Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

745results about How to "Improve anti-scourability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Abrasion resistant ceramic coating

The invention discloses a brushing-proof abrasion-proof and erosion-proof ceramic paint, which is characterized by the following: selecting at least one of electric-melting brown corundum, electric-melting subwhite corundum, electric-melting white corundum, carborundum and electric melting mullite with different grain sizes as main material and at least one of compact corundum, electric-melting subwhite corundum, electric-melting white corundum, carborundum, silicon nitride and boron nitride as auxiliary material; using CA50 calcium aluminate cement or pure calcium aluminate cement as binder and nanometer micro-silica powder and active alpha-Al2O3 micropowder as reinforcer; making hyperdrying active high-effective dehydragent, sodium citrate and sodium hexametaphosphate as composite additive; loading in the strength stirrer to stir 12-17min; blending evenly; packing.

Owner:CHONGQING LUOMAN NEW MATERIAL TECH CO LTD

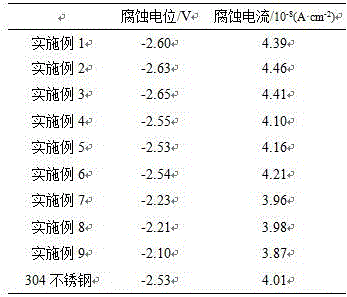

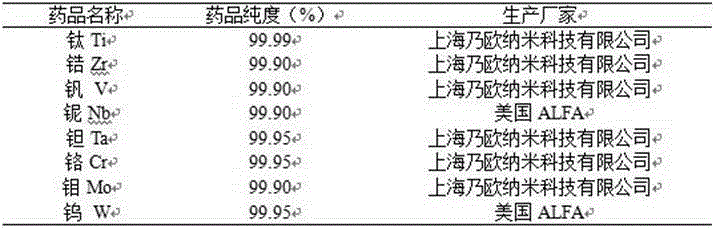

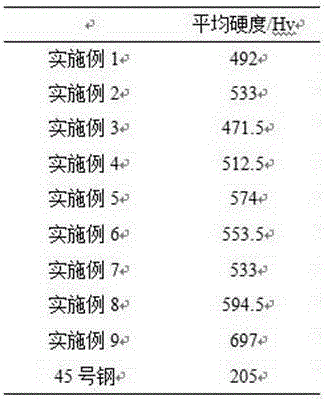

High-entropy alloy powder for laser cladding and preparation method of cladding layer

InactiveCN106086580AHigh bonding strengthEasy to diluteMetallic material coating processesHigh entropy alloysHardness

The invention discloses high-entropy alloy powder for laser cladding and a preparation method of a cladding layer. The high-entropy alloy powder comprises Ti, Zr, V, Nb, Ta and Mo. In addition, high-entropy alloy powder which comprises Ti, Zr, V, Nb, Ta, Mo and W, high-entropy alloy powder which comprises Ti, Zr, V, Nb, Ta, Mo, W and Cr and the preparation method of the cladding layer of the high-entropy alloy powder for laser cladding are provided. The high-entropy alloy powder mainly comprises two characteristics, namely, the high-entropy effect and the cocktail effect, each kind of powder exerts respective advantages, and therefore the cladding layer with high hardness, high corrosion resistance, excellent tempering softening resisting performance and excellent structure performance is obtained. Metallurgical bonding is formed by an alloy layer and a matrix through laser cladding; the bonding strength of the cladding layer and the matrix is greatly improved, and the heating speed is high; metal of the cladding layer is not prone to being diluted by the matrix; little heat deformation is generated; and therefore the part rejection rate is low.

Owner:KUNMING UNIV OF SCI & TECH

Water gap lining layer material for continuous casting

The invention discloses a water gap lining layer material for continuous casting. The material is prepared from the following components in percent by weight: 20-60 percent of corundum, 0-30 percent of electrofusion zirconium mullite, 0-40 percent of fused silica, 3-40 percent of ceramic hollow sphere, 1-10 percent of light burning alumina, 2-6 percent of sintering assistant, 2-6 percent of phosphate bonding agent and 4-8 percent of solid phenolic resin bonding agent. A water gap for continuous casting produced by adopting the material is suitable for cold casting, and a lining basically has no nodule blocking phenomenon; the lining has high strength and does not have phenomena of chambering and abnormal erosion; a water gap has long service life; and the continuous casting production efficiency is improved.

Owner:SHANGHAI BAOMING REFRACTORIES CO LTD

Unburned magnesium-aluminum spinel brick

The invention discloses an unburned magnesium-aluminum spinel brick, which comprises the following components by mass: 50-80% of corundum, 5-30% of magnesia-alumina spinels, 2-5% of magnesia powder, 3-10% of alumina powder, and the balance at least one of elemental silicon powder, metallic aluminum powder and boron carbide powder. All the components of the unburned magnesium-aluminum spinel brick are combined through an additionally added binder. The unburned magnesium-aluminum spinel brick causes no pollution to the environment, has excellent molten steel erosion resistance, slag penetration resistance and scouring resistance, and has a long service life additionally.

Owner:BAOSHAN IRON & STEEL CO LTD

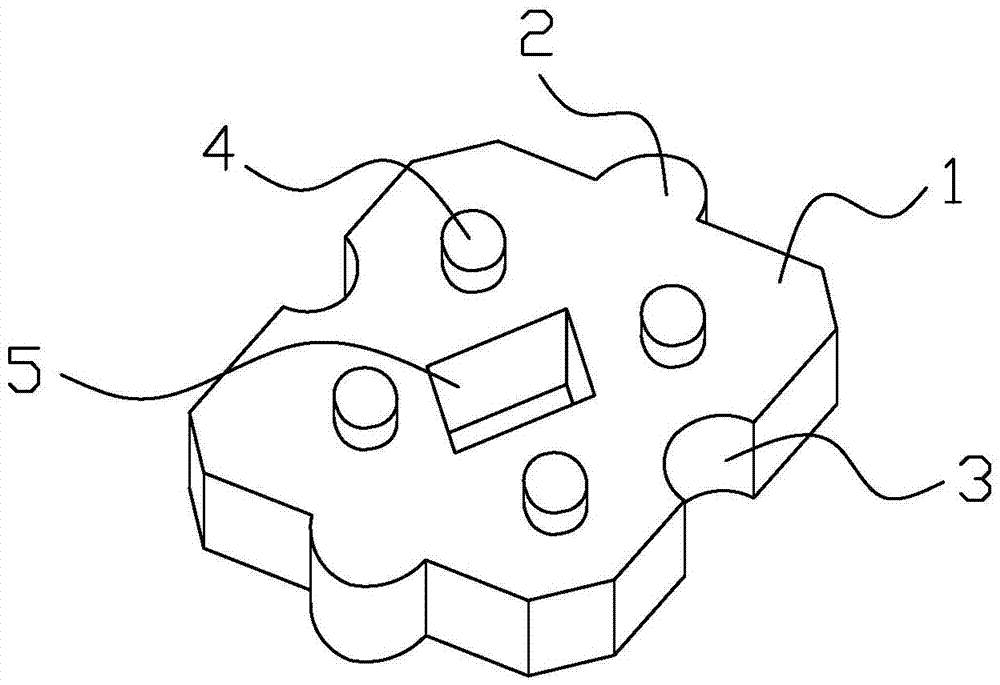

Ecological slope protection building block and slope protection method of ecological slope protection building block

The invention discloses an ecological slope protection building block and a slope protection method of the ecological slope protection building block. Four limiting columns are arranged on the top face of the ecological slope protection building block, four limiting holes matched with the limiting columns are formed in the bottom face of the ecological slope protection building block, a first plant growing hole is formed in the center of the ecological slope protection building block, limiting protruding blocks are arranged on the two opposite lateral sides of the ecological slope protection building block, and limiting grooves matched with the limiting protruding blocks are formed in the other two lateral sides of the ecological slope protection building block, so that connection of two ecological slope protection building blocks can be achieved. The slope protection method of the ecological slope protection building block includes the following steps: (1) carrying out project preparation, (2) processing a slope foundation, (3) forming a slope wall, and beginning to lay the ecological slope protection building blocks when the strength of concrete meets the design requirement, (4) laying the ecological slope protection building blocks, (5) checking the slope flatness, and (5) planting plants with flourished root systems between the first plant growing holes and second plant growing holes.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

High early strength and high corrosion resistant Portland cement and preparation method thereof

ActiveCN106082724AReduce tricalcium contentExtended service lifeClinker productionMass ratioPortland cement

Belonging to the field of cement production and also relating to the field of building materials, the invention provides a high early strength and high corrosion resistant Portland cement and a preparation method thereof. The high early strength and high corrosion resistant Portland cement is mainly applied to engineering projects in complex marine environments and the west harsh environments. The high early strength and high corrosion resistant Portland cement is characterized by containing, by weight percentage, 60%-90% of a high iron and low calcium cement clinker mineral component, 2%-10% of an auxiliary functional component, 5%-25% of an auxiliary cementitious component, and 3%-7% of industrial gypsum. The high iron and low calcium cement clinker mineral component is mainly prepared from high iron and low calcium Portland cement clinker and high iron and low calcium Q phase cement clinker in a mass ratio of 5-15:1. The cement not only has strong seawater erosion resistance and high early strength, but also has the characteristics of low shrinkage and low hydration heat.

