Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1654results about "Alkali metal silicate coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Permeable cement and methods of fracturing utilizing permeable cement in subterranean well bores

Owner:HALLIBURTON ENERGY SERVICES INC

Geopolymer composition and application in oilfield industry

ActiveUS20080028994A1Enhanced pumpabilityImprove stabilitySolid waste managementAlkali metal silicate coatingsGeopolymerSlurry

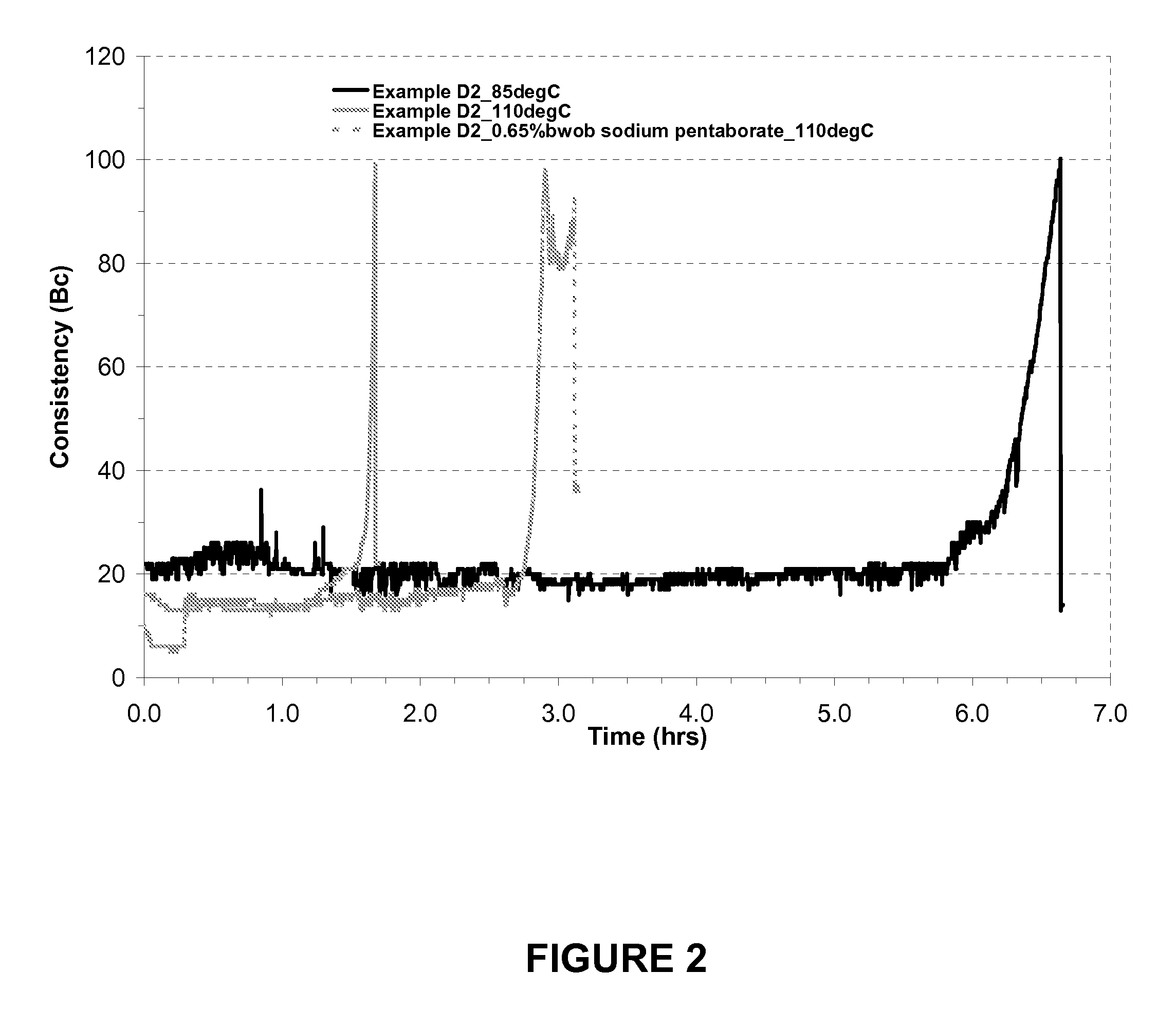

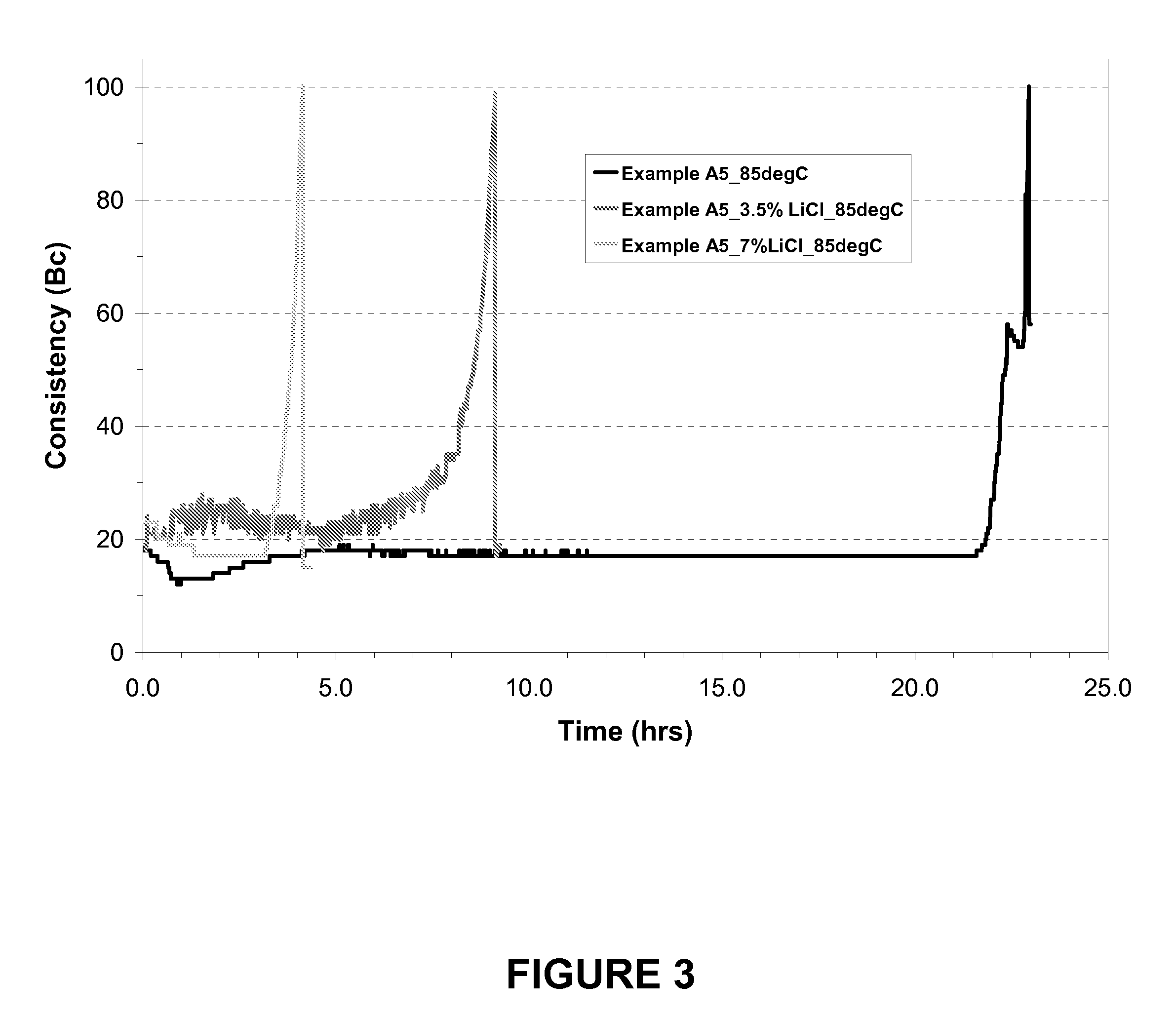

The invention provides geopolymeric compositions, which have controllable thickening and setting times for a wide range of temperatures and a large range of geopolymer slurry densities. The geopolymer slurry compositions have good mixability and pumpability, whilst the set materials develop good compressive strength and permeability. The invention discloses a method for preparing geopolymer for oilfield cementing applications. The geopolymeric compositions according to the invention comprises a suspension comprising an aluminosilicate source, a metal silicate, an alkali activator, lightweight or heavyweight fillers and a carrier fluid wherein the suspension of said geopolymeric composition is pumped in a well and allowed to set.

Owner:SCHLUMBERGER TECH CORP

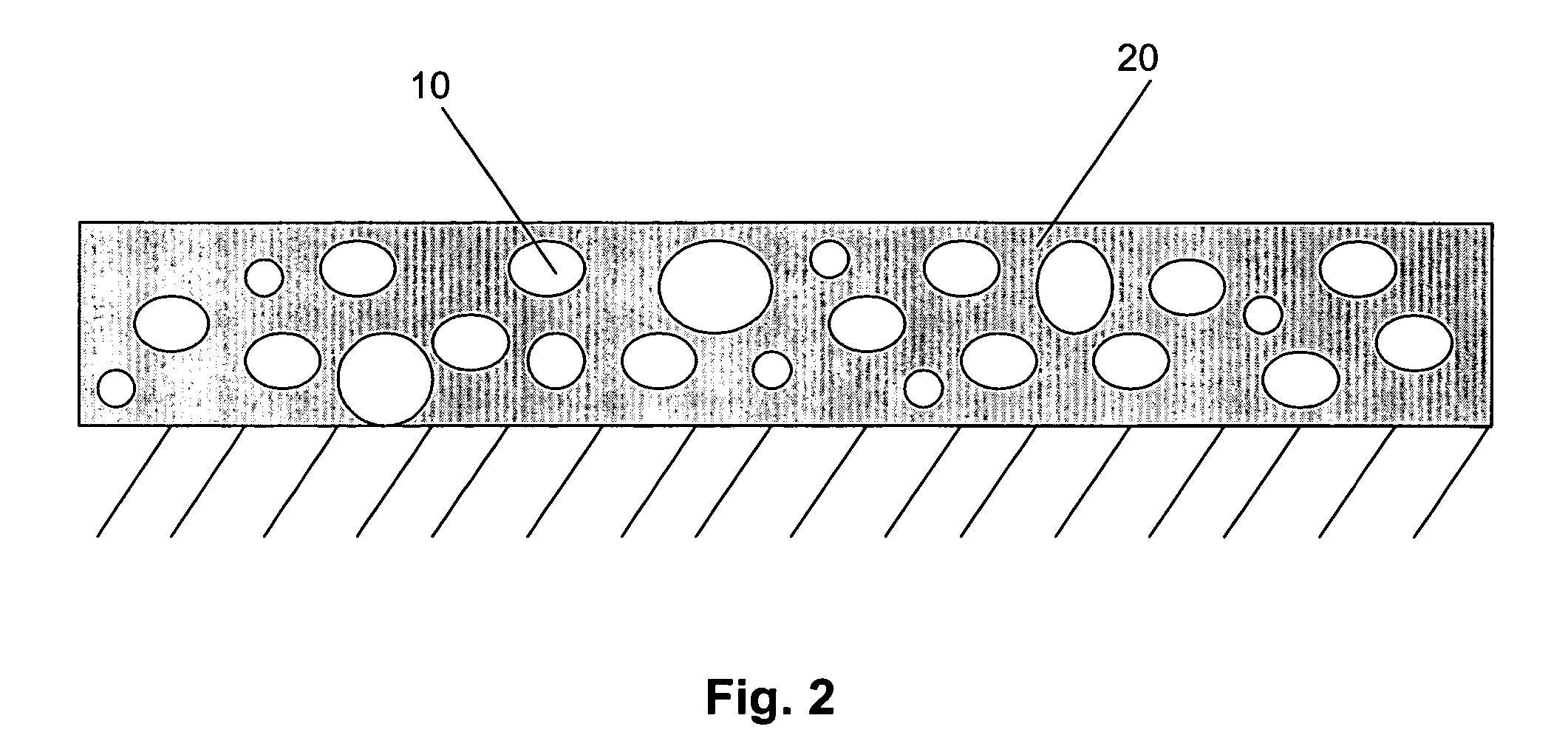

Permeable cement and methods of fracturing utilizing permeable cement in subterranean well bores

InactiveUS20040261999A1Reduce hydrostatic pressureDesirable efficiencyAlkali metal silicate coatingsFluid removalFracturing fluidMaterials science

