Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

94 results about "Frp reinforcement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

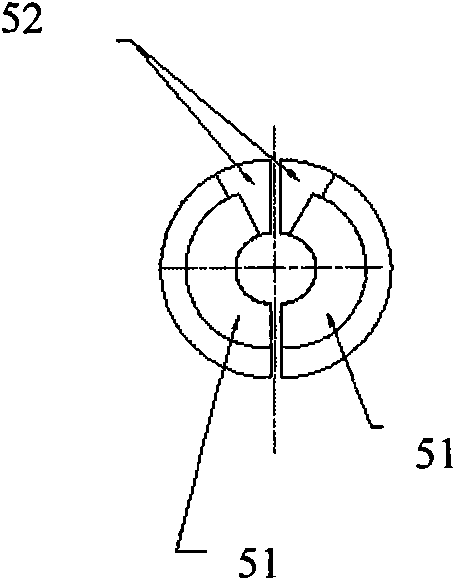

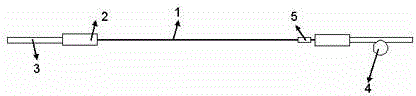

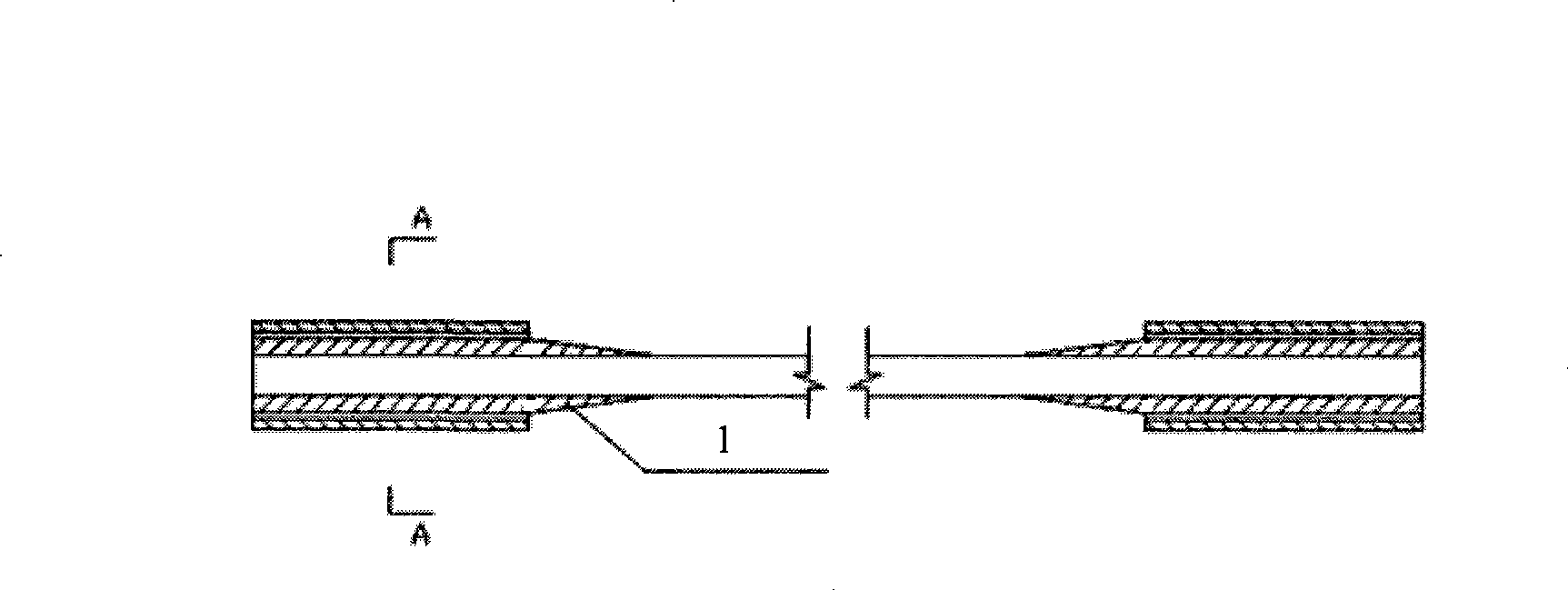

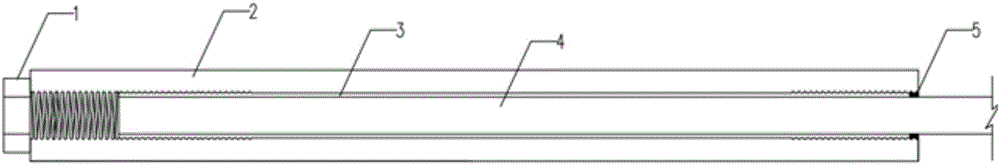

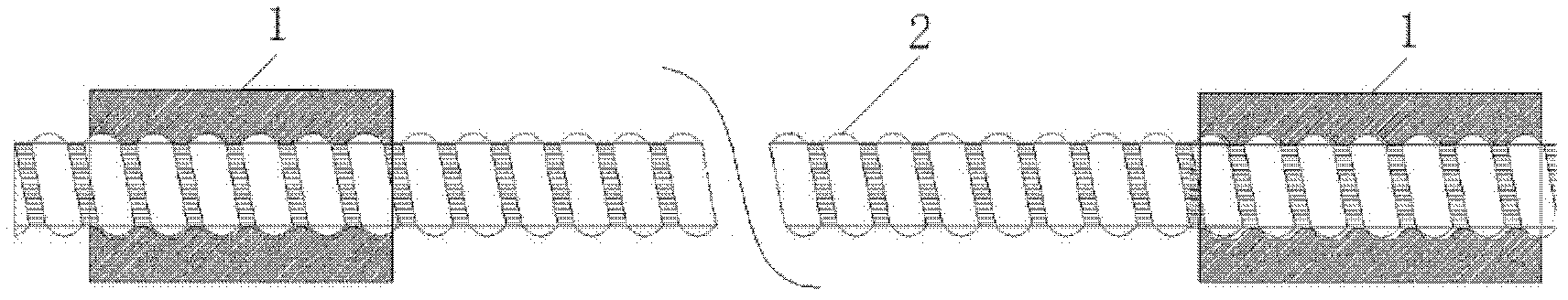

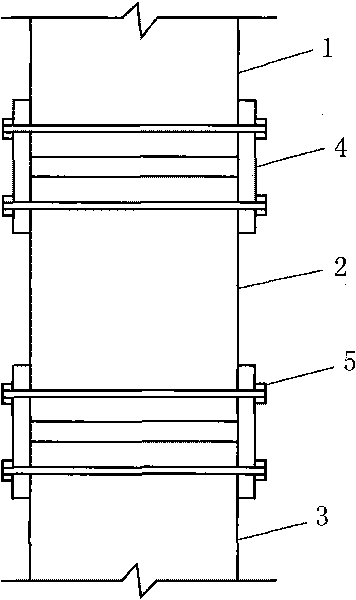

Method for coaxially connecting FRP reinforcements by FRP connecting pipe and expansive cement

The invention provides a method for coaxially connecting two FRP reinforcements by an FRP connecting pipe and an expansive cement, comprising the following steps of respectively perforating two reinforcements to be connected with coaxial holes, coaxially connecting and positioning the two reinforcements by an FRP extruding / pulling rod or a wire rope, sheathing a section of FRP connecting pipe at the joint of the reinforcements; carrying out coaxial positioning by a positioning ring at two ends of the connecting pipe; arranging a pouring opening / air outlet on the positioning ring during horizontal pouring process and injecting expansive cement solution between the reinforcements and the connecting pipe by the pouring opening; needing not to arrange the pouring opening / air outlet on the positioning ring during vertical pouring process, firstly installing and then sealing the lower positioning ring; putting the upper sealing ring in place after completing pouring the cement solution to be expanded from the upper opening along the wall of the FRP connecting pipe, thus ensuring the coaxiality of the reinforcements and the sheathed pipes. The hardening time of the expansive cement is 6-12 hours generally. The FRP pipe can be prefabricated, the quality thereof is easy to be controlled, the cost of the expansive cement is low, the connection construction is simple and convenient, and the connecting part prepared by the expansive cement has light weight, high strength and corrosion resistance and can be used for structures with demagnetization requirements.

