Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

419results about How to "Improve erosion ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production of layered engineered abrasive surfaces

InactiveUS6293980B2Improve featuresImprove erosion abilityPigmenting treatmentOther chemical processesMaterials scienceAbrasive

Coated abrasives comprising shaped structures deposited on a backing can be given increased versatility can be made by a process in which the shaped structure is imposed on a structure deposited in layers on the backing before the shaped structures are formed such that different characteristics are revealed as the structure is eroded during use.

Owner:MORTON CO

Marine concrete corrosion resistant additive and preparation thereof

The invention relates to the technical field of building material, in particular to a maritime work concrete corrosion-proof additive. The maritime work concrete corrosion-proof additive consists of a calcium sulphoaluminate expansion agent, a methyl naphthalene sulphonic acid water reducing agent, organosilicon hydrophobic powder, neopentylene glycol, milled slag powder, polypropylene fibers, silicon ash, superfine fly ash and arenaceous quartz. The maritime work concrete corrosion-proof additive can reduce the water consumption for mixing concrete, improve the water retention and cohesiveness, and improve the resistance of the concrete to seawater erosion and the durability.

Owner:TONGJI UNIV

Anticorrosion expansion compacting agent composition and preparation method thereof

The invention relates to an anticorrosion expansion compacting agent composition and a preparation method thereof; the composition comprises the following components by weight: 15-35% of aluminium-containing compounds, 0-8% of zirconium-containing compounds, 2-10% of magnesium salts, 0-3% of titanium dioxide compounds, 0-6% of lithium salts, 2-6% of alkanolamine salts, 0-10% of super-plasticizers, 0-10% of solidification adjusting agents, 0-5% of acids, and the balance of carriers. The components are reacted in a reaction vessel at 80 DEG C+ / -5 DEG C for 3 hours, and then cooled to 45 DEG C+ / -5 DEG C; thermal insulation is performed for one hour; and anticorrosion expansion compacting agents of a standard type, a solidification-promoting type, or a pumping slow-solidifaction type are obtained according to the added solidification adjusting agents with different types and amounts.

Owner:苏琳

Pouring material for manufacturing pellet ore rotary kiln and manufacturing method thereof

The invention relates to a casting material used for producing pellet rotary kiln and a preparation method thereof, the casting material is a combination, and contained components and weight percentage occupied in the combination contain: 70 to 92 percent of casting material basal body, 3 to 8 percent of micro powder of monox or micro powder of alumina, 0.001 to 5 percent of zirconium mullite or zirconite, 1 to 12 percent of carborundum, 0.005 to 5 percent calcium aluminate cement and 0.01 to 1 percent of dispersant; the casting material basal body is the combination of one or several of corundum, bauxite and porzite. The preparation method of the casting material has the following steps: first uniformly mixing the casting material basal body, then adding other components to be uniformly mixed, and finishing goods. The casting material contains the carborundum, the carborundum has the characteristic of difficult infiltration with furnace burden containing iron, and ring formation materials are difficult to be felted on a furnace brick lining; in addition, the carborundum can increase acidic furnace burden anti-corrosion performance of the casting material, and thus the life of the rotary kiln is enhanced. The preparation method of the casting material is simple and has low cost.

Owner:武钢集团有限公司

Silicone hydride cream-like substance with high solid content and method of manufacturing the same

The invention discloses a high solid content silane paste and a preparation thereof, the components and the quality ratio comprise: the ratio of siloxane monomer, emulsifier and de-ionized water is 70 percent to 85 percent: 5 percent to 10 percent: 10 percent to 25percent, wherein, the siloxane monomer is a mixed system of long-chain alkyl siloxane of C3-C18 or alkyl silane coupling agent of C3-C18; the emulsifier is one or several a fluorine-containing emulsifier, a Tween series emulsifier, a Span series emulsifier and a stearic acid-type emulsifier. The preparation method takes the long-chain alkyl siloxane as the main monomer, is assisted with proper quantities of organic alkyl silane coupling agent containing a functional group, and adopts means of a special composite emulsion to prepare poly organic silane paste having high penetrability and high stability. The invention is used for surface conservation of concrete, and greatly enhances anti-erosion ability to seawater, rain water and acid rain in the atmosphere.

Owner:武汉壁千韧硅涂料有限公司

Wet paved/pre-paved polymer self-adhesive waterproofing rolled material and preparation method thereof

InactiveCN102454226AExtended service lifeWeather resistantUnderground chambersRoof covering using flexible materialsPolymer resinCompound (substance)

The invention provides a wet paved / pre-paved polymer self-adhesive waterproofing rolled material which comprises a modified asphalt self-adhesive layer. The modified bitumen self-adhesive layer contains petroleum asphalt, modifier, softener, tackifier and filler. The wet paved / pre-paved polymer self-adhesive waterproofing rolled material which is prepared from the by taking a polymer resin layer as a base has a long use life, stable chemical properties and excellent waterproof effect, wherein the modified asphalt self-adhesive layer is prepared through single side or double side adhering.

Owner:沈阳蓝光科技发展有限公司

Taphole stemming used for oversize blast furnaces

Belonging to the technical field of refractory materials, the invention relates to taphole stemming used for oversize blast furnaces over 4500m<3>. The taphole stemming used for oversize blast furnaces comprises by weight: 25-50% of brown corundum, 5-20% of silicon carbide, 7-25% of ferro-silicon nitride, 15-30% of a composite carbon material, 5-15% of kaolin, 3-7% of composite refractory material micropowder, and 1-5% of composite metal powder. The stemming is prepared by the steps of: conducting weighing and burdening according to the above ratio of various raw materials, mixing them well and adding a coal tar binder accounting for 15-25% of the total weight of the additionally added dry materials, then conducting rolling and mulling so as to obtain a mud material. The stemming of the invention has good comprehensive performance, stable taphole depth, long tapping time, good erosion and scouring resistance, as well as good construction performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Torpedo tank lining gunning repairing material, preparation method and applications thereof

The invention discloses a torpedo tank lining gunning repairing material, a preparation method and applications thereof, wherein the torpedo tank lining gunning repairing material comprises, by weight, 60-67 parts of a Al2O3-containing fireproof material after-using regenerating material, 3-7 parts of fireproof clay, 2-5 parts of flaky graphite, 3-7 parts of silicon carbide, 10-15 parts of an alumina homogeneous material, 3-6 parts of kyanite, 2-5 parts of alpha-Al2O3 micro-powder, 3-11 parts of a binder, and 1.2-3.4 parts of an admixture. According to the present invention, the torpedo tank lining gunning repairing material has characteristics of low raw material cost, wide regeneration material source, convenient cold-hot state gunning repairing, excellent thermal shock stability, strong repairing layer interface bonding strength, strong slag iron corrosion resistance, high torpedo tank operation rate, long service life, and the like.

Owner:武汉钢铁有限公司

Internal lining casting material of industrial reaction furnace and lining-up method

A casting material for the internal working liner of industrial reduction furnace is prepared from aluminium oxide for insulating layer, high-Al material for intermediate layer and the compact corundum, zirconium mullite, chromium oxide, superfine zircon powder, Al2O3 powder and calcium aluminate cement through weighing raw materials except calcium aluminate cement, stirring, loading in bag for future use, casting external insulating layer, casting mediate layer and casting working liner, which includes proportionally mixing said mixture with calcium aluminate cement, adding water, stirring, moulding, vibrating, demoulding, natural curing and baking.

Owner:西安秦翔科技股份有限公司

Admixture for vegetation-form ecological concrete and compounding method thereof

The invention discloses an admixture for vegetation-form ecological concrete and a compounding method thereof, which relate to the technical field of cement concrete admixtures. The admixture is compounded by, by weight, calcium carbonate 5-10 parts, silica powder 40-50 parts, lignosulfonic acid 5-8 parts, sodium nitrite early strength agent 1-3 parts, hydroxy carboxylic acid high-efficiency water reducing agent 1-3 parts, polyacrylamide water-retaining agent 0.3-0.4 part and dodecyl sodium sulfate air entraining agent 0.01-0.02 part. The admixture compounded by the components is added into the vegetation-form ecological concrete so that the admixture can improve the mechanical strength and durability of the concrete, controls and ensures water permeability, porosity, homogeneity and the like of the concrete, and improves chemical resistance, potential of hydrogen, biocompatibility and other functions of the inside and the surface of the concrete.