Owner:WUHAN UNIV OF TECH

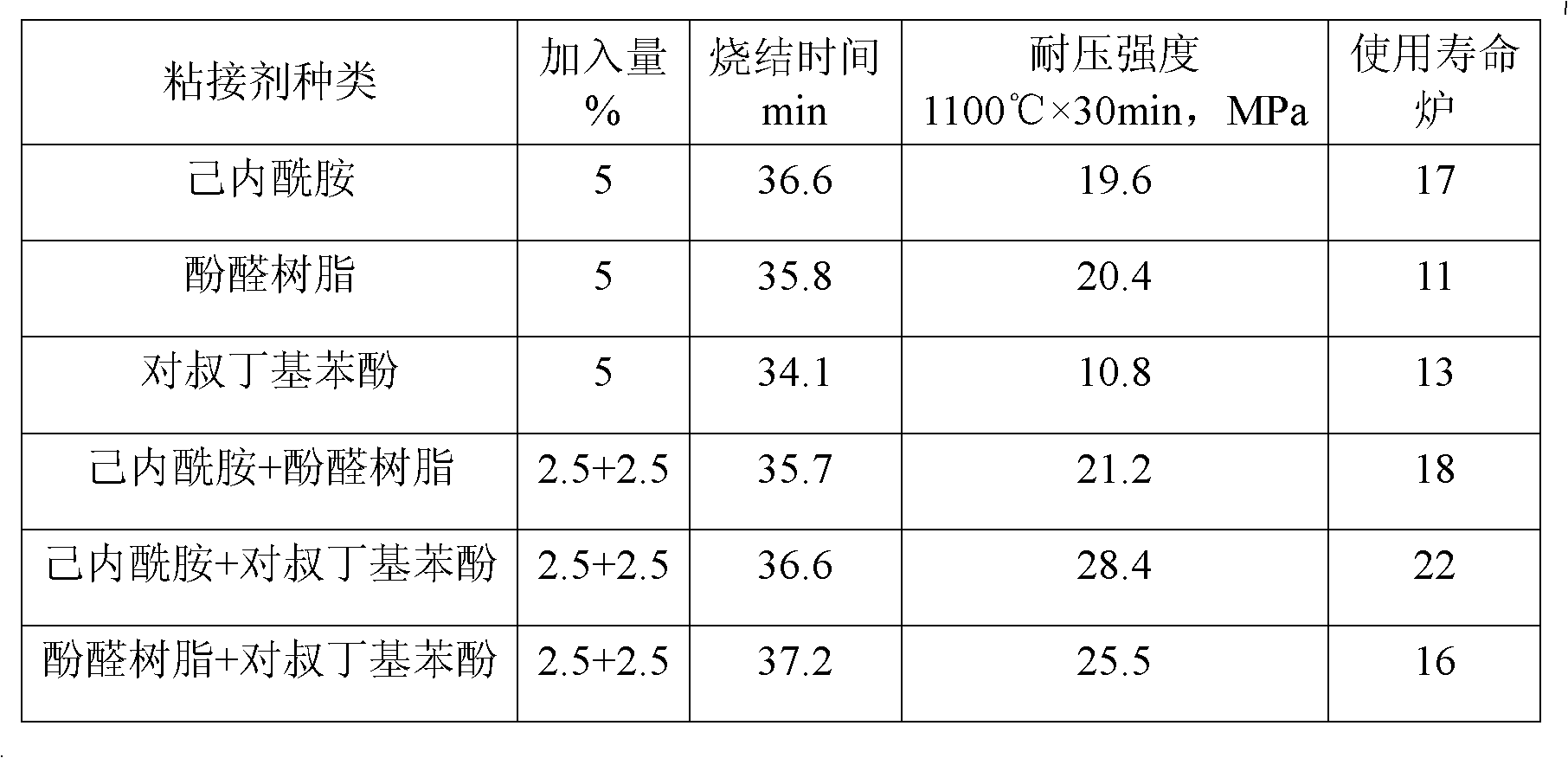

Repairing mass and preparation method thereof

The invention relates to a repairing mass for repairing in the converter production process of steel making and vanadium extracting of steel enterprises, in particular to a repairing mass used for a converter lining made of magnesia carbon bricks and a preparation method thereof, and provides a repairing mass having the advantages of short sintering time and long service life for meeting the requirement of production. The repairing mass per 100 weight parts comprises the following raw materials in parts by weight: 48-60 parts of fused magnesia, 22-28 parts of magnesite clinker, 10-16 parts ofmodified asphalt, 1-5 parts of metallic aluminum powder, 1-4 parts of ferric oxide powder and 2-10 parts of adhesive. The preparation method of the repairing mass is simple and convenient, i.e. all the raw materials are mixed. In the fettling production process of the vanadium extracting converter, when a local breakage appears on the converter lining, the repairing mass is coated on the part to be repaired; the repairing mass is sintered by utilizing the wall temperature of the converter, and production by blending with iron can be carried out after sintering; and under the conditions of lowsmelting temperature (1,360-1,400 DEG C) of the vanadium extracting converter and shorter smelting period (5-10 minutes), the repairing mass still can be quickly sintered with a working lining to form an organic combination with higher strength so as to prolong the service life of the repairing mass.

Owner:攀枝花钢城集团瑞矿工业有限公司

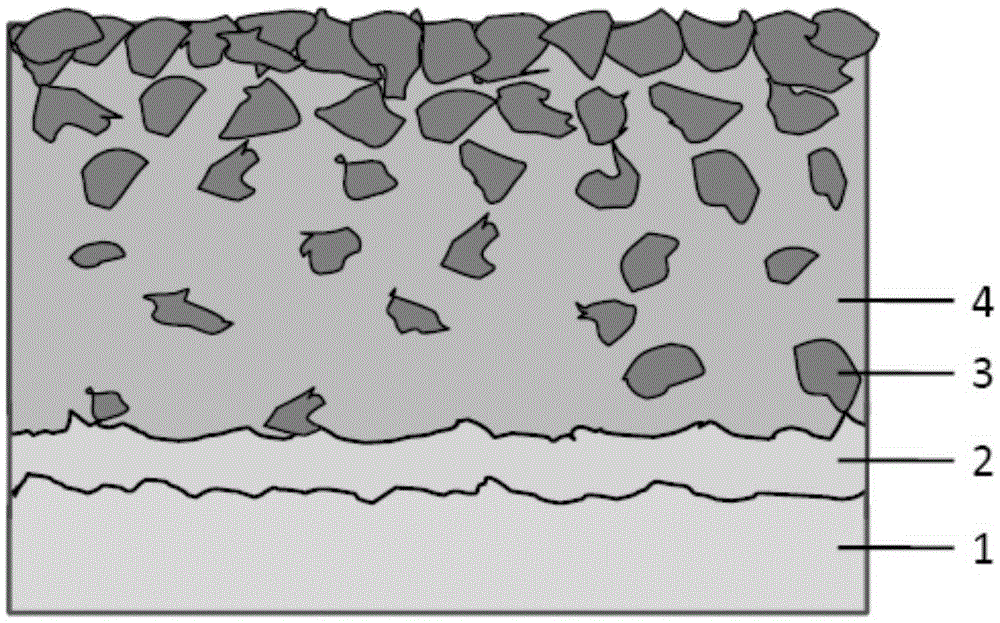

Environmental barrier coating used for ceramic base composite material matrix, and making method thereof

ActiveCN105384467AAlleviate or eliminate spalling and crackingReduce thermal matching differenceSurface layerThermal expansion

The invention provides an environmental barrier coating used for a ceramic base composite material matrix, and a making method thereof. The base layer of the environmental barrier coating selects a chemical vapor deposited SiC coating (transition layer), and the surface layer of the environmental barrier coating selects a plasma sprayed yttrium silicate and / or mullite coating. The SiC base layer and the ceramic base composite material matrix have extremely approaching thermal expansion coefficients, so cracking and spalling of the coating from the matrix are avoided; and the surface layer material selects a yttrium silicate doped mullite material, so the specific gravity of a mullite powder material is gradually increased from inside to outside; the yttrium silicate material has strong combination force with SiC, is matched with SiC in the thermal expansion coefficient, and also has the characteristics of low volatility and low oxygen permeability, so failure of the coating, caused by cracking of a base layer-surface layer interface, is avoided; and the mullite material has the advantages of good scouring resistance and high thermal stability, and can work in high temperature environment.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

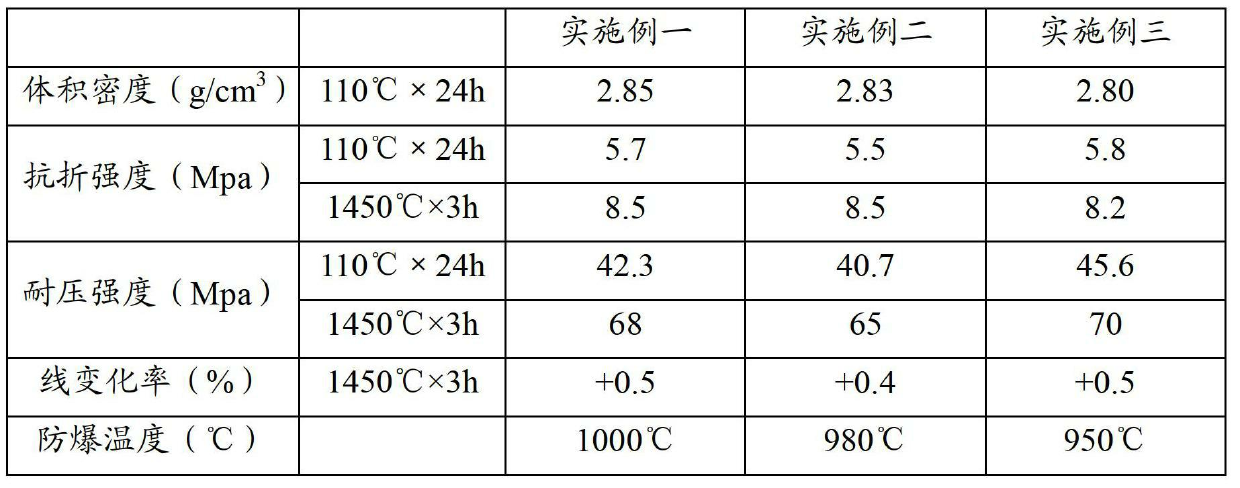

Fast-baking explosion proof type refractory castable for blast furnace iron runner

The invention relates to a fast-baking explosion proof type refractory castable for blast furnace iron runner, which belongs to the field of a refractory matter. The fast-baking explosion proof type refractory castable comprises a main material and an additive, wherein the main material comprises the following ingredients by mass percent: 50-70% of high alumina granules, 10-26% of high alumina fine powder, 10-25% of silicon carbide, 1-3% of silicon oxide micropowder, 4-10% of aluminum oxide micropowder and 1-3% of aluminate cement; the additive occupies 100% in the main material; the additivecomprises the following ingredients by mass percent: 1-3% of compound antiknock substance, 1-3% of silica sol, 1-5% of slag-resistant wetting agent, 0.1-0.2% of water reducing agent and 1-5% of plastic material. According to the invention, crystalline flake graphite is adopted as the slag-resistant wetting agent to improve anti-erosion property of the refractory castable; the plastic material andthe suitable water reducing agent are adopted to prevent segregation of the crystalline flake graphite; and silica sol is adopted to improve the strength of the refractory castable. The fast-baking explosion proof type refractory castable for the blast furnace iron runner provided by the invention adopts site construction and can realize iron influx after being braked by big fire for 3-5 hours; and the fast-baking explosion proof type refractory castable has high density and strength, can bear iron slag scouring and is good in preventing the slag from penetration, good in anti-erosion property and long in service life.