Owner:TONGJI UNIV +1

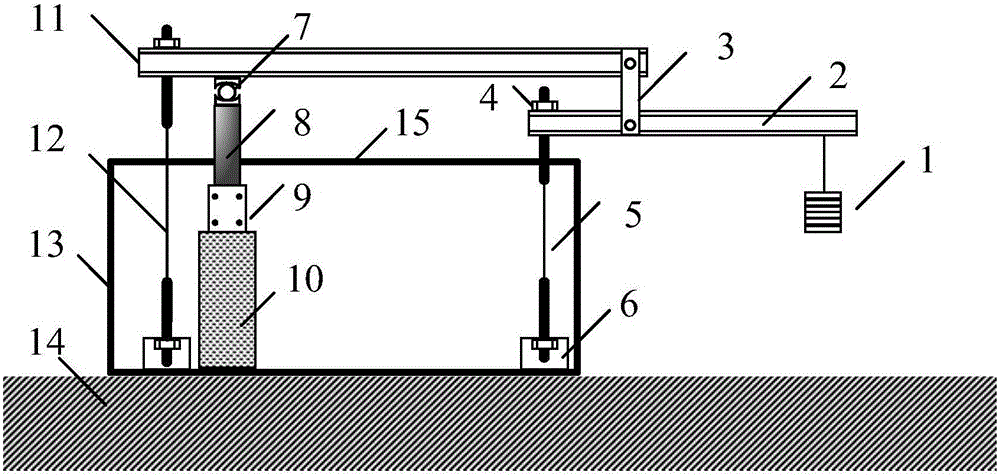

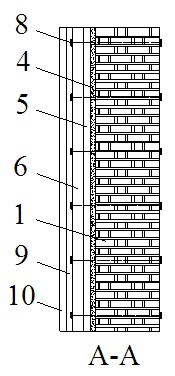

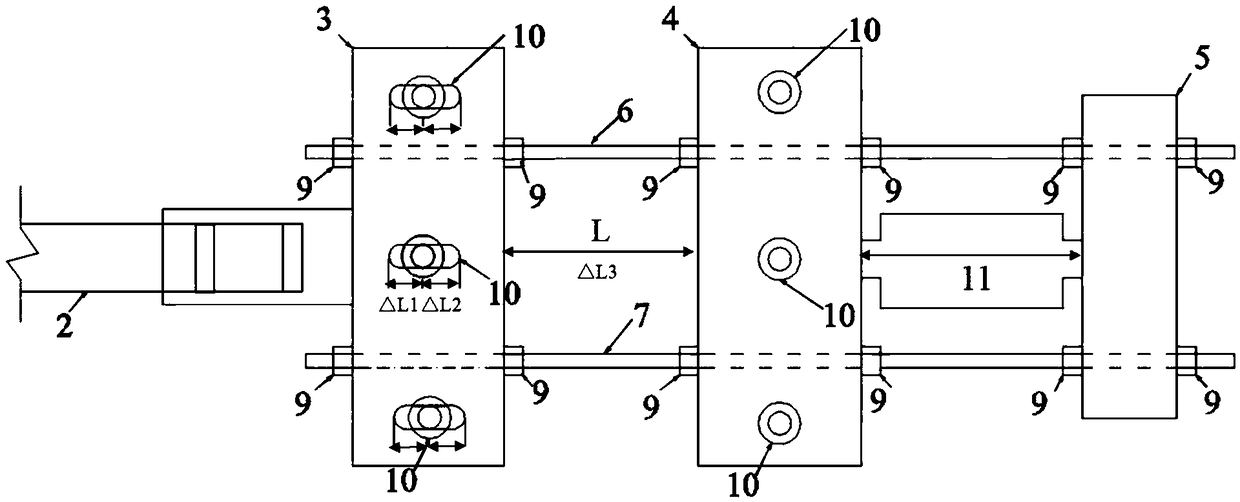

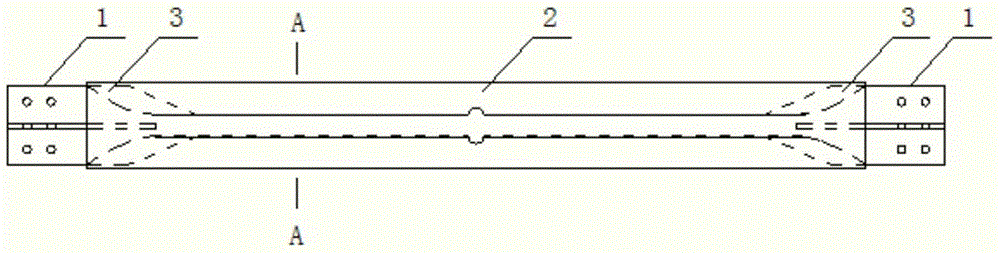

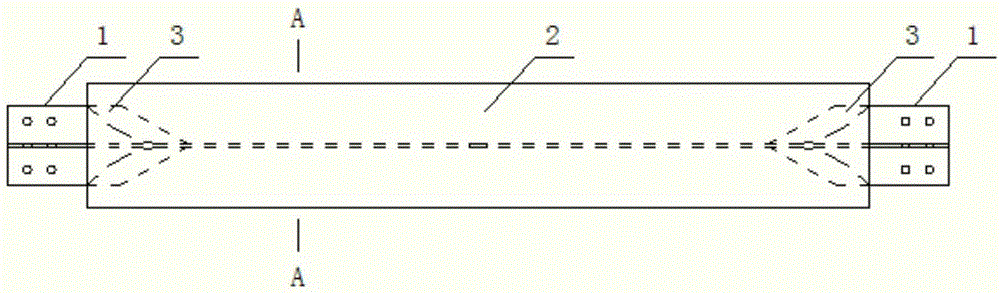

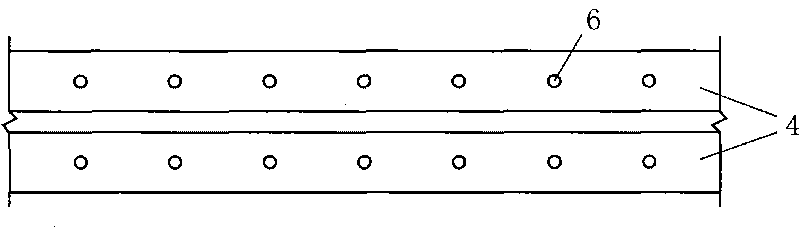