Owner:NANTONG INST OF TECH

Composite spinel-zirconium refractory material for smelting colored heavy metal

The invention discloses a composite spinel-zirconium refractory material for smelting colored heavy metal. The technical scheme is as follows: the material comprises 30-45 parts of 5mm-0mm emery, 10-30 parts of 5mm-0mm magnesia chromite clinker,15-25 parts of 3mm-1mm magnalium spinel clinker, 7-20 parts of 3mm-0mm magnesite clinker, 1-5 parts of chrome green less than or equal to 0.045mm and 2-8 parts of zirconium dioxide less than or equal to 0.045mm by weight part and a bonding agent is aluminium dihydrogen phosphate liquid the adding amount of which is 3-15% of the total weight of the emery, the magnesia chromite clinker, the magnalium spinel clinker, the magnesite clinker, the chrome green and the zirconium dioxide. A hydraulic press is adopted for molding and the composite spinel-zirconium refractory material is sintered by a hyperthermia tunnel kiln. The content of Cr2O3 of the composite spinel-zirconium refractory material is less than 10%, so that the composite spinel-zirconium refractory material not only is environment-friendly, but also has better slag erosion resistance, high-temperature melt washing resistance, metal melt permeation resistance and thermal shock stability performance.

Owner:辽宁青花耐火材料股份有限公司

High-temperature walking beam furnace beam and column insulation lining slag-adhesion-preventing coating

The invention discloses a high-temperature walking beam furnace beam and column insulation lining slag-adhesion-preventing coating. The coating comprises the raw materials of, by weight: 55-60% of the bauxite clinker, 5-10% of magnesium aluminate spinel, 5-10% of calcined anthracite, 2-5% of flake graphite, 3-6% of silicon carbide, 4-6 % of alpha-Al2O3 powder, 4-6% silica micro-powder, 5-7% of calcium aluminate cement, 0.5-1.5% of metal silicon powder, 2.5-3.5% of water-soluble epoxy resin and water-soluble curing agent, 0.05-0.10% of explosion-proof fiber, 0.1-0.15% of sodium hexametaphosphate, 0.05-0.10% of an organic reducing agent, and 0. 04-0.07% of an organic silane coupling agent. With the slag-adhesion-preventing coating, the comprehensive targets are achieved, that service lives of the furnace beam and the column insulation lining are prolonged, furnace energy consumption and insulation lining surface slag adhesion amount are reduced, furnace maintenance cost is reduced, and high-temperature-oriented silicon steel production efficiency is improved.

Owner:武汉钢铁有限公司

High conductive high strength graphite brick for ultralarge blast furnace, its production technology and application

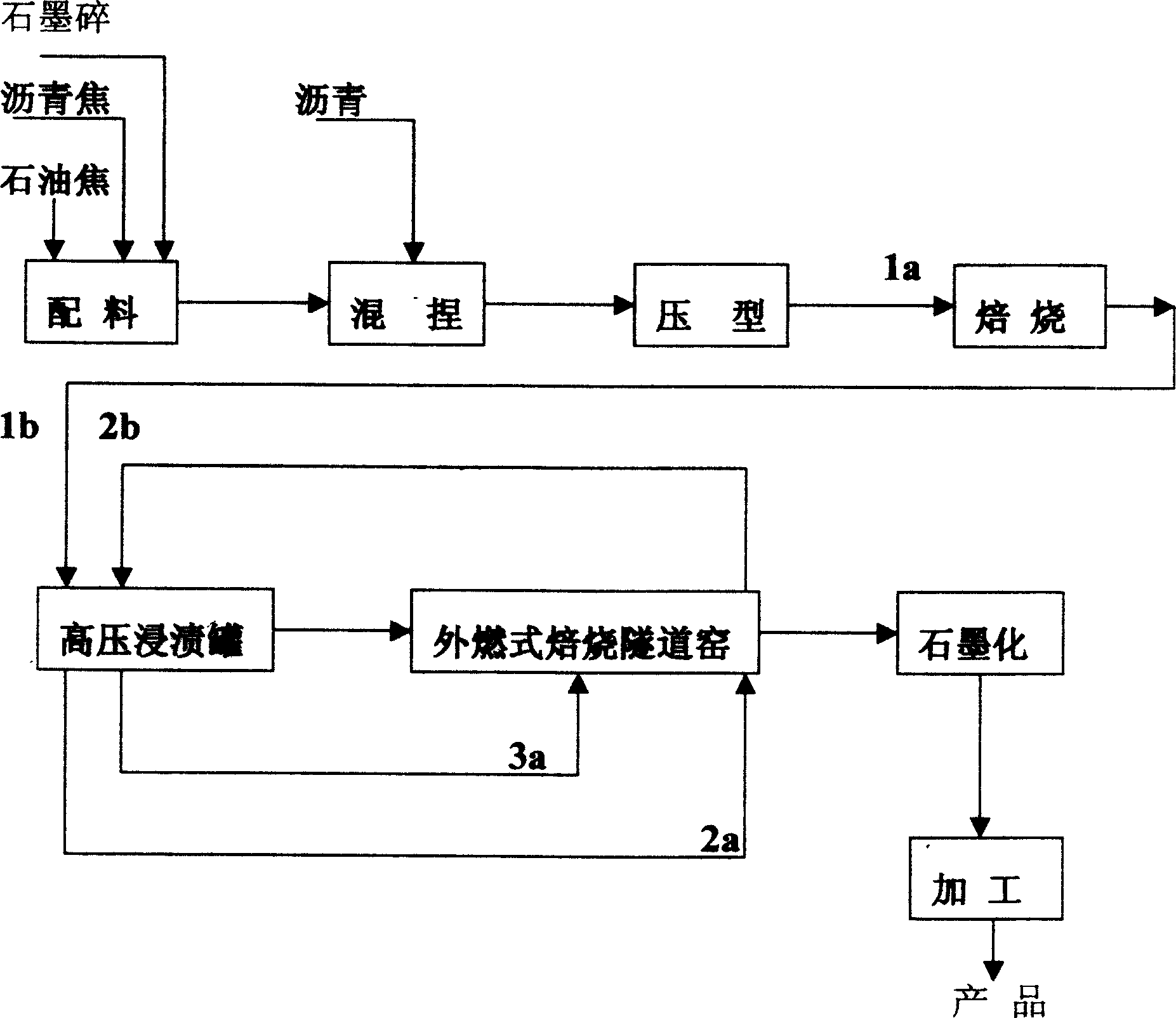

The present invention relates to a high heat conductivity and high strength graphite brick for super-large blast furnace. It is made up by using (by wt%) 92%-94% of mixed coke formed from petroleum coke and pitch coke and 6%-8% of powdered graphite through the processes of pulverizing, grinding, screening, wet kneading, moulding, roasting and graphitization.

