High conductive high strength graphite brick for ultralarge blast furnace, its production technology and application

A high thermal conductivity, graphite brick technology, applied in the field of graphite products, can solve the problems affecting the normal operation of the blast furnace, shorten the service life of the blast furnace, and damage the lining of the blast furnace, and achieve excellent thermal shock resistance, prolong service life, and strong erosion ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Add 100kg of pitch coke to 500kg of petroleum coke, and then add 52.2kg of crushed graphite. After crushing, partial grinding, and screening according to a certain particle size, the particle composition and distribution are as follows:

[0038] In mm, 2≤particle size<3 is 6.52kg (1%); 1≤particle size<2 is 71.74kg (11%); 0.5≤particle size<1 is 65.22kg (10%); 0.075≤particle size<0.5 It is 136.95kg (21%); the particle below 0.075 is 371.74kg (57%);

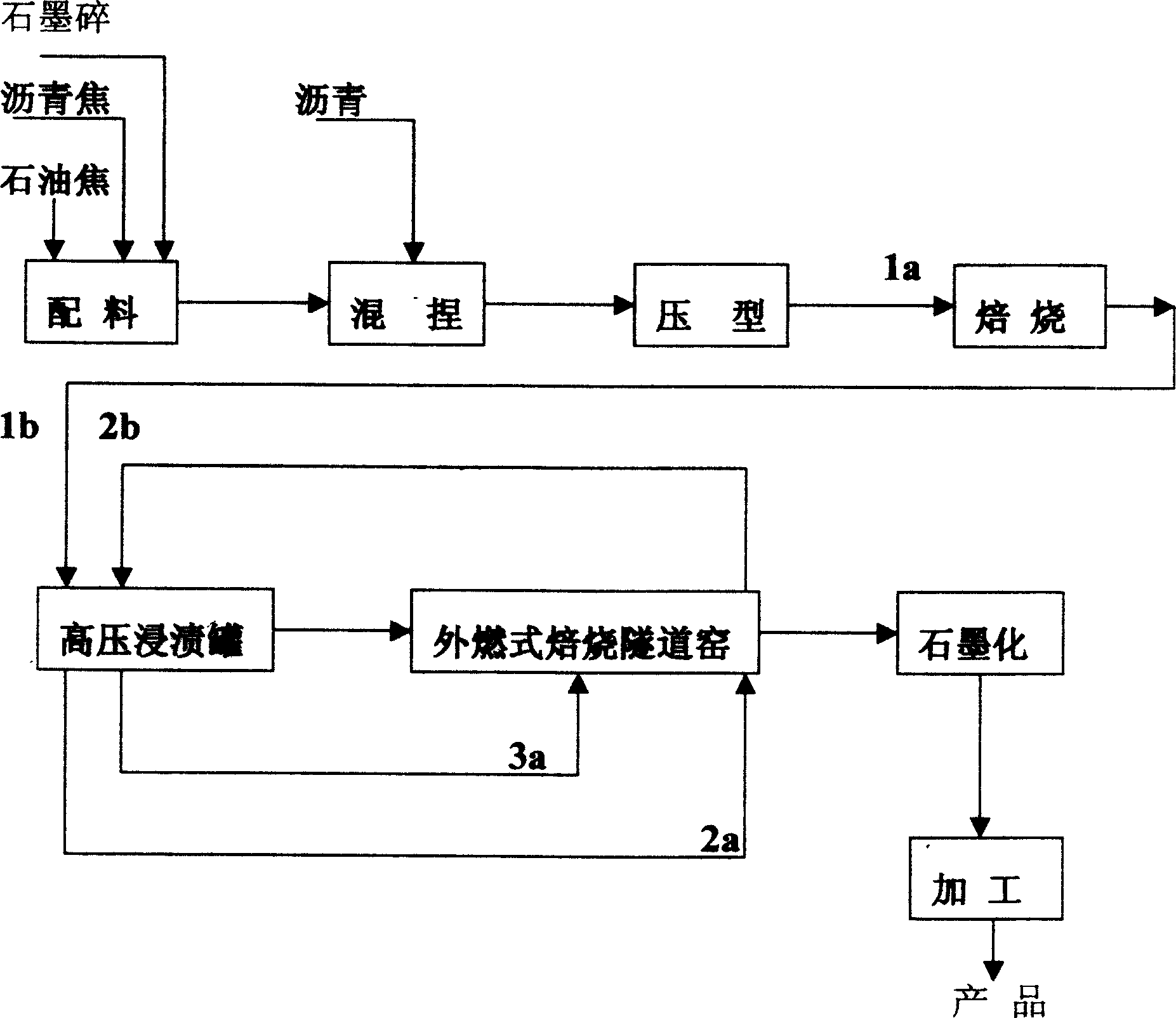

[0039] It can be seen from the drawings that the above-mentioned powders were put into a kneading pot for dry mixing for 30 minutes at a temperature of 105°C. Then add 182.61 kg of medium-temperature coal tar pitch, and carry out wet mixing at the same temperature. The mixing time is 40 minutes, and the temperature of the paste out of the pot is 160 ° C. Then after cooling to about 100°C, put it into the molding machine for molding, the pre-pressing pressure is 16Mpa, the pre-pressing time is 6min, and the volume density of ...

Embodiment 2

[0041] Add 50kg of pitch coke to 250kg of petroleum coke, and then add 22.58kg of crushed graphite. After crushing, partial grinding, and screening according to a certain particle size, the particle composition and distribution are as follows:

[0042] Greater than or equal to 2mm and less than 3mm is 1.61kg (0.5%), greater than or equal to 1mm and less than 2mm is 38.71kg (12%), greater than or equal to 0.5mm and less than 1mm is 35.48kg (11%), greater than or equal to 0.075mm and less than 0.5 mm is 59.68kg (18.5%), and 0.075mm or less is 187.10kg (58%).

[0043] As can be seen from the drawings, the above powders were dry kneaded for 35 minutes at a temperature of 108°C. Then add 93.55 kg of medium-temperature coal tar pitch, carry out wet mixing at the same temperature, the mixing time is 45 minutes, and the temperature of the paste out of the pot is 158°C. Then after cooling to about 100°C, put it into the molding machine for molding, the pre-pressing pressure is 17Mpa, ...

Embodiment 3

[0044] Embodiment 3 (application of high thermal conductivity, high strength small block graphite bricks in super large blast furnace)

[0045] The high thermal conductivity and high strength graphite brick of the present invention is used for the application of the ultra-large blast furnace lining. The dense copper cooling plate + the above-mentioned small pieces of high thermal conductivity and high strength graphite bricks of different specifications are placed in the area above the tuyere of the blast furnace according to the traditional method. Build the furnace lining structure and form a high thermal conductivity layer.

[0046] The blast furnace lining is composed of dense copper cooling plates and the high thermal conductivity and high strength small graphite bricks of the present invention. In this way, the copper cooling plate with high cooling strength (the copper plate cooling layer is cooled with cooling water) and the small graphite bricks together form a high t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com