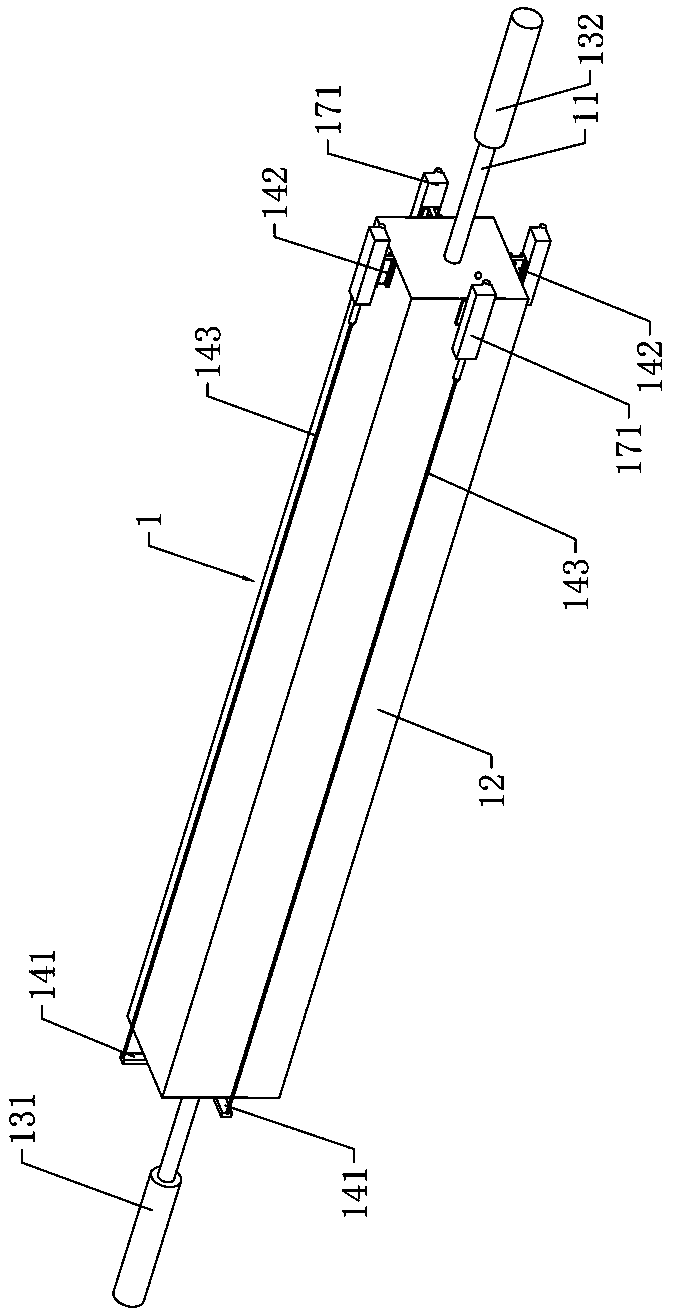

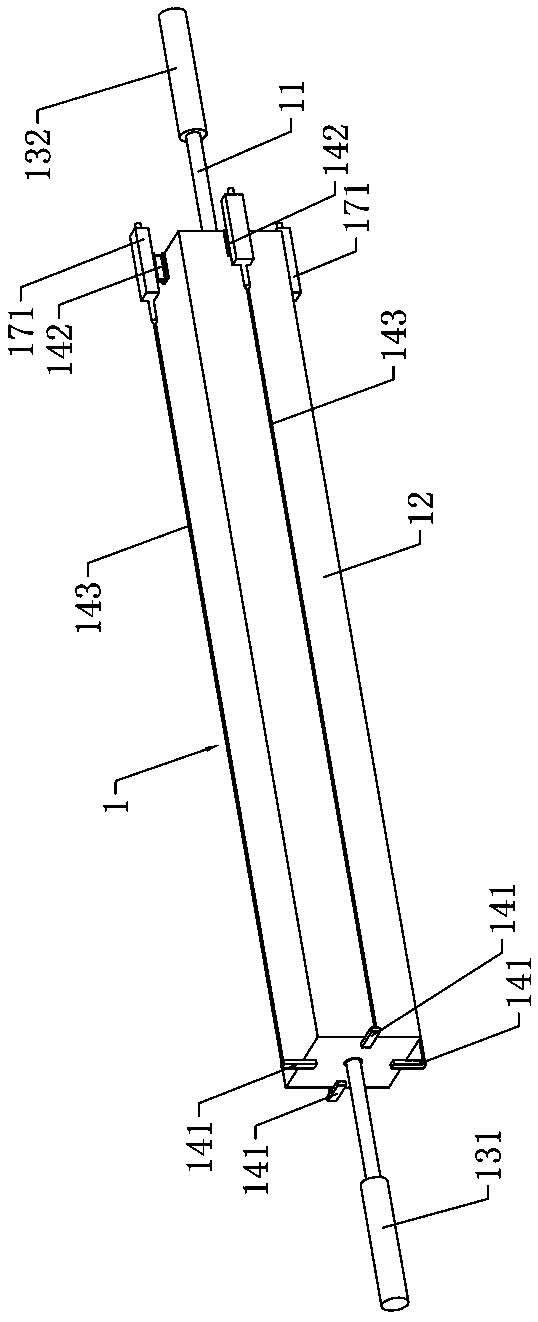

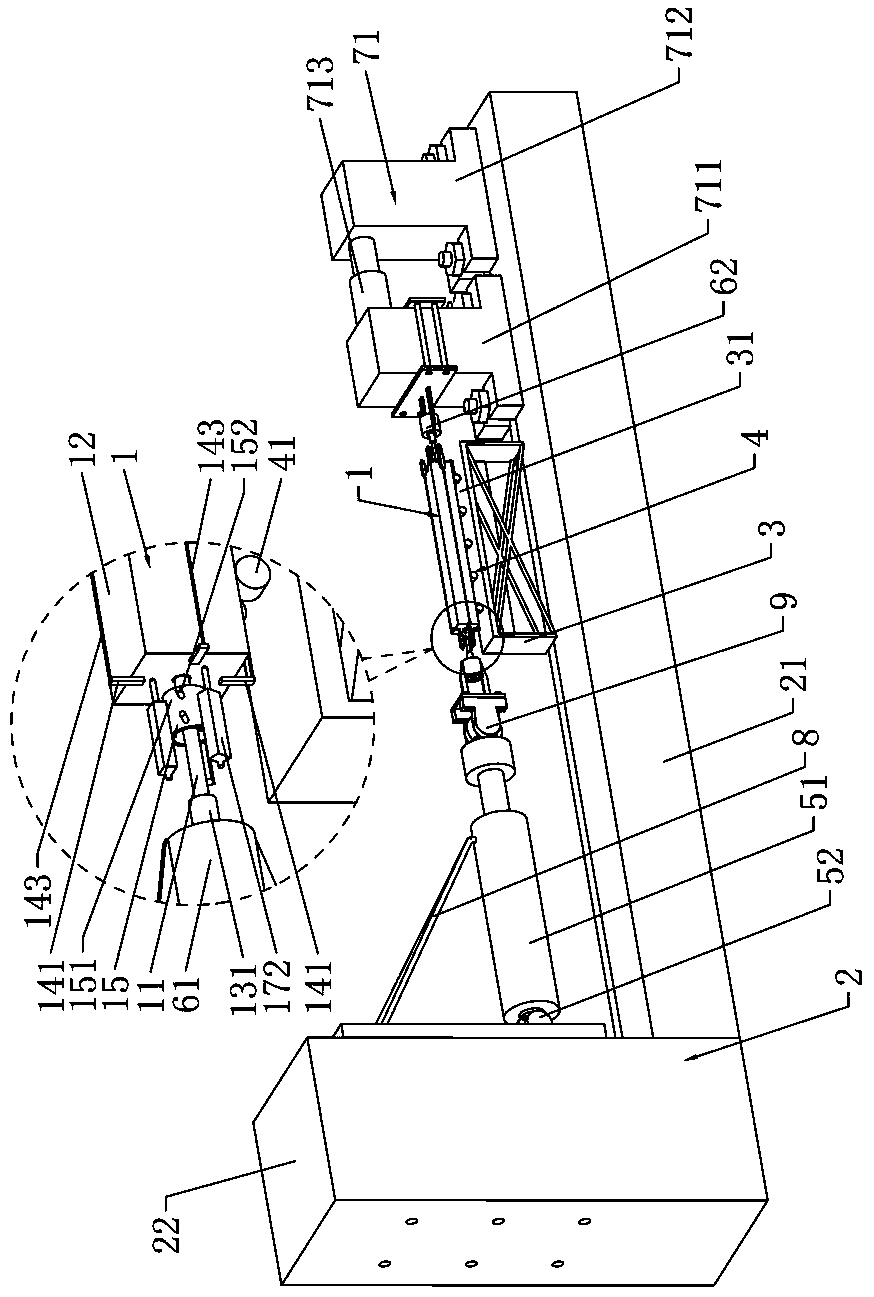

Device and method for simultaneously testing constant-temperature stress corrosion of multiple FRP (Fiber Reinforced Polymer) reinforcements

