Preparation method of composite heat conduction graphene film and composite heat conduction graphene film

A technology of graphene composite and graphene film, which is applied in the direction of layered products, metal layered products, chemical instruments and methods, etc., can solve the problems of complex process, unsuitable film, high cost of heat conduction film, etc., to solve technical problems, Effect of improving density and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

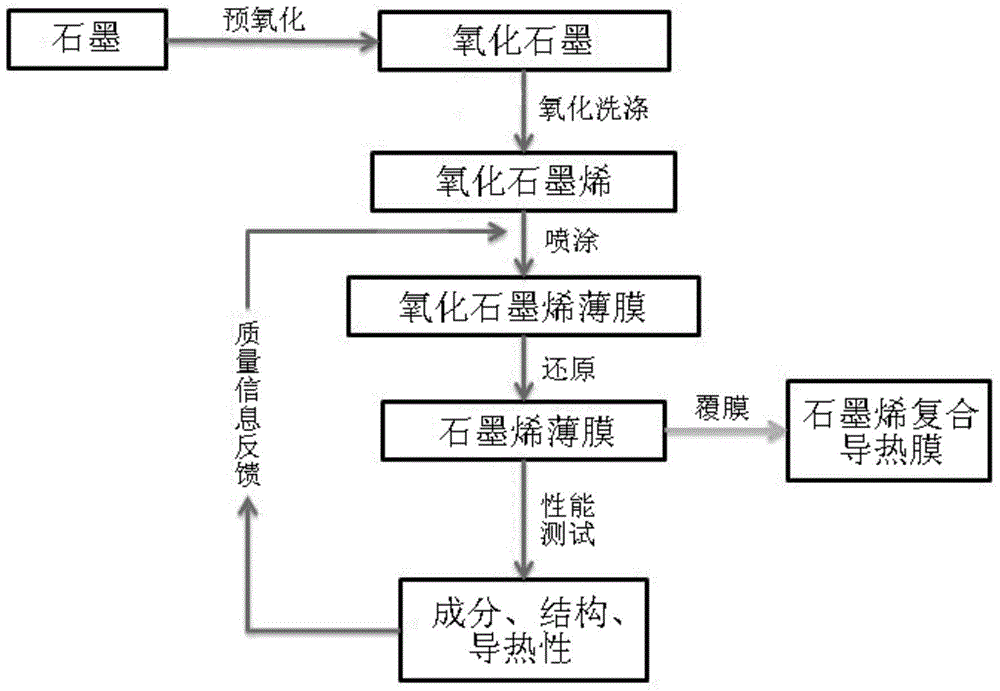

[0054] Embodiment 1 of the present invention: a kind of preparation method of graphene composite heat conduction film, such as figure 1 shown, including the following steps:

[0055] S1, placing flake graphite or graphite powder in the mixed solution of concentrated sulfuric acid, potassium persulfate and phosphorus pentoxide (the mass ratio of concentrated sulfuric acid, potassium persulfate and phosphorus pentoxide in the mixed solution is 0.5-3:1 -4:1-4) soaked for a day and night, then suction filtered and dried to complete the pre-oxidation;

[0056] S2, using the Hummers method to further oxidize the pre-oxidized graphite, that is, fully oxidize in concentrated sulfuric acid and potassium permanganate, the mass ratio of concentrated sulfuric acid, potassium permanganate and pre-oxidized graphite is 0.5-10:250 -400:15-75, then add deionized water to dilute, after repeated washing and suction filtration, obtain graphene oxide aqueous solution;

[0057] S3, using the ther...

Embodiment 2

[0060] Embodiment 2 of the present invention: a kind of preparation method of graphene composite heat conduction film, such as figure 1 shown, including the following steps:

[0061] S11, placing flake graphite or graphite powder in the mixed solution of concentrated sulfuric acid, potassium persulfate and phosphorus pentoxide (the mass ratio of concentrated sulfuric acid, potassium persulfate and phosphorus pentoxide in the mixed solution is 0.5-1.5:1 -2:1-2) soaked in a day and night, then suction filtered and dried to complete the pre-oxidation;

[0062] S12, using the Hummers method to further oxidize the pre-oxidized graphite, that is, fully oxidize in concentrated sulfuric acid and potassium permanganate, the mass ratio of concentrated sulfuric acid, potassium permanganate and pre-oxidized graphite is 0.5-3:250 -280:15-30, then add deionized water to dilute, after repeated washing and suction filtration, obtain the graphene oxide aqueous solution;

[0063] S13, using t...

Embodiment 3

[0066] Embodiment 3 of the present invention: a kind of preparation method of graphene composite heat conduction film, such as figure 1 shown, including the following steps:

[0067] S11, placing flake graphite or graphite powder in the mixed solution of concentrated sulfuric acid, potassium persulfate and phosphorus pentoxide (the mass ratio of concentrated sulfuric acid, potassium persulfate and phosphorus pentoxide in the mixed solution is 1.5-3:2 -4:2-4) soaked for a day and night, then suction filtered and dried to complete the pre-oxidation;

[0068] S12, the pre-oxidized graphite is further oxidized by the Hummers method, that is, fully oxidized in concentrated sulfuric acid and potassium permanganate, and the mass ratio of concentrated sulfuric acid, potassium permanganate and pre-oxidized graphite is 3-10:280 -400:30-75, then add deionized water to dilute, after repeated washing and suction filtration, obtain the graphene oxide aqueous solution;

[0069] S13, using ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com