Owner:北京钢研新冶工程设计有限公司

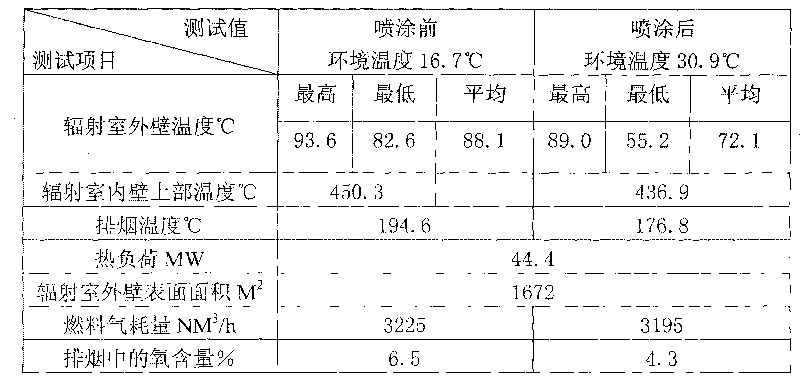

High-temperature counter radiation resistant inorganic coating and preparation method thereof

InactiveCN101760058AImprove thermal shock resistanceImprove thermal efficiencyFireproof paintsAlkali metal silicate coatingsPhosphateOxidation resistant

The invention relates to an energy-saving high-temperature counter radiation resistant inorganic coating for coating the liner of a kiln and a preparation method thereof. The coating mainly comprises oxides, such as cobalt oxide, zirconium oxide powder, aluminum oxide and chromic oxide, and silicon powder, silicon carbide, sodium silicate, aluminium dihydrogen phosphate, silica flour, graphite powder, boron oxide and other components and is prepared by grinding, soaking, heating reaction, stirring and mixing. The coating has high thermal shock resistance, high radiation utilization rate, high corrosion resistance, high cracking resistance, high oxidization resistance and high thermal stability. The inorganic coating of the invention has the advantages of allowing for normal construction without making special modification of the basal body of the kiln, along with small investment, quick response, no toxicity, no corrosion and desirable social and economic benefits.

Owner:上海乐恒石油化工集团有限公司

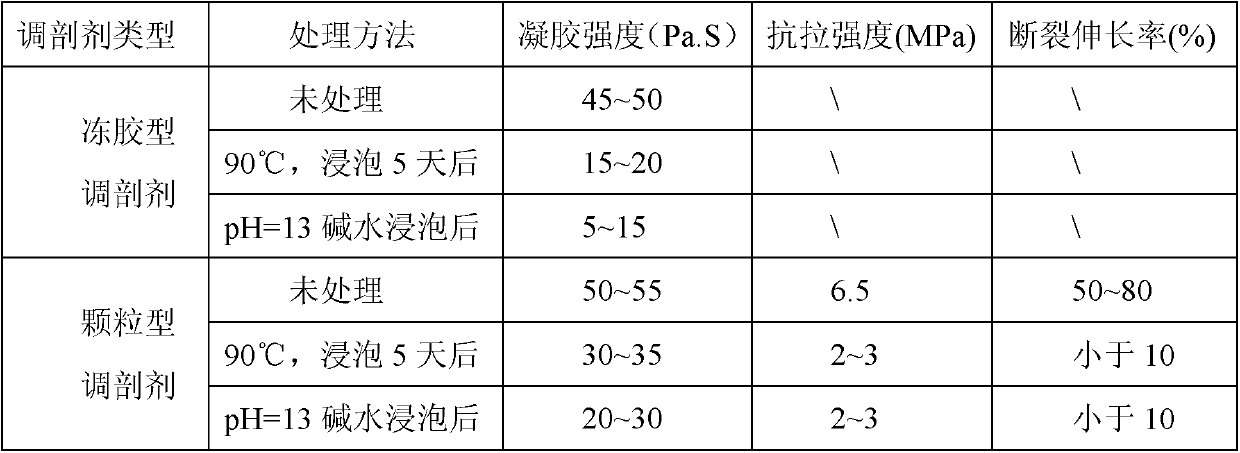

Preparation method for inorganic-organic composite type profile control agent

ActiveCN103102876AImprove temperature resistanceGood alkali resistanceDrilling compositionTemperature resistanceSilicon dioxide

The invention discloses a preparation method for an inorganic-organic composite type profile control agent and relates to a preparation method for a profile control agent. The preparation method is mainly used for solving the problems that the existing profile control agent is poor in temperature resistance, alkali resistance and mechanical properties. The preparation method comprises the following steps of: firstly, preparing silicon dioxide; secondly, modifying the surface of silicon dioxide by silane coupling agent; and thirdly, coating the silicon dioxide by polymer monomer. The profile control agent prepared by the preparation method disclosed by the invention is good in temperature resistance, alkali resistance and mechanical properties, so that the physical plugging and chemical plugging are combined together, and the profile control effect is improved. The preparation method disclosed by the invention is applied to the chemical field.

Owner:黑龙江赛恩思科技信息咨询服务有限公司

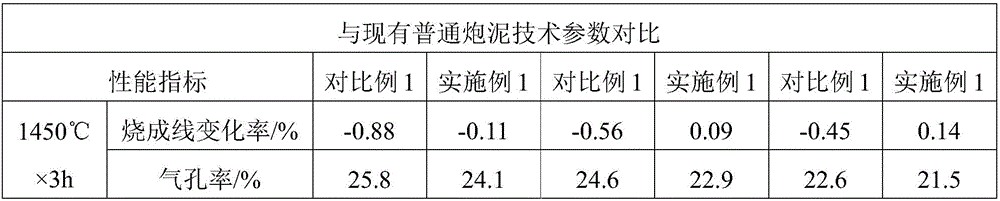

Environment-friendly stemming for blast furnace and preparation method thereof

The invention provides environment-friendly stemming for a blast furnace. The stemming is prepared from aggregate, silicon carbide, titanium dioxide, white mud, coke dust, micropowder and a binding agent. The method for preparing the stemming comprises the following steps: proportioning aggregate, silicon carbide, titanium dioxide, white mud, coke dust and micropowder according to the mass percentage; performing dry mixing and grinding, adding the binding agent, and performing wet mixing and grinding to obtain the environment-friendly stemming for a blast furnace. The stemming has the advantages of small shrinkage rate, excellent thermal shock resistance, excellent washing resistance and excellent erosion resistance, and once tapping time reaches 100-180 minutes; in-situ generated TiC has an effect of protecting the furnace, and the service life of the furnace can be prolonged; T60 carbon-containing resin and phenolic resin are used as the binding agent to reduce generation of cancerogenic smoke and improve the operation environment.

Owner:BEIJING JINGYEYUAN NEW MATERIALS

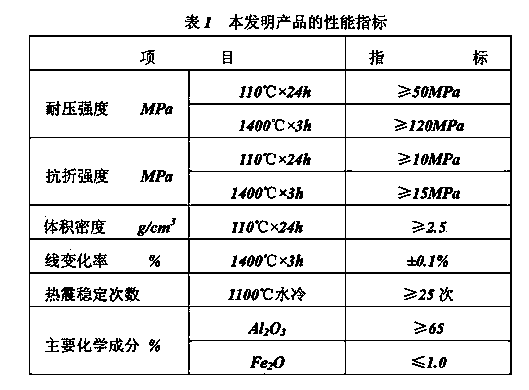

Zirconium-containing high-strength wear-resistant castable

The invention discloses a zirconium-containing high-strength wear-resistant castable, which comprises, by weight: 23-32% of brown fused alumina, 42-52% of sintered mullite, 4-8% of corundum powder, 6-10% of mullite fine powder, 3-5% of a-AI2O3, 2-5% of fused alumina zirconia fine powder, 3-5% of silica powder, 6-10% of pure calcium aluminate cement and 0.1-0.15% of a water reducing agent. The zirconium-containing high-strength wear-resistant castable is prepared by: firstly grinding and mixing the corundum powder, the mullite fine powder, the a-AI2O3 and the fused alumina zirconia powder, then adding the remaining various raw materials, and performing mixing stirring. The castable product disclosed in the invention has the characteristics of high bonding strength, strong anti-scouring performance, high compressive strength, good wear resistance, and good thermal shock resistance and stripping resistance, etc.

Owner:巩义市科恒耐火材料有限公司

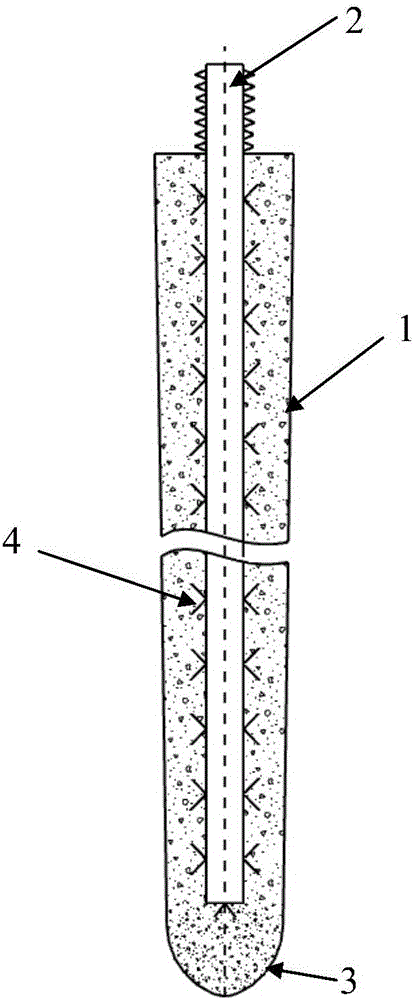

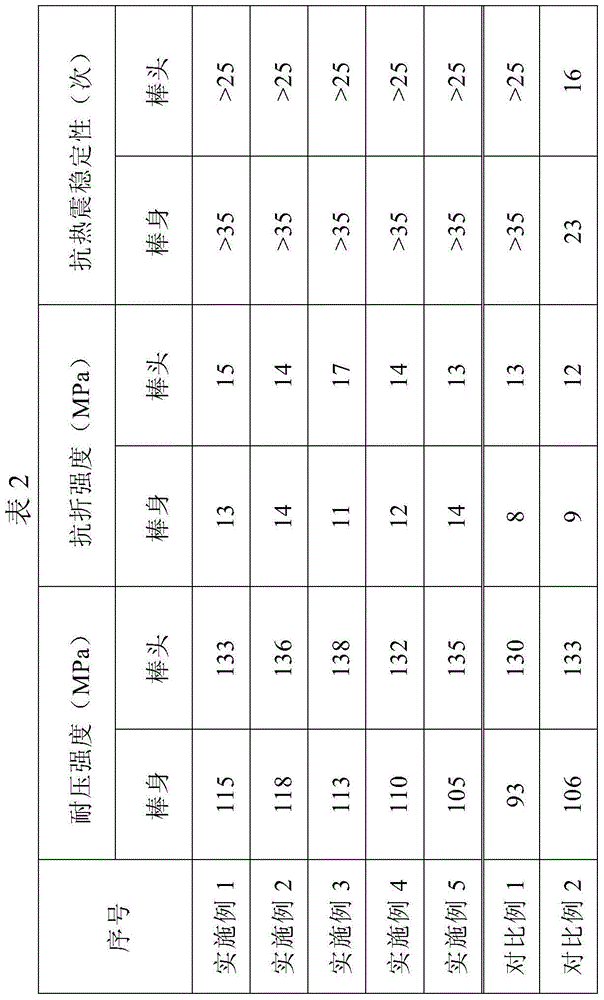

Continuous casting monolithic stopper and method of manufacture thereof

ActiveCN105753489AImprove thermal shock resistanceImprove erosion resistanceMelt-holding vesselsBrickMullite

The invention discloses a continuous casting monolithic stopper and a method of manufacture thereof.The monolithic stopper comprises a stopper body, a steel core inserted into the stopper body and a head connected to the lower end of the stopper body, the surface of the steel core is provided with an anchor, the surface of the monolithic stopper is coated with Al2O3 coating; the stopper body is made by casting castables comprising mullite, the head is made by casting castables comprising corundum and sintered mullite, and the monolithic stopper is manufactured by monolithic casting.The stopper obtained herein is good in monolithicity, is free of brick joint and head shedding problems of sleeve brick stoppers, has good thermal shock resistance, high strength and good resistance to molten steel scour erosion, is simple to manufacture and low in cost, and is suitable for stopping a tundish nozzle under low continuous casting, high-oxygen steel continuous casting and skid flow control.

