A flotation process for treating coal slime with saline wastewater

一种含盐废水、浮选的技术,应用在浮选、固体分离等方向,能够解决煤泥浮选药量大、成本高等问题,达到变废为宝环保要求、缓减生产压力、解决生产和运输成本高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

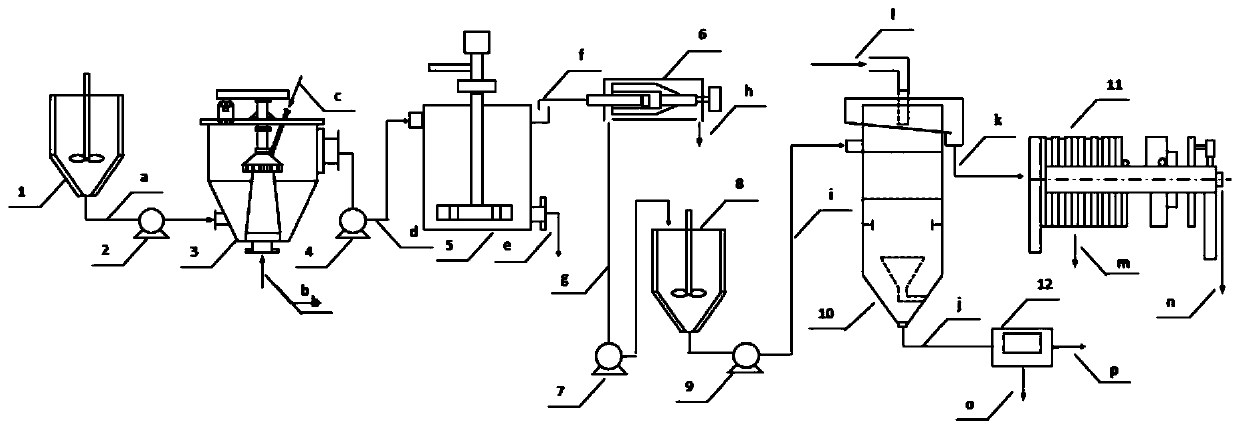

[0028] Attached below figure 2 The implementation of the present invention is further described:

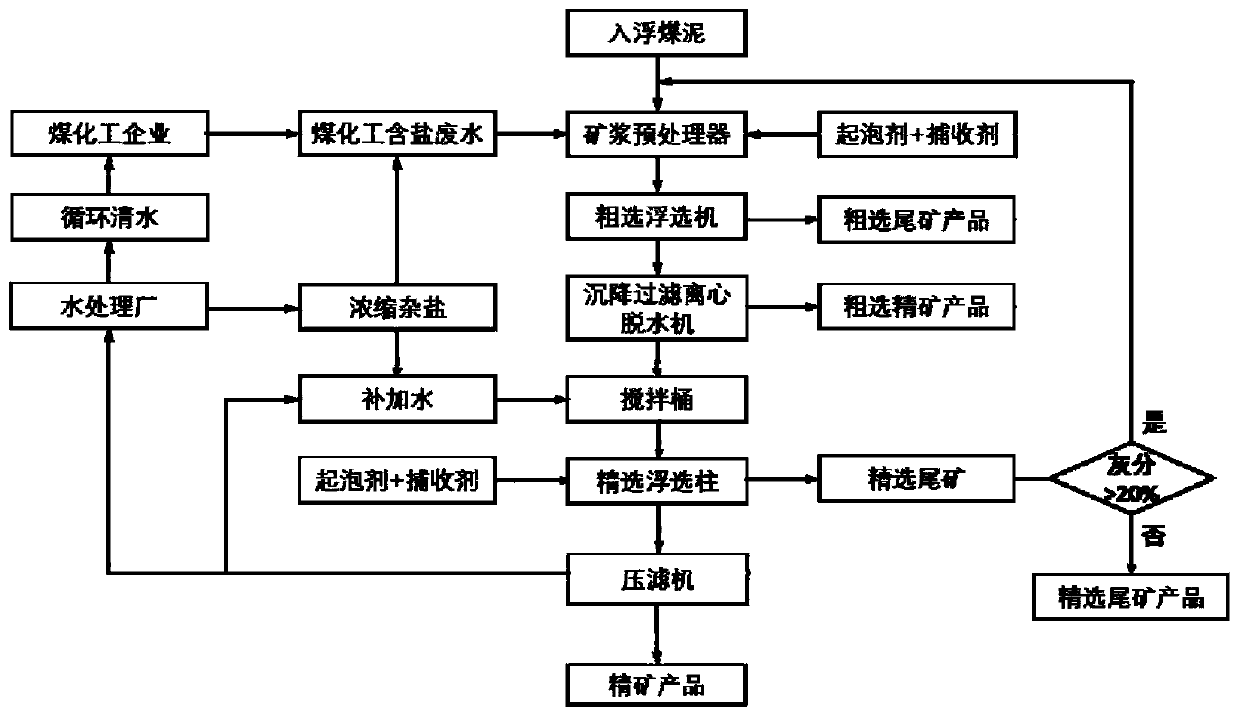

[0029] Such as figure 1 and figure 2 Shown, the present invention utilizes the flotation process of saline waste water treatment coal slime, it is characterized in that comprising steps as follows:

[0030] The floating coal slime enters the slurry preprocessor 3 from the bottom through the pipeline b, and the collector and foaming agent are fed into the slurry preprocessor 3 through the pipeline c to form a mixed slurry;

[0031] Put the coal chemical industry salty wastewater discharged from the coal chemical industry into the mixing tank 1 and stir evenly. The concentration of the brine after stirring is 30000mg / L. The composition of the salt is NaCl, NaCl 2 SO 4 , CaCl 2 and CaSO 4 , through the circulation pump 2, the brine is used as dilution water to enter the pulp preprocessor 3 along the pipeline a, and the salty wastewater from the coal chemical industry is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com