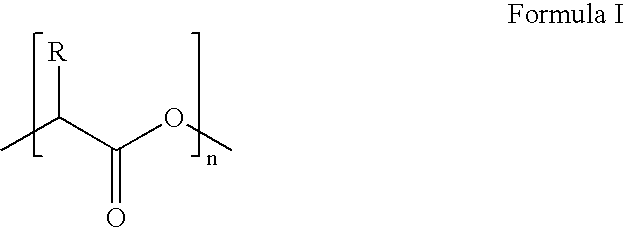

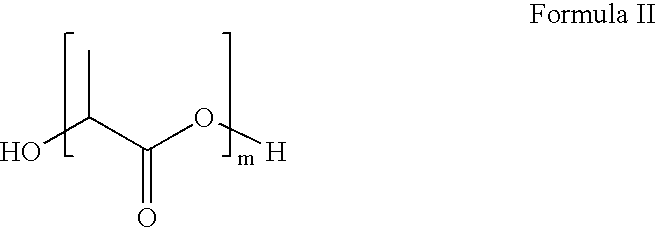

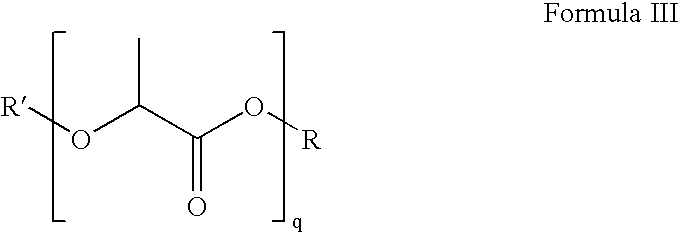

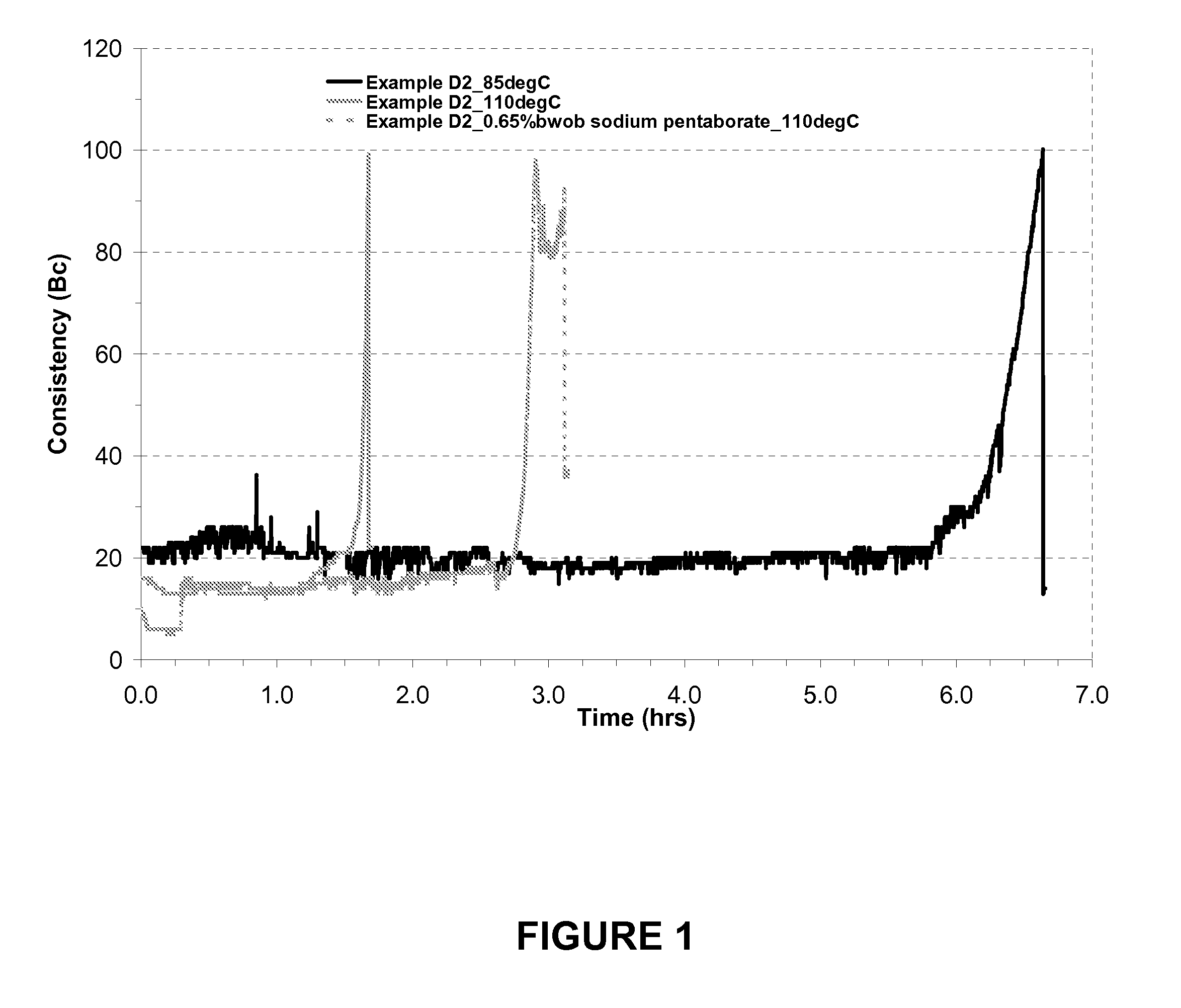

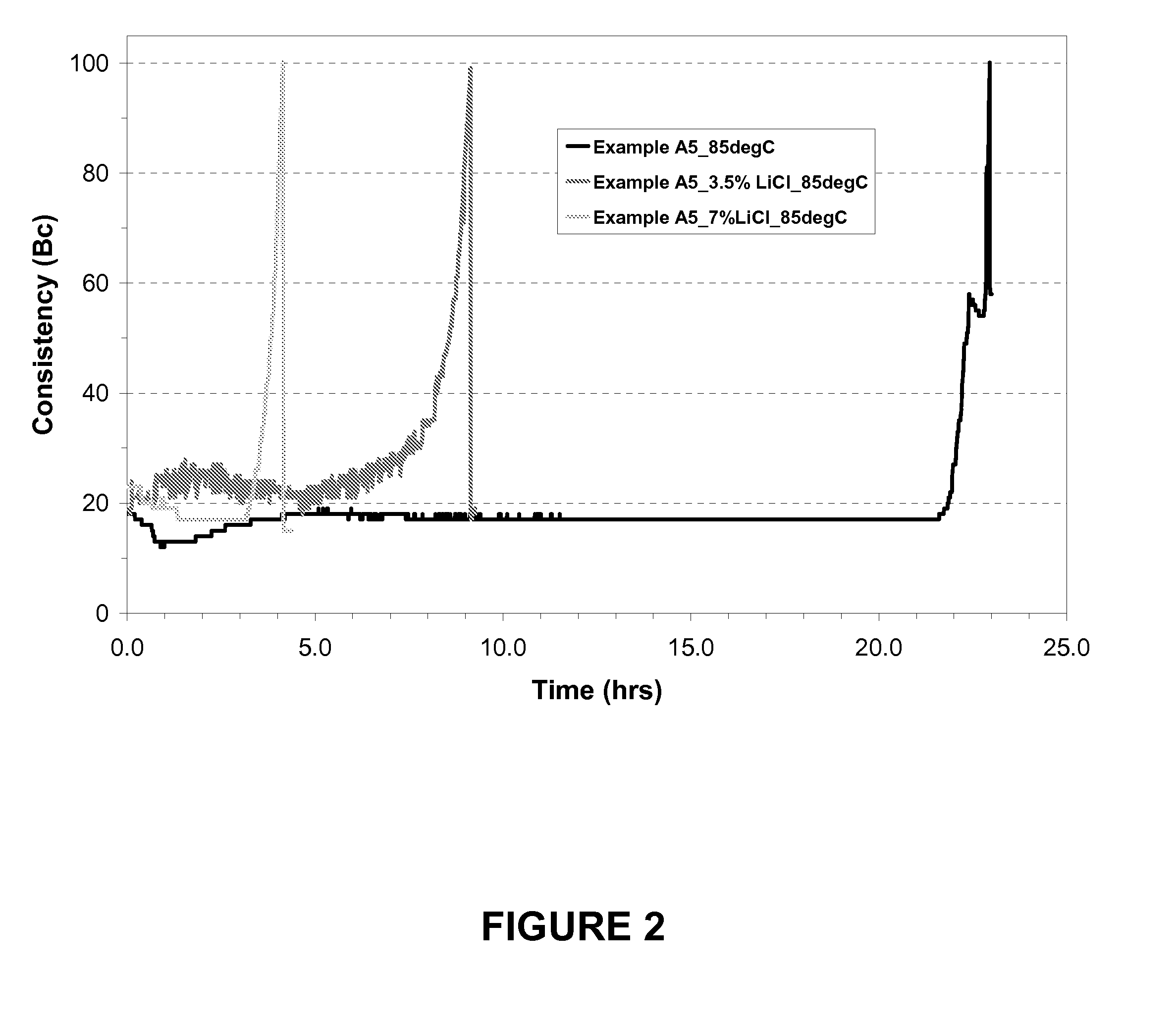

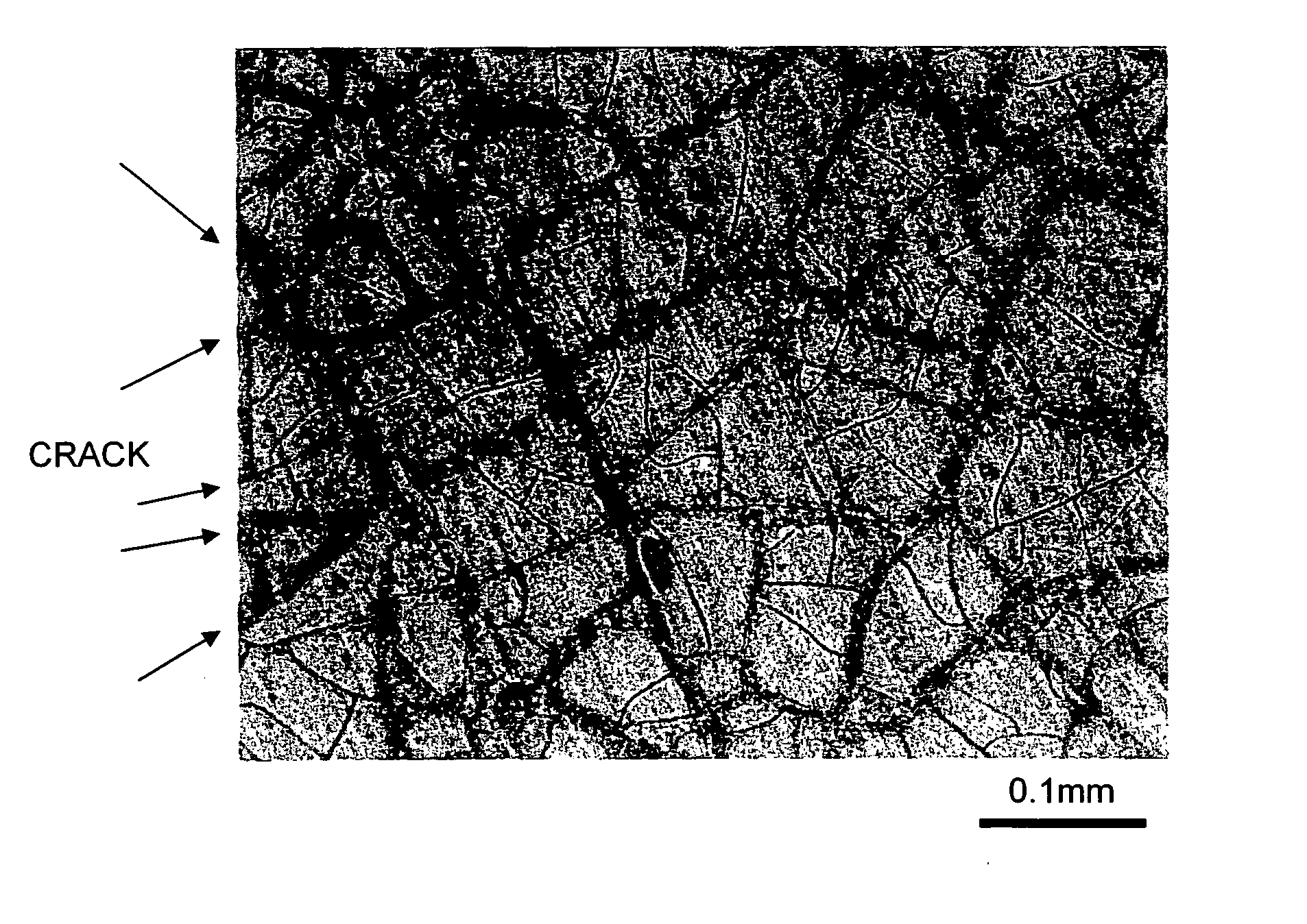

The present invention relates to methods of stimulating a subterranean formation. More particularly, but not by way of limitation, the present invention relates to methods of fracturing subterranean formations utilizing a fracturing fluid comprising a permeable cement composition that may be used as a propping agent. One method of stimulating a subterranean formation of the present invention comprises the following steps: preparing a permeable cement composition comprising a hydraulic cement, water, and a degradable material capable of undergoing an irreversible degradation downhole; injecting the permeable cement composition into the subterranean formation at a pressure sufficient to create a fracture in the subterranean formation; and allowing the permeable cement composition to form a proppant matrix having voids in the fracture.

Owner:HALLIBURTON ENERGY SERVICES INC

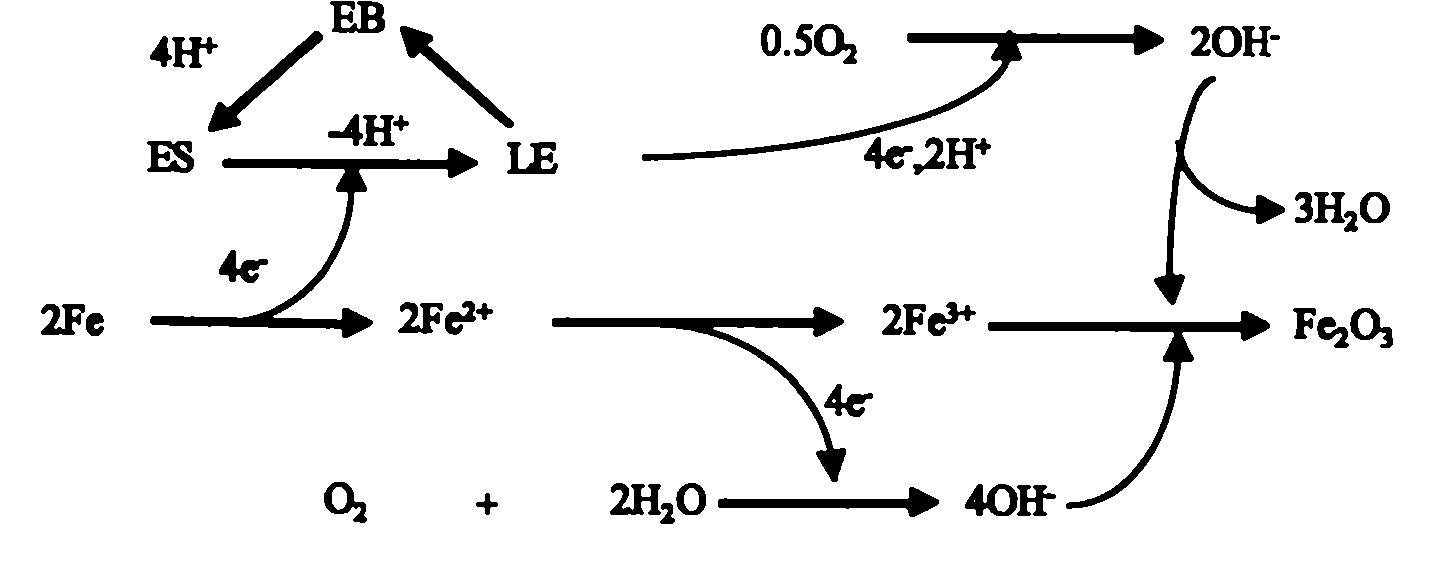

High-performance water-based anticorrosion paint and preparation method thereof

InactiveCN102134410AReduce heavy metal contentImprove heat resistanceAlkali metal silicate coatingsAnti-corrosive paintsAviationWater based

The invention relates to a preparation method of high-performance water-based anticorrosion paint. The high-performance water-based anticorrosion paint comprises 30-60 parts of inorganic material resin, 0.5-30 parts of polyaniline-based nano composite material, 0-30 parts of curing agent, 0.1-1 part of defoaming agent, 0.1-1 part of dispersant and 0.1-1 part of leveling agent. Since the high-performance water-based anticorrosion paint does not contain organic resin or organic solvent, the paint has the advantages of heat resistance, wear resistance, weather resistance, oil resistance, fire resistance and environmental protection; the paint also has the advantages of simple preparation technique, strong binding force with metal, and low cost, can be cured at normal temperature, and can be widely used for corrosion protection in the fields of aviation, navigation, chemical engineering, electronics and the like.

Owner:济宁市产品质量监督检验所

High-temperature thermal-insulation anticorrosive nano coating and its preparing method

InactiveCN1709988AImprove Radiation PerformanceGood heat insulationAlkali metal silicate coatingsPolymer scienceThermal insulation

The invention discloses a kind of new industry dope. It comprises such materials as 95 - 105 weight shares of Component A, and 1 - 3 weight shares of Component B; thereinto, Component A is made from following weight percents of materials: cementing agent 30-60%, pigment 12 - 30%, filling agent 10 - 30%, auxiliary agent 0.1 - 5%, compound nanometer dispersing agent 5 - 15% and solvent 10 - 25%; Component B is comprised of catalyzed membrane forming agent - nanometer Sb2O3 and mixed organic solvent carriers. The invention firstly brings nanometer Sb2O3 into high temperature heat preservation dope as catalyzer in dope membrane forming process. The dope of the invention has following advantages: it has high temperature heat preservation and heavy anticorrosion performances, and the coat has good acid resistance, alkali resistance, salt mist resistance, oil resistance, chemical reagent resistance, waiting resistance and ultraviolet resistance; it has excellent fire protection and waterproof performance; the clinging strength of smearing membrane is good, membrane forming speed is fast, and performance is stable.

Owner:孙启明

Inorganic binders employing waste glass

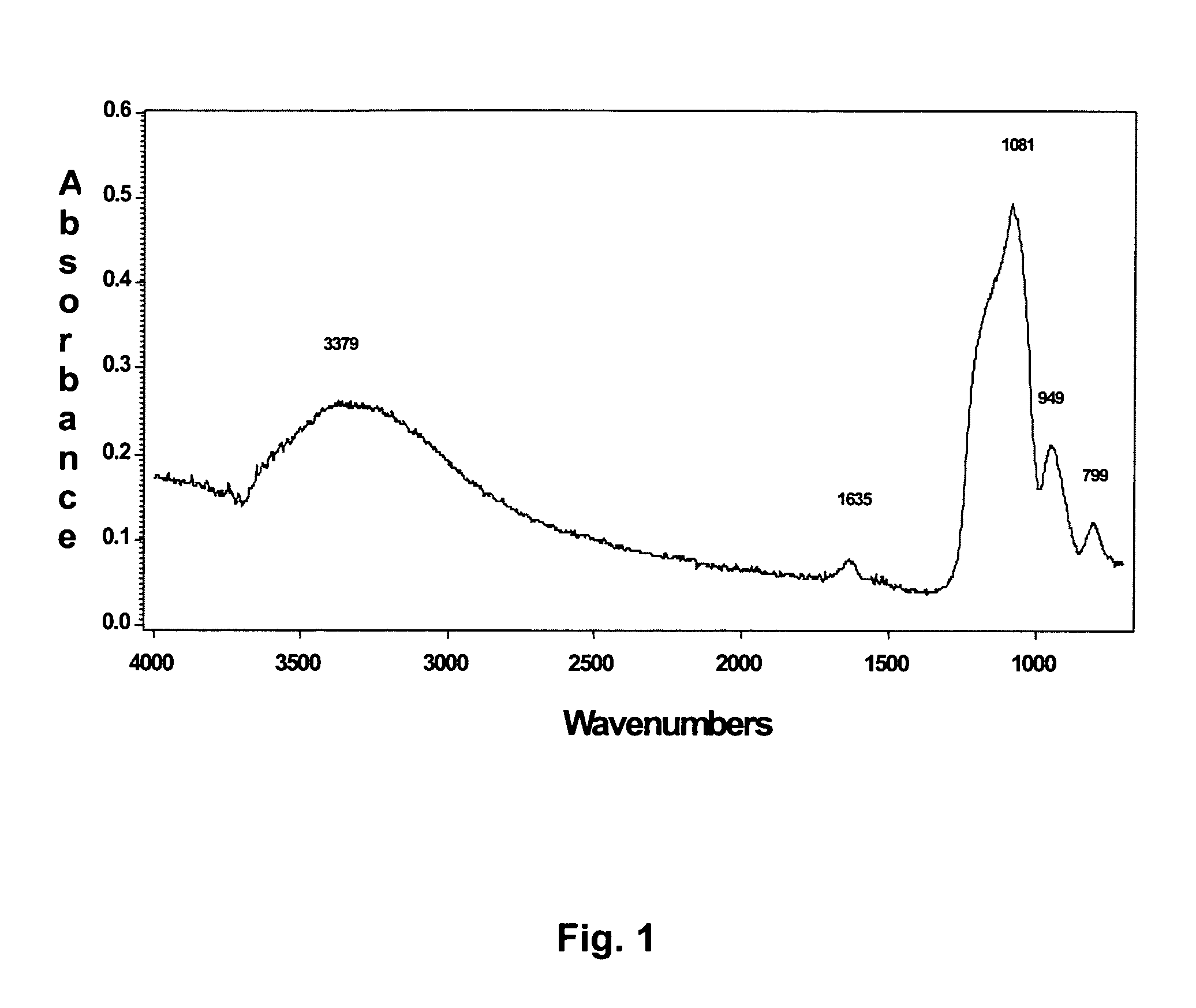

InactiveUS6296699B1Improve processingHighly moldableCovering/liningsAlkali metal silicate coatingsSodium silicateArtificial stone

The present invention relates to a binder composition comprising a glass powder with a particle size of at least less than 0.15 mm and an alkali activator containing at least one alkali metal and at least one silicate. Preferably, a sodium silicate with a SiO2:Na2O weight ratio between about 1.6:1 to about 2.0:1. Mixed with water, the binder composition can be cured at ambient temperature, but rapidly yields a very high strength at an elevated temperature between about 40° C. to about 120° C. Preferably, between about 70° C. to about 90° C. The invention further provides a method of making artificial stone using glass as a sole binder and aggregate.