Owner:SINOSTEEL JILIN CARBON +1

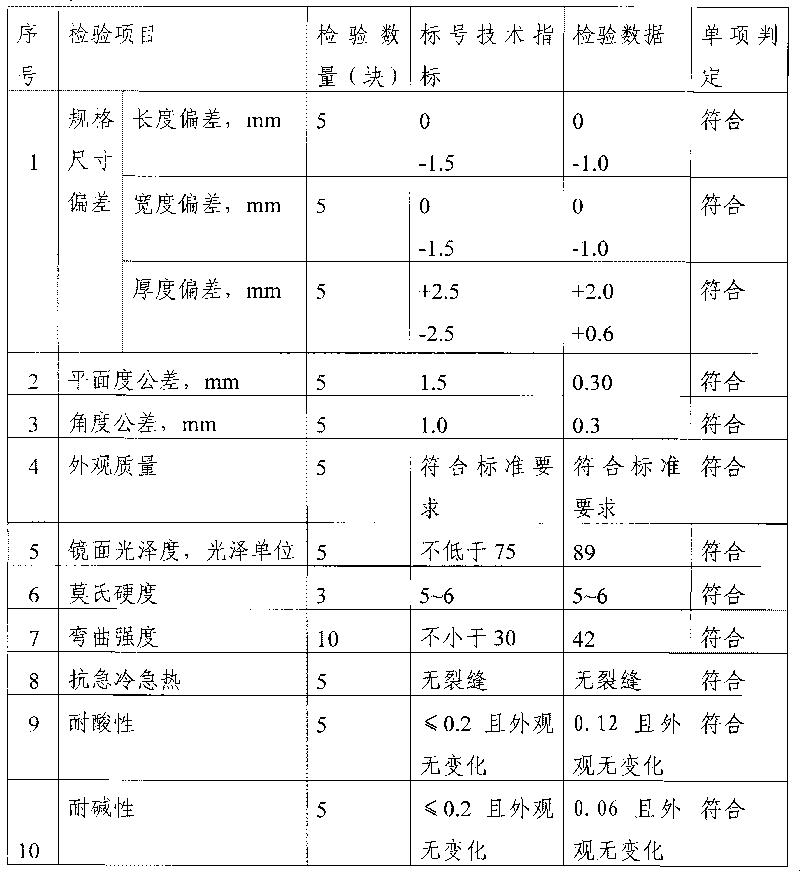

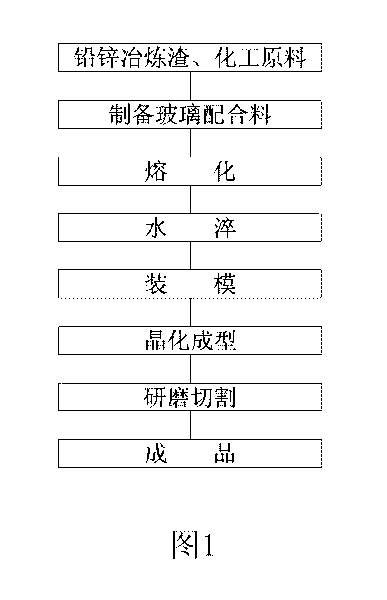

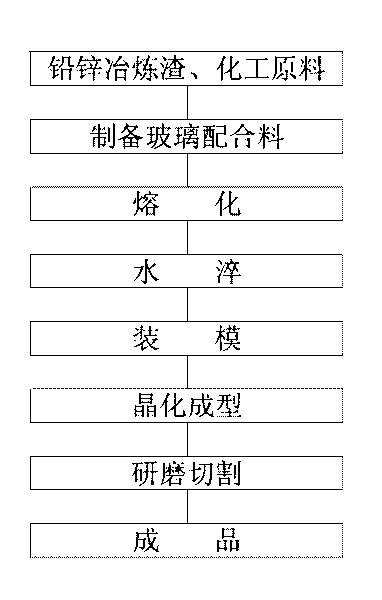

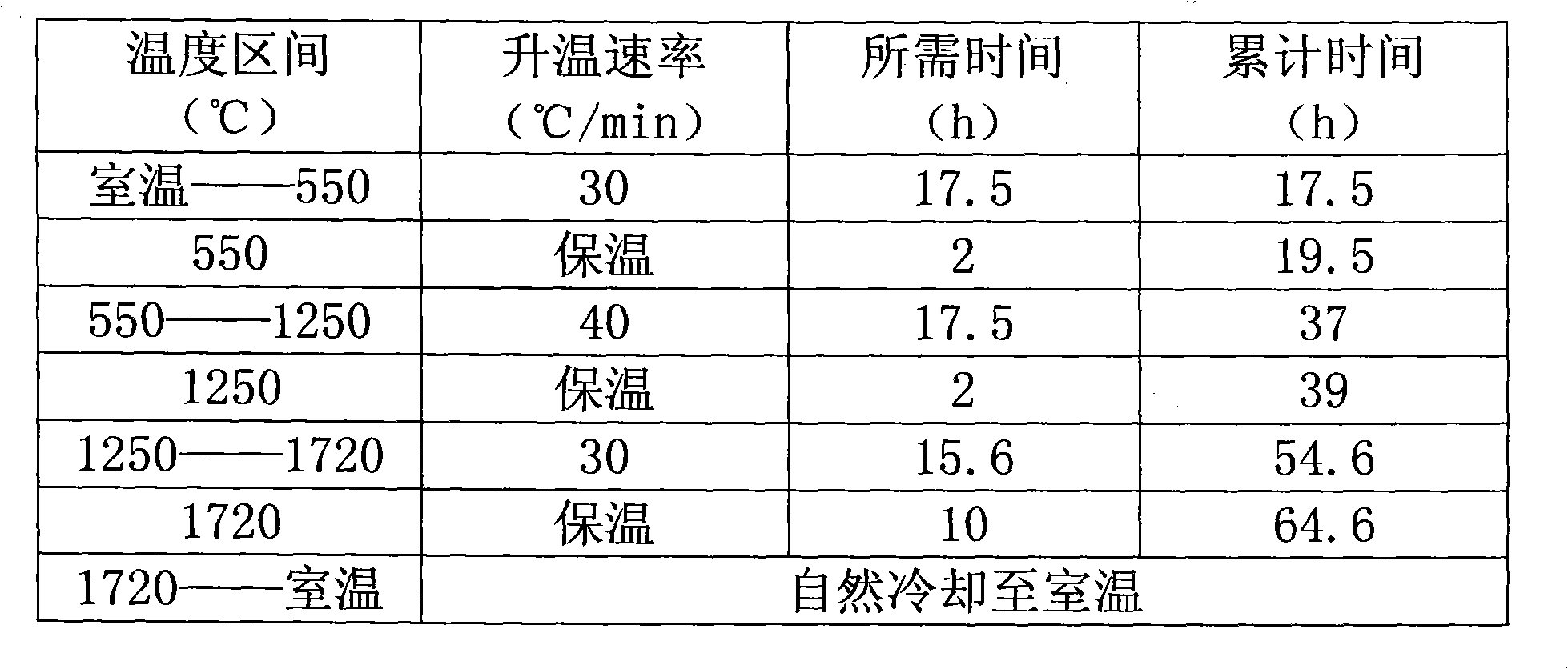

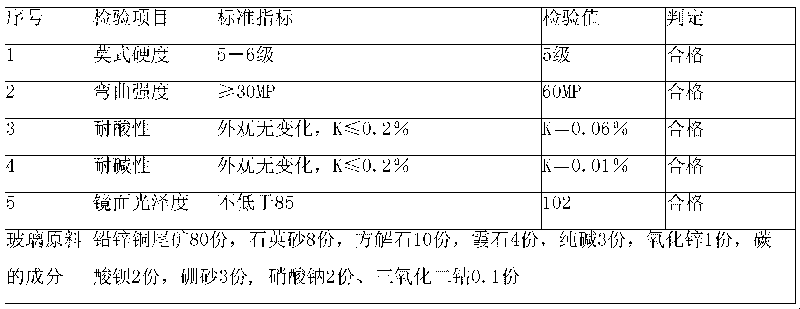

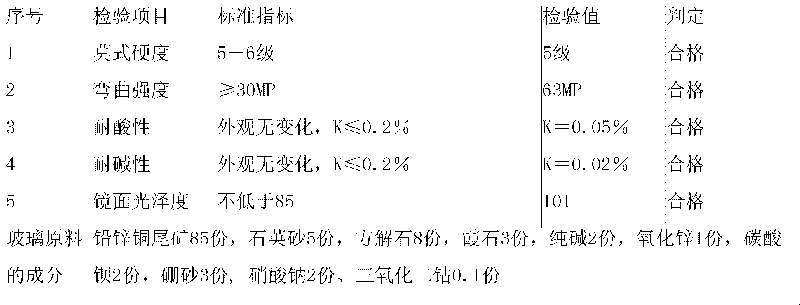

Method for manufacturing black microcrystalline glass plates from molybdenum tailings

The invention discloses a method for manufacturing black microcrystalline glass plates from molybdenum tailings, which comprises the following steps: mixing a certain part by weight of molybdenum tailings, quartz sand, lime stone, sodium carbonate, zinc oxide, barium carbonate, ferric oxide, manganese dioxide, nickel oxide and cobalt oxide to prepare a glass batch; melting the glass batch into molten glass, and then, pouring the molten glass into water to form glass particles; horizontally laying the glass particles in a fire-resistant mold for crystallization heat treatment; and grinding and cutting black microcrystalline glass crude products after crystallization heat treatment to form finished products. By using the molybdenum tailings for manufacturing black microcrystalline glass plates, the invention not only reduces the stockpiling amount of tailings and relieves the environmental pollution, but also can improve the product performance and reduce the production cost, thereby having good social benefit and economic benefit.

