Apparatus and method for moulding porcelain with artificial natural stone patterns

A technology imitating natural stone and ceramic processing, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of rough and monotonous patterns, products that cannot produce small patterns, and clogged patterns, etc., to overcome the poor texture of the whole body, Enhance the whole body texture and strong texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

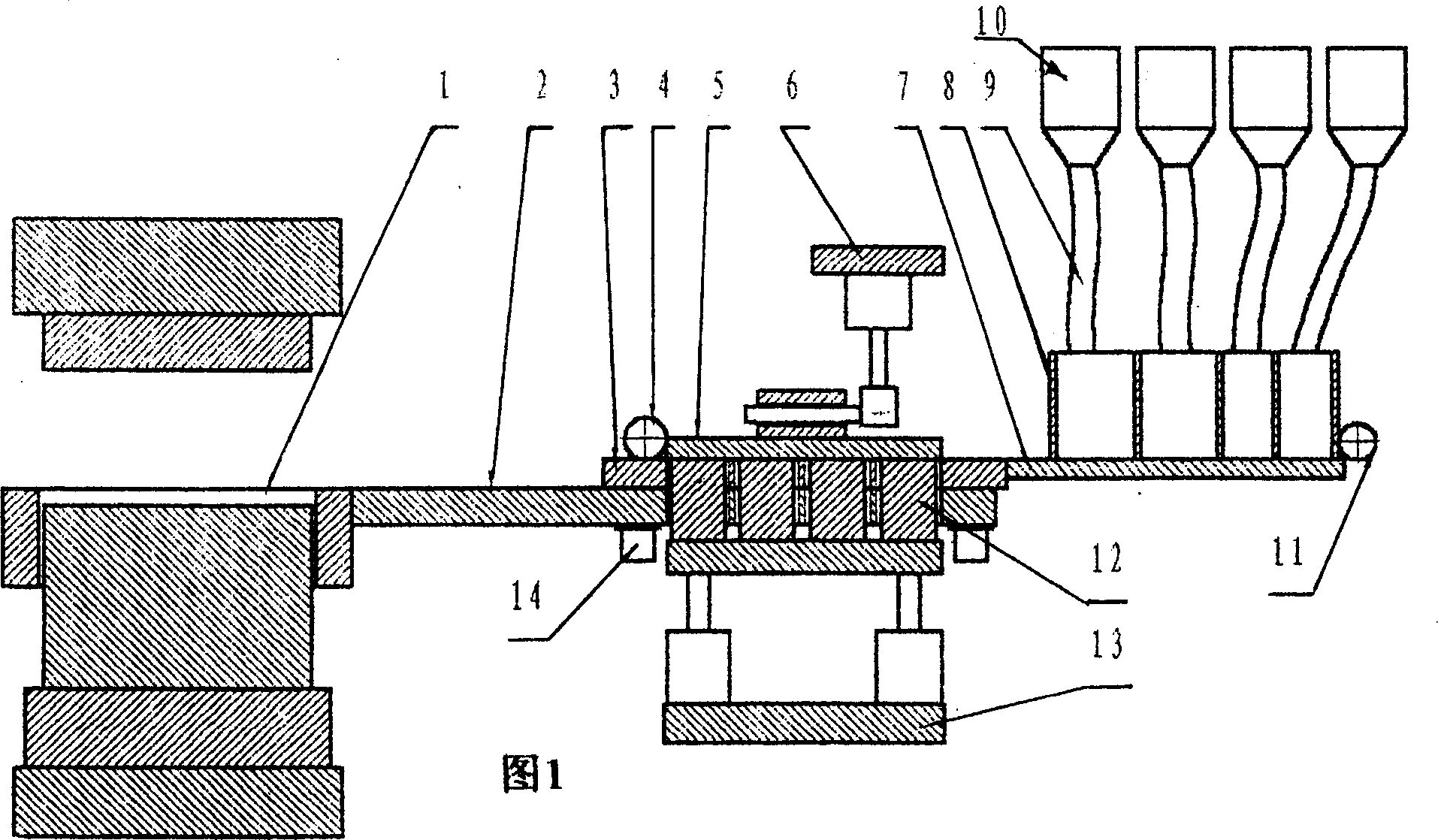

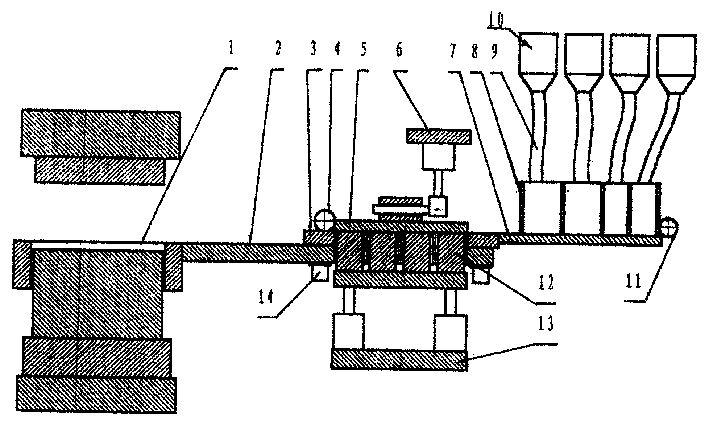

[0030] Set forth in detail below in conjunction with accompanying drawing for realizing the preferred mode method of the present invention:

[0031] The technical scheme adopted by the present invention is composed of a set of equipment and a method for applying the equipment.

