The treatment methods of

tin slag oxide mainly include on-line

processing method, aggregate

reduction treatment method after cleaning, and can be divided into chemical

powder reduction method and reduction machine high temperature stirring

tin slag reduction method according to the

tin slag reduction treatment method. Now known tin slag reduction extraction The solder

metal in the tin slag will not only increase the production cost, cause environmental

pollution, waste a lot of

electricity, but also have adverse effects on product quality, and will cause

pollution and damage to the solder components of the furnace body

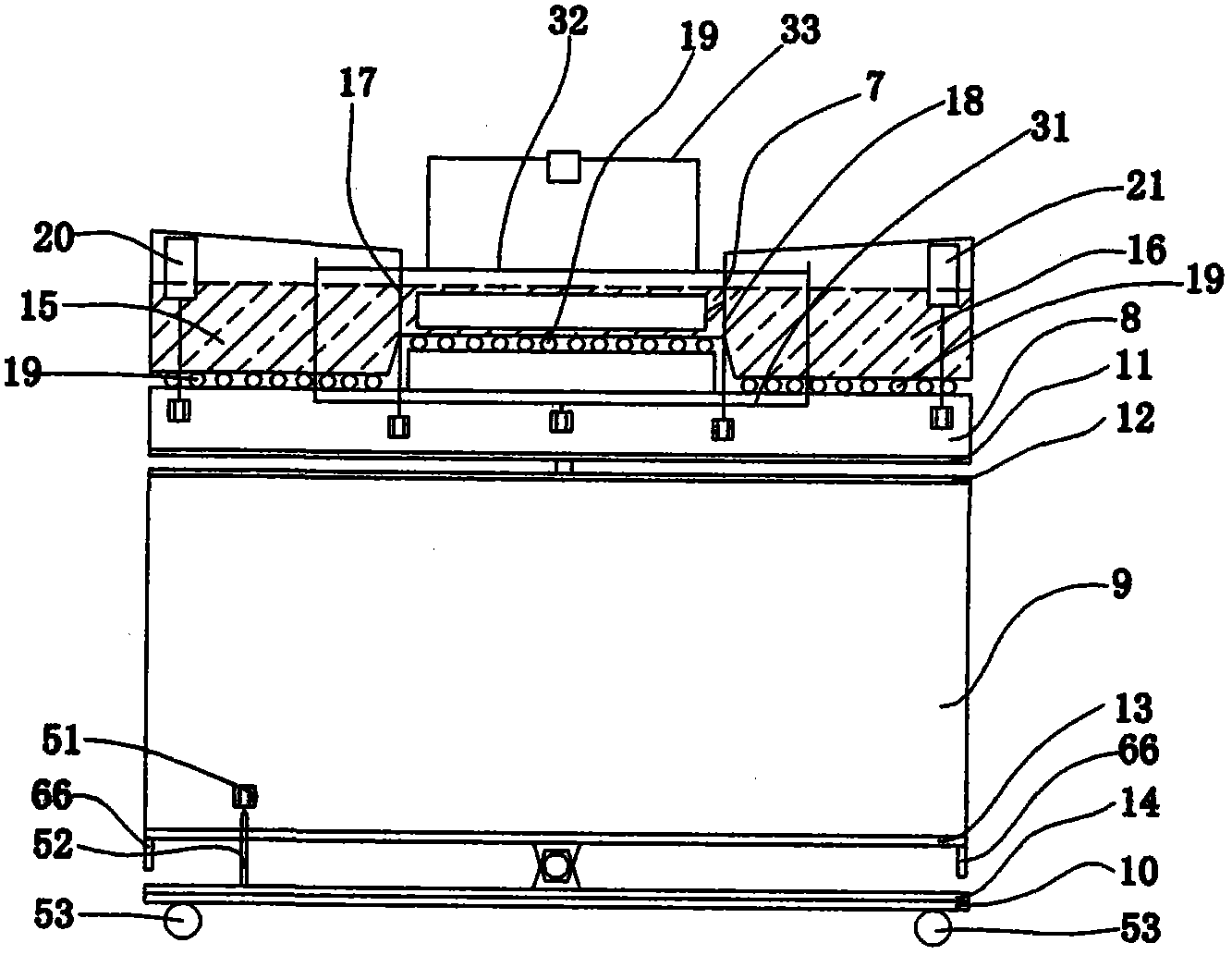

[0009] 3. Due to the need to produce tin wave peaks, tin furnace and tin cylinder need to be designed and manufactured with a certain amount of tin capacity to meet the requirements of tin wave generation, and the larger the tin cylinder capacity will cause the tin furnace to take too long to heat up and consume

electricity Too much, in the constant temperature of the tin furnace, the larger the volume of the tin furnace, the greater the heat loss, and the more solder in the tin tank, the more production input costs, and the more solder in the tin tank is needed in production and operation The ratio of the controlled solder

metal composition is also more difficult to control within the optimal range, which will affect the soldering quality