Owner:BAOSHAN IRON & STEEL CO LTD

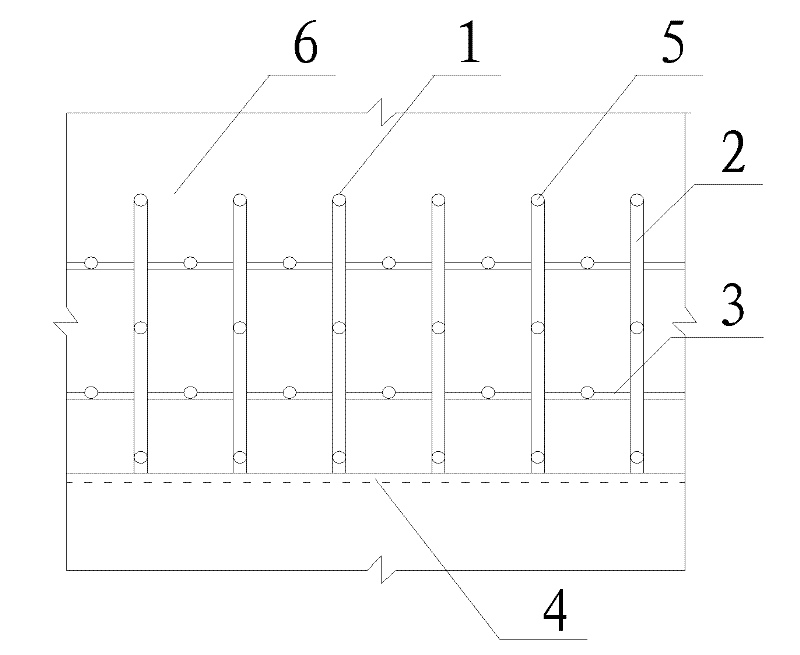

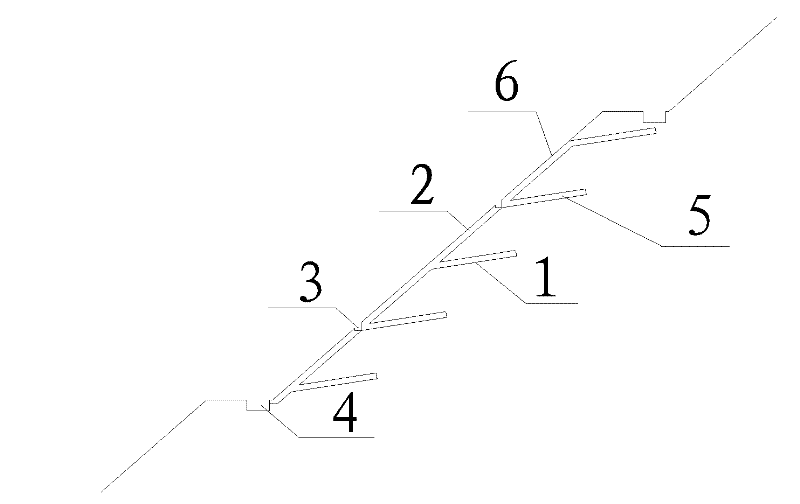

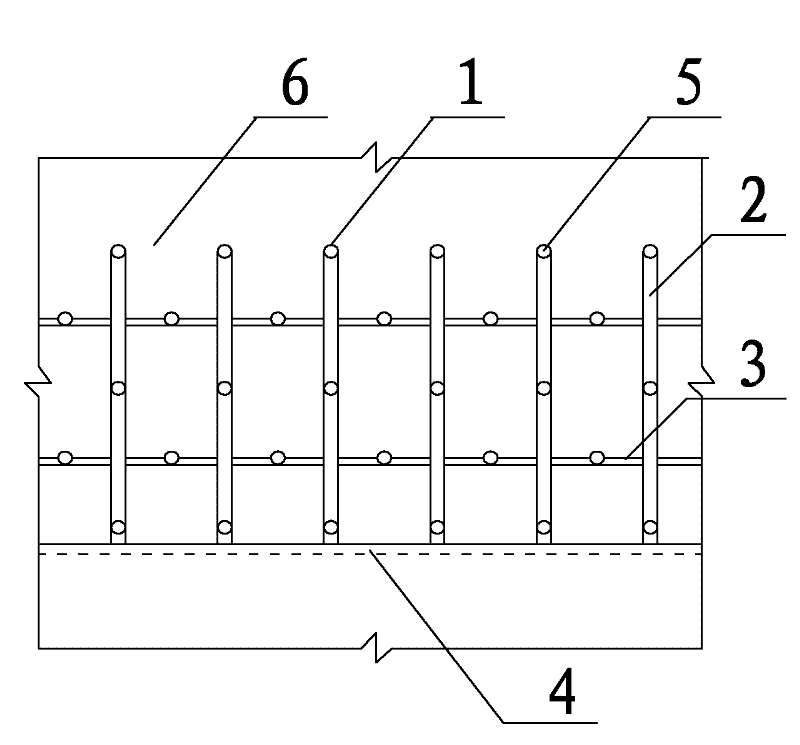

A slope shallow drainage system

The invention discloses a side slope shallow drainage system. The bottom platform of the side slope (6) is provided with drainage ditches (4), and multiple rows and rows of drainage boreholes are densely arranged on the side slope (6). (1), the distance between the drainage boreholes (1) is 2-3m, the depth is 3-4m, and the elevation angle is 0-10°, each of the drainage boreholes (1) is provided with Drainage pipe, the slope of the slope (6) is arranged with a longitudinal micro-drainage ditch (2) and / or a transverse micro-drainage ditch (3) docked with the outlet of each of the drainage pipes, the The longitudinal miniature water collection ditch (2) and / or the horizontal miniature water collection ditches (3) communicate with the drainage ditch (4). The invention is a side slope shallow layer drainage system for quickly and efficiently discharging the groundwater infiltrated by rainfall into the shallow layer soil of the side slope.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Mullite steel fiber castable

The invention discloses a mullite steel fiber castable, which comprises the following raw materials in percentage by weight: 29 to 40 percent of brown alumina, 10 to 15 percent of high alumina bauxite clinker, 18 to 32 percent of sintered mullite, 8 to 12 percent of electric-cast mullite, 3 to 7 percent of silicon micro powder, 2 to 5 percent of coagulant and 1 to 3 percent of stainless steel fiber. The mullite steel fiber castable is prepared by stirring the mixture of raw materials which are prepared according to proportion for 5 to 10 minutes. Compared with the conventional common high alumina castable, the mullite steel fiber castable prepared by the technical scheme of the invention has high compressive strength, high rupture strength and high volume density. The mullite steel fiber castable product of the invention has high thermal shock resistance, high anti-scour performance and high volume stability.