InactiveCN104807712AEasy to controlAccurate monitoringWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceFiberStructural engineering

The invention relates to a device for simultaneously testing constant-temperature stress corrosion of multiple FRP (Fiber Reinforced Polymer) reinforcements. The device comprises a counterforce frame, a soaking box and a stress test piece, wherein the soaking box and the stress test piece are located in the counterforce frame and are connected with a temperature controller; a plurality of through holes are correspondingly formed in each of left and right side plates of the soaking box, snapping grooves are vertically formed above the through holes of the left and right side plates of the soaking box, snapping plates are connected into the snapping grooves in a sealed manner, and a sliding door which can move horizontally is arranged on the top face of the soaking box; the stress test piece comprises a plurality of FRP reinforcements, tensioning anchor devices comprise bonding sleeve anchor devices and worms, the two ends of each FRP reinforcement are sequentially connected with one bonding sleeve anchor device and one worm, one of the worms is connected with a worm gear, and strain gages are arranged on the FRP reinforcements; the counterforce frame comprises a counterforce frame framework and counterforce frame side plates which are located at the left and right sides, and the worms respectively penetrate through the left and right sides and are fixedly arranged on the side faces of the counterforce frame. The device is used for carrying out stress corrosion only on the middle test section of the FRP reinforcement test piece and is simpler in operation.

Owner:ZHENGZHOU UNIV

Test piece end reinforcing method in test for FRP rib/anchor rod tensile property

InactiveCN101398357AEliminate or significantly reduce stress concentrationsMaterial strength using tensile/compressive forcesFiberStress concentration

The invention provides a method used for reinforcing the end of a specimen during the tensile performance test of FRP reinforcement / anchor, comprising the steps as follows: the end reinforced section of the specimen is provided with a gradient transition section, thus avoiding the stress concentration which is caused by obvious section change at the starting position of the reinforced section; the gradient transition section is achieved by enwinding fiber cloth at the end of the FRP reinforcement / anchor specimen to be processed; according to the nominal external diameter of the reinforcement / anchor and the internal diameter of an external steel sleeve, the length of the transition section and the dimension of the fiber cloth are determined; substrate material with low curing shrinkage rate can be adopted for the substrate to enwind the fiber cloth; the external diameter and the wall thickness of the external steel sleeve can be determined according to the external diameter of the FRP reinforcement / anchor, type and performance of filler, shape and dimension of the clamp of a testing machine and the like; and resin or expansion cement is poured between the fiber cloth reinforced layer and the external steel sleeve so as to form a whole end reinforced section. The method leads the damaged position of the specimen to be distributed at a free section and is beneficial for measuring exact material strength performance.

Owner:TONGJI UNIV +1

Nanometer-modified fiber reinforced plastic reinforcement sea sand concrete fence board and preparation method thereof

The invention discloses a nanometer-modified fiber reinforced plastic reinforcement sea sand concrete fence board which is mainly made of sea sand concrete and nanometer-modified FRP (Fiber Reinforced Plastic) reinforcements, wherein the nanometer-modified FRP reinforcements are mainly prepared from the following raw materials in percentage by mass: 65-75 percent of fiber reinforce plastic, 21.5-29.5 percent of resin, 0.045-0.6 percent of nanometer material, 0.15-0.45 percent of accelerant, 0.04-0.05 percent of polymerization inhibitor, 0.3-0.6 percent of curing agent and 1.5-4.5 percent of ethylene glycol. The invention also discloses a preparation method of the nanometer-modified fiber reinforced plastic reinforcement sea sand concrete fence board. The FRP reinforcements in the nanometer-modified FRP reinforcement sea sand concrete fence board have the advantages of high strength, high mass ratio, small elastic modulus, good fatigue property, small stress relaxation, good corrosion resistance and the like; and sea sand is directly utilized, so that not only the economic and social effect is huge, but also the ecological environmental protection is favorably promoted.

Owner:HOHAI UNIV

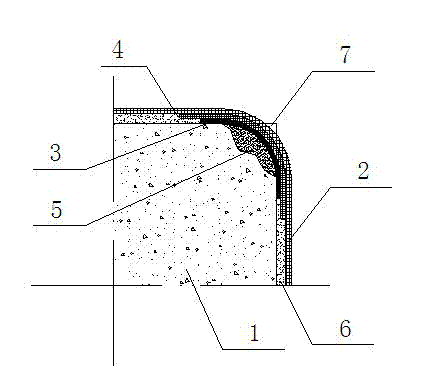

Device and method for reinforcing concrete shear wall by FRP (fiber reinforced plastics)

The invention relates to the technical field of civil engineering structure reinforcement, in particular to a device and a method for reinforcing a concrete shear wall by FRP (fiber reinforced plastics). The device comprises the concrete shear wall, epoxy resin layers, a first FRP strip belt and second FRP strip belts, wherein the epoxy resin layers coat two wall surfaces of the concrete shear wall; the first FRP strip belt is fully and transversely bonded on the surface of the oxygen resin layer of the lower part of the concrete shear wall; a plurality of second FRP strip belts are uniformly and transversely bonded at equal intervals at the upper part of the first FRP strip belt; a plurality of through holes are uniformly formed in the lower part of the concrete shear wall; the device for reinforcing the concrete shear wall by FRP also comprises steel plates, a screw rod and a screw nut; installing holes are formed in the steel plate; the steel plates cover the two ends of the through holes, and the installing holes and the through holes are opposite; the screw rod simultaneously passes through the concrete shear wall, the epoxy resin layers, the first FRP strip belt and the steel plate; screw nuts are arranged at the two ends of the steel plate. The quake-proof capability of the concrete shear wall can be improved; the FRP peeling damage can be prevented.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Method for reinforcing steel structure through FRP (Fiber Reinforced Polymer)

InactiveCN104695720AHigh specific strengthHigh strengthBuilding repairsBridge erection/assemblyPolymer scienceRapid construction

The invention discloses a method for reinforcing a steel structure through FRP (Fiber Reinforced Polymer). The FRP adopted in the invention is carbon fibre reinforced polymer (CFRP), specifically, mesophase pitch (MP) based carbon fiber is used as raw material, the mesophase pitch based carbon fiber is the fiber obtained by spinning processing of pitch obtained through thermal polymerization of isotropic pitch with high aroma content, and having a mesophase or liquid-crystal structure, and the stress performance of the fiber is improved, so that a reinforcing effect is realized. The method has the characteristics that since the fiber reinforced polymer (FRP) has the characteristics of being high in specific strength and specific stiffness, and corrosion-resistant, the fiber reinforced polymer (FRP) is widely applied to reinforcing of a concrete structure, and the steel structure reinforced through the fiber reinforced polymer (FRP) has a good effect. The method for reinforcing the steel structure through the fiber reinforced polymer (FRP) has the characteristics that the specific strength is high, rapid construction is achieved, and bearing capacity of the structure is obviously improved after construction.