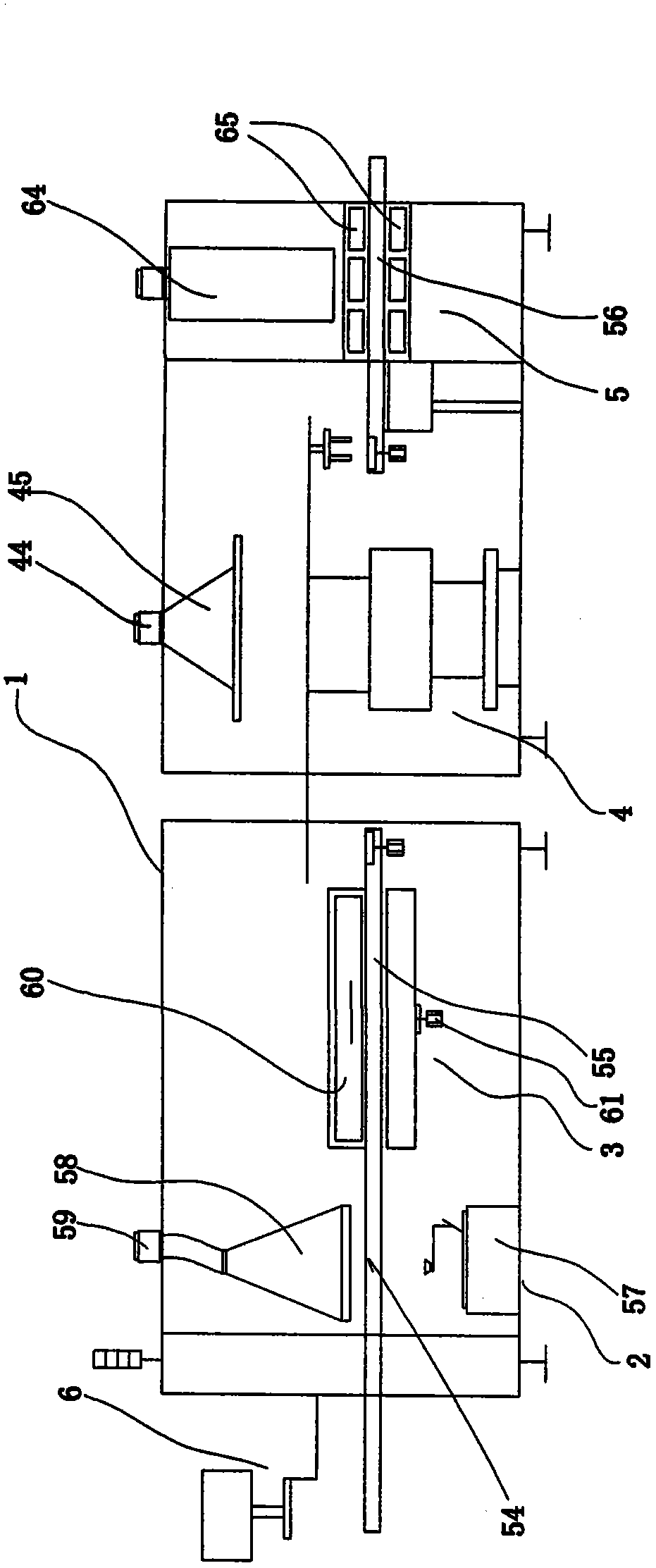

[0010] 4. In order to meet the requirements of automatic operation, the

wave soldering furnace needs to adopt the method of clamping the chain claw to drive the circuit board into the

wave soldering. When the flux spraying

system, preheating

system, soldering

system and cooling device are controlled by the same transmission and transportation mechanism, It often happens that each function has different requirements for the transportation speed, which creates mutual constraints and conflicts. It does not make the best performance of each function, which ultimately affects the

welding quality and increases the

welding cost. Because the

wave soldering furnace is an

integrated design, it can During the movement, specific equipment is required to be lifted and removed, which brings inconvenience and waste to the actual installation and commissioning