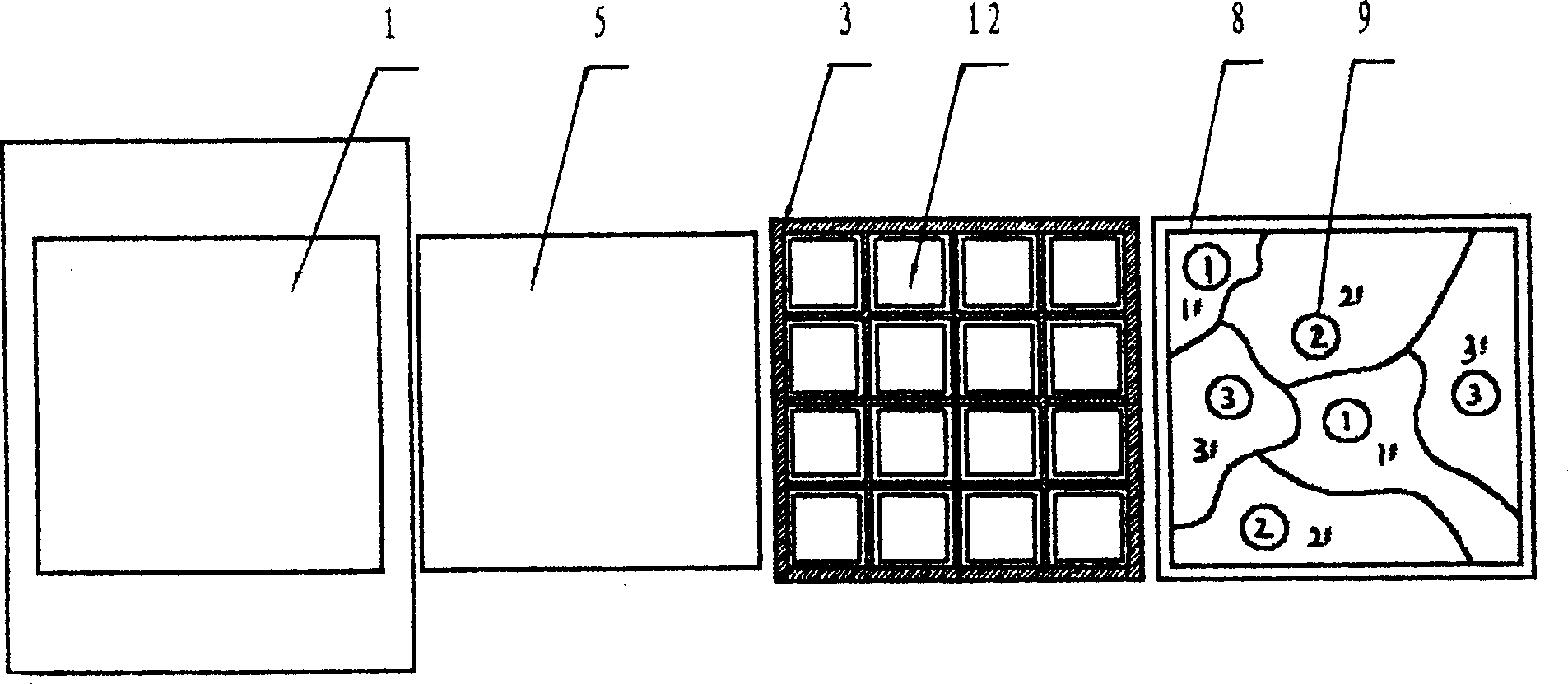

[0032] Fig. 1 shows that the present invention imitates the equipment structural representation of natural stone material pattern continuing material ceramic processing molding, and this cover equipment except comprising known hydroforming machine and press mold frame 1 thereof, it is particularly in the described press mold The frame 1 is connected with a replica small mold 2, a grid 3 is arranged on the replica small mold 2, a grid driver 4 is installed on one end of the grid 3, a pressing plate 5 is arranged on the grid 3, and a pressing plate is arranged on the pressing plate 5 The lifting mechanism 6 is connected with a platform 7 at the other end of the grid 3, a pattern material box 8 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com