Owner:陕西乾盛环保建材工程有限公司

Overflow water level warning method for glacial lake outburst and application thereof

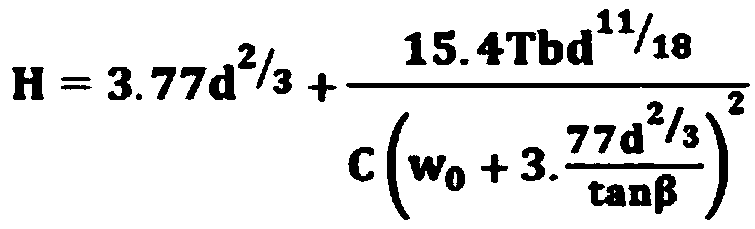

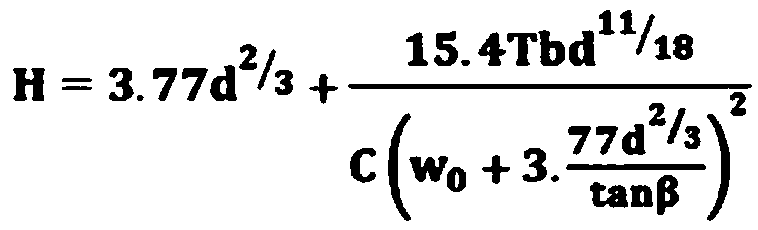

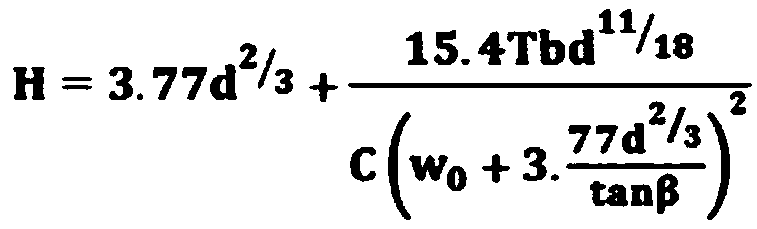

ActiveCN107749144AImprove the accuracy of early warningImprove applicabilityHuman health protectionAlarmsCalculated resultWidth ratio

The invention discloses an overflow water level warning method for glacial lake outburst, which comprises the following steps: (a) the thickness T of the top of an ice trace dam, the width b of the outburst mouth, the average width w0 of a glacial lake, the length-to-width ratio c of the glacial lake, the average slope Beta of the shore slope of the glacial lake before outburst, and the characteristic particle size d of incipient sediment are surveyed; (b) the critical overflow water depth H of glacial lake outburst is calculated; and (c) the water level of the glacial lake above the overflowmouth rises suddenly for more than 30s, and when HCr<0.6H, there is very small probability that the glacial lake bursts; when 0.6H<=HCr<0.8H, there is small probability that the glacial lake bursts; when 0.8H<=HCr<H, there is medium probability that the glacial lake bursts; and when the HCr>=H, there is large probability that the glacial lake bursts. The method fully considers the factors influencing the critical overflow water depth of glacial lake outburst. The calculated result is more in line with the actual situation. The accuracy of warning is high. The method is of higher applicability.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Green glass-ceramic plate made from lead-zinc smelting slag and manufacturing method thereof

The invention relates to a green glass-ceramic plate made from lead-zinc smelting slag and a manufacturing method thereof. The glass raw material is prepared from the following components in parts by weight: 40 to 60 parts of lead-zinc smelting slag, 26 to 38 parts of quartz, 15 to 24 parts of lithium feldspar, 2 to 4 parts of soda ash, 2 to 3 parts of zinc oxide, 2 to 5 parts of barium carbonate, 1 to 3 parts of borax, 2 to 2.5 parts of chromium oxide, 0 to 0.2 part of copper oxide and 0.04 to 0.2 part of carbon powder. The invention is not only in line with the common glass-ceramic produced by completely adopting industrial materials on the aspect of the performance, but also can realize waste utilization, reduce the environmental pollution, the product cost and the melting temperature of glass, improve the melting speed and the melting furnace efficiency of the glass, decrease the energy consumption and can be widely applied to building decoration materials, especially applied in various building decoration engineering, such as inside and outer walls, floors, pillars, table boards of the building, and the like.

Owner:FENGXIAN SANLIAN BUILDING MATERIALS

95 chromium-aluminum-zirconium brick for coal water slurry pressurized gasifier and preparation method thereof

The invention belongs to the technical field of refractory materials, and discloses a 95 chromium-aluminum-zirconium brick for a coal water slurry pressurized gasifier and a preparation method thereof. The 95 chromium-aluminum-zirconium brick comprises electrically fused chromium oxide, chromium oxide green, fine zirconium oxide powder, fine alpha-Al2O3 powder and an adhesive serving as raw materials in percentage by weight; the preparation method comprises the following steps of: (1) weighing the raw materials in percentage by weight; (2) mixing and rolling the raw materials in a wet mill toform slurry; (3) pressing the slurry in a friction press to prepare a half-finished product; (4) drying the half-finished product in a drying kiln; (5) firing the dried half-finished product in an automatic shuttle kiln; and (6) taking the finished product out of the kiln, and checking the appearance and the physicochemical property of the product. Compared with the conventional 90 chromium-aluminum-zirconium brick, the 95 chromium-aluminum-zirconium brick has the advantages that the scour resistance, corrosion resistance, volume density, and ambient compressive strength are improved and the service life of the 95 chromium-aluminum-zirconium brick is improved by 20 to 50 percent.

Owner:李正平

Pouring forming high life corundum mullite ladle lower nozzle brick and preparation method thereof

InactiveCN110526722AImproved thermal shock stabilityImproved thermal shock stability and improved spalling resistancePrillBrick

The invention discloses a pouring forming high life corundum mullite ladle lower nozzle brick and a preparation method thereof, and belongs to the technical field of lower nozzle bricks. The raw materials of aggregate for the lower nozzle brick of a ladle are prepared from 30-40wt% of recycled particles of a waste heavy mullite brick, 20-30wt% of bauxite particles, and 1-10wt% of raw quartz sand particles; the raw materials for co-grinding power are prepared from 2-18wt% of recycled fine powder of the waste heavy mullite brick, 10-20wt% of electrofused corundum fine powder, 1-10wt% of alpha-Al2O3micro powder, 0.5-3.0wt% of silica micro powder, and 3-8wt% of pure calcium aluminate cement; total weight percentage of each raw material is 100%; and in addition, water accounts for 8wt% of totalweight of the raw materials. According to the corundum mullite, thermal shock stability of the ladle lower nozzle brick is improved, and spalling resistance and erosion resistance of slag and moltensteel of the ladle lower nozzle brick are improved.

Owner:MAANSHAN LIER KAIYUAN NEW MATERIAL

Wear-resistant propping agent

ActiveCN101768431AImprove wear resistanceImprove impact resistanceFluid removalDrilling compositionWear resistantCarbon nanotube

The invention relates to a wear-resistant propping agent comprising a matrix and a matrix coating. The matrix coating is formed by the solidification of a resin binder and is added with a carbon nano tube, wherein the weight ratio of the resin binder and the matrix is 0.1-15:100, and the carbon nano tube accounts for 0.1-5wt% of the weight of the resin binder. The wear-resistant propping agent has the advantage of resisting environmental corrosion.