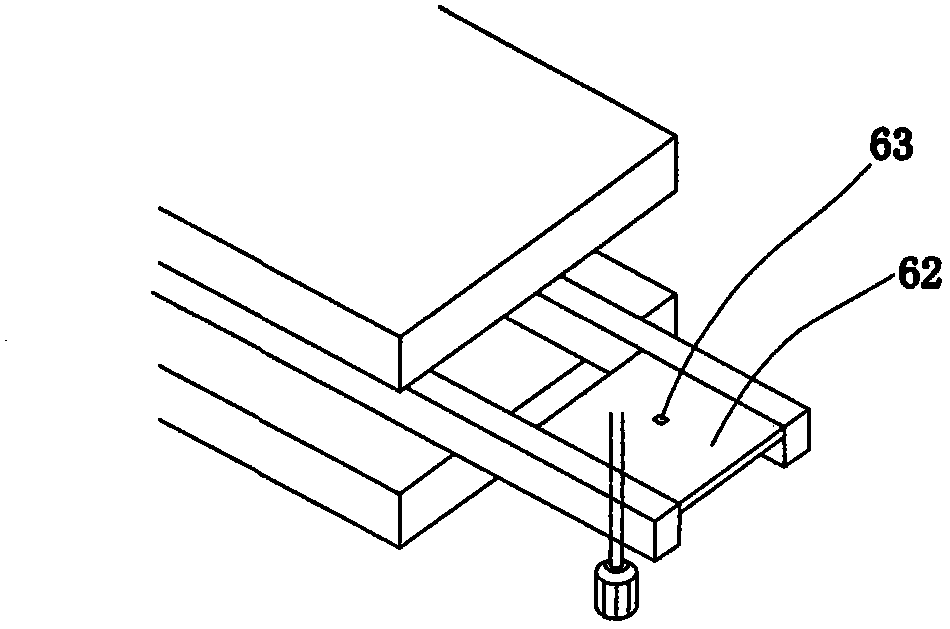

[0011] 5. The flux spraying in the wave soldering furnace adopts scanning full

coating, but this method does not meet the actual production requirements. If there is a certain area of the circuit board that does not need to be sprayed or less sprayed, the existing device will be subject to transportation. Influenced by the method and flux spraying design, the flux is not accurately sprayed; if some parts of the circuit board need to be sprayed more to achieve the soldering quality effect, the entire board will increase the amount of flux sprayed, resulting in flux Flux waste, and product quality is also affected

The second type, if there are SMD components on the bottom of the circuit board, it will fall off during wave soldering

[0016] Furnace-passed carriers must be regularly inspected and cleaned according to actual needs during production and maintenance, and cleaning the furnace-passed carriers requires a certain amount of cleaning

solvent and man-hours

[0017] 7. The extraction and exhaust system has not been precisely controlled. Because the size and output of various circuit boards are different in actual production, the amount of

exhaust gas generated should also be different. At present, there is no selection to adjust the exhaust according to actual needs. The size of the

air volume depends on the energy saving. The flux spraying area and the welding area are each equipped with an exhaust hood for exhausting

exhaust gas to facilitate exhaustion. However, when

exhaust gas overflows the exhaust hood, the exhaust gas will float up and cannot be exhausted. It will overflow from the gap of the furnace body, which will pollute the air in the workshop and damage the health of the workshop personnel.

[0020] Due to the improvement of the integration of electronic circuits and the immutability of the circuit board design of electronic products, the wave furnace cannot fundamentally solve the bad points of welding.

When soldering a circuit board that needs to use double peaks, because the first wave (disturbed wave) and the second wave (advective wave) must be separated by a certain distance, the temperature of the circuit board will drop after one wave is soldered, and the circuit that drops the temperature When the board enters the second wave soldering,

poor quality often occurs, which affects the quality of the solder joints. This also increases the soldering temperature, making the circuit board and electronic components withstand the peak temperature for too long, and the product is affected to a certain extent.

Moreover, the double-wave soldering circuit board needs to increase the amount of flux spraying compared with single-wave soldering, because the circuit board will remove part of the flux during one wave soldering, which will reduce the original flux performance.

Login to View More

Login to View More  Login to View More

Login to View More