High-entropy alloy powder for laser cladding and preparation method of cladding layer

A technology of laser cladding and high-entropy alloys, which is applied in the coating process of metal materials, coatings, etc., can solve the problems of small thermal influence of heating and cooling rates, and less high-entropy alloys, so as to improve the bonding strength and scrap rate of parts Low, small thermal deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

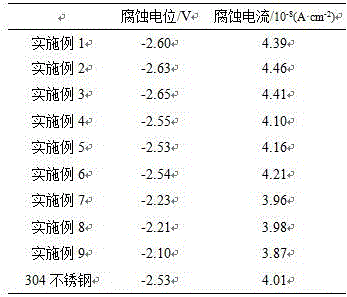

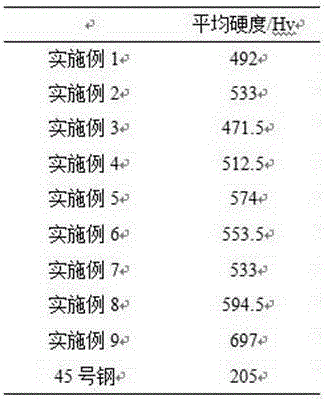

Examples

Embodiment 1

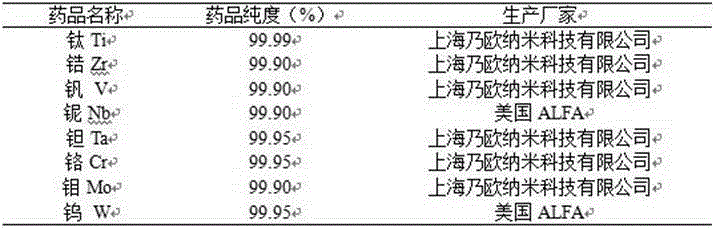

[0023] The high-entropy alloy powder for laser cladding described in this embodiment is composed of Ti, Zr, V, Nb, Ta and Mo element powders, and the atomic percentages of each component are 16% Ti, 17% Zr, and 16% V , 14% Nb, 23% Ta, 14% Mo.

[0024] The preparation method of the high-entropy alloy powder cladding layer for laser cladding is provided, comprising the following steps:

[0025] (1) After mixing the various powders in proportion, all of them are introduced into a vacuum ball mill tank, ball milled for 3 hours, and fully mixed to obtain alloy powder with a particle size of 180-250 mesh;

[0026] (2) Mix the alloy powder obtained in step (1) with absolute ethanol to obtain a coating material, which consists of 91% by mass alloy powder and 9% absolute ethanol, and evenly coat the coating material on the Coarsely grind to remove the surface scale, and then clean the surface of the 45# steel base material with an ultrasonic cleaning machine filled with alcohol to rem...

Embodiment 2

[0029] The high-entropy alloy powder for laser cladding described in this embodiment is composed of Ti, Zr, V, Nb, Ta and Mo element powders, and the atomic percentages of each component are 18% Ti, 18% Zr, and 19% V , 15% Nb, 15% Ta, 15% Mo.

[0030] The preparation method of the high-entropy alloy powder cladding layer for laser cladding is provided, comprising the following steps:

[0031] (1) After mixing each alloy powder in proportion, all of them are introduced into a vacuum ball mill tank, ball milled for 4 hours, and fully mixed to obtain alloy powder with a particle size of 200-300 mesh;

[0032](2) Mix the alloy powder obtained in step (1) with absolute ethanol to obtain a coating material, which consists of 90% by mass alloy powder and 10% absolute ethanol, and uniformly coat the coating material at 45 The surface of No. 45 steel base material, in which the No. 45 steel base material is coarsely ground to remove surface scale, and then cleaned by an ultrasonic cle...

Embodiment 3

[0035] The high-entropy alloy powder for laser cladding described in this embodiment is composed of Ti, Zr, V, Nb, Ta and Mo element powders, and the atomic percentages of each component are 19% Ti, 19% Zr, and 21% V , 17% Nb, 8% Ta, 16% Mo.

[0036] The preparation method of the high-entropy alloy powder cladding layer for laser cladding is provided, comprising the following steps:

[0037] (1) After mixing each alloy powder in proportion, all of them are introduced into a vacuum ball mill tank, ball milled for 3.5 hours, and fully mixed to obtain alloy powder with a particle size of 250-325 mesh;

[0038] (2) Mix the alloy powder obtained in step (1) with absolute ethanol to obtain a coating material, which consists of 95% by mass alloy powder and 5% absolute ethanol, and uniformly coat the coating material at 45 The surface of No. 45 steel base material, among them, the No. 45 steel base material is coarsely ground to remove the surface scale, and then cleaned by an ultras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com