Owner:QINGDAO PINGDU JIUDIAN GOLD MINE

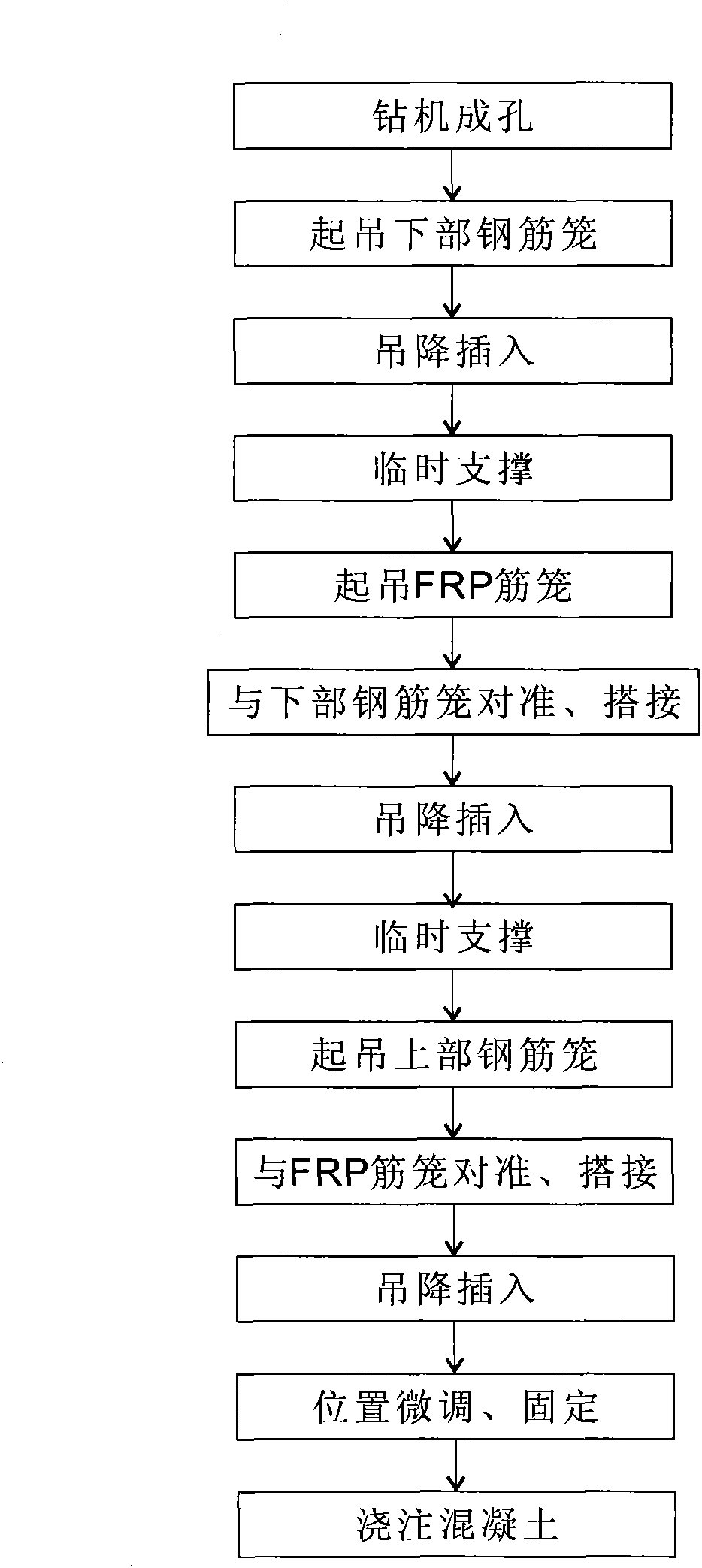

Construction method for directly cutting guard post for tunnel end well by shield machine

InactiveCN101614126AEasy constructionFast constructionUnderground chambersTunnel liningRebarFrp reinforcement

The invention discloses a construction method for directly cutting a guard post for a tunnel end well by a shield machine. A reinforcement body in the guard post consists of an upper steel reinforcement cage, a lower steel reinforcement cage and a middle FRP reinforcement cage, wherein the position of the middle FRP reinforcement cage corresponds to the position of the tunnel end well for the shield machine to access. The construction method comprises the following steps: hoisting, lapping and binding the lower steel reinforcement cage, the middle FRP reinforcement cage and the upper steel reinforcement cage in turn, and then inserting a conduit into the bound reinforcement cages to pour concrete so as to form a guard post structure of the tunnel end well; and when the shield machine tunnels to the position of the end well, firstly exchanging a cutter head of the shield machine into a hob, a serrated knife or a scraper, and then cutting the guard post. The construction method overcomes the defects of the prior construction method such as high expense, long period, large construction difficulty and the like, avoids chiseling a reinforced concrete guard at a corresponding position by using a manual softening method so as to improve the safety, and has the advantages of short period, low manufacturing cost and high safety.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +3

Combined beam of FRP, wood and steel reinforced concrete

InactiveCN103603462AIncreased bending stiffnessImprove flexural strengthBuilding repairsGirdersEngineeringRebar

The invention discloses a combined beam of FRP, wood and steel reinforced concrete. The combined beam comprises steel reinforced concrete wing panels, shearing force connecting pieces, wood beams, FRP reinforcing members, FRP cloths, steel ribs and U-shaped stirrups, wherein the shearing force connecting pieces are disposed between the steel reinforced concrete wing panels and the wood beams; the FRP reinforcing members are disposed at the bottom of, in a cross section at the middle and lower part of and in the side surface of the wood beams; the bending zone of the combined beam is reinforced by transverse winding the FRP cloths; and the FRP reinforcing members in the bending shear zone of combined beam are anchored by using the U-shaped stirrups. The combined materials play the functions of their own and work cooperatively, so that cross sectional inertia of the wood-steel reinforced concrete combined beam is greatly increased; and strength and rigidity of original components are effectively increased. The combined beam has the advantages of light self-weight, good mechanical performances, low energy consumption and renewability, and can be widely applied in the fields of reinforcement of ancient architectures and modern wood structures.

Owner:NANJING UNIV OF TECH

Concrete structure FRP end anchor device

The invention relates to a concrete structure FRP end anchor device, belonging to the technical field of civil engineering structural strengthening. The invention is characterized in that: the two ends of a fiber cloth are wound on a steel strap, and then a bolt is used for fixing the steel strap on a concrete beam. The invention solves the technical problems that utilization factor of fiber material is reduced and multiple construction technologies are restricted as a strengthening member in externally bonding FRP strengthening method is peeled and strengthening becomes invalid. Construction is complex and cost is high when special strengthening way is adopted, thus being not applicable to practical project. The invention has the benefits and effects that peeling-off of fiber cloth can be delayed, the fiber cloth can bear force with a beam until the fiber cloth is broken even midspan is in peeling-off failure, so that FRP material can be fully utilized, bearing capacity of beam is effectively improved, and time delay of beam damage is obviously improved.

Owner:DALIAN UNIV OF TECH

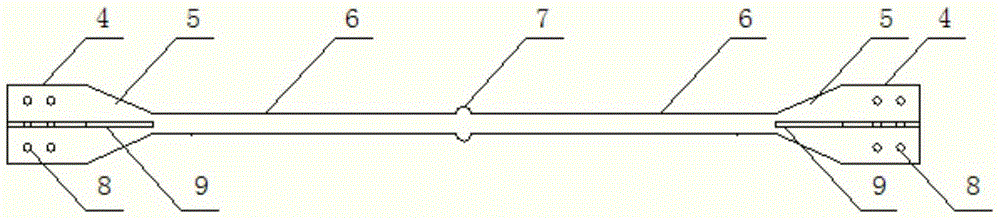

FRP reinforcement tension test apparatus and test method

InactiveCN106568646AAccurate measurementConstrained Relative SlipMaterial strength using tensile/compressive forcesEpoxySlurry

The invention provides an FRP reinforcement tension test apparatus and test method. The apparatus comprises two same anchorage devices and two same clamps, the anchorage devices are used for anchoring two ends of an FRP reinforcement, and every anchorage device comprises an octagon bolt, a steel tube, an epoxy resin-curing agent and a steel ring pad; two ends of every steel tube are provided with internal screw threads with the same length, an FRP reinforcement is arranged in every steel tube, a space between the FRP reinforcement and the steel tube is filled with the epoxy resin-curing agent, and ports at two ends of the steel tubes are respectively sealed with the octagon bolts and the steel ring pads; and the clamps clamp the anchorage devices through notches in the middle portions of the clamps, and the facing notch surfaces of the clamps, used for clamping the anchorage devices, are provided with transverse rib lines. The arrangement of the octagon bolts and the steel ring pads at the two ends of the steel tubes reduces the slurry leakage phenomenon of original anchorage devices, and makes effective bonding anchorage formed between the FRP reinforcements and the anchorage devices; and the surfaces of the clamps are provided with the rib lines, so the relative slip between the anchorage devices and the clamps is reduced.