Owner:JIN WEIHUA

Process aid for preparing a flowable slurry

A process for preparing a flowable slurry comprising mixing 25-70 wt. % water; an alkaline material selected from the group consisting of chlorosilicon manufacturing byproducts, direct process residue gels, cement kiln dust, and mixtures thereof; and a process aid selected from the group consisting of sucrose, raffinose, lignin, methylglucopyranoside, lactose, fructose, sodium polyphosphate, trehalose and mixtures thereof to form a flowable slurry. This slurry is especially useful in the manufacture of cement.

Owner:DOW CORNING CORP

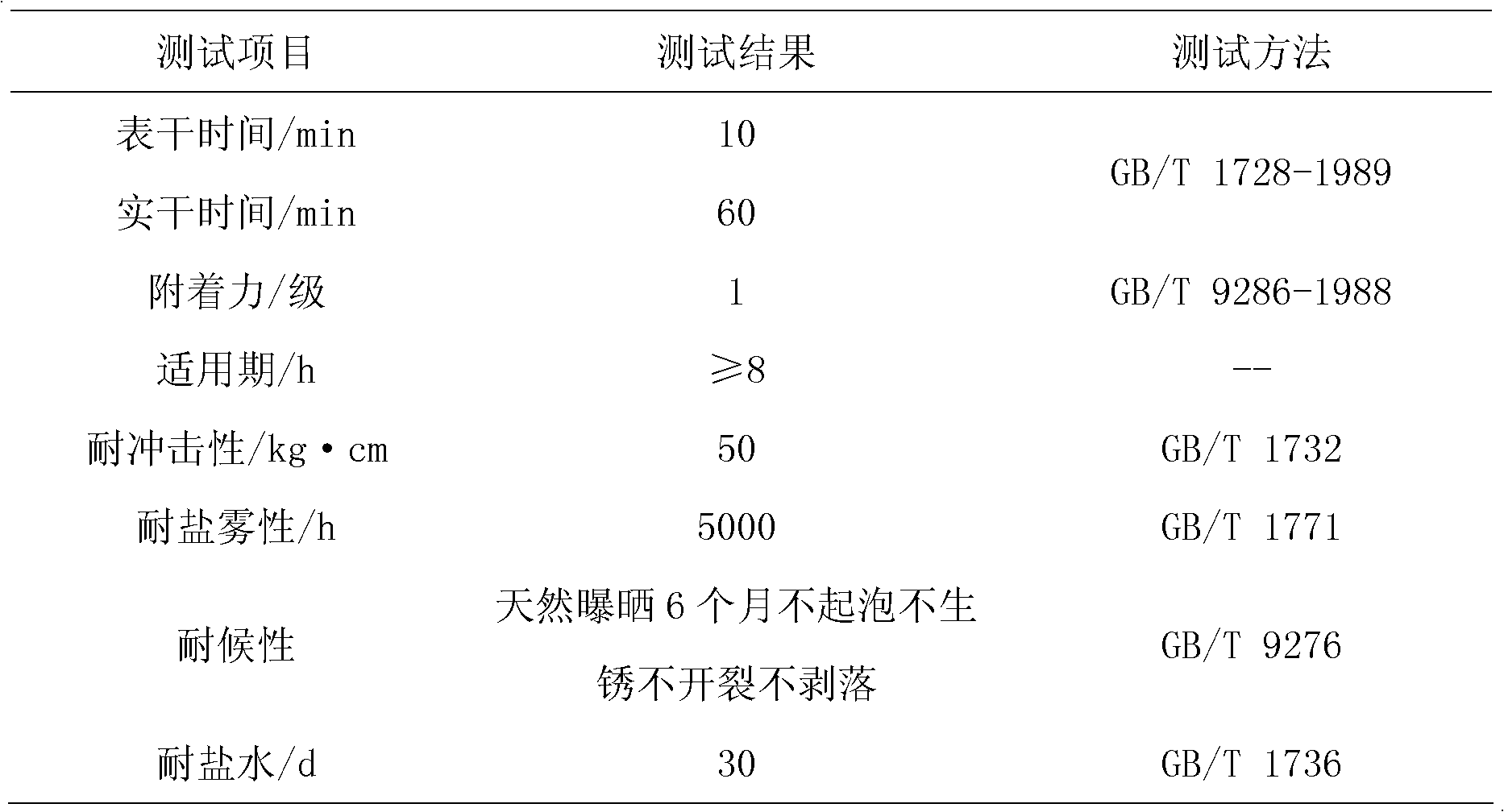

Waterborne room-temperature self-curing inorganic zinc rich coating

ActiveCN102146225AStrong adhesionHigh modulusAlkali metal silicate coatingsAnti-corrosive paintsEnvironmental resistanceMaterials science

The invention discloses waterborne room-temperature self-curing inorganic zinc rich coating. The coating is prepared by uniformly mixing a prepared base stock and powder in a mass ratio of 1:1.5-3.5, wherein the process of preparing the base stock comprises the following steps of: adding 5 to 10 parts of water into alkali metal silicates solution with the mode number of 2.5 to 3.7 and stirring the mixture at low speed; then adding silica sol drops with the grain diameter of 7 to 20nm and the solid content of 25 to 32 percent, dripping 1 to 10 parts of silane coupling agent and adding 0.5 to 2parts of stabilizing agent; and filtering out precipitates to obtain the transparent base stock. The inorganic zinc rich coating has high drying speed and good early-period waterproofness and can resist to washing with certain pressure after being dried for 20 minutes, has good salt spray corrosion resistance due to the adoption of multiple anticorrosion mechanisms and can resist to the high temperature of 400 DEG C. Meanwhile, the constructability of the conventional waterborne inorganic zinc rich coating is greatly improved; and the corrosion resistance year limit can reach over 15 years. The paint is prepared at normal temperature under normal pressure and has low production cost. The environmental protection requirement is met.

Owner:SOUTH CHINA UNIV OF TECH +1

Cement-based materials system for producing ferrous castings using a three-dimensional printer

ActiveUS20110177188A1Improve accuracyHigh strengthAdditive manufacturing apparatusAlkali metal silicate coatingsMaterials scienceMaterial system

Owner:MASSACHUSETTS INST OF TECH

Thermal protective coating for ceramic surfaces

ActiveUS6921431B2Extended shelf lifeConvenience to workFireproof paintsOther chemical processesColloidal silicaSodium Bentonite

A coating admixture, method of coating and substrates coated thereby, wherein the coating contains colloidal silica, colloidal alumina, or combinations thereof; a filler such as silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides, copper chromium oxides, cerium oxides, terbium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide is also added.

Owner:WESSEX

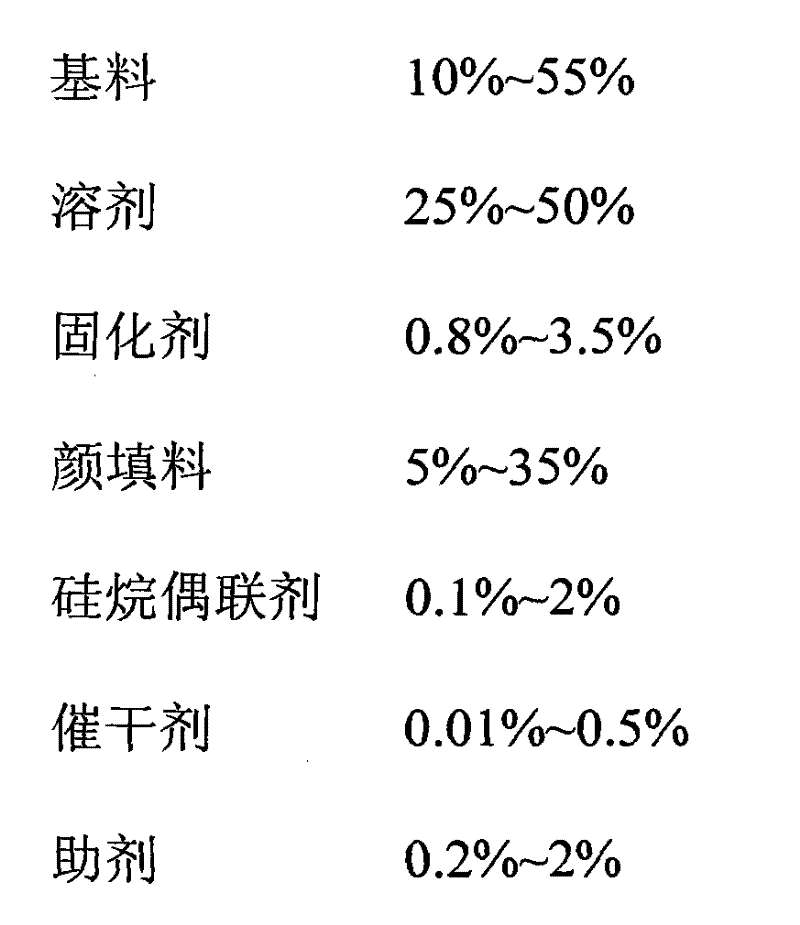

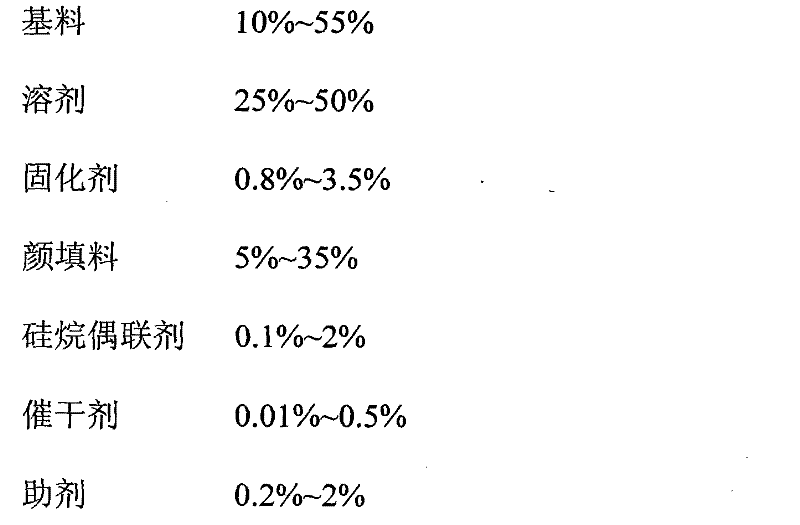

anti-corrosion coating

InactiveCN102260450AStrong adhesionEasy constructionAlkali metal silicate coatingsAnti-corrosive paintsMetal coatingSolvent

The invention belongs to the field of metal coatings, and in particular relates to a coating that can be used at high temperatures and is corrosion-resistant; the technical problem to be solved by the invention is to provide a coating that still has strong mechanical strength, strong adhesion, Corroded paint; in order to solve the above problems, the technical solution provided by the present invention is: a high-temperature anti-corrosion paint, including base material, solvent, curing agent, pigment and filler, silane coupling agent, drier, auxiliary agent; the present invention The beneficial effect is that: it has good adhesion, impact resistance and mechanical strength, the thickness of the coating film is 50 μm, the coating can withstand the temperature of 600 ° C, and has good corrosion resistance.

Owner:SNTO TECH GRP

Photocatalytic composition and method for preventing algae growth on building materials

InactiveUS6881701B2Reduce light transmittanceLow UV transmittanceRoof covering using sealantsAlkali metal silicate coatingsBuilding materialMaterials science

The present invention provides a coating composition for substrates. The coating composition of the present invention generally includes a silicate binder and a plurality of photocatalytic particles. The silicate binder functions as a bonding agent to establish the coating on the substrate. A plurality of photocatalyst particles are dispersed throughout the silicate binder. The particles are included in an amount that provides sufficient distribution of the particles in the resulting coating. The incorporation of the present invention onto substrates prevents algal growth on building materials utilizing the coated substrates.

Owner:3M INNOVATIVE PROPERTIES CO

Thermal protective coating for ceramic surfaces

ActiveUS20050051057A1Extend working lifeReduce surface temperatureFireproof paintsOther chemical processesColloidal silicaSodium Bentonite

A coating admixture, method of coating and substrates coated thereby, wherein the coating contains colloidal silica, colloidal alumina, or combinations thereof; a filler such as silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides, copper chromium oxides, cerium oxides, terbium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide is also added.

