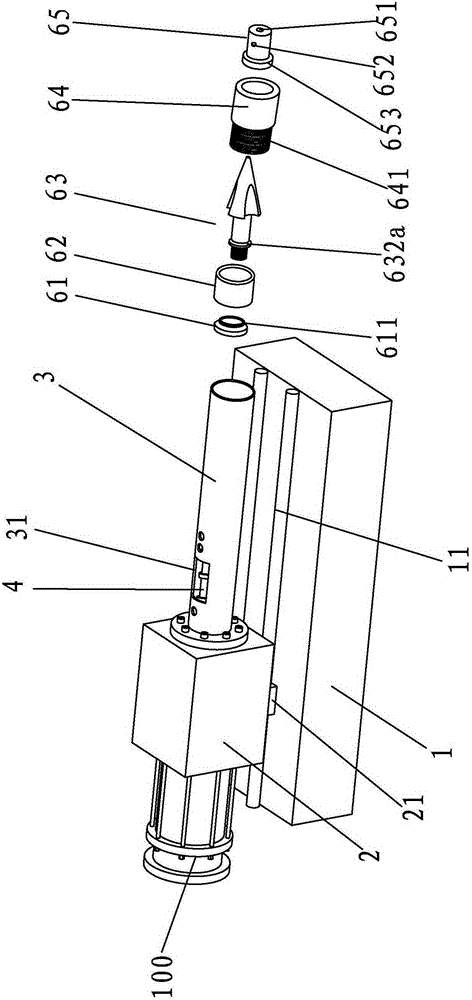

Recovering and manufacturing process for polyurethane shoe materials and polyurethane-shoe-material injection-molding feeding mechanism for recovering and manufacturing process

The invention discloses a recovering and manufacturing process for polyurethane shoe materials. The process includes the following steps that firstly, crushing is carried out, specifically, waste polyurethane shoe materials are poured into a strong crusher to be crushed; secondly, stirring is carried out, specifically, waste particle materials are poured into a low-speed heating stirrer, rosin powder and auxiliaries are added and stirred, and polyurethane injection molding materials can be obtained under the condition of stirring for 80-100 minutes at the stirring temperature of 100-110 DEG C; the weight of the rosin powder accounts for 0.8%-1.2% of the total weight, the auxiliaries are dioctyl phthalate, and the weight of the auxiliaries accounts for 1%-1.3% of the total weight; and thirdly, injection molding is carried out, specifically, the polyurethane injection molding materials are subjected to injection molding through a disc injection molding machine, so that the polyurethane shoe materials are obtained. Compared with the prior art, the waste polyurethane shoe materials are completely recycled, resources are effectively utilized, a large number of other auxiliary components are not needed, and the recovery cost is low; the process has the advantages that the recovery cost is low, and recovery products are soft. The invention further discloses a polyurethane-shoe-material injection-molding feeding mechanism used for achieving injection molding of polyurethane.

Owner:范焱林

Regeneration charcoal manufactured from durian shells

InactiveCN108264912AReduce generationExtended burn timeBiofuelsSpecial form destructive distillationROSIN POWDERPollen

The invention discloses regeneration charcoal manufactured from durian shells. The regeneration charcoal is manufactured from, by weight, 50-80 parts of durian shell powder, 10-15 parts of Arabian jasmine flower powder, 60-80 parts of sawdust, 5-8 parts of rosin powder and 5-8 parts of kieselguhr. The particle diameters of the durian shell powder, the Arabian jasmine flower powder, the sawdust andthe rosin powder range from 2 mm to 4 mm. The manufacturing method of the regeneration charcoal comprises the following steps of 1, preparing materials, wherein the raw materials are dried until thewater content is 15-20%; 2, manufacturing rods, wherein the dried machining powder and kieselguhr are mixed to be uniform, hollow cylinder firewood rods are manufactured, and the cylinder firewood rods are provided with a plurality of small holes running through the inner and outer walls of the cylinder firewood rods; 3, charring, wherein the firewood rods are placed into a container, under the anaerobic condition, under the temperature of 200-300 DEG C, the firewood rods are burnt and charred for 80-90 h, natural cooling is performed, and the regeneration charcoal is obtained. The charcoal has the durian flavor, and the durian shells are recycled.

Owner:黎娟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com