Repairing mass and preparation method thereof

A technology for repairing furnace charge and raw materials, applied in the field of furnace repairing charge and its preparation, can solve the problems of low high temperature flexural strength and adhesion strength, high high temperature strength, short sintering time, etc., so as to shorten the furnace repair time, increase the compressive strength and The effect of anti-scour performance and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The preparation of embodiment 1 present invention repair charge

[0057] Weigh 55 parts by weight of fused magnesia, 21 parts by weight of sintered magnesia, 15 parts by weight of modified pitch, 2 parts by weight of metal aluminum powder, 2 parts by weight of iron oxide powder, 2.5 parts by weight of caprolactam and 2.5 parts by weight of p-tert-butylphenol , fully mix and stir the weighed fused magnesia, sintered magnesia, modified pitch, metal aluminum powder, iron oxide powder, caprolactam, p-tert-butylphenol, that is, use a mixing mixer to mix and stir, and the mixing time is about for 5min. After the product is formed, it is loaded into a woven bag lined with plastic film from the outlet of the mixer. Simultaneous sampling and detection of chemical composition indicators (see Table 3 for index detection)

Embodiment 2

[0058] Embodiment 2 The preparation of the present invention's mending charge

[0059] Weigh 55 parts by weight of fused magnesia, 22 parts by weight of sintered magnesia, 14 parts by weight of modified pitch, 2 parts by weight of metal aluminum powder, 2 parts by weight of iron oxide powder, 2.5 parts by weight of caprolactam, and 2.5 parts by weight of p-tert-butylphenol , fully mix and stir the weighed fused magnesia, sintered magnesia, modified pitch, metal aluminum powder, iron oxide powder, caprolactam, p-tert-butylphenol, that is, use a mixing mixer to mix and stir, and the mixing time is about for 5min. After the product is formed, it is loaded into a woven bag lined with plastic film from the outlet of the mixer. Simultaneous sampling and detection of chemical composition indicators (see Table 3 for index detection)

Embodiment 3

[0060] Embodiment 3 The preparation of the present invention repair charge

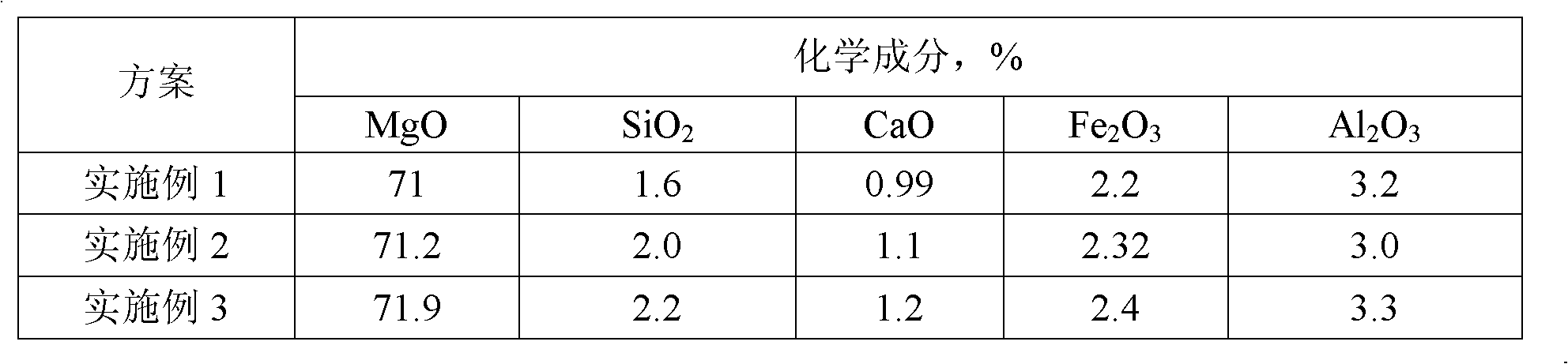

[0061] Weigh 55 parts by weight of fused magnesia, 23 parts by weight of sintered magnesia, 13 parts by weight of modified pitch, 2 parts by weight of metal aluminum powder, 2 parts by weight of iron oxide powder, 2.5 parts by weight of caprolactam, and 2.5 parts by weight of p-tert-butylphenol , fully mix and stir the weighed fused magnesia, sintered magnesia, modified pitch, metal aluminum powder, iron oxide powder, caprolactam, p-tert-butylphenol, that is, use a mixing mixer to mix and stir, and the mixing time is about for 5min. After the product is formed, it is loaded into a woven bag lined with plastic film from the outlet of the mixer. Simultaneous sampling and detection of chemical composition indicators (see Table 4 for index detection)