Owner:WESSEX

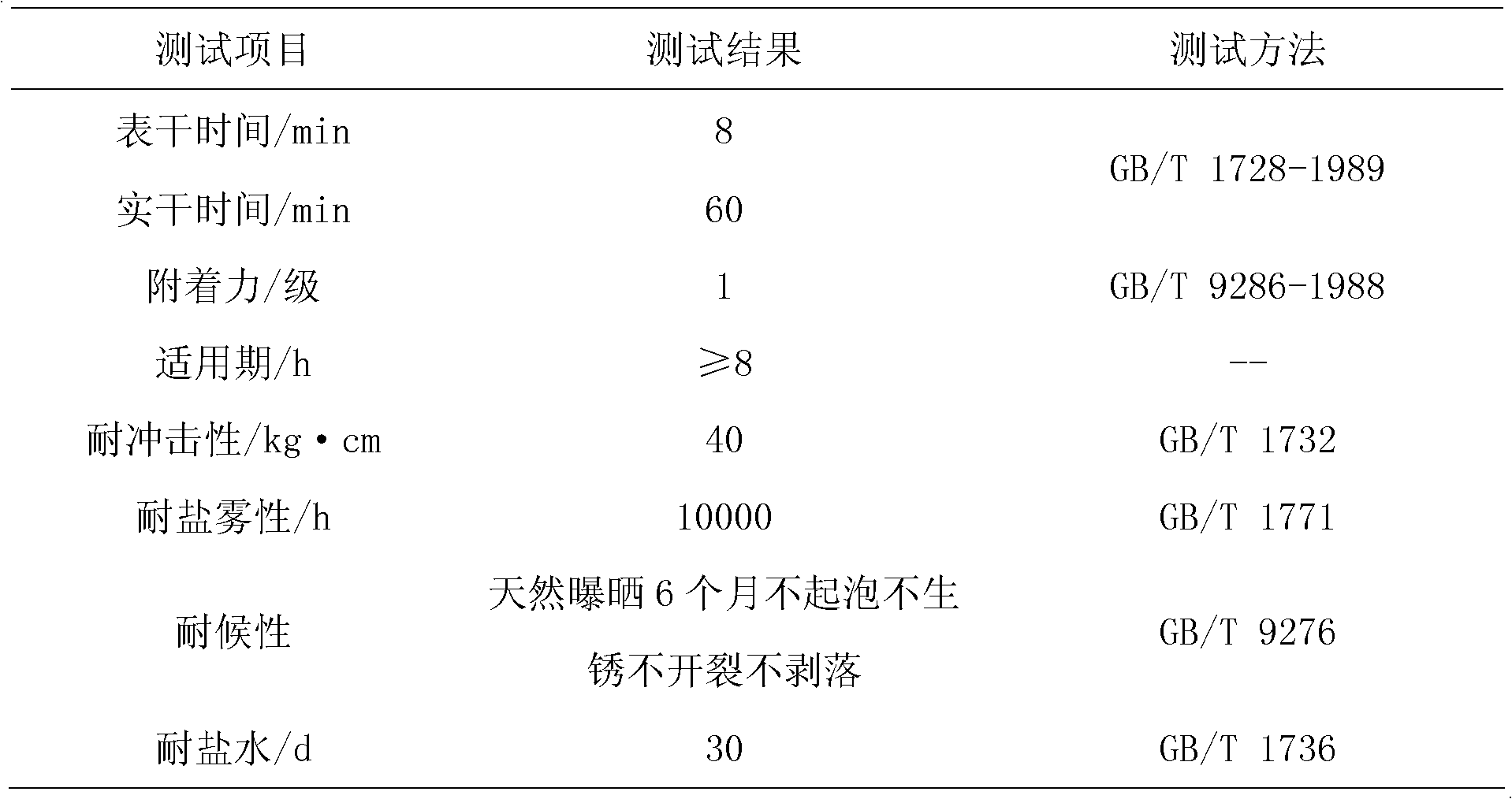

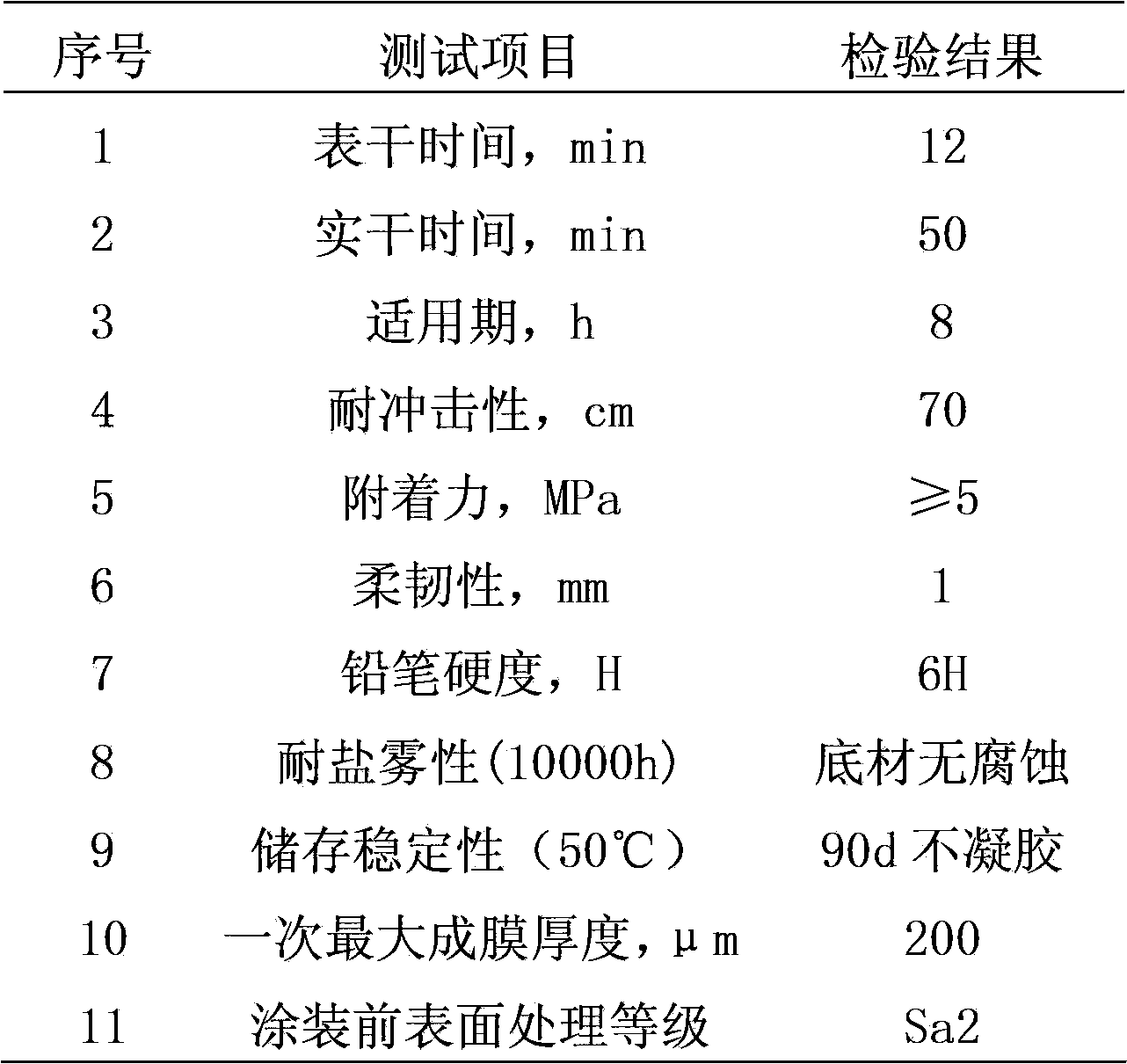

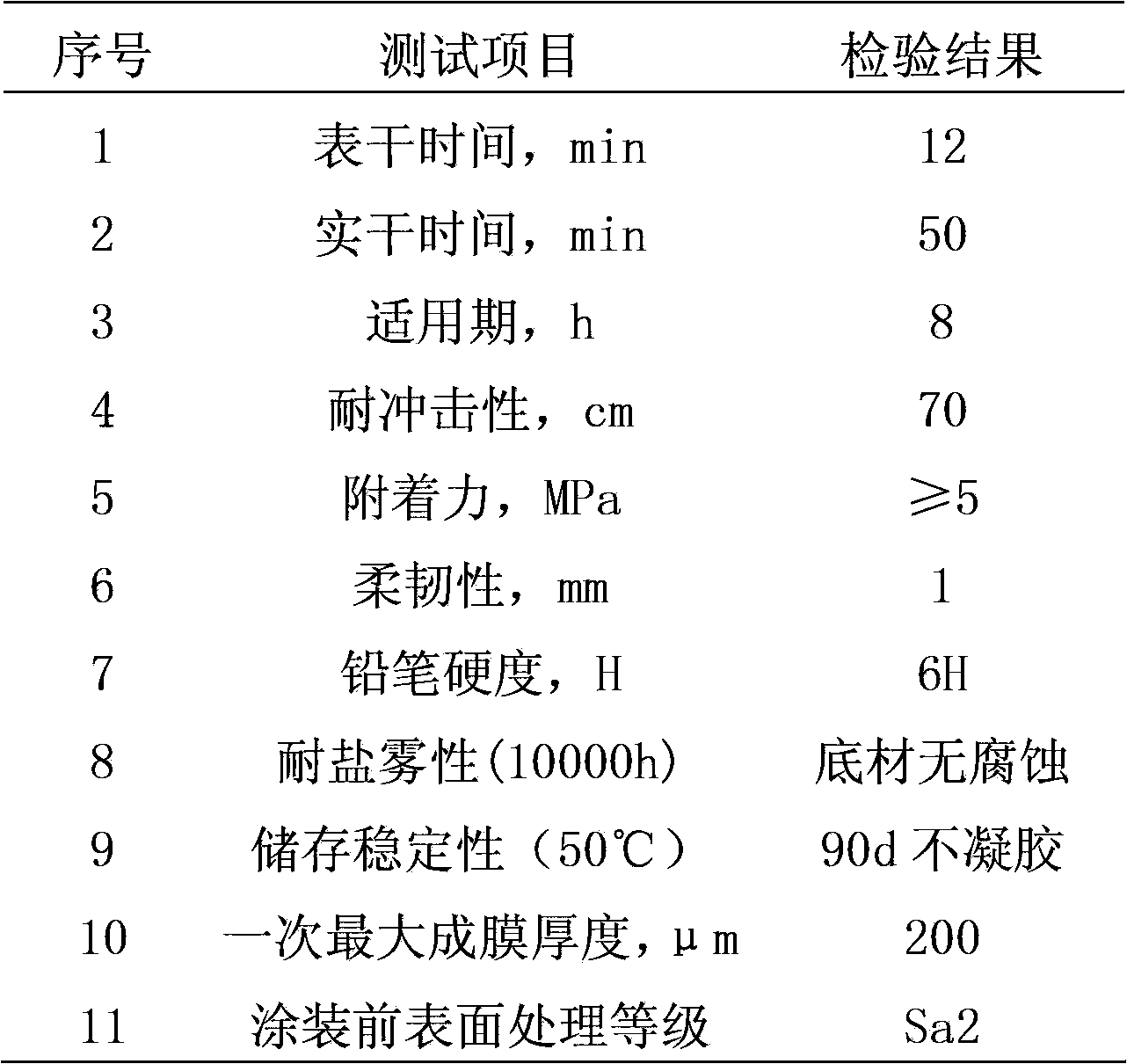

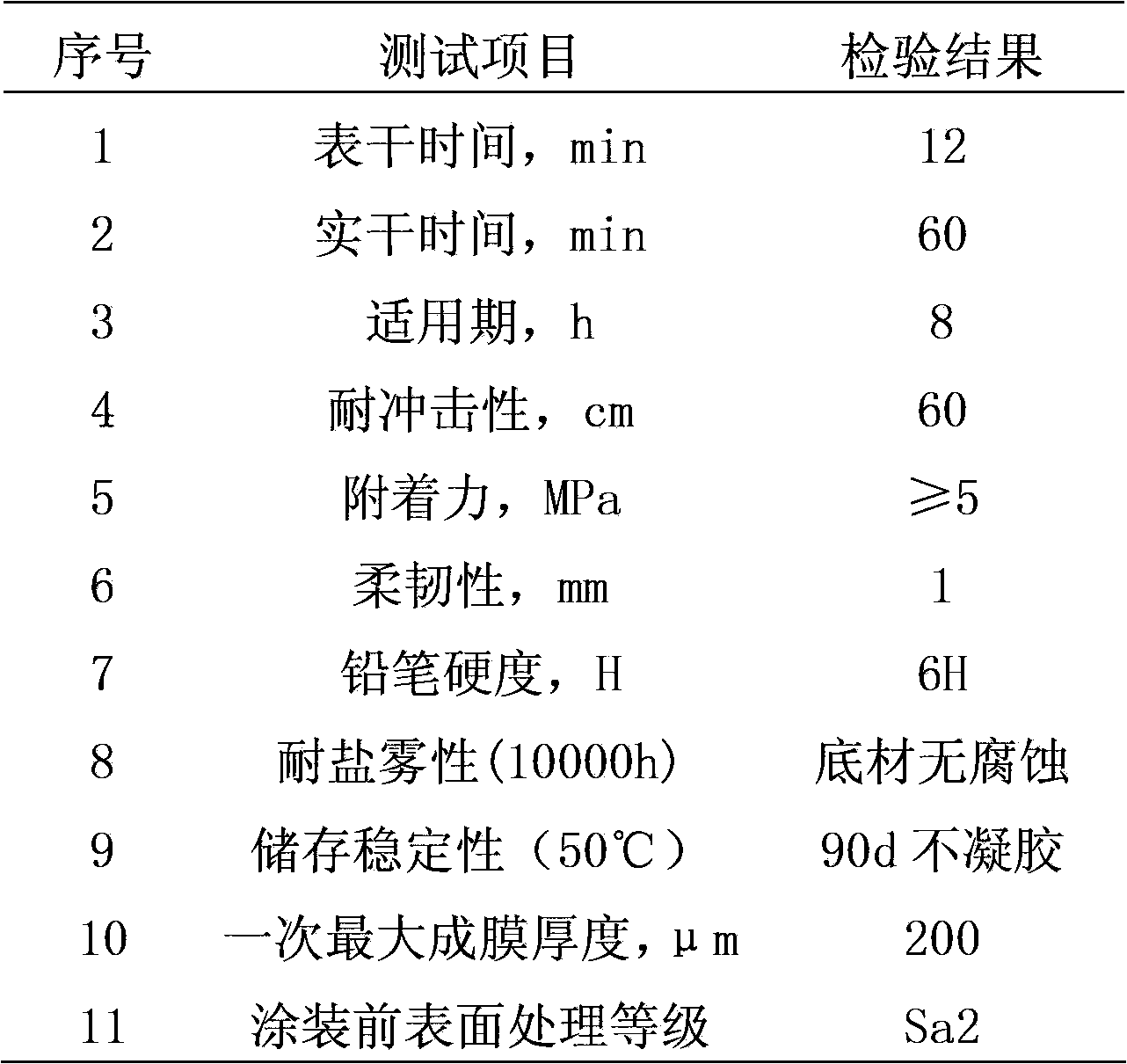

Water-soluble inorganic zinc-rich paint and preparation method thereof

ActiveCN103788734AUniform particle size distributionUniform reaction rateAlkali metal silicate coatingsStress concentrationPowder mixture

The invention provides a water-soluble inorganic zinc-rich paint and a preparation method thereof. The preparation method comprises the following steps: dropwise adding aluminum-modified silica sol into potassium silicate solution with low modulus, so as to obtain a high-modulus potassium silicate solution as a binder; and adding a catalyst, a siloxane oligomer and a modifier to ensure that the high-modulus potassium silicate solution are uniform in size distribution, and does not have gelatinization reaction for a long time, wherein after the high-modulus potassium silicate solution and a zinc powder mixture are stirred uniformly, the zinc-rich paint has the advantages that reaction rates of all parts of a coating are uniform, and no stress concentration phenomenon exist. Proved by experiments, the zinc-rich paint provided by the invention has no gel after being stored for 90 days at 50 DEG C, the thickness of a film formed once can reach 200 mu m, no cracking or bubbling phenomenon exists, construction can be carried out after the treatment level of the steel surface reaches Sa2, and the salt fog resistance of the coating can reach 10000 hours.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

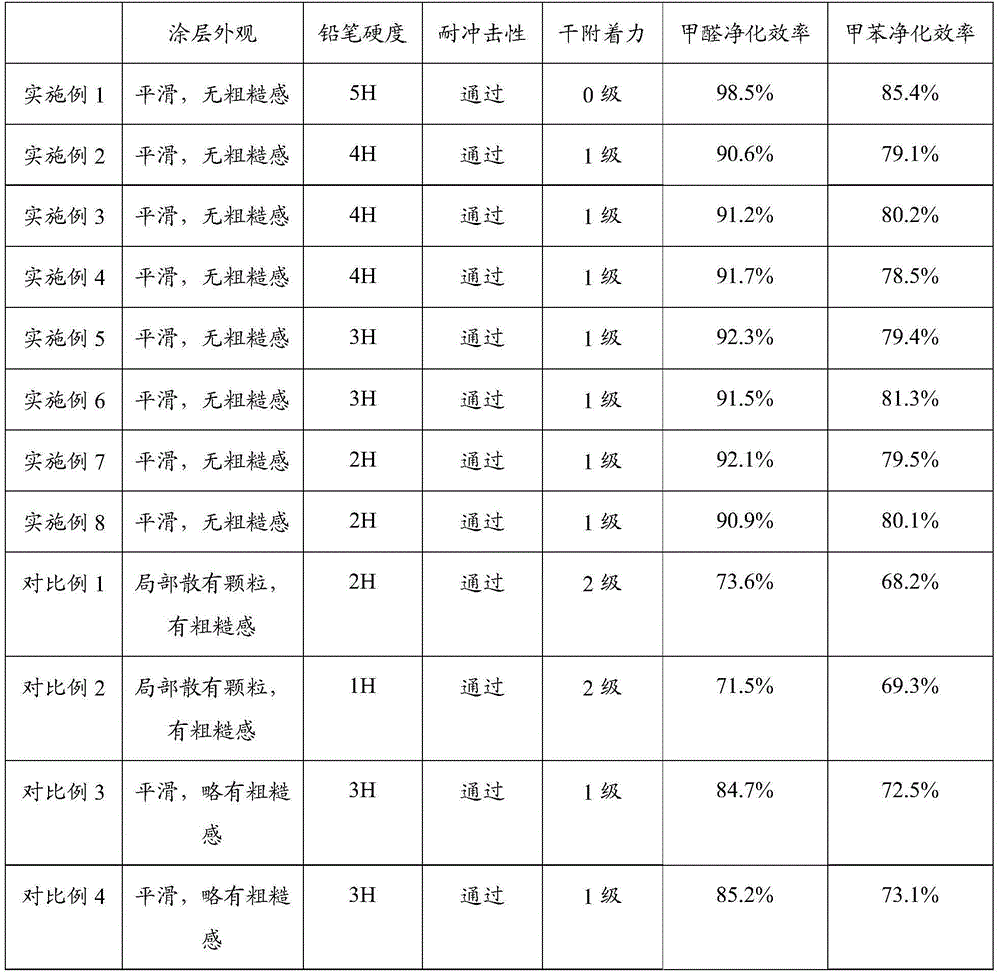

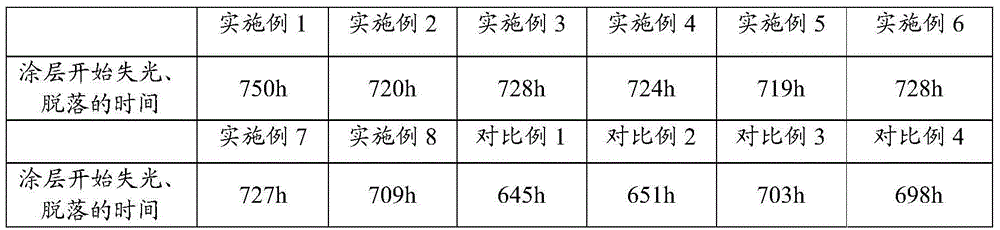

Multifunctional inorganic diatom ooze coating and preparation method thereof

InactiveCN104387816AStir wellNot easy to reuniteAntifouling/underwater paintsAlkali metal silicate coatingsCelluloseEmulsion

The invention relates to a multifunctional inorganic diatom ooze coating, which is prepared from the following components in percentage by mass: 10%-25% of water, 0.4%-0.8% of cellulose, 10-30% of a mixture of potassium metasilicate and silica sol, 0.2%-0.4% of a stabilizer, 0.1%-0.3% of a dispersing agent, 0.1%-0.3% of a silicon additive, 0.3%-0.5% of a defoaming agent, 0.1%-0.3% of an antibacterial agent, 0-20% of titanium dioxide, 5%-15% of nanometer kieselguhr, 10%-30% of coarse whiting, 2%-4% of talcum powder, 1%-3% of medical stone, 0-1.5% of anion, 0-2% of a nano-photocatalyst, 1%-2% of inorganic gel powder, 0-9% of an order-removing emulsion and 0-1.5% of pigment, wherein the sum of the components is 100%. The invention also provides a preparation method of the coating. The coating disclosed by the invention has the functions of sterilizing, preventing mold, purifying air and the like; and the preparation method disclosed by the invention is simple and easy to operate.