Owner:巩义市科恒耐火材料有限公司

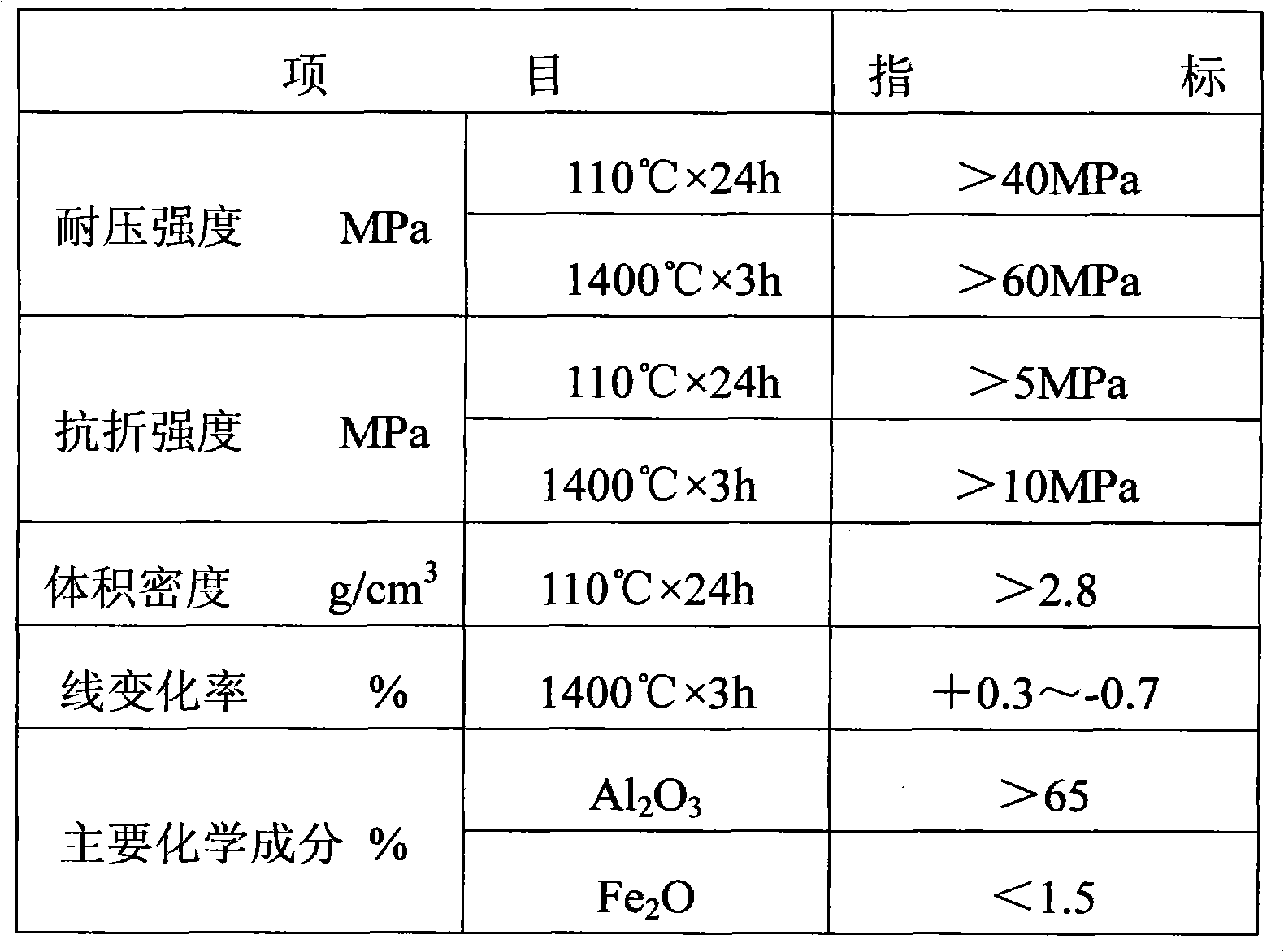

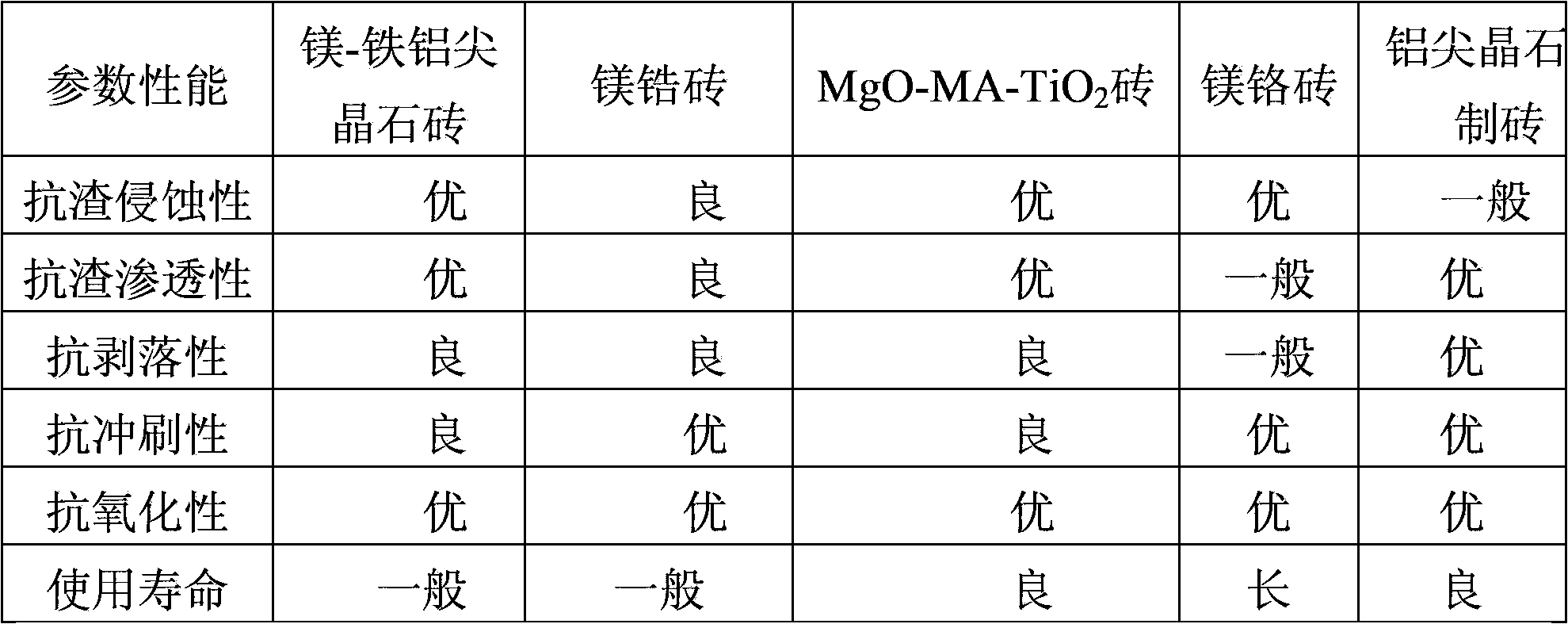

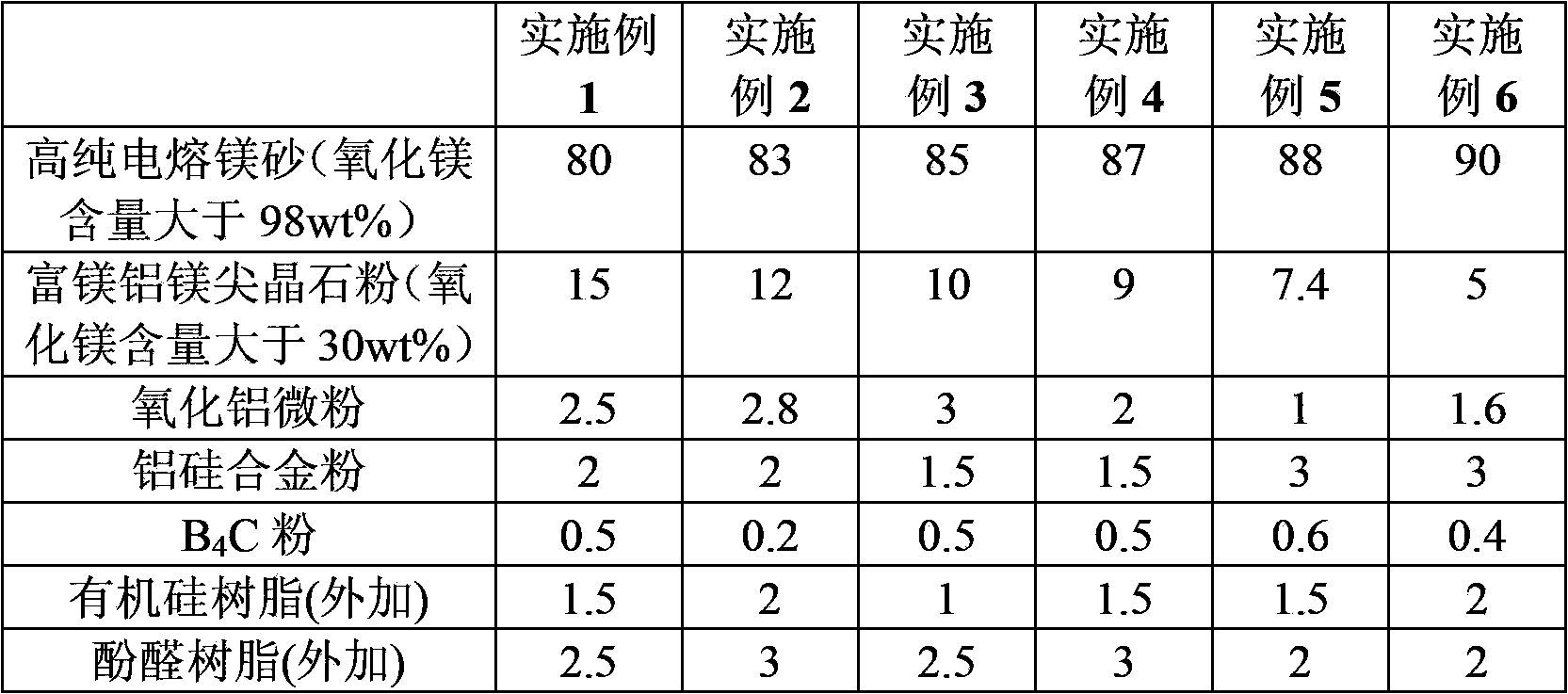

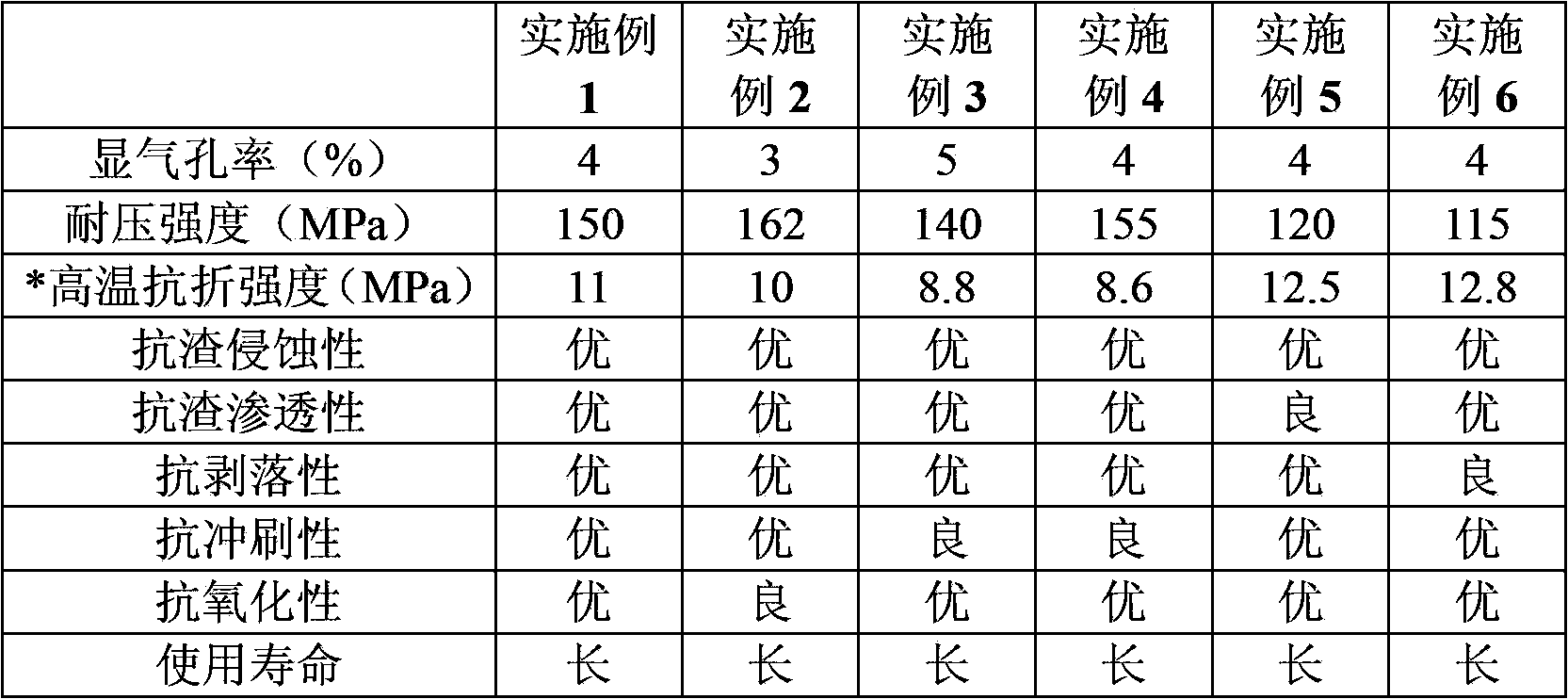

Unfired magnesia-alumina spinel brick

The invention discloses an unfired magnesia-alumina spinel brick. The unfired magnesia-alumina spinel brick comprises the following chemical components by mass: 80 to 90% of fused magnesia, 5 to 15% of magnesium-rich magnesia-alumina spinel, 1 to 3% of micro alumina powder, 1 to 3% of aluminum-silicon alloy powder and 0.2 to 0.6% of B4C. The chemical components are bonded together by using 3.5 to 5 wt% of an added binder. The content of magnesium oxide in the fused magnesia is greater than 98 wt%, and the content of magnesium oxide in the magnesium-rich magnesia-alumina spinel is greater than 30 wt%. The unfired magnesia-alumina spinel brick provided by the invention has excellent slag reaction resistance, slag penetration resistance, anti-stripping performance, anti-scouring performance, resistance to oxidation and a long service life, does not include the harmful element--chromium, avoids pollution and harm to human beings and the environment, needs low production cost and has a wide application scope.