Owner:BEIJING RECHSAND SCI & TECH GRP

Method for manufacturing microlite by using high-silicon iron tailings

The invention discloses a method for manufacturing microcrystalline glass plates by using iron tailings, which comprises the steps of adding 30 to 70 percents of iron tailings in a glass batch, wherein quartz sand, aluminum oxide, sodium carbonate, calcium carbonate and other raw materials can be partially replaced by the iron tailings; melting the glass batch for four hours in a crucible or an electric box furnace, wherein the melting temperature is 1480-1500 DEG; introducing the molten glass liquid into water directly to form glass particles after the melting process; laying the glass particles in a refractory mould to carry out crystallization heat treatment in a tunnel kiln, a shuttle kiln or an electric box furnace with the crystallization temperature to be 1020-1050 DEG. The invention utilizes castoff microcrystalline glass, thereby not only reducing the stockpiling amount of tailings and relieving the environmental pollution, but also improving the product performance. Meanwhile, the production cost is reduced. Thus, the method for manufacturing microcrystalline glass plates by using iron tailings has good social benefit and economic benefit.

Owner:BEIJING QING MAI HUA QING HLDG GRP CO LTD

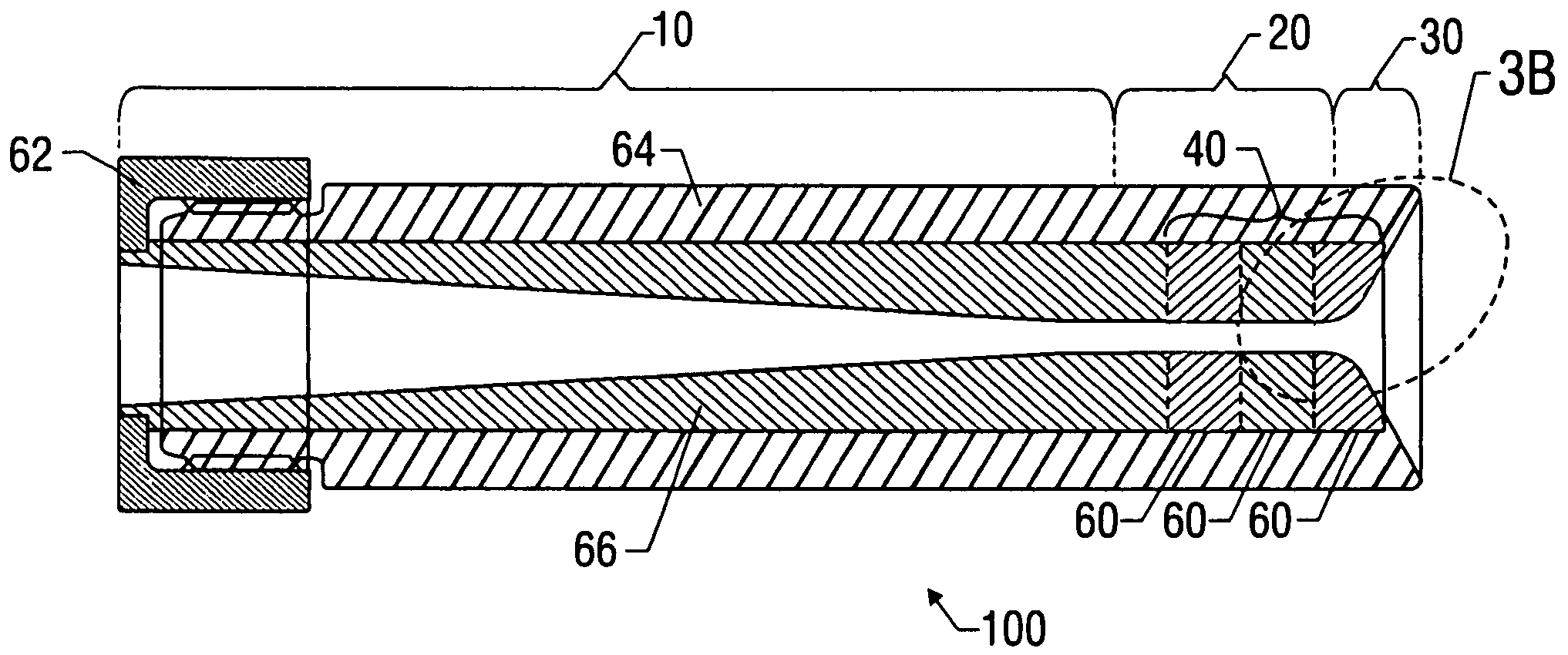

Downhole oilfield erosion protection by using diamond

ActiveUS7347259B2Reduce erosionImprove erosion abilityDrilling rodsCleaning apparatusThroatPolycrystalline diamond

A device for use with components for a downhole tool—such as a throat, a nozzle, or a diffuser—used for cleaning a wellbore, are disclosed which decreases the erosion of the components. The device may be comprised of a hardened material, such as stack of pure diamond disks brazed to form an insert for a throat. The device may also be comprised of polycrystalline diamond (PCD) washers stacked together and mechanically secured within the component such as a throat. The device may also be comprised of diamond grown on a mandrel into a trumpet shape, which may then be brazed or epoxied into the component. As each of these materials is harder than materials previously utilized, erosion performance is enhanced. A method of improving erosion performance of components utilized to clean a wellbore is also disclosed.