Owner:佛山市南海万磊建筑涂料有限公司

Thermal protective coating

ActiveUS7105047B2Extended shelf lifeReduce weightAlkali metal silicate coatingsPretreated surfacesCalcium silicateSodium Bentonite

A coating, method of coating and substrates coated thereby, wherein the coating contains an inorganic adhesive such as an alkali / alkaline earth metal silicate such as sodium silicate, potassium silicate, calcium silicate, and magnesium silicate; a filler such as a metal oxide for example silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides and copper chromium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide may be added.

Owner:WESSEX

Geopolymer composition and application for carbon dioxide storage

InactiveUS20080028995A1Enhanced pumpabilityImprove stabilityLiquid surface applicatorsSolid waste managementCo2 storageGeopolymer

The invention provides geopolymeric compositions intended for use in carbon dioxide injection or production wells or storage reservoirs and preferably in a supercritical carbon dioxide conditions. The geopolymeric composition is formed from a suspension comprising an aluminosilicate source, a metal silicate, an alkali activator, a retarder and / or an accelerator and a carrier fluid wherein the oxide molar ratio M2O / SiO2 is greater than 0.20 with M an alkali metal.

Owner:SCHLUMBERGER TECH CORP

Aerogel Particles and Methods Of Making Same

Aerogel particles having a mean particle size less than 1 micron, products containing the same, processes of making the same, and uses thereof are described. A process of making the particle is also described wherein starting aerogel particles are homogenized or wet milled. The starting aerogel particles can be surface treated during the milling process to prevent agglomeration or aggregation. The aerogel particles can be used in a variety of products and applications.

Owner:CABOT CORP

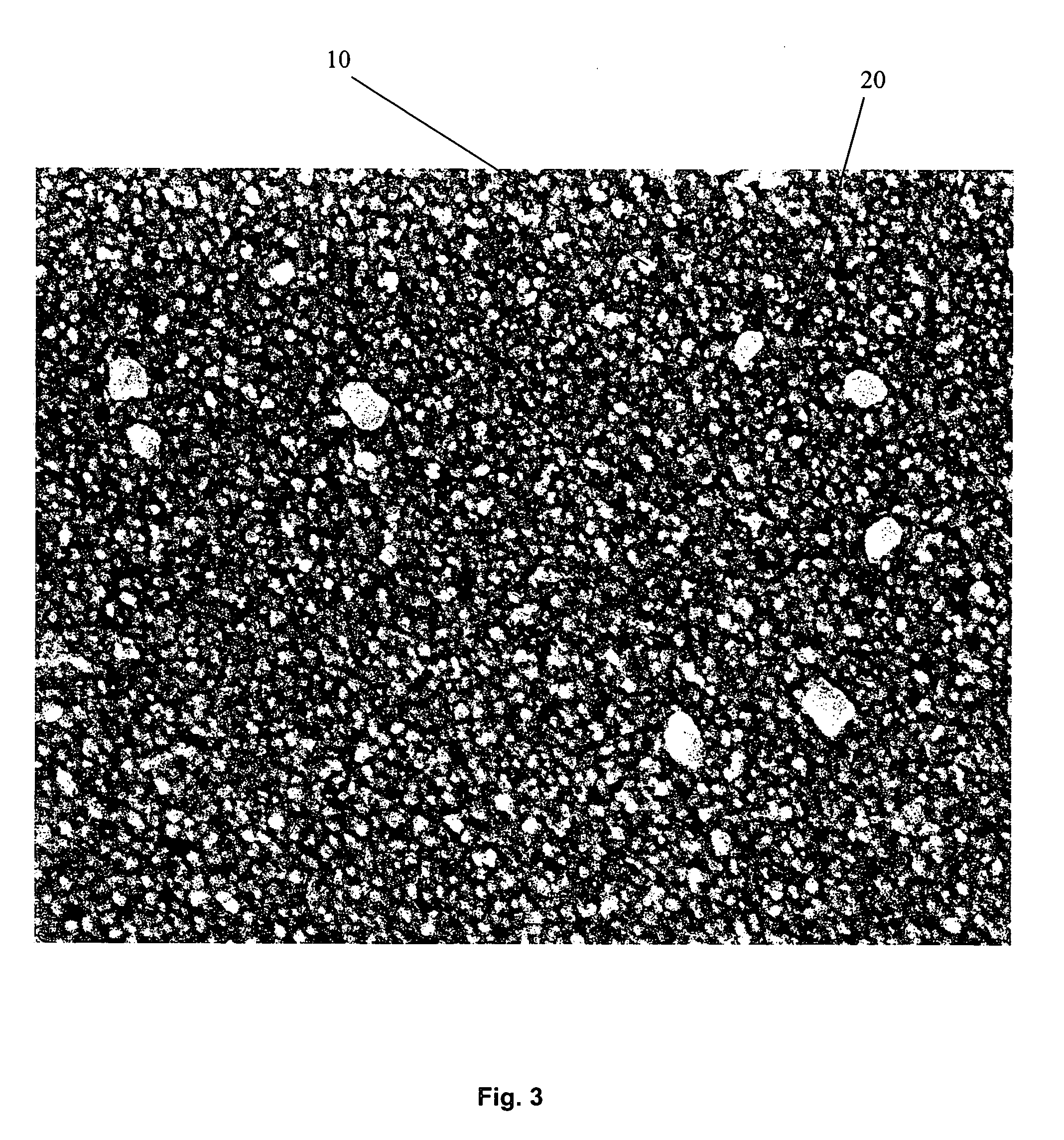

Inorganic matrix composition and composites incorporating the matrix composition

InactiveUS6969422B2Good physical and mechanical propertiesIncrease loadAlkali metal silicate coatingsCement productionSlurryOragene

A modified alkali silicate composition for forming an inorganic network matrix. The modified alkali silicate matrix is made by reacting an alkali silicate (or its precursors such as an alkali hydroxide, a SiO2 source and water), an acidic inorganic composition, such as a reactive glass, water and optional fillers, additives and processing aids. An inorganic matrix composite can be prepared by applying a slurry of the modified aqueous alkali silicate composition to a reinforcing medium and applying the temperature and pressure necessary to consolidate the desired form. The composite can be shaped by compression molding as well as other known fabrication methods. A notable aspect of the invention is that, although composite and neat resin components prepared from the invention can exhibit excellent dimensional stability to 1000° C. and higher, they can be prepared at the lower temperatures and pressures typical to organic polymer processing.

Owner:THE BF GOODRICH CO

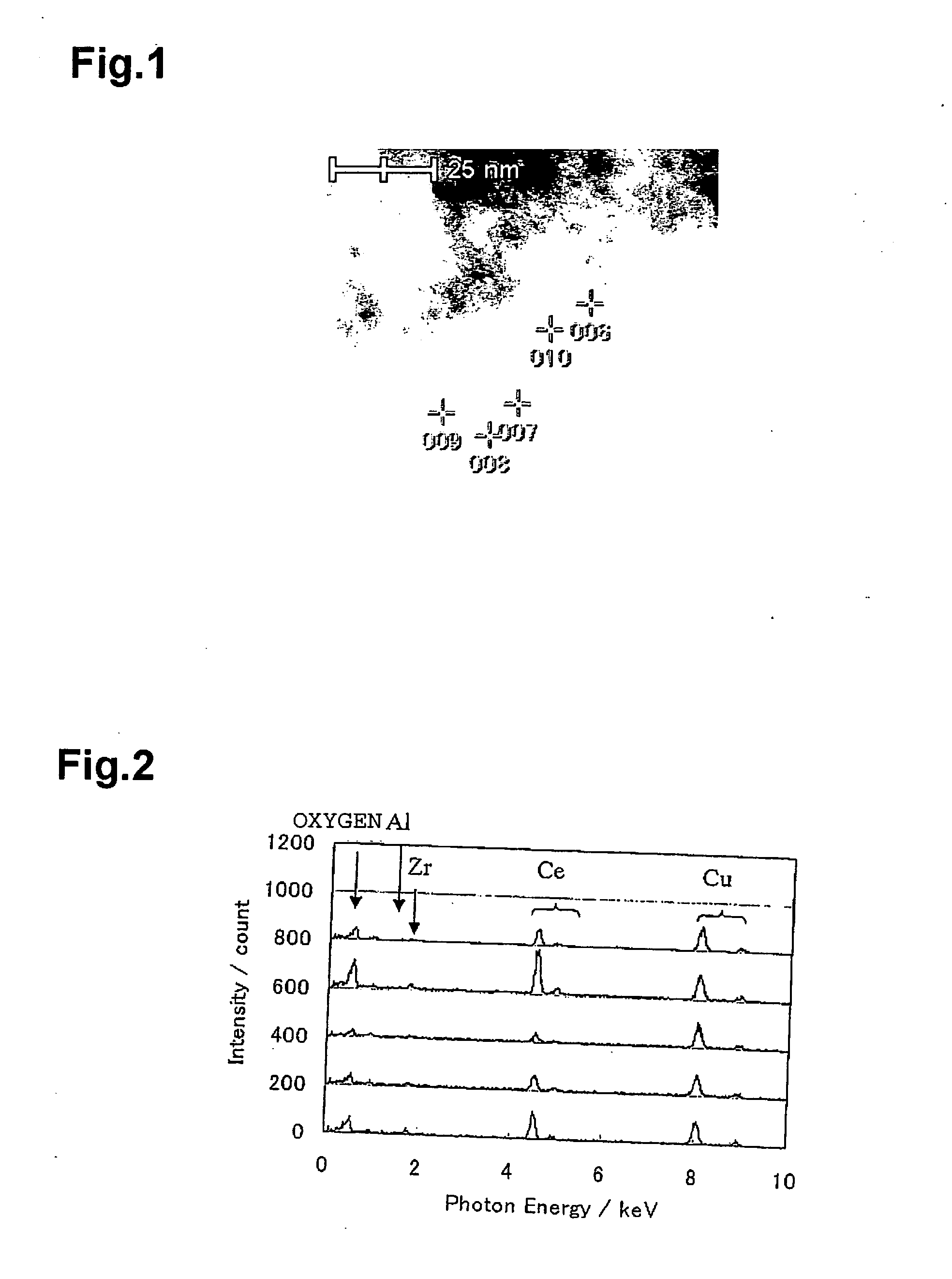

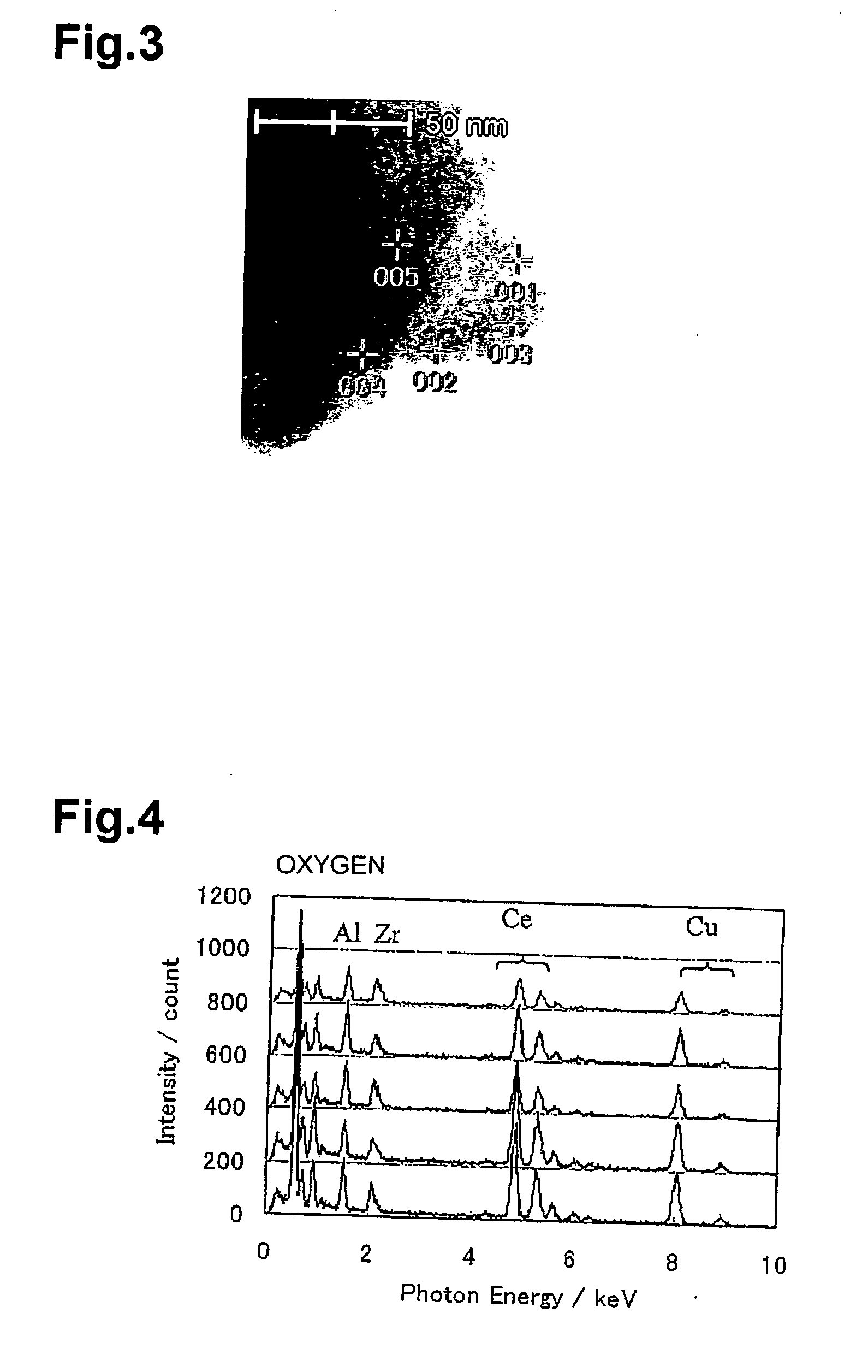

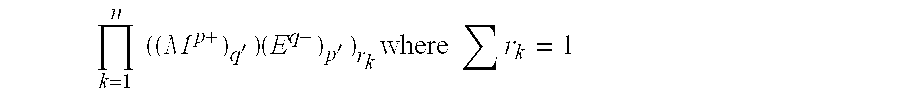

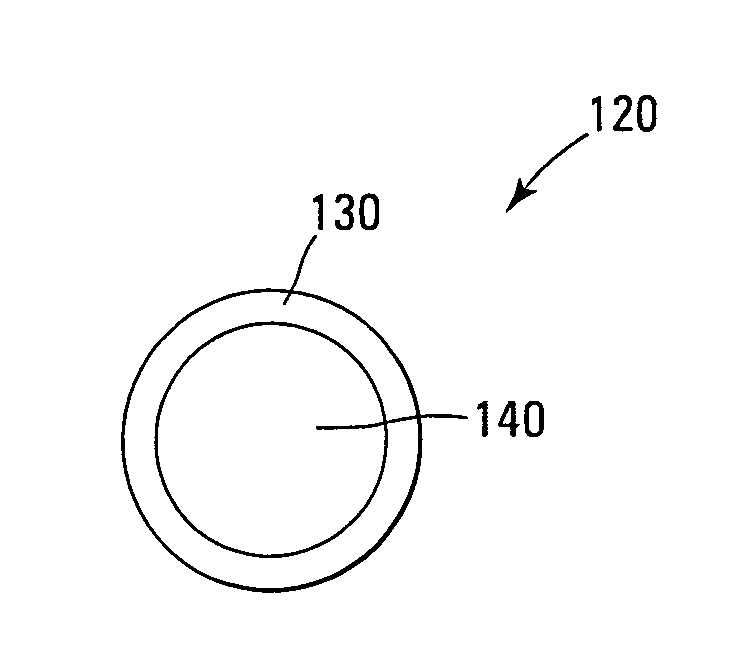

Metal Oxide Nanoporous Material, Coating Composition to Obtain the Same, and Methods of Manufacturing Them

ActiveUS20070215009A1Improve adhesionImprove heat resistanceInternal combustion piston enginesAlkali metal silicate coatingsAlkali metal oxideRare earth

A metal oxide nanoporous material comprises two or more kinds of first metal oxides selected from the group consisting of alumina, zirconia, titania, iron oxide, rare-earth oxides, alkali metal oxides and alkaline-earth metal oxides. The metal oxide nanoporous material has nanopores, each with a diameter of 10 nm or smaller, in which the metal oxides are dispersed homogeneously in the wall forming the nanopores.

