Green glass-ceramic plate made from lead-zinc smelting slag and manufacturing method thereof

A technology of glass-ceramic and a manufacturing method, applied in the field of glass-ceramic products and their manufacture, can solve the problems of high melting temperature and high raw material cost, and achieve the effects of reducing melting temperature, energy consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

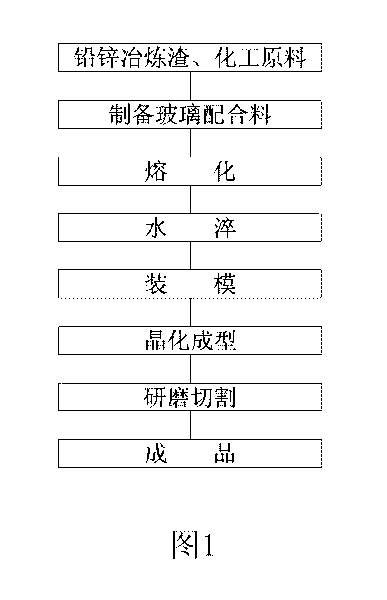

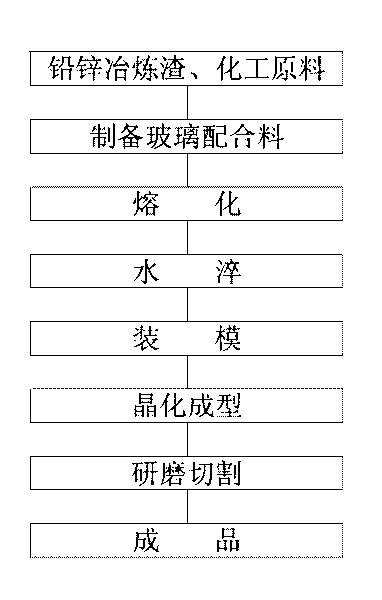

Method used

Image

Examples

Embodiment 1

[0048] The glass batch is made by weighing and mixing. The composition (weight) of the glass batch is: 60 parts of lead-zinc smelting slag, 26 parts of quartz, 15 parts of lithium feldspar, 4 parts of soda ash, 2 parts of zinc oxide, barium carbonate 4 parts, 2 parts of borax, 2 parts of chromium oxide, 0.2 part of copper oxide, and 0.04 part of carbon powder.

[0049] The composition and content of the lead-zinc smelting slag are SiO 2 40.20%, AL 2 o 3 13.60%, CaO19.84%, MgO3.31%, K 2 O+Na 2 O1.93%; Fe 2 o3 9.66%, ZnO0.71%, PbO0.06%.

[0050] Put the above-mentioned glass batch material in a mullite crucible and melt it in a box-type electric furnace at a temperature of 1480°C for 3 hours. After the melting is completed, pour the glass liquid into water to become glass pellets. 700 grams of glass granules were spread flat in a refractory mold with a size of 120×120 mm and crystallized in a box-type electric furnace at a crystallization temperature of 1020° C. Thereby, ...

Embodiment 2

[0053] The glass batch is made by weighing and mixing. The composition (weight) of the glass batch is: 50 parts of lead-zinc smelting slag, 33 parts of quartz, 15 parts of lithium feldspar, 3 parts of soda ash, 3 parts of zinc oxide, barium carbonate 4 parts, 2 parts of borax, 2.2 parts of chromium oxide, 0.06 part of copper oxide, and 0.1 part of carbon powder. The composition and content of the lead-zinc smelting slag are the same as in Example 1.

[0054] The above-mentioned glass batch materials were melted in a glass tank furnace with a temperature of 1480° C. for 3 hours, and after the melting was completed, the molten glass was directly poured into water to become glass pellets. 26 kg of glass granules were spread flat in a refractory mold with a size of 6000×9000 mm and crystallized in a shuttle kiln fueled by liquefied petroleum gas, with a crystallization temperature of 1060°C. Thus, a green glass-ceramic product of 600×900×18 mm can be obtained.

[0055]

Embodiment 3

[0057] The glass batch is made by weighing and mixing. The composition (weight) of the glass batch is: 40 parts of lead-zinc smelting slag, 38 parts of quartz, 24 parts of lithium feldspar, 7 parts of limestone, 2 parts of soda ash, and 2 parts of zinc oxide. 4 parts of barium carbonate, 2 parts of borax, 2.5 parts of chromium oxide, and 0.2 parts of carbon powder. The composition and content of the lead-zinc smelting slag are the same as in Example 1.

[0058] The above-mentioned glass batch materials were melted in a glass tank kiln at a temperature of 1480° C. for 3 hours, and after the melting was completed, the molten glass was directly flowed into water to become glass pellets. Spread 26 kg of glass pellets in a refractory mold with a size of 6000×9000 mm and crystallize in a shuttle kiln fueled by liquefied petroleum gas at a crystallization temperature of 1050°C. Thus, a green glass-ceramic product of 600×900×18 mm can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com