Method for avoiding overheat tube burst in tubular boiler of power station boiler

A power plant boiler and piping system technology, which is applied in the direction of boiler working status indication, control system, steam generation, etc., can solve the problems of slowing down scale, impossible to monitor scale rate and thickness, no accurate calculation of steam temperature and wall temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

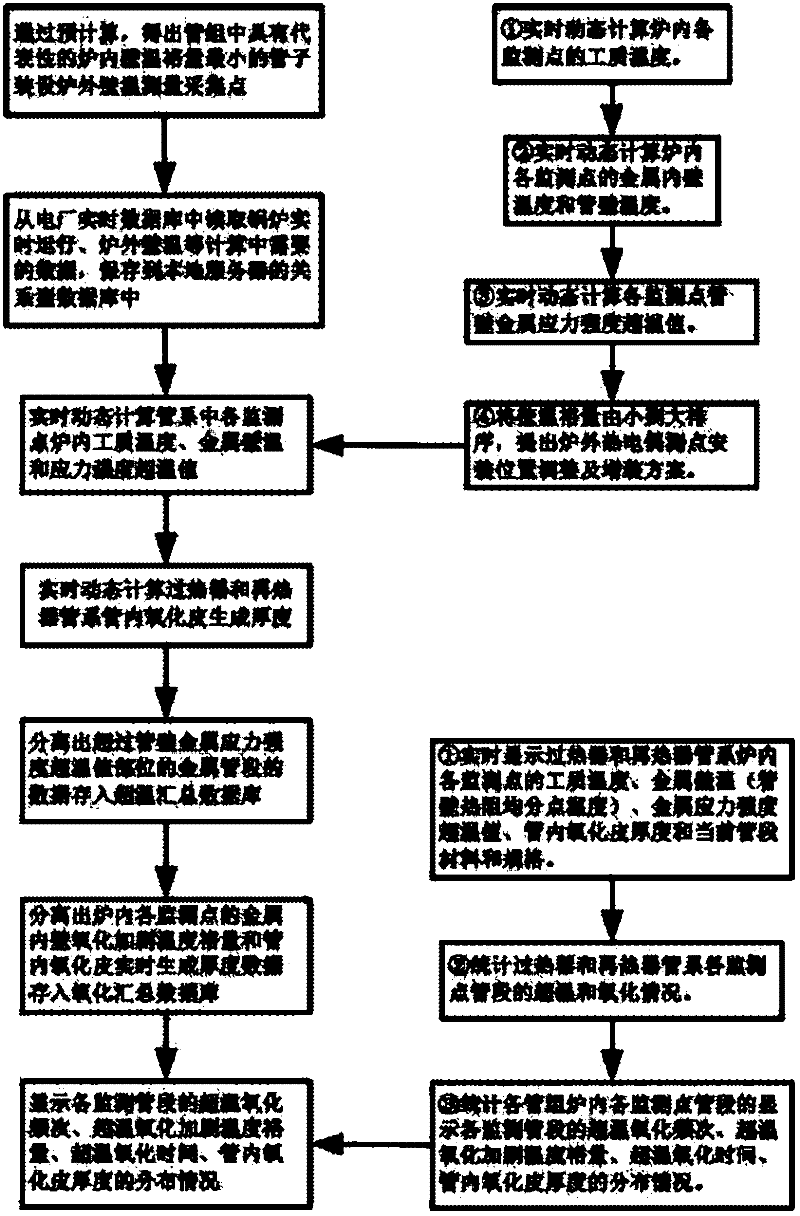

[0155] In this example, a 1000MW ultra-supercritical power station boiler high-temperature reheater piping system in a power plant is selected to adopt figure 1 The block schematic diagram of the implementation steps is shown.

[0156] The high-temperature reheater of the 1000MW ultra-supercritical boiler in this embodiment has 44 screens in total, and each screen has 24 tubes. There are 1056 pipes in total, and 6336 calculation points are calculated.

[0157] This embodiment includes the following steps:

[0158] Step 1: Through pre-calculation, it is obtained that the typical temperature margin of the inner wall of the furnace in the piping system of the high-temperature reheater of the 1000MW ultra-supercritical boiler is installed to measure and collect the temperature of the outer wall of the furnace.

[0159] a. Calculate the enthalpy increase Δia of the pipe section

[0160] Δia=Kr y (Q d +Q p +Q q +Q qq +Q z +Q h +Q x ) / ga

[0161] Where: Kr y The width en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com