Owner:TOYOTA CENT RES & DEV LAB INC

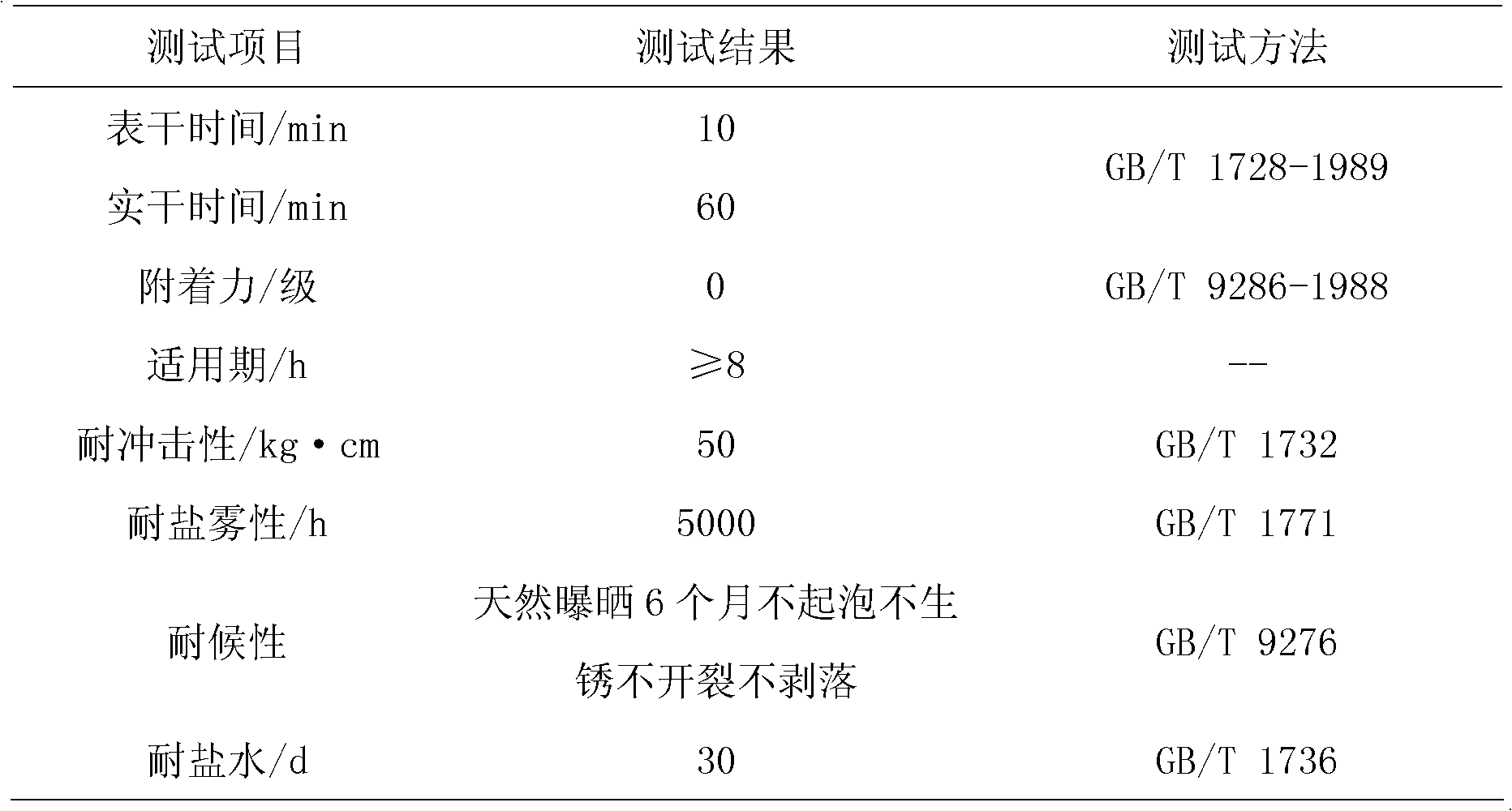

Aqueous inorganic zinc-enriched coating and preparation method thereof

InactiveCN101735674AHigh bonding strengthImprove early water resistanceAlkali metal silicate coatingsAnti-corrosive paintsCorrosionChemistry

The invention relates to an aqueous inorganic zinc-enriched coating and a preparation method thereof. The coating is prepared by mixing a component A and a component B in a weight ratio of 1: 1.5-3.5. The preparation method for the component A comprises the following steps of: mixing 45 to 70 weight parts of alkaline metal silicate solution, 0 to 8 weight parts of water-soluble resin, 0.1 to 15 weight parts of modifying agent with stirring at an intermediate speed; and then adding 10 to 35 weight parts of deionization water, 2 to 18 weight parts of inorganic filling, 1 to 10 weight parts of crystal whisker reinforced material, 0.5 to 3.5 weight parts of aqueous auxiliary agent which comprises a dispersant, a thickening agent and a foam suppressor, and mixing the mixture to obtain the component A. The component B is prepared by the following steps of: mixing 95 to 98 weight parts of spherical zinc powder and 2 to 5 weight parts of curing agent. The coating prepared by the method has good early waterproof resistance, good flexibility, good impact resistance, strong construction adaptability and good salt mist corrosion resistance.

Owner:REAR SERVICE TECH EQUIP INST NAVY PLA

Inorganic matrix compositions and composites incorporating the matrix composition

InactiveUS20050022698A1Maintain good propertiesExcellent thermalAlkali metal silicate coatingsCement productionCompression moldingInorganic composition

A modified alkali silicate composition for forming an inorganic network matrix. The modified alkali silicate matrix is made by reacting an alkali silicate (or its precursors such as an alkali hydroxide, a SiO2 source and water), an acidic inorganic composition, such as a reactive glass, water and optional fillers, additives and processing aids. An inorganic matrix composite can be prepared by applying a slurry of the modified aqueous alkali silicate composition to a reinforcing medium and applying the temperature and pressure necessary to consolidate the desired form. The composite can be shaped by compression molding as well as other known fabrication methods. A notable aspect of the invention is that, although composite and neat resin components prepared from the invention can exhibit excellent dimensional stability to 1000° C. and higher, they can be prepared at the lower temperatures and pressures typical to organic polymer processing.

Owner:THE BF GOODRICH CO

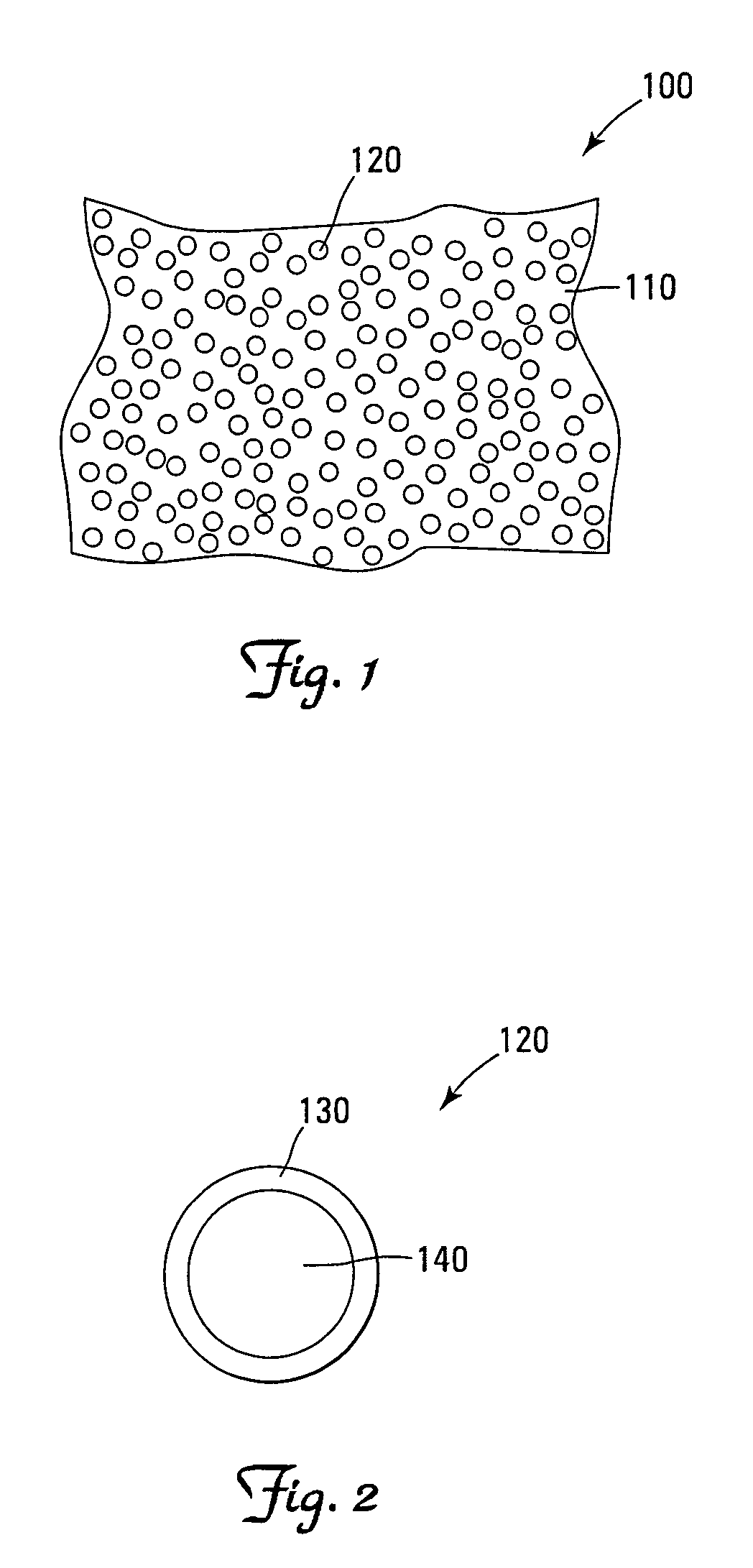

Coatings and methods for corrosion detection and/or reduction

Coatings and methods are provided. An embodiment of the coating includes microcapsules that contain at least one of a corrosion inhibitor, a film-forming compound, and an indicator. The microcapsules are dispersed in a coating vehicle. A shell of each microcapsule breaks down in the presence of an alkaline condition, resulting from corrosion.

Owner:NASA

Multi-layer coatings with an inorganic oxide network containing layer and methods for their application

InactiveUS7354650B2Good antifoulingImprove self-cleaningAlkali metal silicate coatingsPretreated surfacesAnti-fogInorganic oxide

Multi-layer coatings are disclosed that include (1) a first layer comprising an inorganic oxide network, and (2) a second layer applied over at least a portion of the first layer, wherein the second layer is deposited from at least one liquid composition that is hydrophilic and includes an essentially completely hydrolyzed organosilicate. Also disclosed are substrates coated with such multi-layer coatings, methods of applying such multi-layer coatings to a substrate and methods for improving the anti-fouling, self-cleaning, easy-to-clean, and / or anti-fogging properties of an article.

Owner:PPG IND OHIO INC

Protective coating comprising boron nitride for refractory material members of an ingot mold for continuous casting of metals

InactiveUS6051058AImprove protectionLow wettabilityMelt-holding vesselsAlkali metal silicate coatingsIngot castingCarbon nitride

The invention relates to a protective coating for a refractory material member of an ingot mold for continuous casting of metals, especially of steel, which consists of a dispersion of particles in a solvent, said particles including essentially boron nitride and at least one of the following metal oxides: zircon, zirconia, alumina and silica, the boron nitride representing between 20 and 50% by weight of said particles.

Owner:USINOR SA +1

Thermal barrier coating compositions, processes for applying same and articles coated with same

ActiveUS20080113218A1Liquid surface applicatorsAlkali metal silicate coatingsChemical compoundCrystal structure