Owner:BAKER HUGHES INC

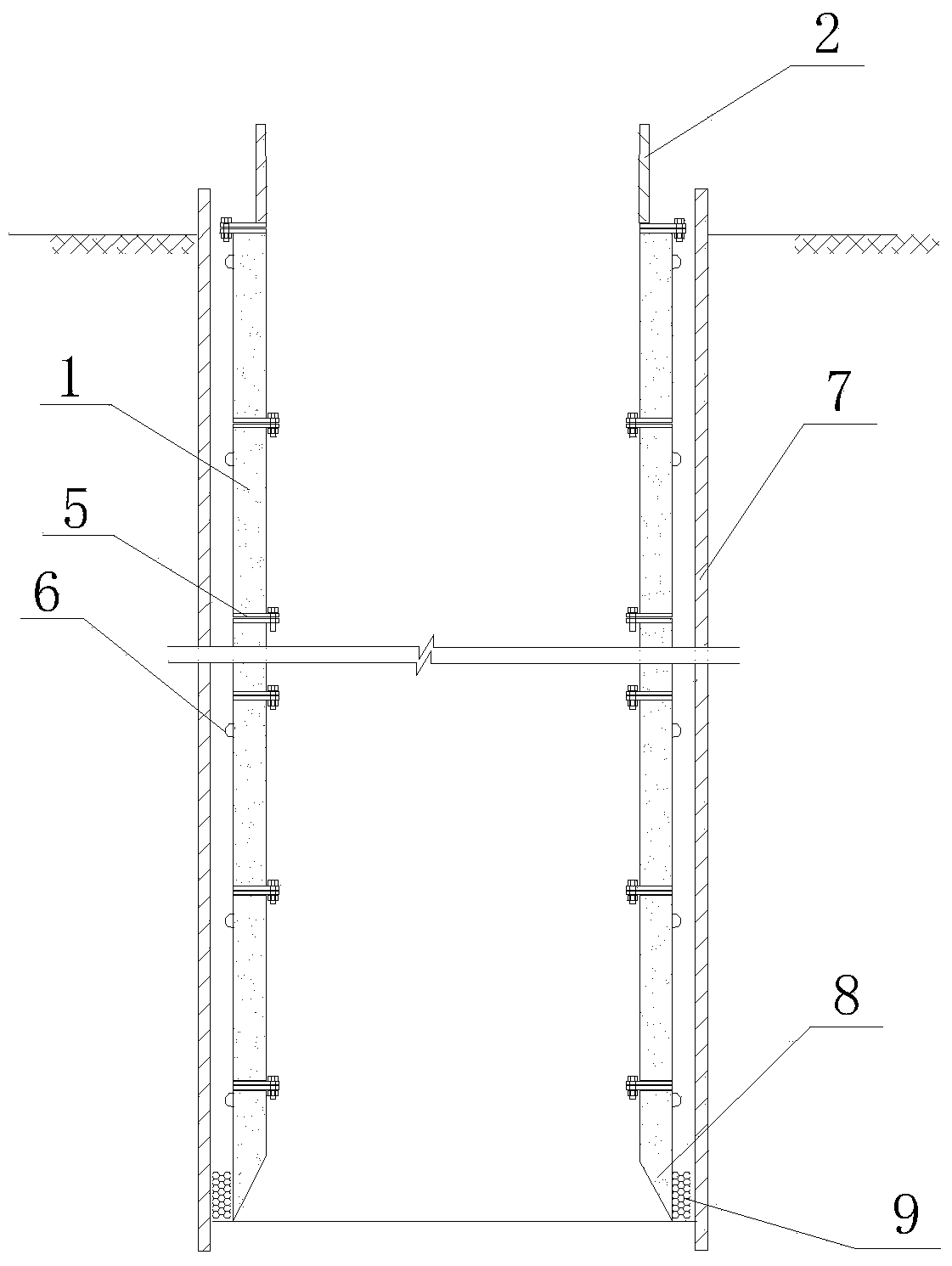

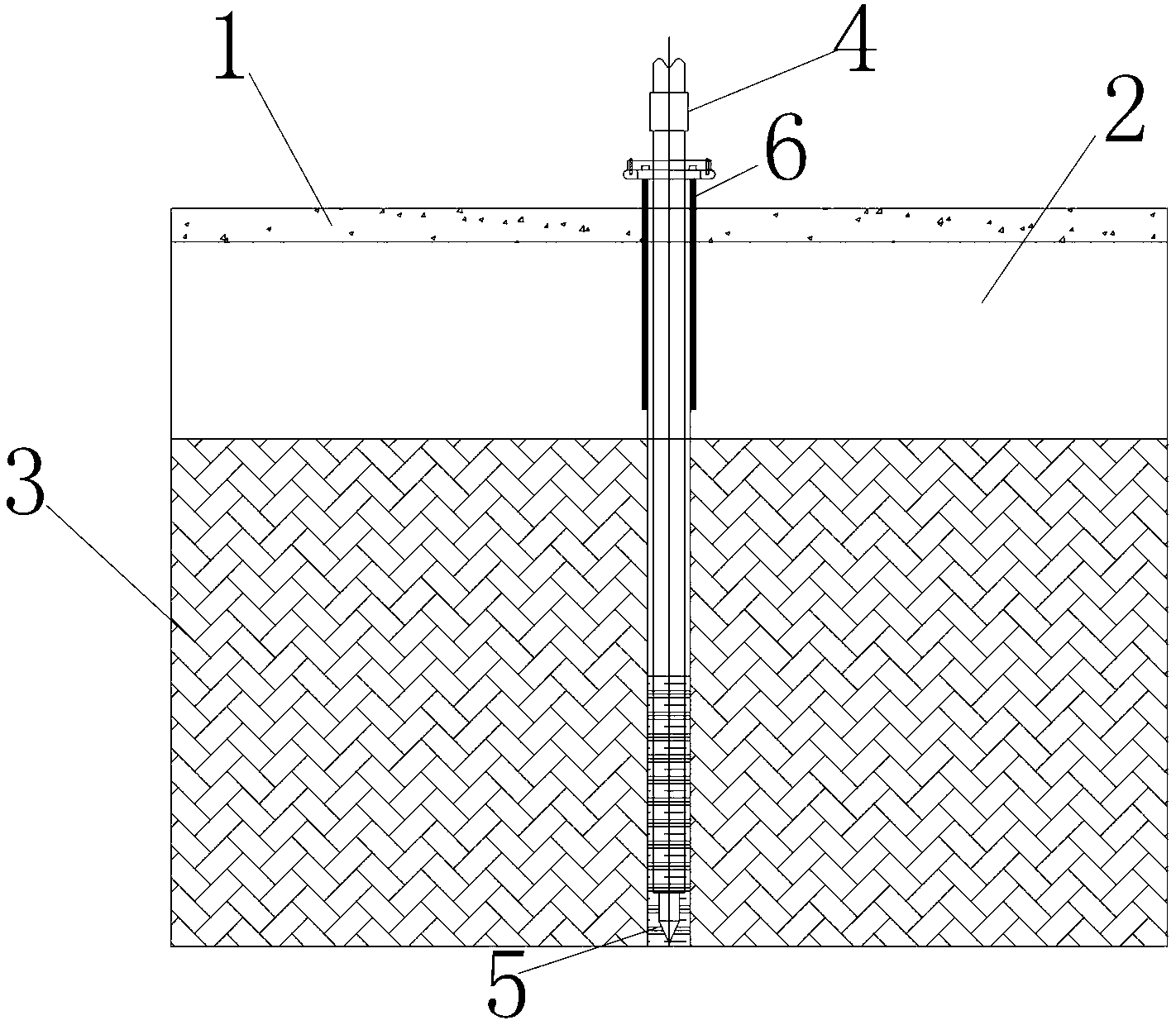

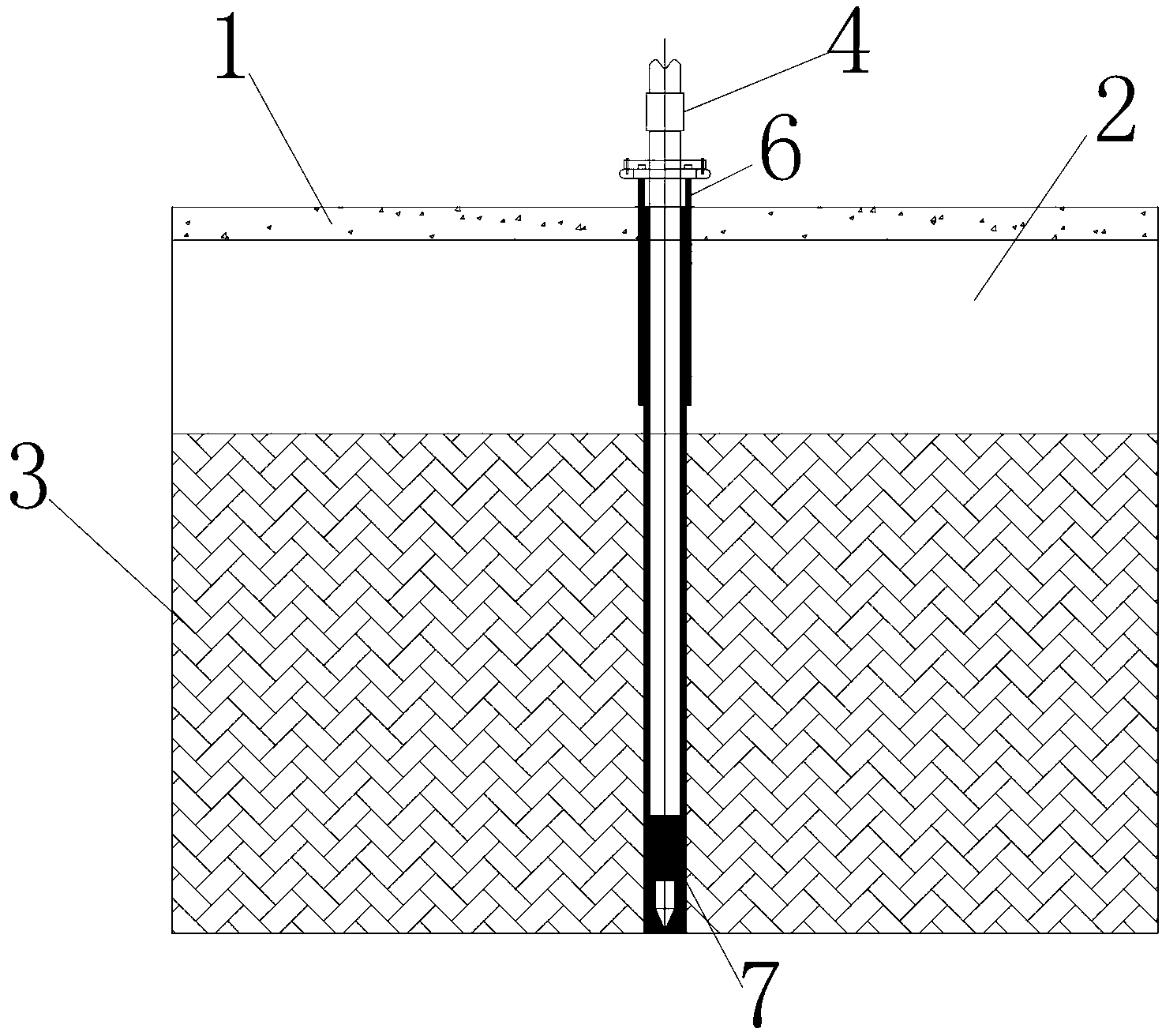

Double-protective-cylinder cast-in-situ bored pile used for highly-corrosive salty soil and construction method of double-protective-cylinder cast-in-situ bored pile