Owner:BAOSHAN IRON & STEEL CO LTD

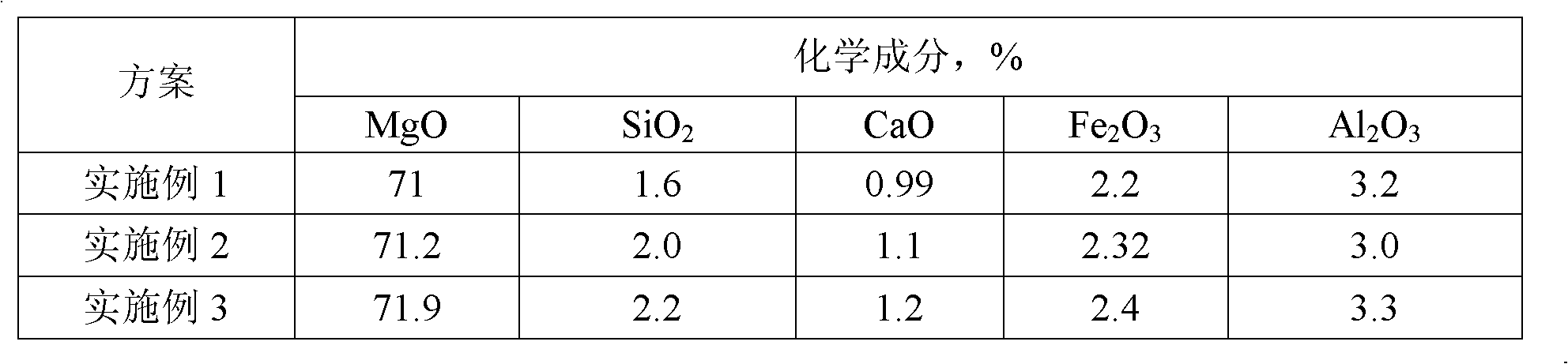

Low-cost slag regulating agent for vanadium-extracting converter splash protection

ActiveCN102912072AEfficient use ofEffective recoveryManufacturing convertersBrickChemical composition

The invention provides a low-cost slag regulating agent for vanadium-extracting converter splash protection. The slag regulating agent comprises, by weight, from 20% to 50% of C, from 40% to 72% of MgO, from 4% to 7% of CaO and less than or equal to 3% of H2O, and the MgO in the slag regulating agent comprises waste magnesia carbon bricks. The low-cost slag regulating agent for vanadium-extracting converter splash protection has the advantages that waste refractory materials can be effectively utilized; and FeO in vanadium slag can be effectively reduced, the melting point and the adhesion of modified vanadium slag are improved, accordingly, a slag adhering effect can be improved after the slag regulating agent is used for regulating the vanadium slag and the modified vanadium slag is used for converter splash protection, the erosion resistivity of a furnace lining is improved, and the service life of the furnace lining of a vanadium-extracting converter is effectively prolonged.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Anhydrous stemming for large and medium sized blast furnace and preparation method of anhydrous stemming

The invention relates to an anhydrous stemming for a large and medium sized blast furnace and a preparation method of the anhydrous stemming. The stemming comprises the raw materials of bauxites aggregate and fine powder, silicon carbide aggregate and fine powder, coke, plastic clay powder, asphalt powder and a micro powder additive, the micro powder additive comprises metallic silicon powder, metallic aluminum powder, high-carbon resin powder, alumina micro powder, silica fume, sodium carboxymethyl cellulose and sodium hexametaphosphate in parts by weight, and tar is taken as a binding agent in the producing and stirring processes. The anhydrous stemming realizes high-temperature rapid sintering of the stemming, the binding degree of new and old stemming is strengthened, the capability of resisting scouring of an iron slag of a mud drum of an iron notch is improved, the porosity of the stemming material is low, the compactness of the stemming material is good, the property of resisting corrosion and permeation of an iron slag liquid of the stemming is strengthened, the stemming is favorable for keeping the depth of the iron notch and the stability of the pore size of the iron notch, and can well adapt to the performance requirement of enlargement of the blast furnace on the stemming of the iron notch.

Owner:CHINA JINGYE ENG +1

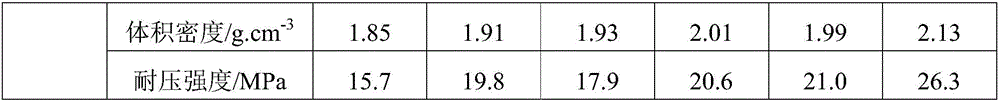

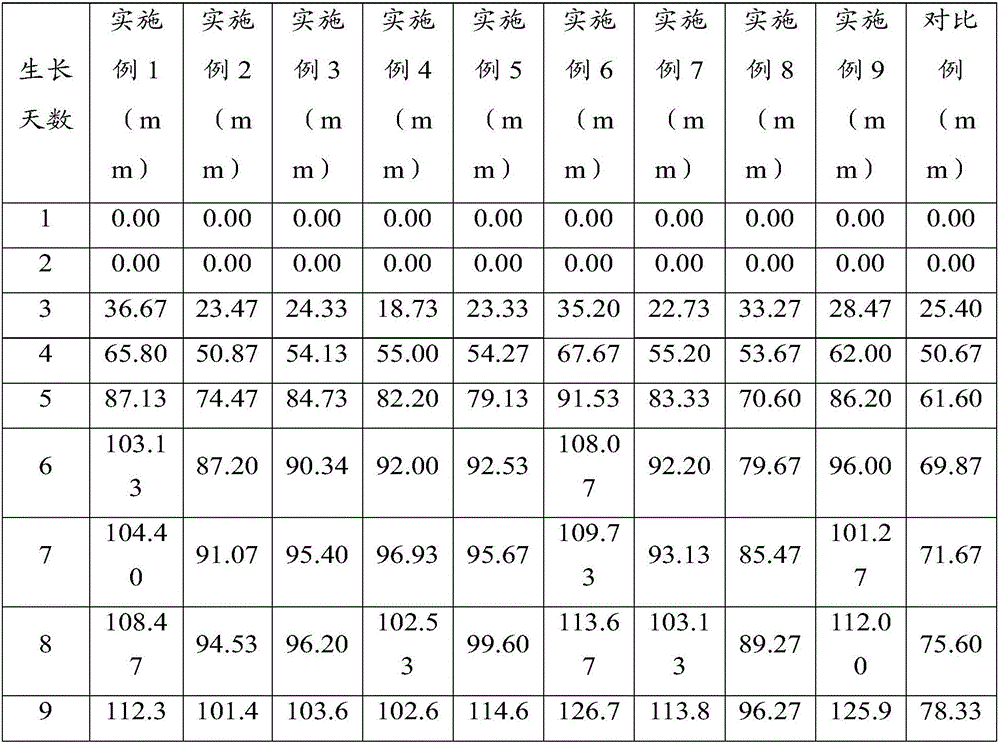

Spray seeding matrix and preparation method thereof

InactiveCN105859408AHigh strengthFertilizer effect time is longExcrement fertilisersGrowth substratesAdhesiveInstability

The invention provides a spray seeding matrix and a preparation method thereof. In the spray seeding matrix provided by the invention, the soil, straw, adhesive and fertilizer are used as main raw materials which are doped with some of construction waste; and by adopting a combination of special dosage ratio, the obtained spray seeding matrix has high strength, the stability can be maintained for a long time, the fertilizer efficiency lasts long, the cost is low, and the greening effect can be effectively improved. By adding the spray seeding matrix into the construction waste, the slope stability can be effectively improved, the greening quality is increased, and the investment cost is lowered. The spray seeding matrix provided by the invention improves the problems such as relatively bad structure, relatively few granular structures and nutrient lack of the soil formed after the spray seeding of the traditional matrix and the problem of instability caused by adhesive failure. The indexes of the spray seeding matrix can reach the traditional matrix standard, wherein the early-stage growth condition of the plant, the plant biomass, the soil fertility, the erosion resistance and the like are all greatly improved. The preparation method of the spray seeding matrix provided by the invention is simple in technology, low in cost and suitable for large-scale production.