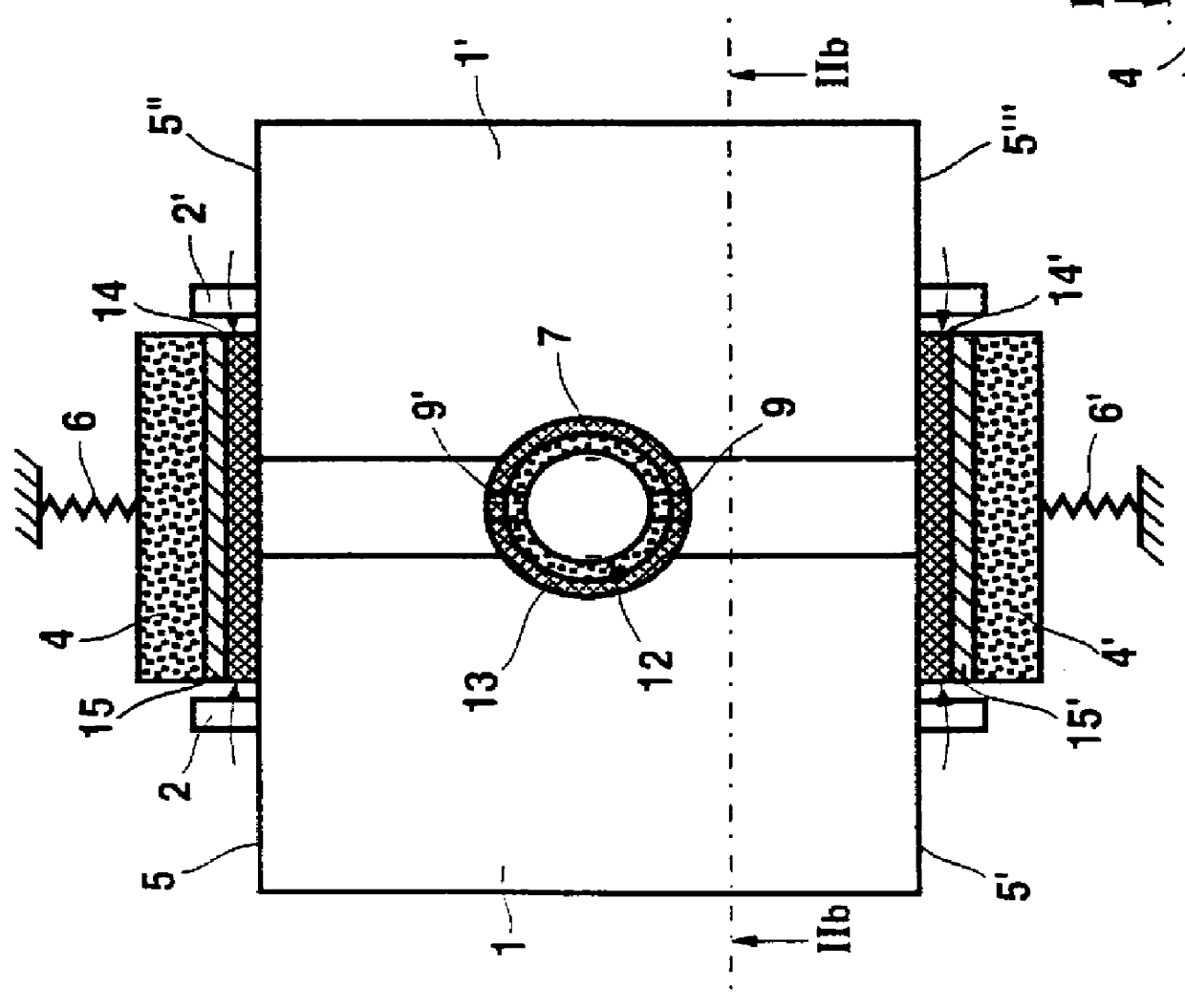

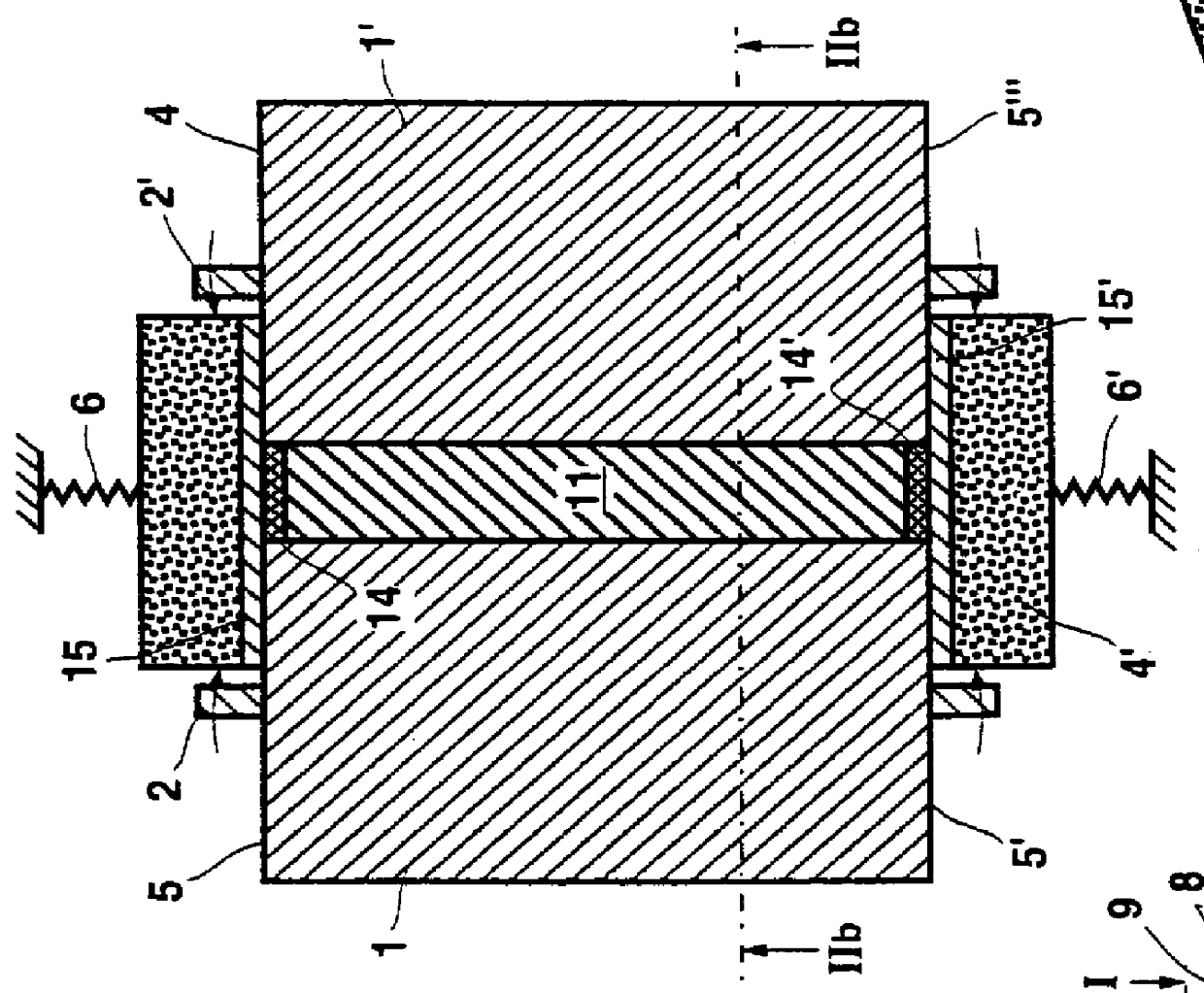

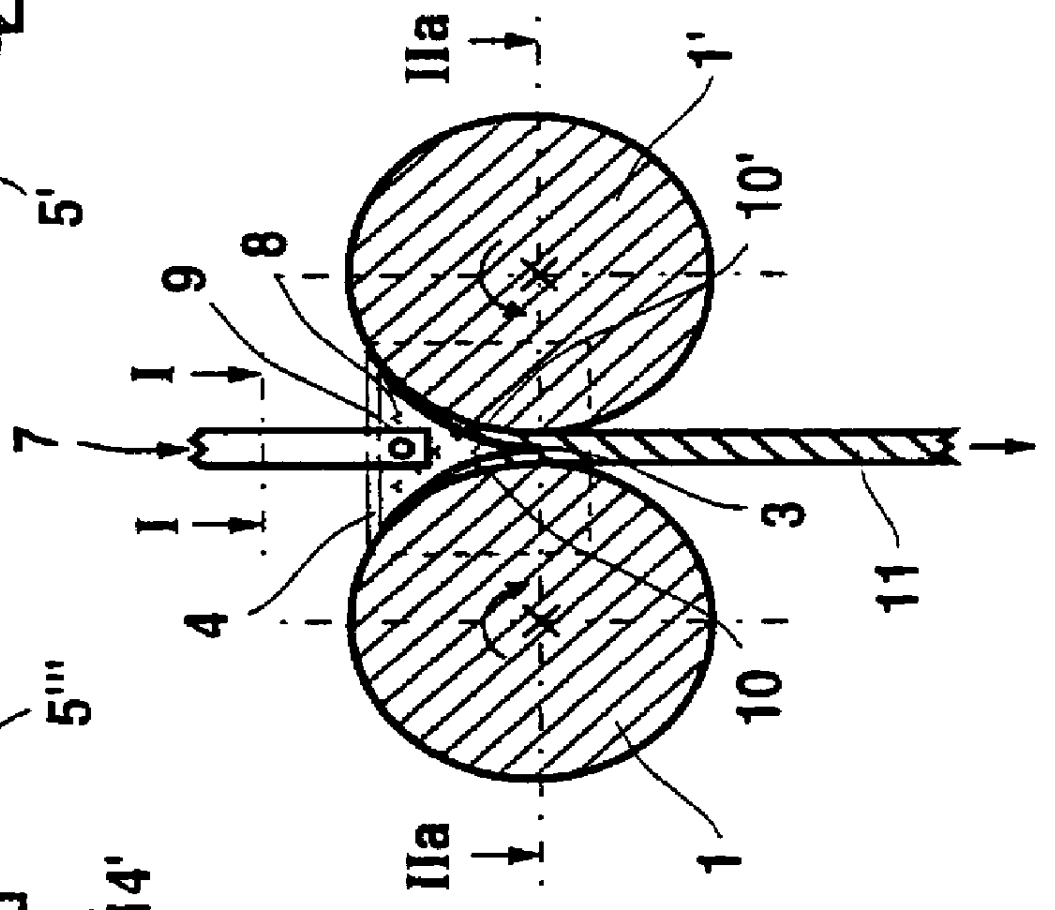

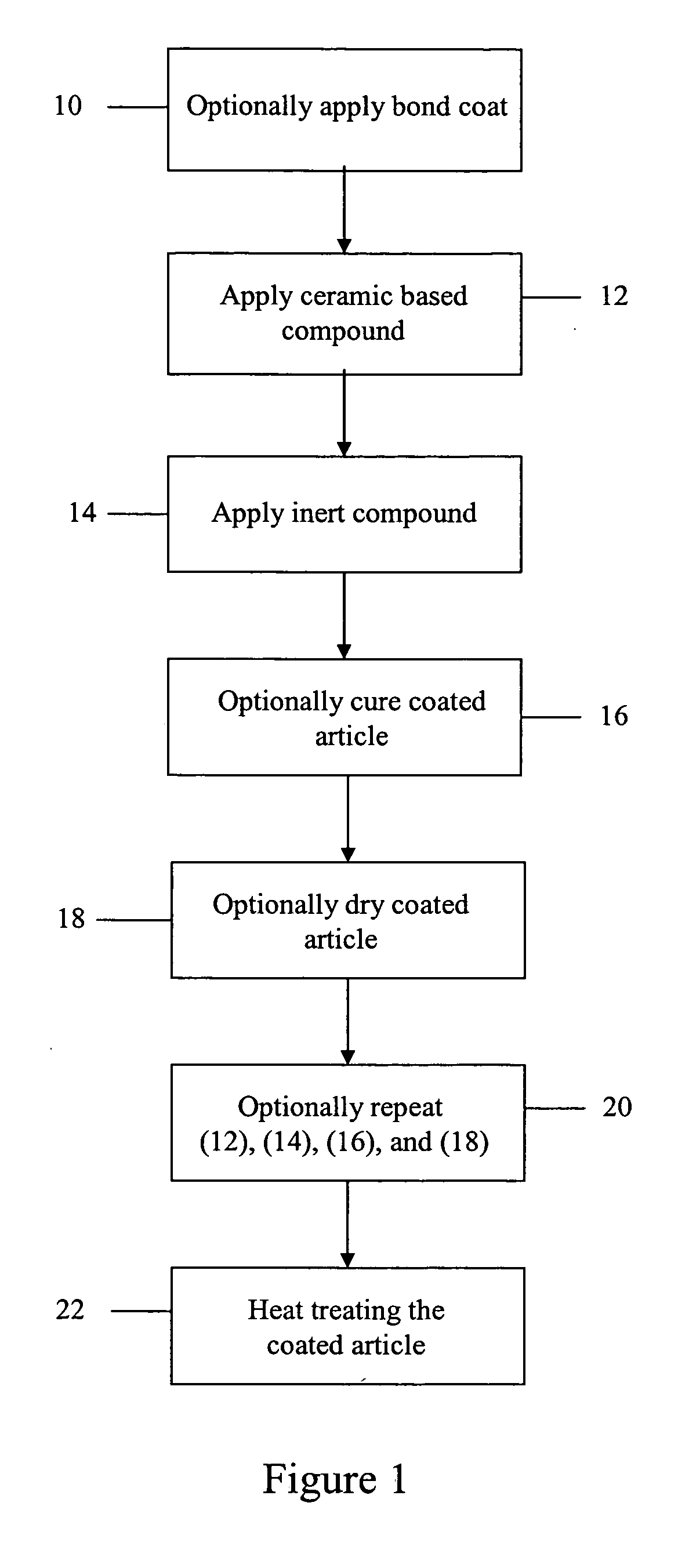

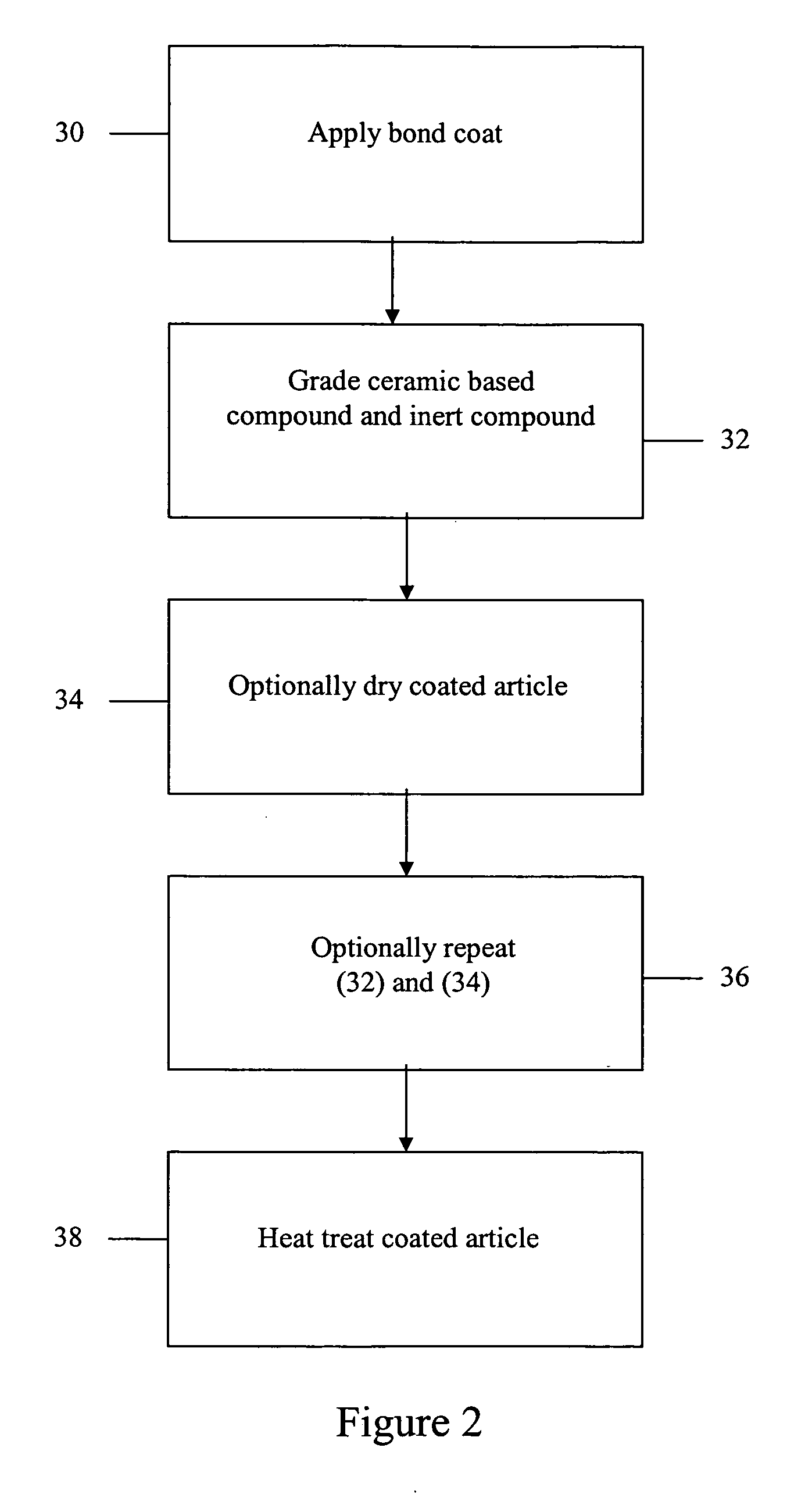

A process of coating an article includes the steps of (1) applying a ceramic based compound to at least one surface of an article to form a layer of ceramic based compound; (2) applying at least one inert compound upon the ceramic based compound layer to form a protective layer, wherein the at least one inert compound is composed of a first inert compound having a cubic crystalline structure of formula (I) A3B2X3O12, or a second inert compound comprising a hexagonal crystalline structure of formula (II) A4B6X6O26, or a mixture of the first inert compound and the second inert compound; (3) optionally drying the coated article; (4) optionally repeating steps (2) and (3); and (5) heat treating the coated article.