Owner:JIANGSU UNIV

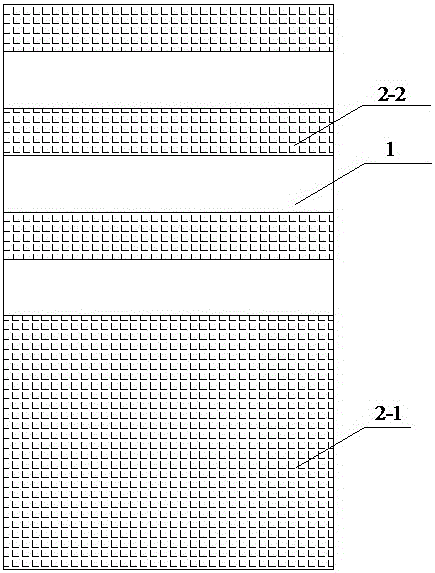

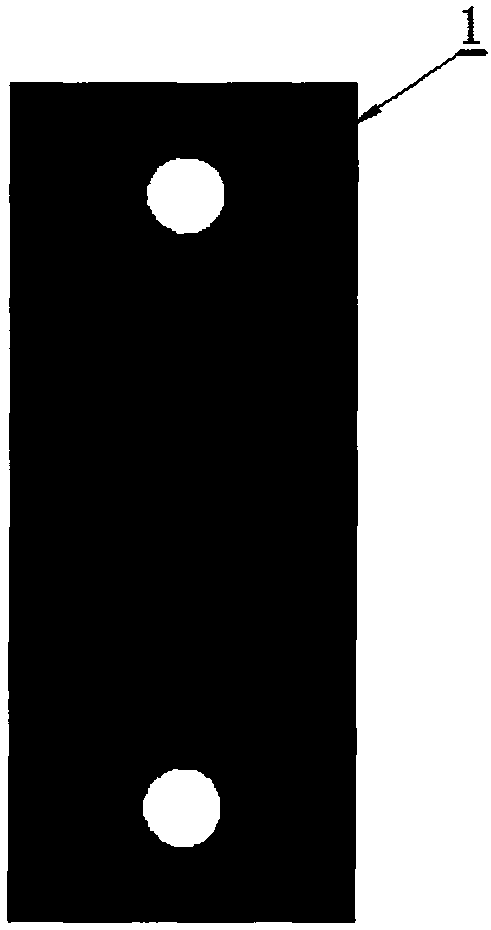

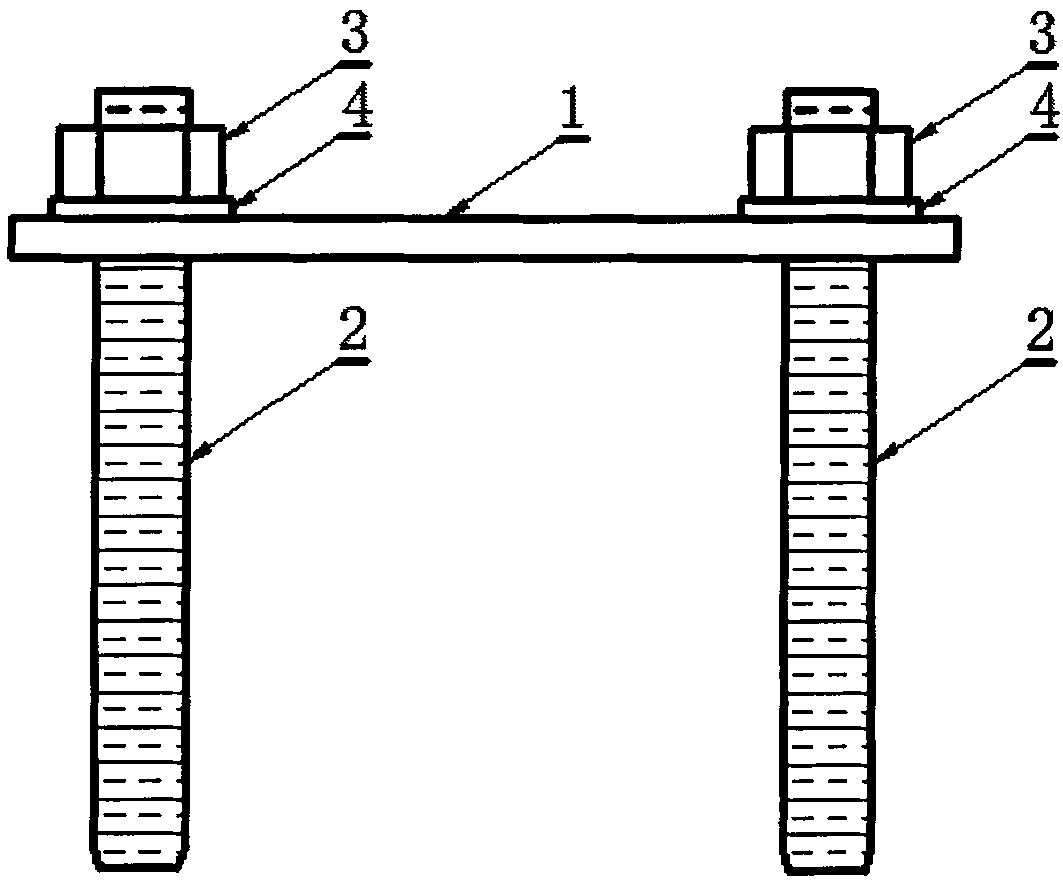

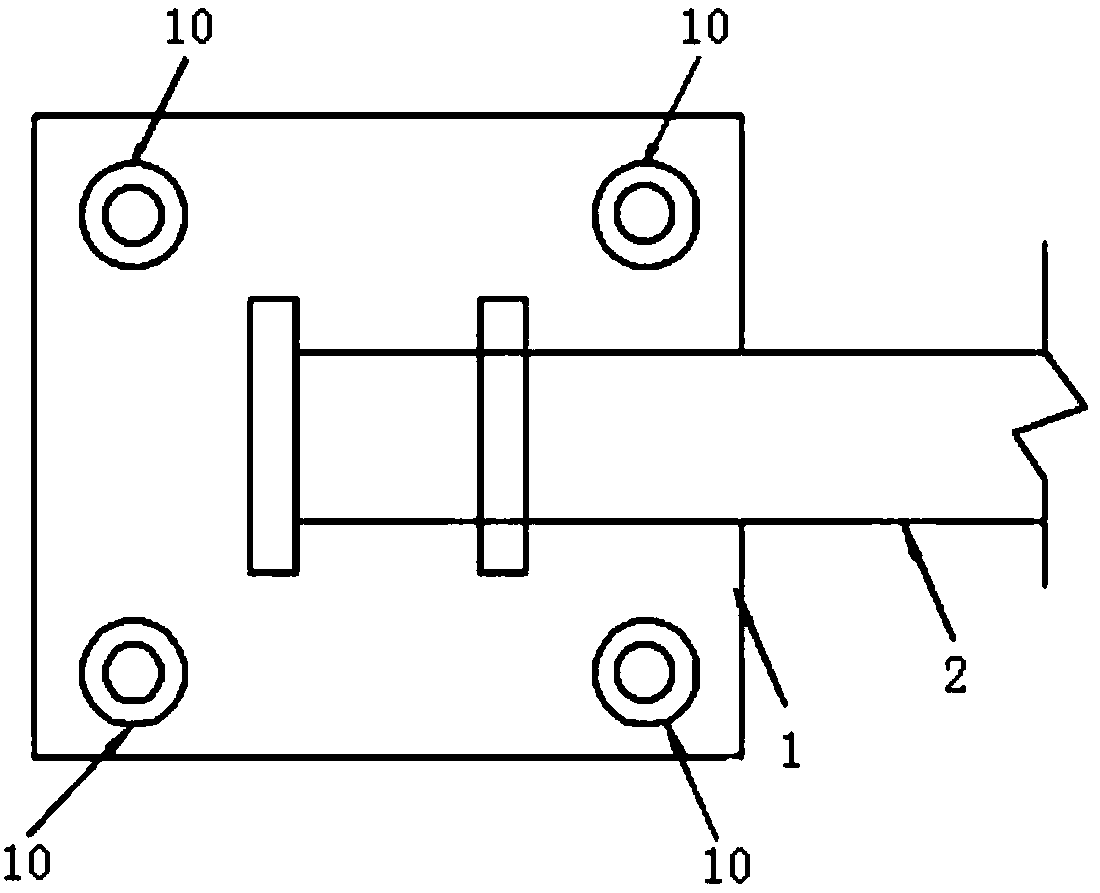

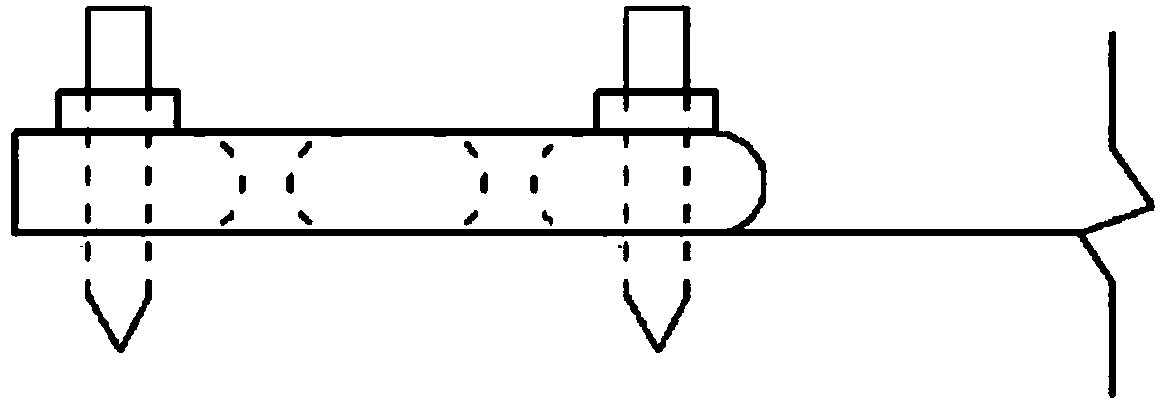

FRP reinforcement material end nut and manufacturing method and application thereof

InactiveCN103132654ASimple and fast operationReduce lossBuilding reinforcementsCompression moldingPre stress

The invention discloses an FRP reinforcement material end nut, a manufacturing method and an application thereof, and relates to a fitting of an FRP reinforcement material. The FRP reinforcement material end nut (1) has a structure that: the inner wall of the FRP reinforcement material end nut (1) is a structure fitting with the external diameter of an FRP thread reinforcing bar (2); the cross section of the FRP reinforcement material end nut (1) is round or polygonal at the outer edge, and the profile is a cylinder, a circular truncated cone, a prism, or a frustum of a prism. The FRP reinforcement material end nut can be used at an end part of a FRP thread reinforcing bar, playing a role of a reinforcing steel bar bend; is applicable to pre-stress FRP thread reinforcing bars for improving bond stress of concrete to the RP thread reinforcing bars; and is simple in operation when in use. The FRP reinforcement material end nut (1) is manufactured by a mechanical, semi-automatic compression molding method which increases production efficiency, reduces labor intensity, reduces raw material loss and working land occupation, and has the effects of energy saving and emission reduction.

