Dual-alloy nanocrystal rare earth permanent magnet and preparation method therefor

A technology of rare earth permanent magnets and nanocrystals, which is applied in the direction of magnetic objects, inductors/transformers/magnets, magnetic materials, etc., can solve the problems of nanocomposite magnets that cannot be sintered and thermally deformed, so as to reduce material costs, improve density, The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

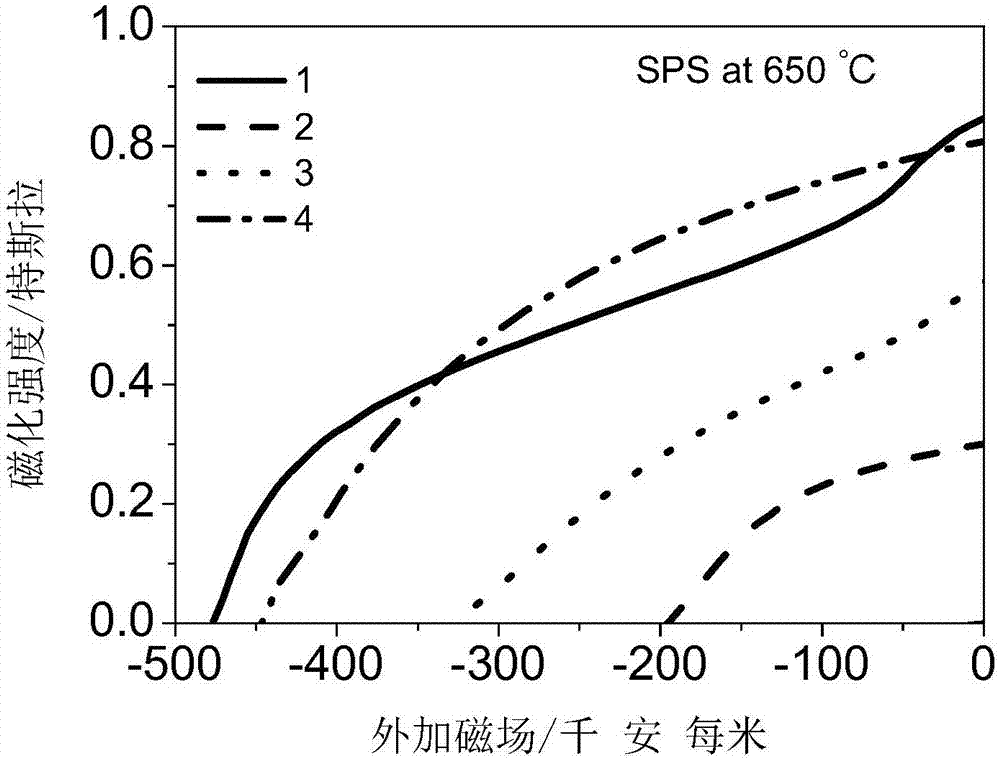

Embodiment 1

[0033] Sieve the commercial nanocomposite Nd-Fe-B (rare earth 10%, Fe 84%, B 6%) magnetic powder, and screen the magnetic powder with a particle size of 105-300 μm. Take 10g of magnetic powder and put it into a graphite mold with a diameter of 20mm, and then sinter it on SPS-825 spark plasma sintering equipment. The sintering pressure is 50MPa. Set the sintering temperature T sps is 650°C, the heating time is 7min, and the sintering holding time is t sps For 7min, the vacuum degree during sintering is less than 6Pa. This sintered sample is designated as No. 1 sample.

Embodiment 2

[0035] According to the alloy composition ratio Ce 17 Fe 78 B 6 (Atomic percentage) Ce, Fe and FeB alloys with a purity greater than 99.95% were weighed, and the weighed alloys were put into an electric arc melting furnace to be melted into button-shaped ingots. The ingot was broken into small pieces of 3-5g. In the belt throwing machine, under the protection of Ar gas and the roll speed of 18m / s, alloy thin strips were obtained by melt quenching technology.

[0036] Ce will be obtained 17 Fe 78 B 6 Put the alloy strip into a glove box, grind it into magnetic powder with a mortar, and then sieve the magnetic powder with a particle size of 105-300 μm. Take Ce with a mass of 10g 17 Fe 78 B 6 The magnetic powder is put into a graphite mold with a diameter of 20mm, and then sintered on the SPS-825 spark plasma sintering equipment. The sintering pressure is 50MPa. Set the sintering temperature T sps is 650°C, the heating time is 7min, and the sintering holding time is t...

Embodiment 3

[0038] MQ magnetic powder (Example 1) with a particle size of 105-300 μm and a mass fraction of 50% and 50% of Ce 17 Fe 78 B 6 A total of 10 g of magnetic powder (Example 2) was put into a graphite mold with a diameter of 20 mm, and sintered on a SPS-825 spark plasma sintering equipment. The sintering pressure is 50MPa. Set the sintering temperature T sps is 650°C, the heating time is 7min, and the sintering holding time is t spsFor 7min, the vacuum degree during sintering is less than 6Pa. This sintered sample is designated as sample No. 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com