Owner:BEIJING FORESTRY UNIVERSITY

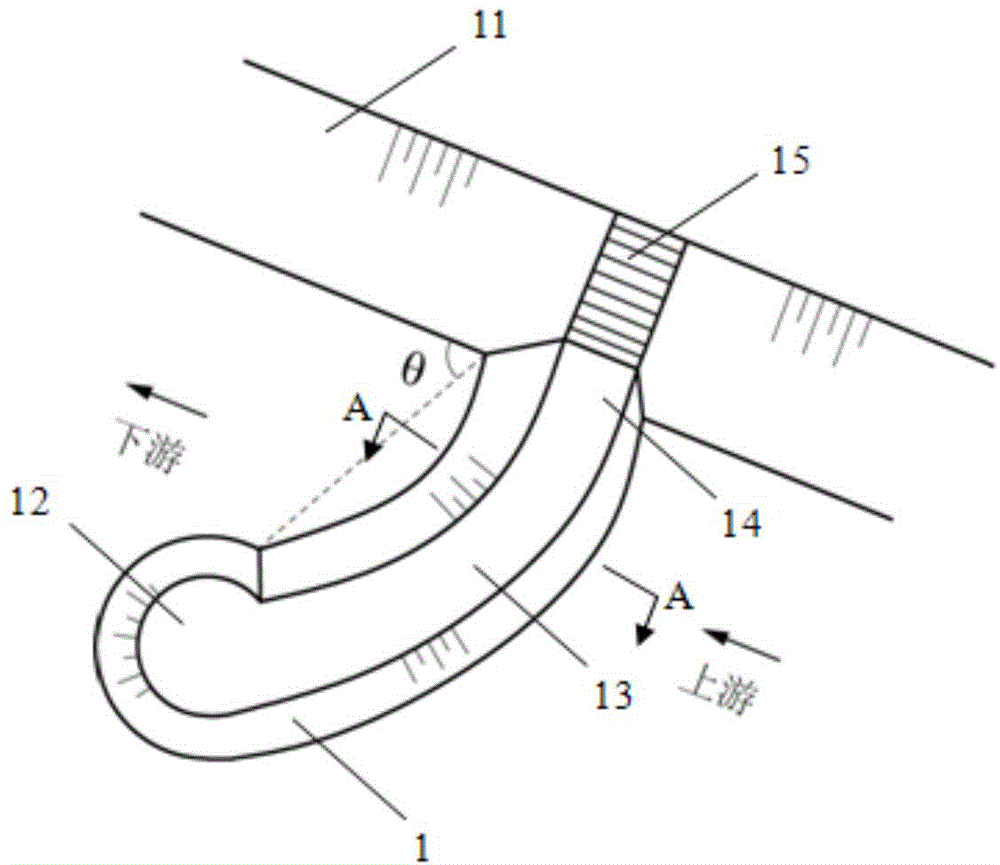

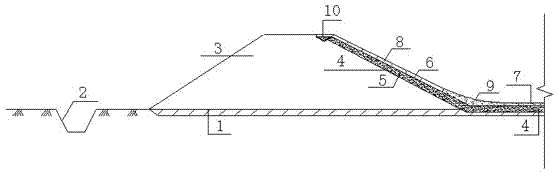

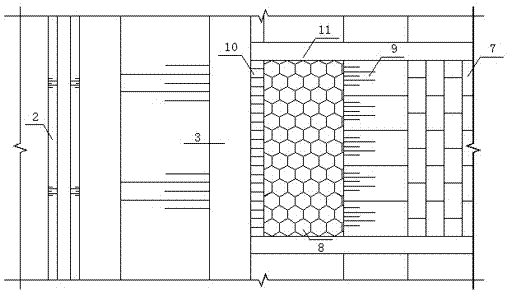

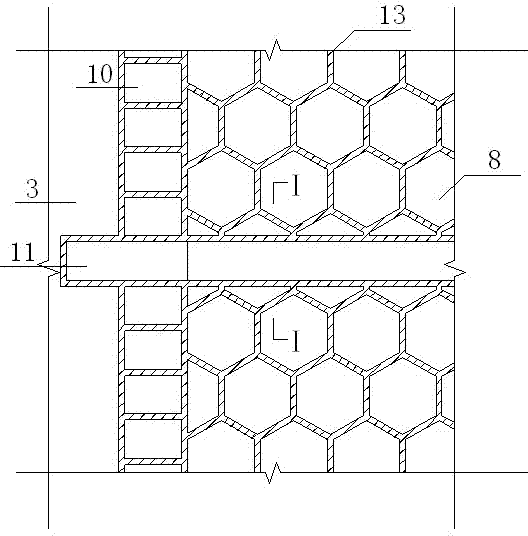

Flexible ecological spur dike system

The invention discloses a flexible ecological spur dike system. The flexible ecological spur dike system comprises a spur dike body, the spur dike body is connected with a bank on the horizontal plane to form a T shape and comprises an arc jetty head, an arch dike body and a bank-connection dike root in sequential connection, and the bank-connection dike root is connected to the bank through stairs; an included angle formed by the spur dike body and a downstream water flow direction is smaller than 90 degrees; on the longitudinal section, the spur dike body comprises a reinforced earth dike core, a flexible ecological dike slope, dike toe slope pressure parts and a water affinity platform, the flexible ecological dike slope covers the reinforced earth dike core, dike toe portions on two sides of the flexible ecological dike slope are filled by the dike toe slope pressure parts by means of dumping fill, and the water affinity platform is arranged on the top of the flexible ecological dike slope. The flexible ecological dike slope comprises waste tire reinforced planting soil, geogrids and aquatic plants in hierarchical staggered stacking arrangement. By adoption of waste tires for construction of the spur dike system with dual functions of flexibility and ecology, utilization rate of the waste tires is greatly increased, resource regeneration is realized, and construction cost is saved; in addition, conformance to river regimes, decrease of ship collision accident rate and providing of the ecological plant platform are realized.

Owner:HOHAI UNIV

Method for preparing high-hardness and high-toughness abrasion resistant balls through laser cladding

InactiveCN105297005AGood wear resistanceRefined crystal structureFoundry mouldsFurnace typesScrapTungsten

The invention discloses a method for preparing high-hardness and high-toughness abrasion resistant balls through laser cladding. The method comprises the following steps that scrap steel, chrome steel, rare earth alloy, manganese steel, molybdenum steel, vanadium steel, tungsten residues, silicon iron, titanium ingots, zirconium ingots, aluminum ingots and magnesium ingots are smelted, so that liquid alloy is obtained; ball billets are obtained by pouring the liquid alloy; tempered balls are obtained by conducting heat treatment on the ball billets; and laser cladding is conducted with Fe-based alloy and wolfram carbide (WC) powder serving as cladding powder after the tempered balls are cleaned, and the high-hardness and high-toughness abrasion resistant balls are obtained. The Fe-based alloy comprises C, Cr, Co, Ni, Mo, Ti, V and B. The power of laser cladding is 2500-3000W. The diameter of a light spot is 3-5 mm. The movement speed of the light spot is 10-15 mm / s. The thickness of a cladding layer is 5-10 [mu]m. According to the method for preparing the high-hardness and high-toughness abrasion resistant balls through laser cladding, the process is simple, conditions are easy to control, and an obtained finished product is high in hardness, good in toughness and long in service life.

Owner:NINGGUO SOUTHERN WEAR RESISTANT MATERIALS

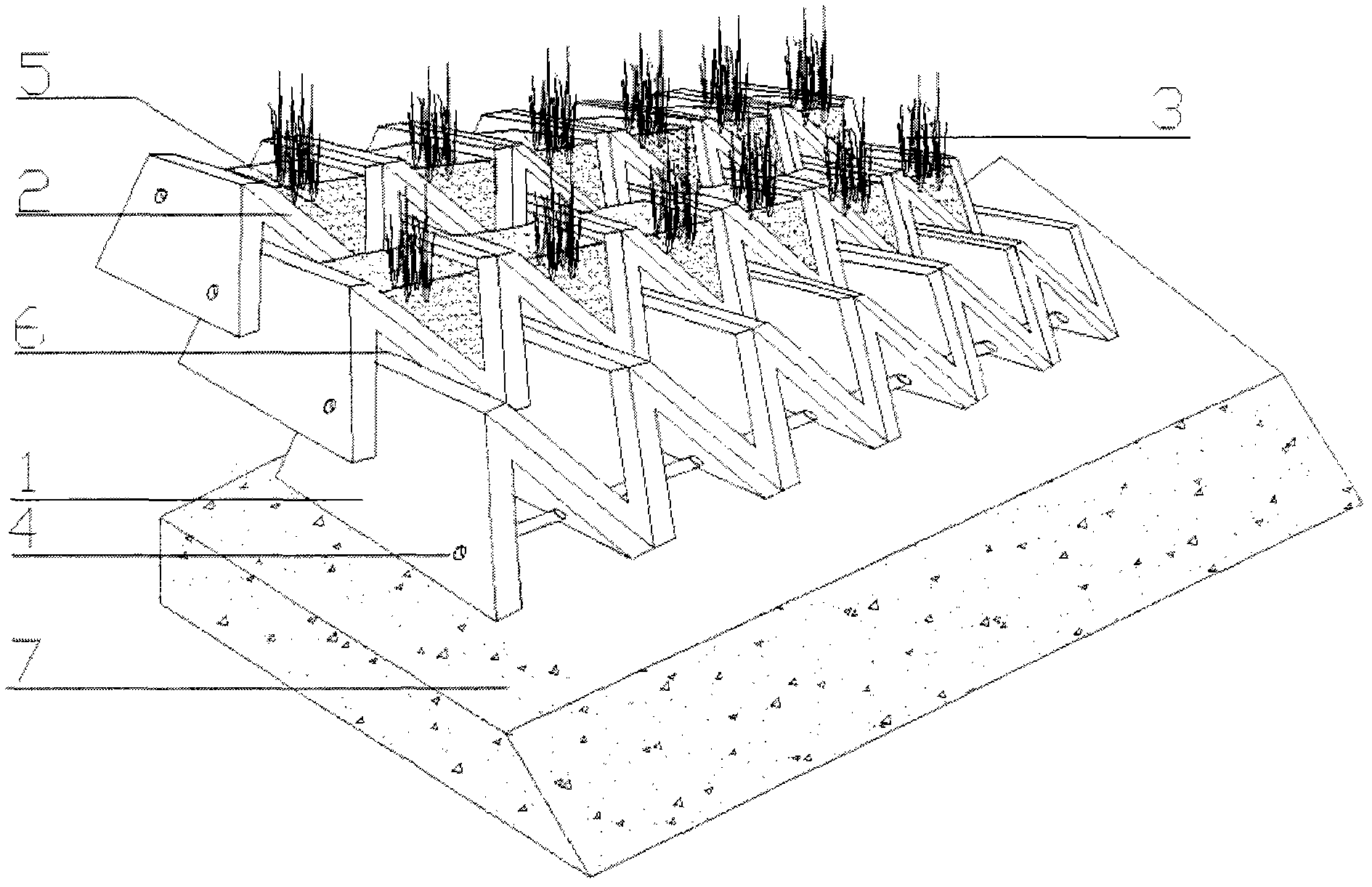

Novel ecological landscape type bank revetment system

ActiveCN102660934ALight in massReduce project cost and construction periodWater resource protectionCoastlines protectionTriangular prismEcosystem

The invention relates to a construction method of ecological bank revetment, in particular to a construction method of ecological bank revetment with landscape function and simple construction. In the method, triangular prism shaped building blocks are built on a bank from bottom up and connected with connection members, plant is planted on each layer of the building blocks, and an ecological corridor is formed under each layer of the building blocks. The system solves the problem that channel revetment landscape function and ecological function can not be achieved simultaneously at present. When the bank revetment is constructed, flower / grass is planted in a plant flume on the building block and matches with a shaped pattern to form a landscape wall, and the ecological corridor provides a living and habitat place for aquatic animals and microbes. The building blocks in horizontal rows are connected in series by connection members and anchored to enhance the stability of the overall structure and water flow impact resistance. The inventive landscape ecological bank revetment provides multiplication and living conditions for aquatic plant / animals and microbes, forms a small-sized ecological system where plant / animals and microbes are symbiotic and coexistent at the water area-land transitional zone of a river channel, and plays the role of river channel ecological regulation and water purification.