Owner:湖北金力工程复合材料有限公司

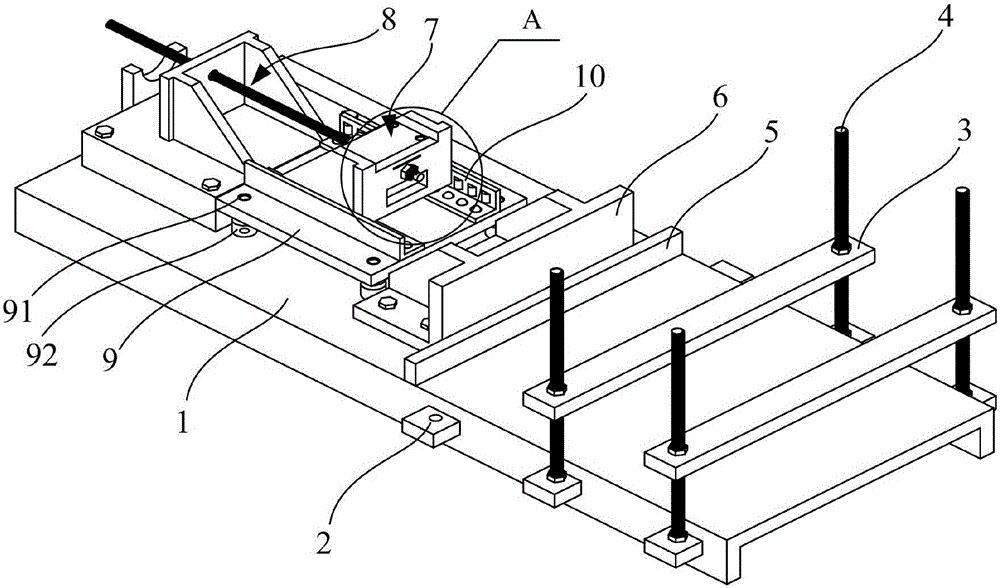

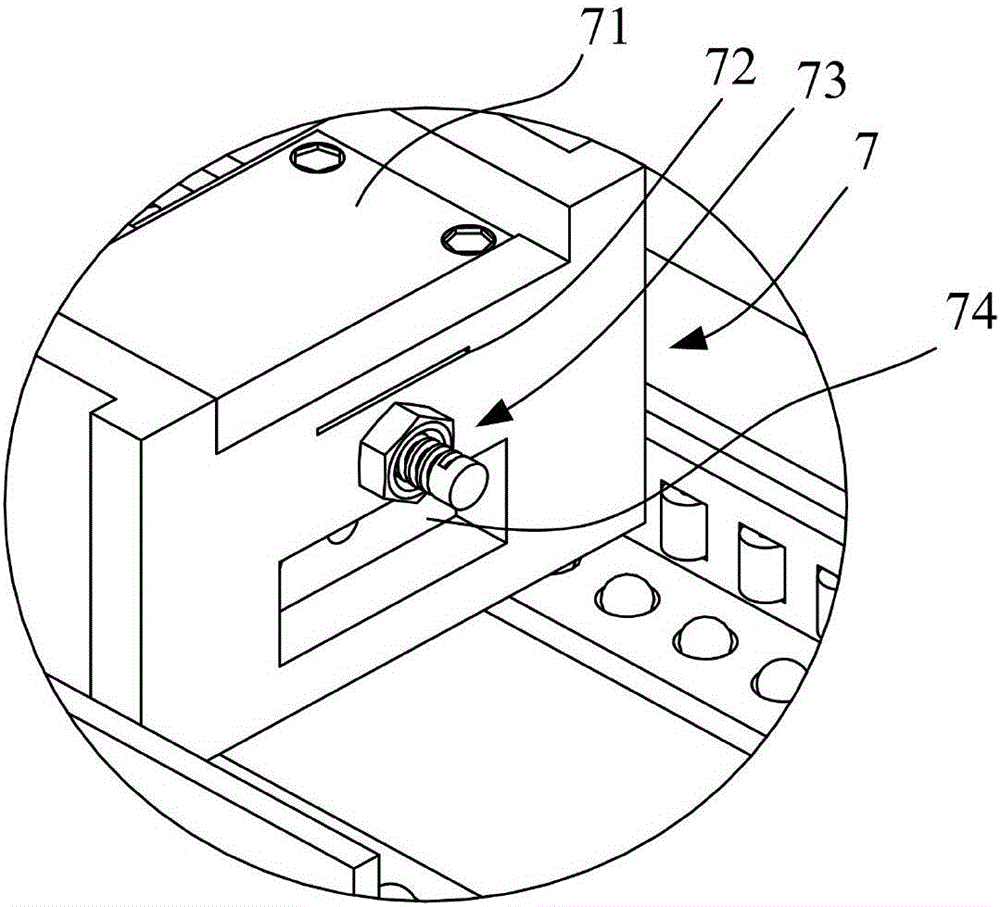

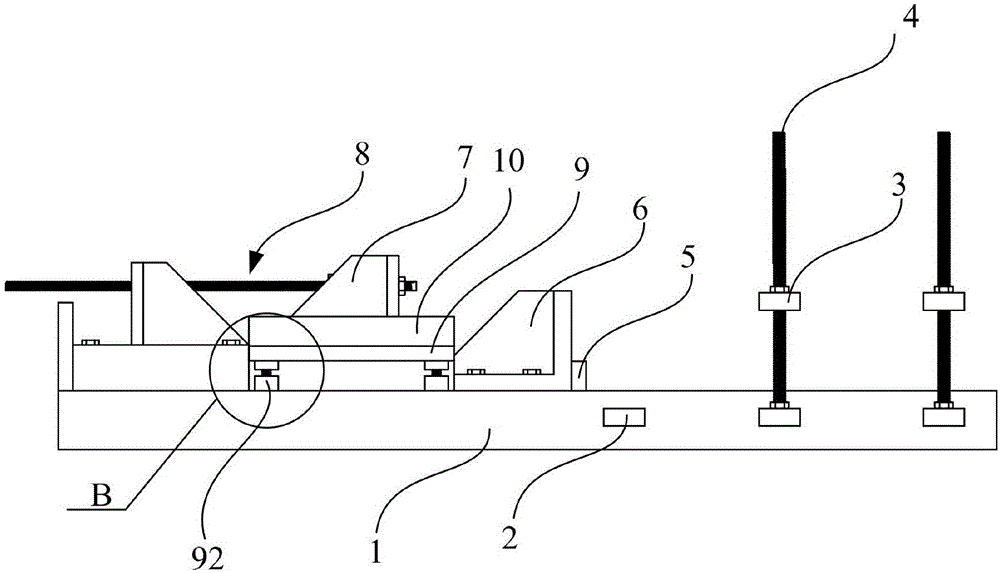

Accelerated corrosion test device and method for FRP reinforcement sea water and sea sand concrete members

ActiveCN105806769AAccelerated corrosionHighly integratedWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesButtressConcrete beams

The invention discloses an accelerated corrosion test device for FRP reinforcement sea water and sea sand concrete members. The accelerated corrosion test device comprises a tide environment simulating system, a loading system and an FRP rebar anchoring system. The tide environment simulating system comprises two water tanks, two water pumps are arranged between the water tanks, a water outlet of one water tank is communicated with a water inlet of the other water tank through one water pump, a water inlet of one water tank is communicated with a water outlet of the other water tank through the other water pump, and a heating rod and a wave making pump are further arranged in each water tank. The loading system comprises a set of support columns arranged in the water tanks, FRP reinforcement sea sand concrete beams are arranged on the support columns in an erected mode, levers are supported at the top of each FRP reinforcement sea sand concrete beam through a plurality of evenly-distributed buttresses respectively, one end of each lever is hinged to an FRP rebar which is anchored in the corresponding water tank through the FRP rebar anchoring mechanism, and the other end of each lever is connected with a load. The accelerated corrosion test device can simulate sea waves in the soaking process and simulate sea wind in the drying process, is high in integration level and practicality and can effectively test the long-term performance of the FRP reinforcement sea sand concrete beams after load / wetting-drying cycle accelerated corrosion.

Owner:SOUTHEAST UNIV

Measuring device and method for describing fracture toughness of FRP-concrete bond surface

ActiveCN109357937ASimple calculationAvoid influenceMaterial strength using tensile/compressive forcesCantilevered beamTip position

The invention discloses a measuring device and method for describing the fracture toughness of an FRP-concrete bond surface, comprising a fixing fixture, a test piece frame and a cantilever beam. In the invention, the FRP-concrete bond surface does not need preserved cracks, thereby avoiding the need for the measurement of the crack tip position in the test and the effects of the length of the preserved cracks and the tip shape on the test results. The height of the cantilever beam is along the axis of the cantilever beam, and linearly increases from the cantilever end to the trailing end. Thecross sections of the cantilever end and the trailing end are rectangular. The height of a single cantilever beam used in the invention increases linearly along the beam axis direction. During the fracture process, the flexibility of the single cantilever beam increases with the cracks, and the gradient change of the length is constant, which simplifies the calculation of the critical strain energy release rate of a type I fracture of the FRP-reinforced concrete.

