Preparation method for inorganic-organic composite type profile control agent

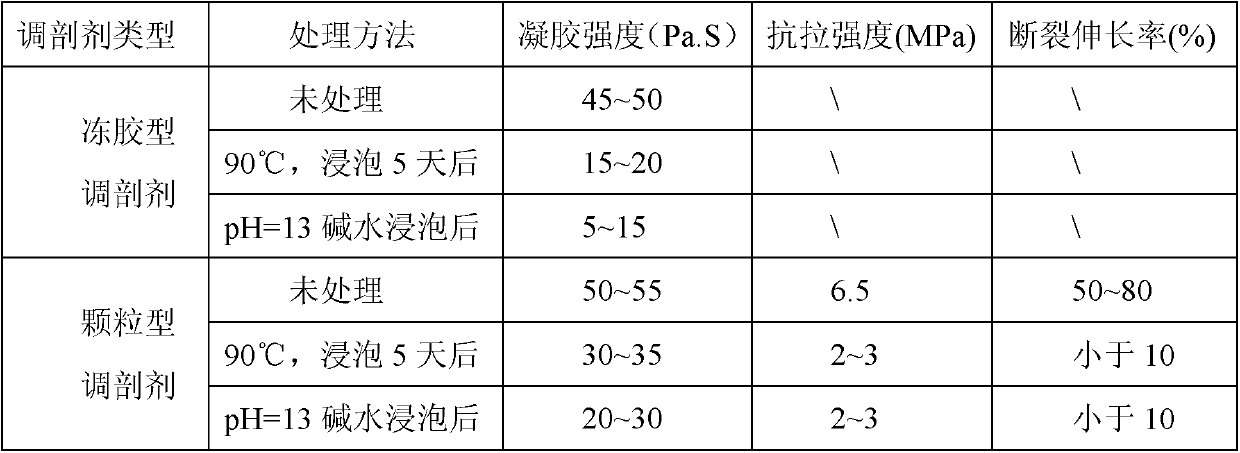

A composite profile control agent technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of profile control agent temperature resistance, alkali resistance and poor mechanical properties, and achieve alkali resistance and Good mechanical properties, stable structure, good plugging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0009] Specific embodiment one: In this embodiment, a method for preparing an inorganic-organic composite profile control agent is carried out through the following steps:

[0010] 1. Preparation of silicon dioxide: a. Weigh 10-20mL of ammonia water, 10-20mL of absolute ethanol and 8-12mL of ethyl orthosilicate; b. Mix the ammonia water and absolute ethanol weighed in step a, and stir for 9 ~11min, then put it into a three-necked flask at a temperature of 55-65°C, turn on the electronic stirrer and reflux condensed water, add the tetraethyl orthosilicate weighed in step a, continue the reaction for 4-6h, then transfer it into a centrifuge tube, Centrifuge at 2000r / min for 4-6min, take the solid phase, and then use absolute ethanol to ultrasonically disperse and wash for 3-4 times until the pH value is neutral, then put it into an oven at a temperature of 55-70°C. Dry for 5-7 hours to obtain silicon dioxide;

[0011] 2. Surface modification of silica by silane coupling agent: ...

specific Embodiment approach 2

[0014] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in Step 1, 10 mL of ethyl orthosilicate, 15 mL of ammonia water, and 15 mL of absolute ethanol are weighed. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the silane coupling agent in step 2 is KH-570. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com