InactiveCN103967032AQuality improvementImprove corrosion resistanceBulkheads/pilesReinforced concreteEngineering

The invention belongs to the field of civil engineering, and particularly relates to a double-protective-cylinder cast-in-situ bored pile used for highly-corrosive salty soil and a construction method of the double-protective-cylinder cast-in-situ bored pile. The double-protective-cylinder cast-in-situ bored pile used for the highly-corrosive salty soil comprises an outer protective cylinder (7) and an inner protective cylinder (1), wherein the inner protective cylinder (1) is located in the outer protective cylinder (7), the inner protective cylinder (1) is prefabricated concrete, and a reinforced framework is arranged in the concrete. The inner protective cylinder made of reinforced concrete can be prefabricated in a prefabricated component factory or on site, construction requirements for quality of protective cylinder concrete, the thickness of a protection layer and the like can be fully met, the inner protective cylinder can be conveniently spliced and placed in the right position, and accordingly much trouble can not be caused for construction.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

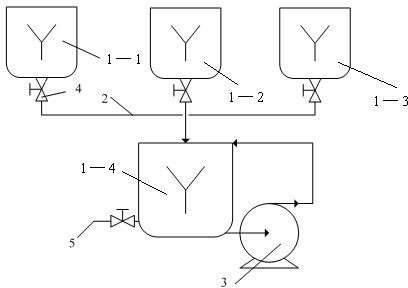

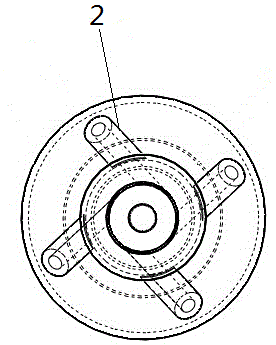

Integrated rotary cavitating jet nozzle

The invention relates to an integrated rotary cavitating jet nozzle comprising a cylindrical inlet segment, a cylindrical resonant cavity, a cylindrical pore and a cylindrical outlet segment. The cylindrical outlet segment is provided with a plurality of intake tubes; bores of the intake tubes are tangent to a bore of the cylindrical outlet segment. The inner diameter of the intake tubes is half a difference between the inner diameter of the cylindrical outlet segment and the diameter of the cylindrical pore. The section of the bore of each intake tube is round, square, or in any special shape. The intake tubes can be axially distributed in multiple rows at the cylindrical outlet segment of a nozzle body. Compressed air is led into the intake tubes, the compressed air led in from the intake tubes enters in the tangent direction, air swirls surrounding a water jet are formed in the cylindrical outlet segment and drive the water jet to turn into a rotating vortex in the cylindrical outlet segment, and cavitating effect is further enhanced; meanwhile, cavitating bubbles are concentrated to the center of the water jet, energy of the cavitating water jet is more concentrated, the shear action of the jet upon a target is enhanced, and eroding capacity of the cavitating jet is greatly improved accordingly.

Owner:XIHUA UNIV

Biomass carbon matrix environment-friendly brick and making method

InactiveCN107324773AGood environmental protection functionIncrease profitCeramic materials productionClaywaresBiomass carbonToxic gas

The invention discloses a biomass carbon matrix environment-friendly brick and a making method. The biomass carbon matrix environment-friendly brick is characterized by comprising the following components (in percentage by weight): 35-45% of biological black carbon, 55-65% of an earth material and 1-3% of molding aids, wherein the brick is made by treating the earth material, mixing with the biological black carbon, molding, drying and roasting; the biological black carbon is biological black carbon granules or powder ash made of biomasses via high-temperature carbonization; the earth material comprises 15-35% of clay, 15-25% of shale powder ash, 15-25% of coal gangue powder ash and 15-25% of coal ash; the 1-3% of molding aids comprise bentonite, fulvic acid powder and tapioca flour. The making method comprises the following steps: performing high-temperature carbonization on various types of biomass straw so as to obtain biological black carbon granules or powder ash; grinding shale, coal gangue and coal residues into a powder material; uniformly mixing with the clay and the molding aids; making bricks by using a brick making machine, drying, and sintering. Due to adoption of a biomass black carbon material, the biomass carbon matrix environment-friendly brick is capable of adsorbing toxic gases as a whole for a long time, is light and environmentally friendly, and is capable of purifying indoor polluted air and lowering cost.

Owner:湖北金日生态能源股份有限公司

Hole sealing grout stop material and grouting hole sealing process

The invention discloses a hole sealing grout stop material, which is a hole sealing grout stop material for guaranteeing grouting pressurization under the condition of loose permeable rock-soil body, high underground level or confined water. The hole sealing grout stop material is mainly prepared from clay primary grout, cement and sodium metaaluminate, wherein every 2 L of clay primary grout is mixed with 700-900 g of cement and 12.5-17.5 g of sodium metaaluminate. A grouting hole sealing process comprises hole sealing operation and grouting operation, wherein the hole sealing operation specifically comprises the following steps of: after forming a hole, dropping a grouting pipe to the bottom of the hole and mounting a orifice closer; opening the orifice closer and injecting the hole sealing grout stop material; closing the orifice closer and flushing the grouting pipe by using stable grout; and opening the orifice closer, performing grouting operation after solidifying the hole sealing grout stop material, and guaranteeing reliable hole sealing grouting through continuous lift grouting. The grouting hole sealing process has the advantages of simple steps, less equipment investment, high applicability, capabilities of guaranteeing the reliability of the hole sealing grout and increasing the grouting efficiency and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Nanometer-modified fiber reinforced plastic reinforcement sea sand concrete fence board and preparation method thereof

The invention discloses a nanometer-modified fiber reinforced plastic reinforcement sea sand concrete fence board which is mainly made of sea sand concrete and nanometer-modified FRP (Fiber Reinforced Plastic) reinforcements, wherein the nanometer-modified FRP reinforcements are mainly prepared from the following raw materials in percentage by mass: 65-75 percent of fiber reinforce plastic, 21.5-29.5 percent of resin, 0.045-0.6 percent of nanometer material, 0.15-0.45 percent of accelerant, 0.04-0.05 percent of polymerization inhibitor, 0.3-0.6 percent of curing agent and 1.5-4.5 percent of ethylene glycol. The invention also discloses a preparation method of the nanometer-modified fiber reinforced plastic reinforcement sea sand concrete fence board. The FRP reinforcements in the nanometer-modified FRP reinforcement sea sand concrete fence board have the advantages of high strength, high mass ratio, small elastic modulus, good fatigue property, small stress relaxation, good corrosion resistance and the like; and sea sand is directly utilized, so that not only the economic and social effect is huge, but also the ecological environmental protection is favorably promoted.

