Flotation technology for treating coal slime by utilizing salt-containing wastewater

A saline wastewater and flotation technology, which is applied in flotation, solid separation, etc., can solve the problems of high cost and large amount of coal slime flotation, achieve the requirements of reducing production pressure, turning waste into treasure, and improving environmental protection. The effect of action efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

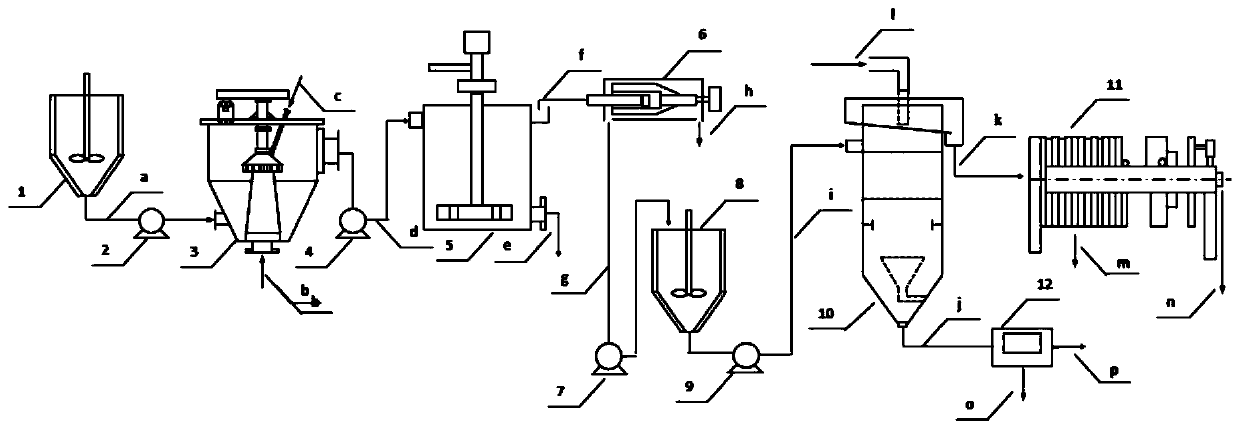

[0028] Attached below figure 2 The implementation of the present invention is further described:

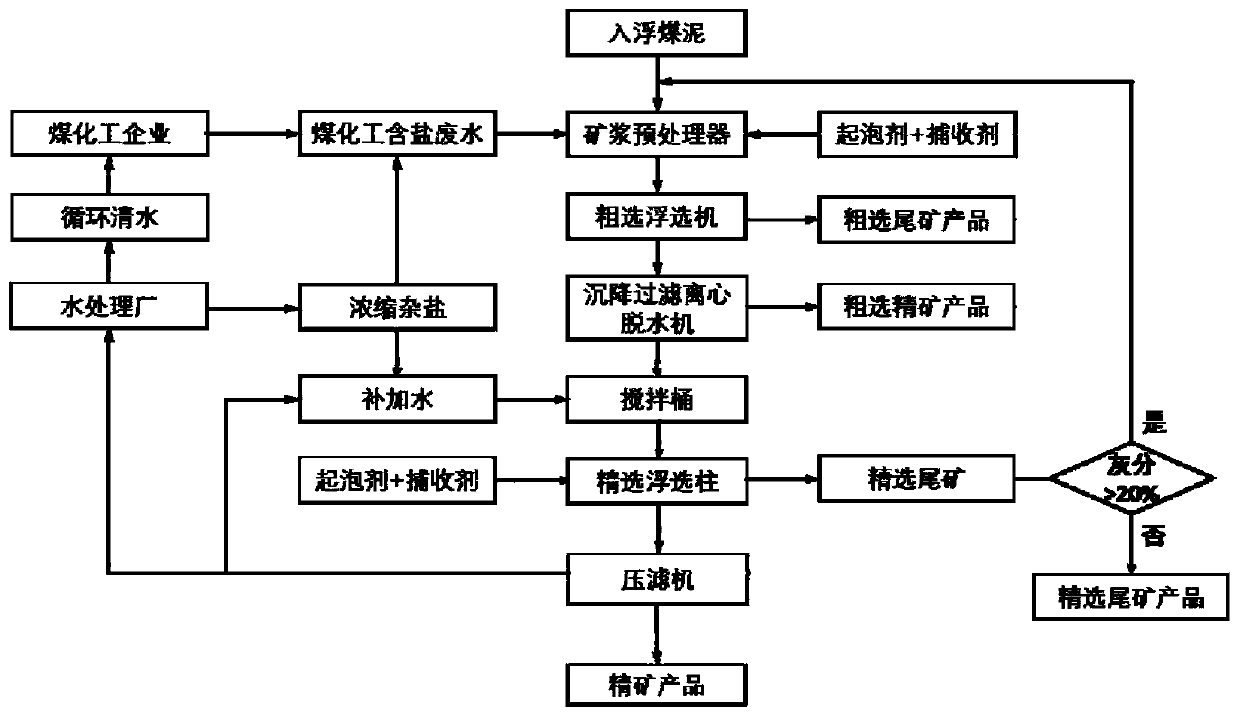

[0029] Such as figure 1 with figure 2 Shown, the present invention utilizes the flotation process of saline waste water treatment coal slime, it is characterized in that comprising steps as follows:

[0030] The floating coal slime enters the slurry preprocessor 3 from the bottom through the pipeline b, and the collector and foaming agent are fed into the slurry preprocessor 3 through the pipeline c to form a mixed slurry;

[0031] Put the coal chemical industry salty wastewater discharged from the coal chemical industry into the mixing tank 1 and stir evenly. The concentration of the brine after stirring is 30000mg / L, and the composition of the salt is NaCl, NaCl 2 SO 4 , CaCl 2 and CaSO 4 , through the circulating pump 2, the brine is used as dilution water to enter the pulp preprocessor 3 along the pipeline a, and the salty wastewater from the coal chemical industry is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com