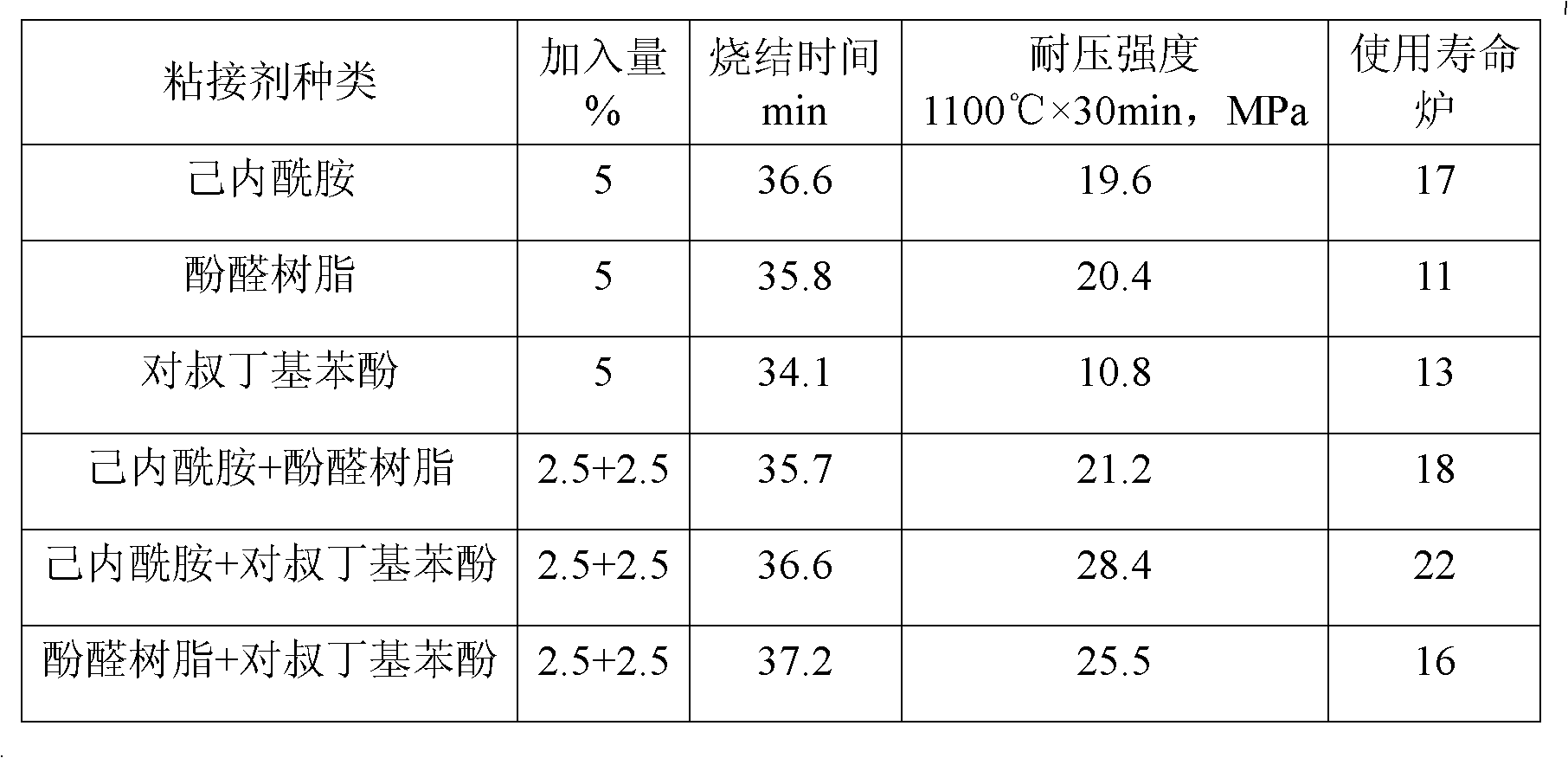

[0062] Table 4 physical and chemical index detection

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com