Owner:HOHAI UNIV

Lightweight periclase-magnesium aluminate spinel refractory material and preparation method thereof

The invention relates to a lightweight periclase-magnesium aluminate spinel refractory material and a preparation method thereof. The refractory material contains 14-21 wt% of porous periclase-magnesium aluminate spinel ceramic material particles with the particle size of 3-5 mm, 27-36 wt% of porous periclase-magnesium aluminate spinel ceramic material particles with the particle size being less than 3 mm and not less than 1 mm, 12-18 wt% of porous periclase-magnesium aluminate spinel ceramic material particles with the particle size of nano-apertures being less than 1 mm and not less than 0.1 mm as aggregates, contains 10-20 wt% of nano-aperture porous periclase-magnesium aluminate spinel ceramic material fine powder, 8-10 wt% of magnesium aluminate spinel fine powder and 10-20 wt% of magnesia fine powder as a matrix, and also contains 2-8 wt% of a binder. The preparation method comprises the following steps: placing the aggregates in a vacuum stirrer, carrying out vacuum pumping, adding the binder, stirring the aggregates and the binder, and stopping a vacuum pumping system; and adding the matrix, stirring the aggregates, the binder and the matrix, forming the obtained mixture, drying the formed mixture, keeping the temperature in a range of 1500-1650 DEG C for 3-8 h, and cooling the obtained mixture to obtain the lightweight periclase-magnesium aluminate spinel refractory material. The apertures of the lightweight periclase-magnesium aluminate spinel refractory material are nanometer level apertures, and the lightweight periclase-magnesium aluminate spinel refractory material has the advantages of low heat conduction coefficient, excellent thermal shock stability and strong erosion resistance.

Owner:河南瑞泰耐火材料科技有限公司 +1

High volume stability marine concrete and its preparation method

The present invention relates to marine engineering concrete and its preparation process. The marine engineering concrete with high volume stability consists of fine synthetic fiber in 0.05-0.15 vol%, cementing material in 400-500 kg / cu m, crushed stone in 1000-1300 kg / cu m, sand in 600-1000 kg / cu m, and plasiticizer accounting for 0.5-2.0 wt% of the cementing material. The cementing material includes Portland cement, ground ore slag and silica fume. The marine engineering concrete with high volume stability has high anticorrosion capacity to sulfate and chloride in sea water, low hydration heat, high microscopic compatibility, high strength, low cost, greatly raised volume stability and durability and raised resistance to environment temperature and humidity change.

Owner:TONGJI UNIV

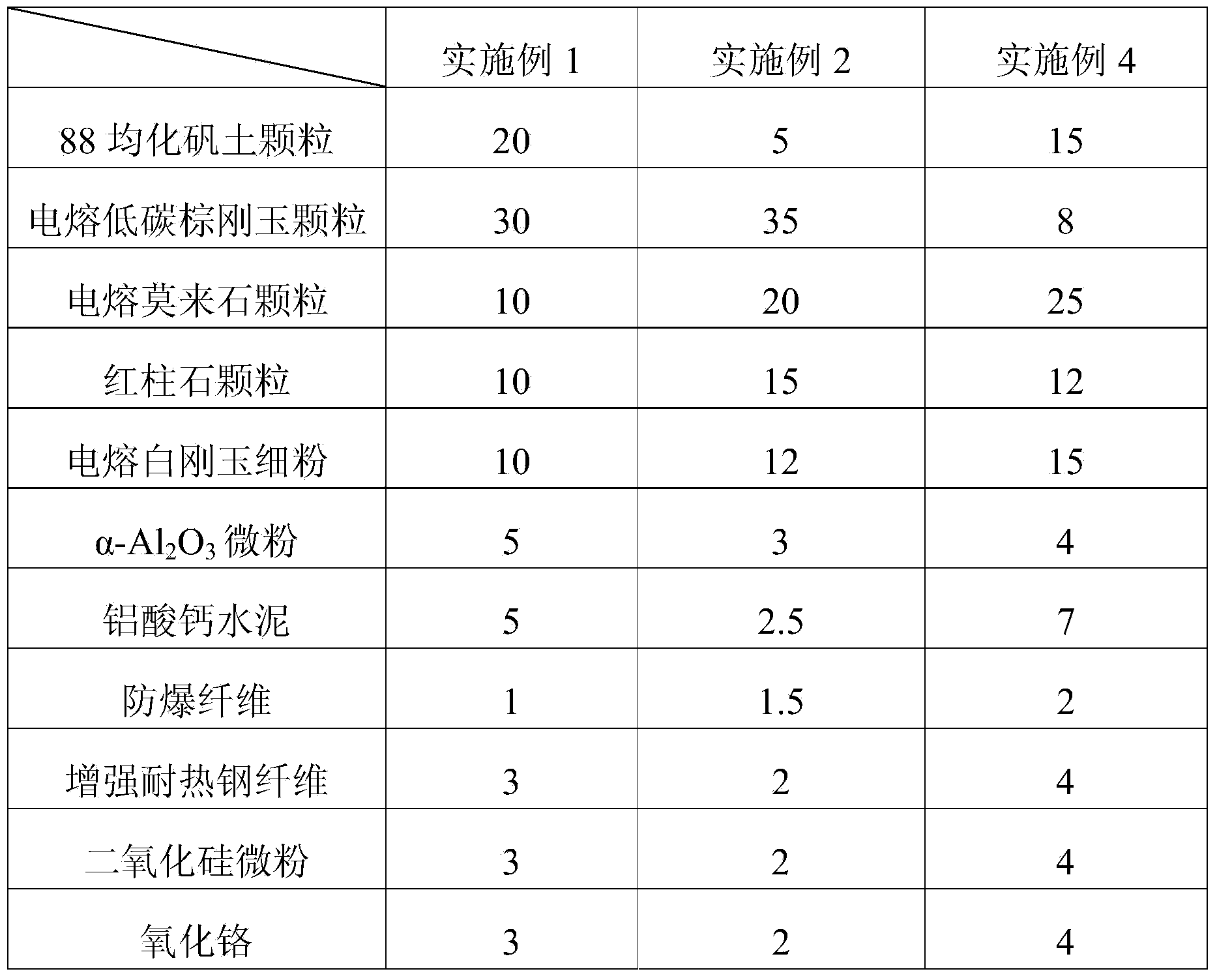

Alumina electric furnace cover and preparation method thereof

The invention aims to provide an alumina electric furnace cover, which is high in thermal shock resistance, density and iron slag erosion resistance and long in service life. The alumina electric furnace cover comprises the following components in percentage by weight: 5 to 20 percent of 88 homogenized alumina particles, 8 to 35 percent of electrofused low-carbon brown aluminum oxide particles, 10 to 25 percent of electrofused mullite particles, 10 to 15 percent of andalusite particles, 10 to 15 percent of electrofused white corundum fine powder, 3 to 5 percent of alpha-Al2O3 micro powder, 2.5 to 7 percent of calcium aluminate cement, 1 to 2 percent of explosion-proof fibers, 2 to 4 percent of reinforced heat-resistant steel fibers, 2 to 4 percent of silicon dioxide micro powder and 2 to 5 percent of chromium oxide. A preparation method comprises the following steps of uniformly mixing the electrofused white corundum fine powder, the alpha-Al2O3 micro powder, the silicon dioxide micro powder and the explosion-proof fibers; adding the electrofused mullite particles and the andalusite particles, stirring the mixture for at least 3min, adding the other raw materials, and stirring the mixture for at least 8min; adding water and a water reducing agent, performing stirring and casting molding, and performing natural curing, de-molding and drying.

Owner:北京利尔高温材料股份有限公司

Black micro-crystal glass plate manufactured from lead-zinc-copper tailings and manufacturing method thereof

The invention relates to a black micro-crystal glass plate manufactured from lead-zinc-copper tailings, which is manufactured from the following raw materials in parts by weight: 60-90 parts of lead-zinc-copper tailings, 5-10 parts of quartz sand, 8-20 parts of calcite, 3-7 parts of nepheline, 2-4 parts of soda, 1-6 parts of zinc oxide, 2-8 parts of barium carbonate, 2-5 parts of borax, 2-6 parts of sodium nitrate and 0.1-0.5 part of cobalt oxide. The manufacturing method of the black micro-crystal glass plate comprises the following steps: grinding the lead-zinc-copper tailings, the quartz sand, the calcite and the nepheline into powder; removing cyanides from the lead-zinc-copper tailings by using an ion exchange method; weighing in proportion and preparing into a mixture; melting at 1250 DEG C-1350 DEG C; pouring the mixture into water for water quenching to obtain glass particles; horizontally laying the glass particles into a fire-resistant mold for crystallization treatment; and grinding and cutting black micro-crystal glass samples. The invention can relieve the harm of the tailings to the environment, reduce the cost of raw materials, and improve the product quality.

Owner:君达环保科技(宝鸡)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com