Owner:北京东方利禾景观设计有限公司

Preparation method of hydrophobic catalyst for hydrogen-water isotope exchange

InactiveCN103551202AHigh strengthVarious shapes and specificationsOrganic-compounds/hydrides/coordination-complexes catalystsMicro structurePolymer science

The invention discloses a preparation method of a hydrophobic catalyst for hydrogen-water isotope exchange, which belongs to the technical field of catalyst exchange and aims at solving the problems of single shape, low utilization rate of reactive metals, and the like in an existing hydrophobic catalyst for hydrogen-water isotope exchange. The preparation method comprises the steps of suspension liquid preparation, loading, and heat treatment. The hydrophobic catalyst prepared by the method can meet the requirements of water tritium removal and heavy water purification and production on special filling configuration (in bulk, in order and the like) and performance in produced exchange columns with different scale grades. According to the method, a metal fiber felt serves as a support carrier and a foaming agent is used for modifying the micro structure of a hydrophobic membrane, the prepared hydrophobic catalyst has the characteristics of controllable shape, varied shape specifications, honeycomb-structure of the hydrophobic membrane, high utilization rate of reactive metals, high strength, and the like, and can meet the requirements of tritium removal and heavy water purification and production on filling configuration and performance in exchange columns with different scale grades.

Owner:SICHUAN INST OF MATERIALS & TECH

95 chromium-aluminum-zirconium brick for coal water slurry pressurized gasifier and preparation method thereof

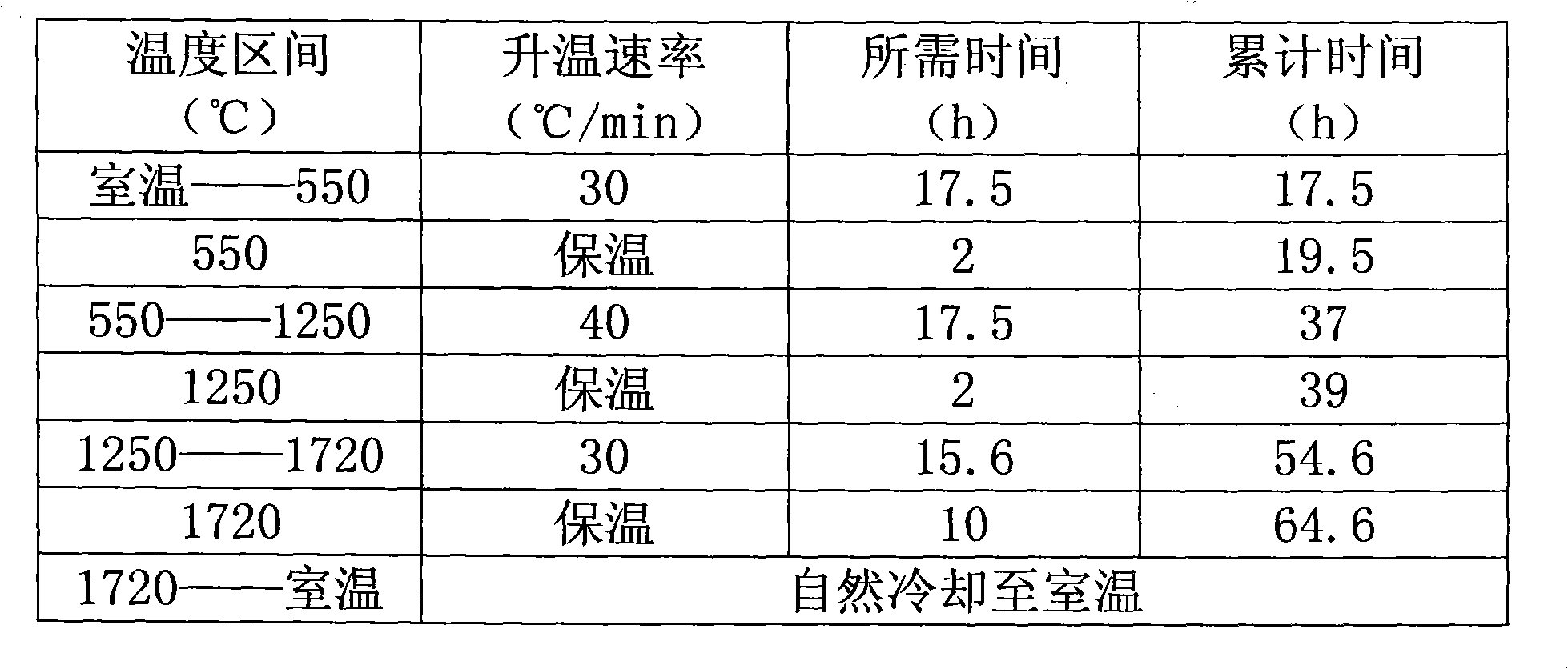

The invention belongs to the technical field of refractory materials, and discloses a 95 chromium-aluminum-zirconium brick for a coal water slurry pressurized gasifier and a preparation method thereof. The 95 chromium-aluminum-zirconium brick comprises electrically fused chromium oxide, chromium oxide green, fine zirconium oxide powder, fine alpha-Al2O3 powder and an adhesive serving as raw materials in percentage by weight; the preparation method comprises the following steps of: (1) weighing the raw materials in percentage by weight; (2) mixing and rolling the raw materials in a wet mill toform slurry; (3) pressing the slurry in a friction press to prepare a half-finished product; (4) drying the half-finished product in a drying kiln; (5) firing the dried half-finished product in an automatic shuttle kiln; and (6) taking the finished product out of the kiln, and checking the appearance and the physicochemical property of the product. Compared with the conventional 90 chromium-aluminum-zirconium brick, the 95 chromium-aluminum-zirconium brick has the advantages that the scour resistance, corrosion resistance, volume density, and ambient compressive strength are improved and the service life of the 95 chromium-aluminum-zirconium brick is improved by 20 to 50 percent.

Owner:李正平

Pouring material for cement kiln tertiary air duct

The invention relates to a pouring material for a cement kiln tertiary air duct. The pouring material comprises aggregate and a matrix material according to a weight ratio of 2-8: 1-3. The aggregate has particle sizes of 1-10mm and the matrix material has the particle sizes of 0.1-0.5mm. The aggregate comprises, by weight, 28-50 parts of fused magnesia, 25-45 parts of modified white alundum, 5-15 parts of zirconium mullite and 8-20 parts of magnesium aluminate spinel. The matrix material comprises magnesia powder, silicon oxide fine powder, mullite powder, alumina fine powder and andalusite. The pouring material utilizes appropriate aggregate and the matrix material and has wear resistance and corrosion resistance, a uniform degree of expansion and good thermal shock stability. Through use of a fiber additive, pouring material integrality is improved, and pouring material flexural performances and anti-erosion performances are improved. The cement kiln tertiary air duct has the advantages of long service life, long replacement period, small production cost and high production efficiency under bad conditions.

Owner:长兴兴鹰新型耐火建材有限公司

Low-cost slag splashing protection method of vanadium extraction converter

The invention provides a low-cost slag splashing protection method of a vanadium extraction converter. The slag splashing protection method comprises the following steps of: reserving a certain quantity of vanadium slag in the converter after vanadium extraction blowing is finished and semi-steel is tapped; adding 100-200 kg of slag regulating agent into one ton of vanadium slag, and blowing oxygen to melt the vanadium slag via an oxygen gun; and blowing nitrogen for slag splashing protection via the oxygen gun, wherein the slag regulating agent is waste magnesia carbon brick particles. With the slag splashing protection method, the problems of low melting point and difficult adhesion of vanadium slag can be effectively solved, the slag adhering effect can be improved during slag splashing protection, the erosion resistibility of a converter lining is increased, and the service life of the vanadium extraction converter lining is effectively prolonged.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Aluminum-carbon refractory material and its preparation

A Alc refractory used for conticasting of steel features use of composite adhesive, liquid phenolic resin and powdered aluminium dihydrogen phosphate. Its advantages are excellent resistance to corrosion, flush and oxidation, and low cost.

Owner:维苏威高级陶瓷(鞍山)有限公司

Fill channel anti-frost heaving and anti-seepage structure and construction method

ActiveCN104514216AGuaranteed compactnessGuaranteed StrengthIrrigation ditchesMarine site engineeringStress concentrationStress conditions

The invention discloses a fill channel anti-frost heaving and anti-seepage structure and a construction method. The structure is characterized in that drainage channels are arranged on the two sides of the channel; a wind-blown sand layer is arranged on the bottom and two sides of an embankment of the channel; a plastic film is arranged on the wind-blown sand layer; a slope toe on a connection position of the bottom and the embankment of the channel is cast-in-place concrete; prefabricated concrete blocks are laid on the plastic film; and a capping concrete board is arranged on the top of the embankment of the channel. The construction method comprises the following steps: digging a drainage open channel; clearing channel base earth; carrying out filling to form the embankment of the channel; laying wind-blown sand; laying the plastic film; casting the arc channel-bottom concrete in place; laying the prefabricated concrete blocks; and laying the capping concrete board. The problems of the common channel design such as seepage, frost heaving and destruction, and not stable quality are eliminated, the wind-blown sand layer is arranged on the bottom and the two sides of the embankment of the channel, the foundation bearing force is increased, the frost heaving is lightened; the polyethylene plastic film is laid on the wind-blown sand layer to prevent seepage of the channel; concrete is arranged on the film to prevent water flow from scouring and seeping; the concrete arc channel bottom is cast in place, the stress condition is good and the stress concentration is prevented; and the drainage open channel prevents underground water retention and eliminates frost heaving.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Castable for ladle and preparation method thereof

The invention relates to castable for ladle and a preparation method thereof, and belongs to the technical field of ladle. The castable for the ladle comprises the following raw materials by weight percent: 48 to 77 percent of sintered corundum mullite, 13 to 27 percent of high-aluminum auxiliary materials, 9 to 15 percent of 95 sintered magnesia, 2 to 5 percent of spinel cement, 1.5 to 3.5 percent of silica fume and 0.1 to 0.25 percent of additives. The castable for the ladle has advantages that compared with the traditional ladle castable, the anti-scouring performance and anti-erosion capacity are excellent, the running period of the ladle tends to be fixed, and the schedulability of the ladle repairing time can be improved.

Owner:TONGDA REFRACTORY TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com