Mullite steel fiber castable

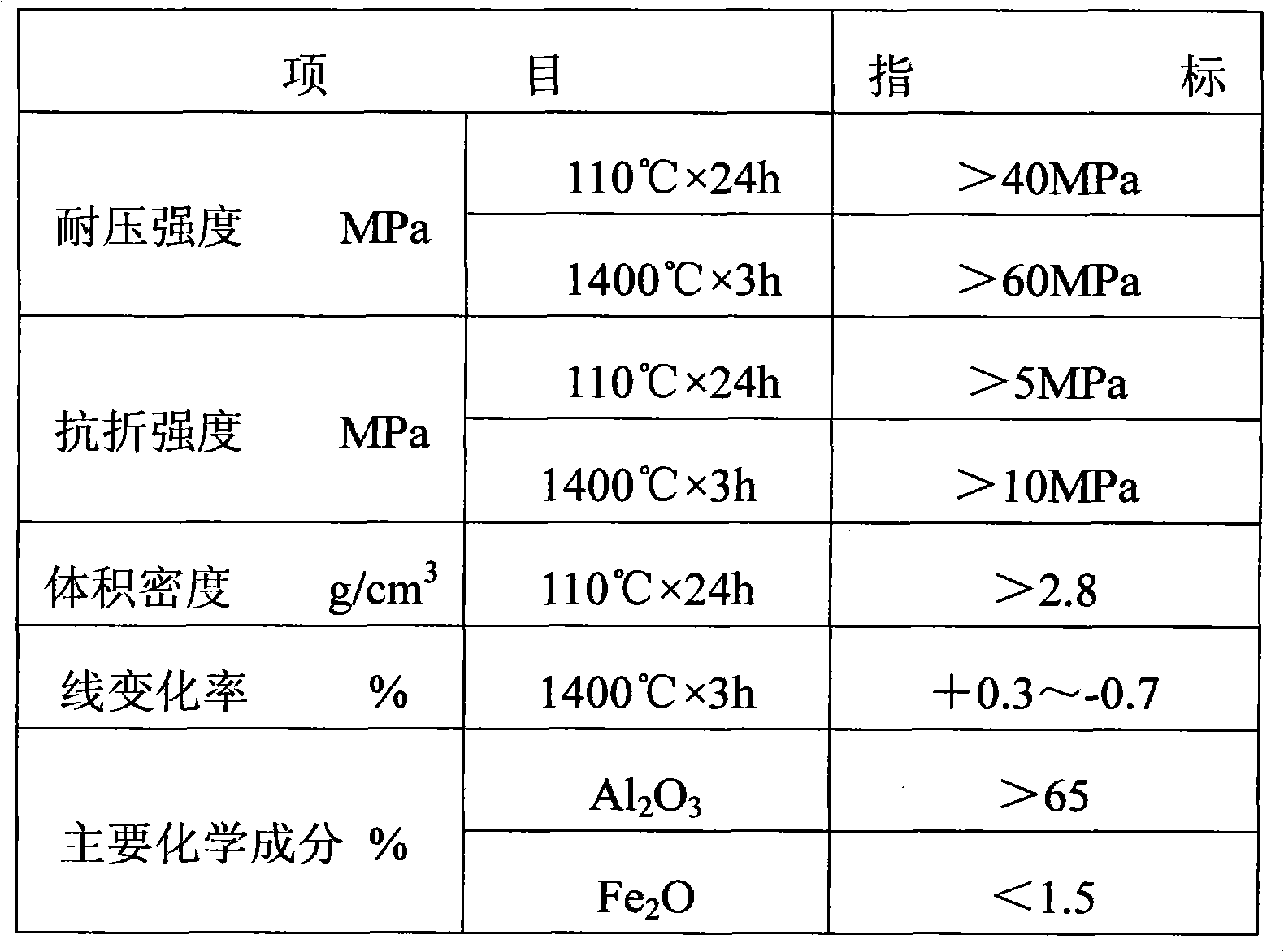

A mullite steel and castable technology, applied in the field of unshaped refractory materials, can solve the problems of poor thermal shock performance and erosion resistance, affecting service life, and prone to cracks, etc., to achieve good thermal shock resistance, high resistance Compressive strength and flexural strength, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Raw material ratio of the mullite steel fiber castable of the present invention: represented by weight percent, consisting of 35% of brown corundum, 15% of Shanxi high-quality high-alumina bauxite clinker (grain size is 5-8mm), and 30% of sintered mullite , 10% fused mullite (200 mesh fineness), 5% silica powder, 3% coagulant (Lafarge cement) and 2% stainless steel fiber.

[0025] Medium Al in brown corundum used as raw material 2 o 3 The content of ≥95%; Al in high-quality high-alumina bauxite clinker in Shanxi 2 o 3 The content of ≥85%; Al in the sintered mullite 2 o 3 The content of ≥72%; Al in the fused mullite 2 o 3 content ≥ 72%;

[0026] 35% of the raw material brown corundum used in the mullite steel fiber castable of the present invention is composed of 10% of 3-5mm brown corundum, 15% of 1-3mm brown corundum and 10% of brown corundum with a fineness of 200 mesh;

[0027] 30% of the raw material sintered mullite used in the mullite steel fiber castable ...

Embodiment 2

[0030] Embodiment 2: basically the same as Embodiment 1, the difference is:

[0031] Raw material ratio of the mullite steel fiber castable of the present invention: represented by weight percent, consisting of 29% of brown corundum, 15% of Shanxi high-quality high-alumina bauxite clinker (grain size is 5-8mm), and 32% of sintered mullite , 12% fused mullite (200 mesh fineness), 6% silica powder, 3.5% coagulant (Lafarge cement) and 2.5% stainless steel fiber.

[0032] The mullite steel fiber casting material of the present invention uses 29% of brown corundum as a raw material, which is composed of 8% of 3-5mm brown corundum, 13% of 1-3mm brown corundum and 8% of brown corundum with a fineness of 200 mesh.

[0033] The 32% sintered mullite used in the mullite steel fiber casting material of the present invention is composed of 20% sintered mullite of 1-3mm and 12% of sintered mullite of 0-1mm.

Embodiment 3

[0034] Embodiment 3: basically the same as Embodiment 1, the difference is:

[0035] Raw material ratio of the mullite steel fiber castable of the present invention: represented by weight percent, consisting of 40% of brown corundum, 10% of Shanxi high-quality high-alumina bauxite clinker (grain size is 5-8mm), and 30% of sintered mullite , 8% fused mullite (fineness: 200 mesh), 7% silica powder, 2% coagulant (Lafarge cement) and 3% stainless steel fiber.

[0036] The mullite steel fiber casting material of the present invention uses 40% of the raw material brown corundum, which is composed of 12% of the 3-5mm brown corundum, 16% of the 1-3mm brown corundum and 12% of the fineness of the 200 mesh brown corundum.

[0037] The 30% sintered mullite used in the mullite steel fiber casting material of the present invention is composed of 18% 1-3mm sintered mullite and 12% 0-1mm sintered mullite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com