Owner:RTX CORP

Film made from denatured clay

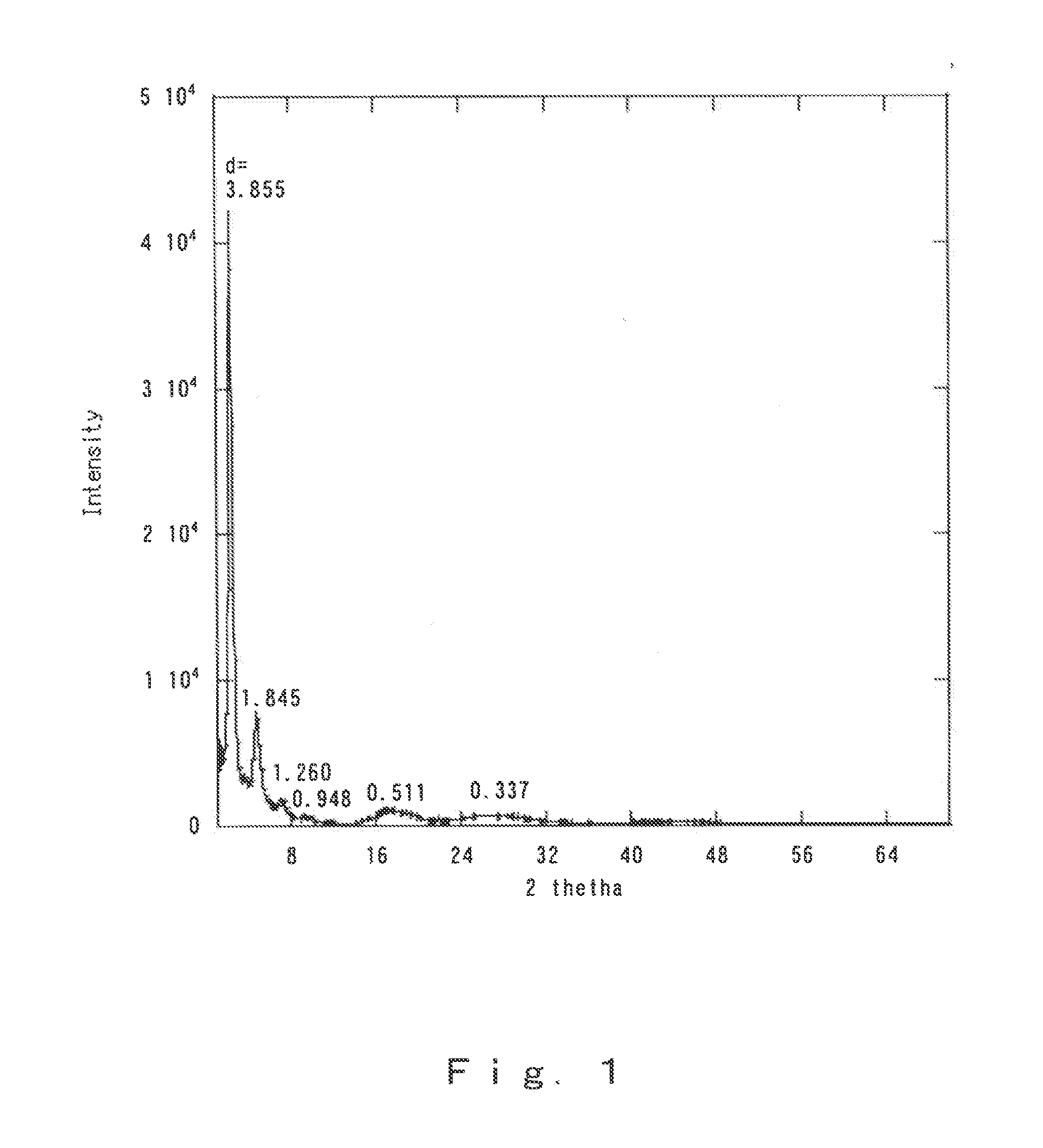

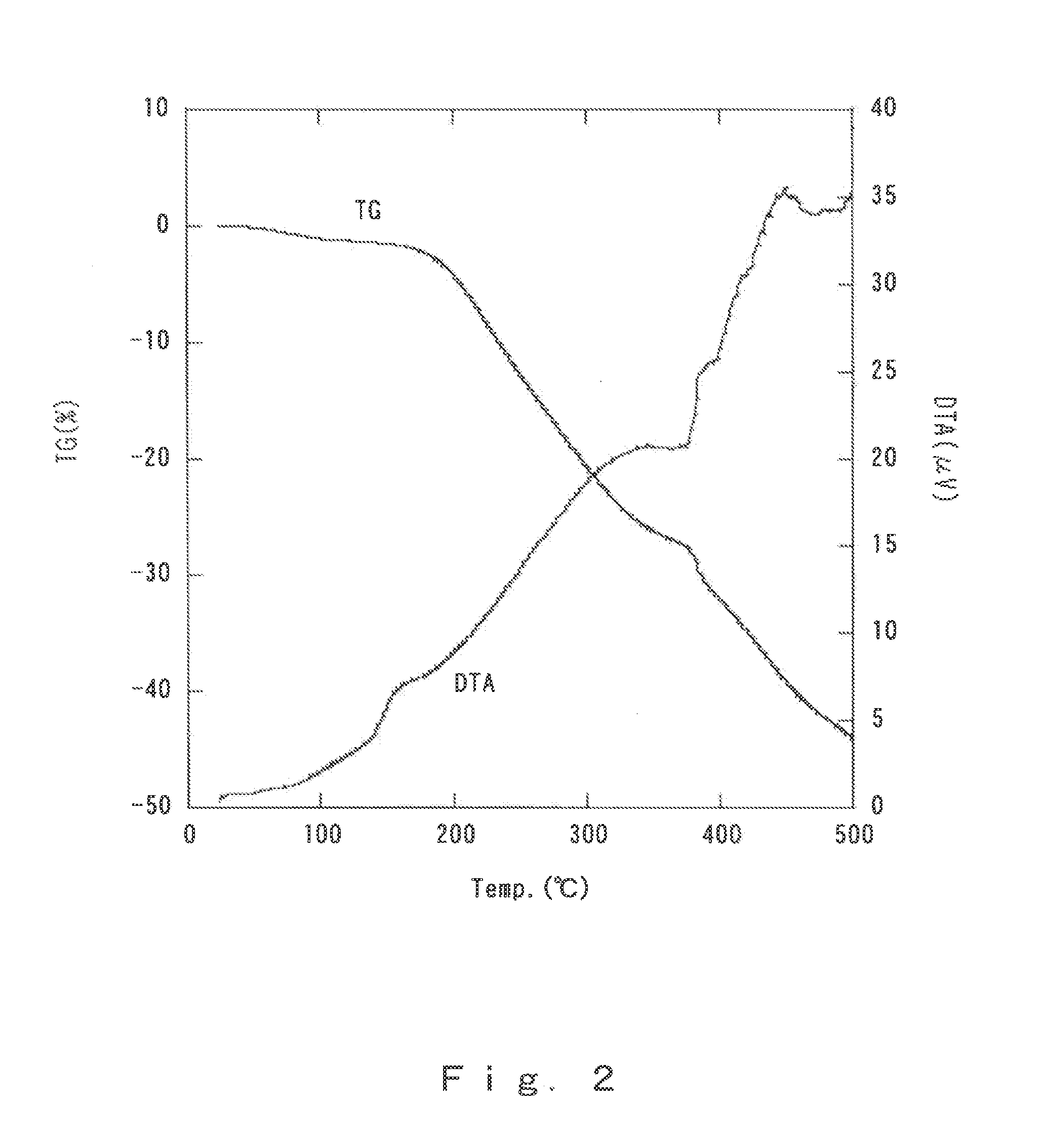

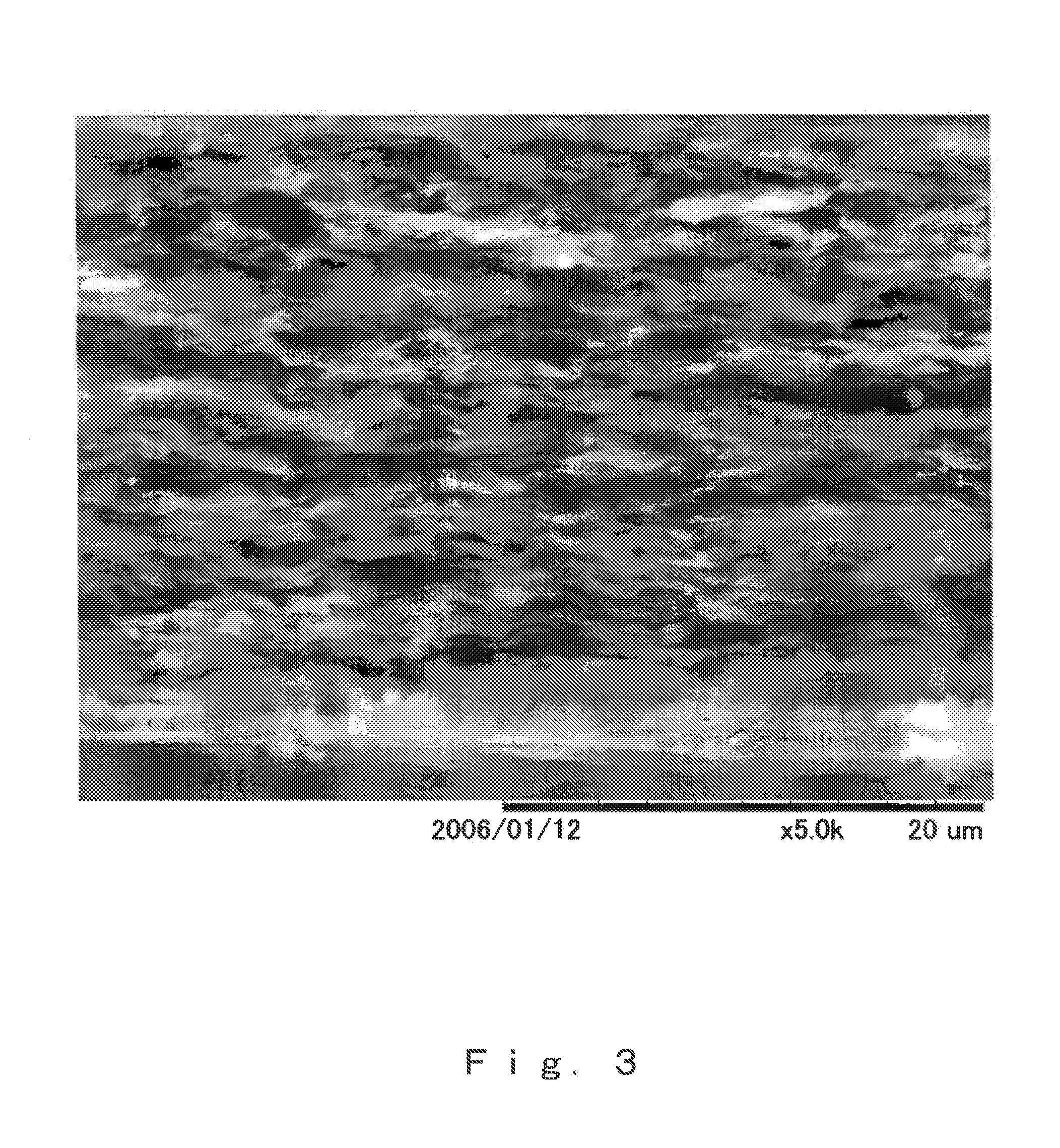

ActiveUS20090202806A1High mechanical strengthGood flexibilityAlkali metal silicate coatingsCellulose coatingsHeat resistanceWater vapor

The present invention provides a novel technology and a novel material having excellent pliability, gas barrier properties and water resistance, for the technical fields of packaging materials, sealing materials, electric insulating materials and the like, the present invention relates to a film of a material having a denatured clay as a main constituent thereof, wherein (1) the film comprises a denatured clay and an additive, (2) the weight ratio of the denatured clay is not less than 70% relative to total solids, (3) the film has gas barrier properties and water-vapor barrier properties, (4) the film has heat resistance, (5) the film has water resistance, (6) the film has sufficient mechanical strength to be used as a self-supporting film, and (7) the film can be formed on the surface of metals, plastics, rubber, paper and the like, and the present invention can provide a material comprising the denatured clay film in which denatured clay particles are highly oriented and which has excellent heat resistance, excellent pliability, excellent gas barrier properties, excellent water-vapor barrier properties, and high water resistance.

Owner:NAT INST OF ADVANCED IND SCI & TECH

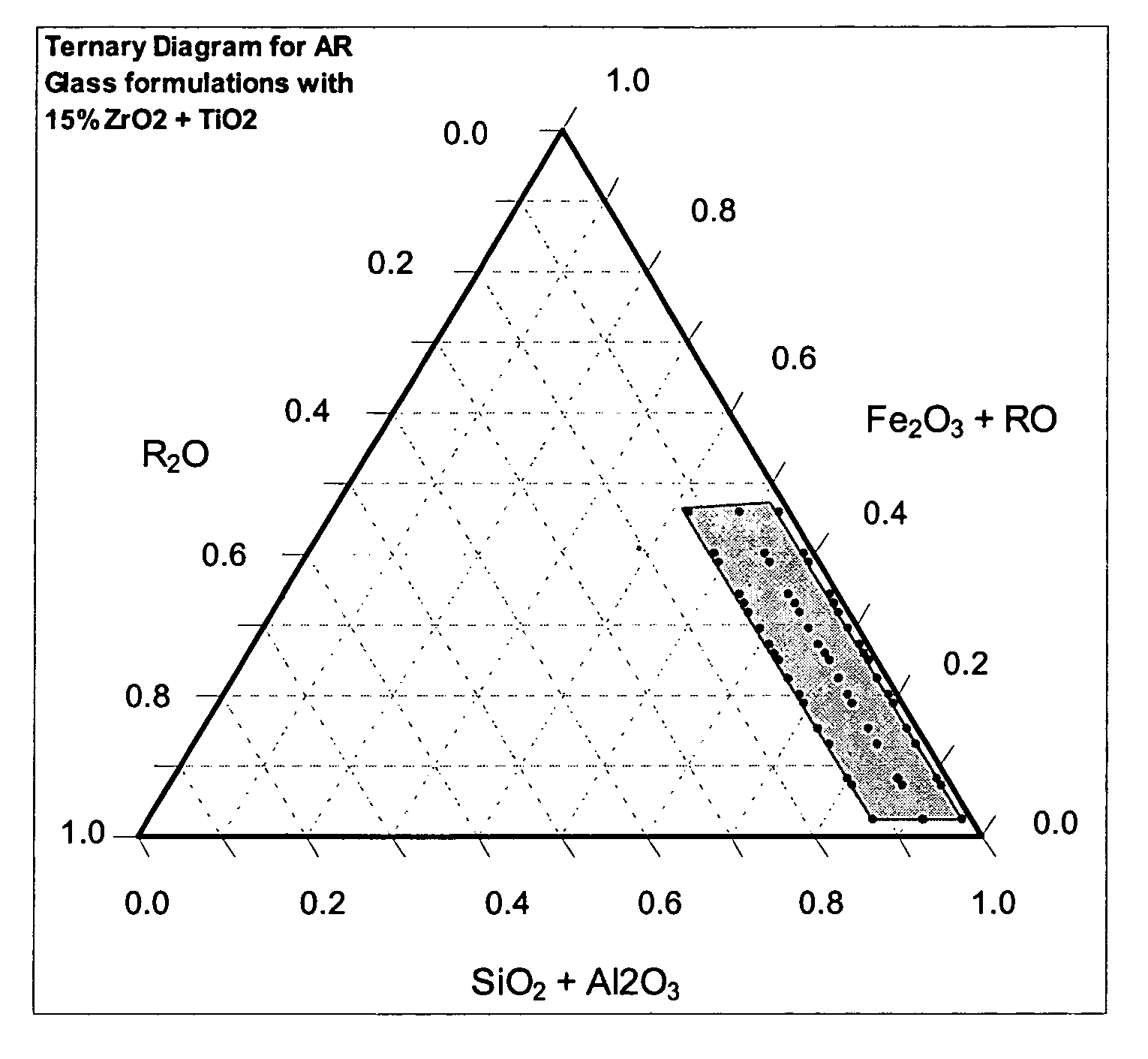

Alkali resistant glass compositions

ActiveUS7744689B2Good alkali resistanceReduce manufacturing costAlkali metal silicate coatingsInorganic adhesivesAlkali metalTitanium dioxide

An alkali resistant glass composition having improved durability to withstand highly alkali environments at elevated temperatures, such as curing of cementitious products in an autoclave, is conveniently formed from economical and abundant materials. The glass composition includes increased levels of calcium and iron, and relatively low levels of alkali metals, as compared to many other alkali resistant glass products, and comprises essentially of, by weight, >35% Si2O3, 1-25% CaO, 1-15% Fe2O3, 1-10% R2O, and an amount of Al2O3 such that the ratio of Si2O3:Al2O3 is greater than or equal to 1. Alkali resistance can be improved by forming a passivity layer on the surface of glass articles by treating the articles hydrothermally in a basic environment. Optionally zirconia and / or titania may be added to the composition to further improve alkali resistance.

Owner:JAMES HARDIE TECH LTD

Cement-based materials system for producing ferrous castings using a three-dimensional printer

ActiveUS8211226B2Improve accuracyHigh strengthAdditive manufacturing apparatusAlkali metal silicate coatingsGranularityMaterial system

Owner:MASSACHUSETTS INST OF TECH

Dry Mix Cement Composition, Methods and Systems Involving Same

InactiveUS20090071374A1Modifies strengthEnhances polymerisationSolid waste managementAlkali metal silicate coatingsMulti phaseMaterials science

A dry mix cement composition including an alkaline multi-phase aluminosilicate material, wherein the alkaline multi-phase aluminosilicate material provides a source of alkaline and soluble silicate to the cement composition.

Owner:ZEOBOND RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com