Owner:NANJING HYDRAULIC RES INST

Bearing wall reinforcing body and method for reinforcing bearing wall by using same

InactiveCN102635246AIncrease stiffnessImprove seismic performanceBuilding repairsSize increaseEconomic benefits

The invention relates to a bearing wall reinforcing body and a method for reinforcing a bearing wall by using the same. The reinforcing body comprises a rigid mesh layer, and a fiber reinforced polymer layer (5) is arranged at one side of the rigid mesh layer. The method provided by the invention has the following advantages: the method is applicable to reinforcement on common brickwork bearing walls, organically combines the advantages of reinforcement of the fiber reinforced polymer FRP and reinforcement of a steel plate screen and reinforcement mesh, thus not only improving the whole property and collapse resistance capacity of brickwork walls, but also increasing the brickwork rigidity, improving the axial load bearing capacity and shearing-resistance bearing capacity of the brickwork, improving the anti-shock property of the brickwork, and being good in reinforcement effect; and the method not only is good in reinforcement effect and high in reliability, but also is simple to operate, convenient to construct, does not need special construction tools, needs small size increase of the brickwork, does not influence production, has high economic benefits and is especially applicable to large-scale maintenance and reinforcement on the bearing walls with brickwork structures.

Owner:WUHAN UNIV

Special adhesive for FRP-reinforced concrete

InactiveCN108546517AHigh bonding strengthPromote wettingMacromolecular adhesive additivesOrganic non-macromolecular adhesiveEpoxyAdhesive

The invention discloses a special adhesive for FRP-reinforced concrete, and belongs to the technical field of concrete structure repair. 5-8 parts by weight of phanerochaete chrysosporium, 1 to 2 parts by weight of a glucose solution and 20-30 parts by weight of deionized water are stirred and mixed at a constant temperature to obtain a phanerochaete chrysosporium bacteria solution; 60 to 80 partsby weight of epoxy resin, 20 to 30 parts by weight of acrylic acid, 8 to 10 parts by weight of a curing agent, 8 to 10 parts by weight of calcium hydrogencarbonate, 8 to 10 parts by weight of urea, 10 to 20 parts by weight of a modified sodium alginate liquid, 5-8 parts by weight of a silane coupling agent, 10-20 parts by weight of phospholipids, 10-20 parts by weight of the phanerochaete chrysosporium bacteria solution and 10-20 parts by weight of alkaline phenolic resin are placed in a mixing machine for mixing and stirring for 40-60min at the rotation speed of 500-800r / min to obtain the special adhesive for the FRP-reinforced concrete. The the special adhesive for the FRP-reinforced concrete has the characteristics of excellent shear resistance and flame retardant performance.

Owner:郦璋

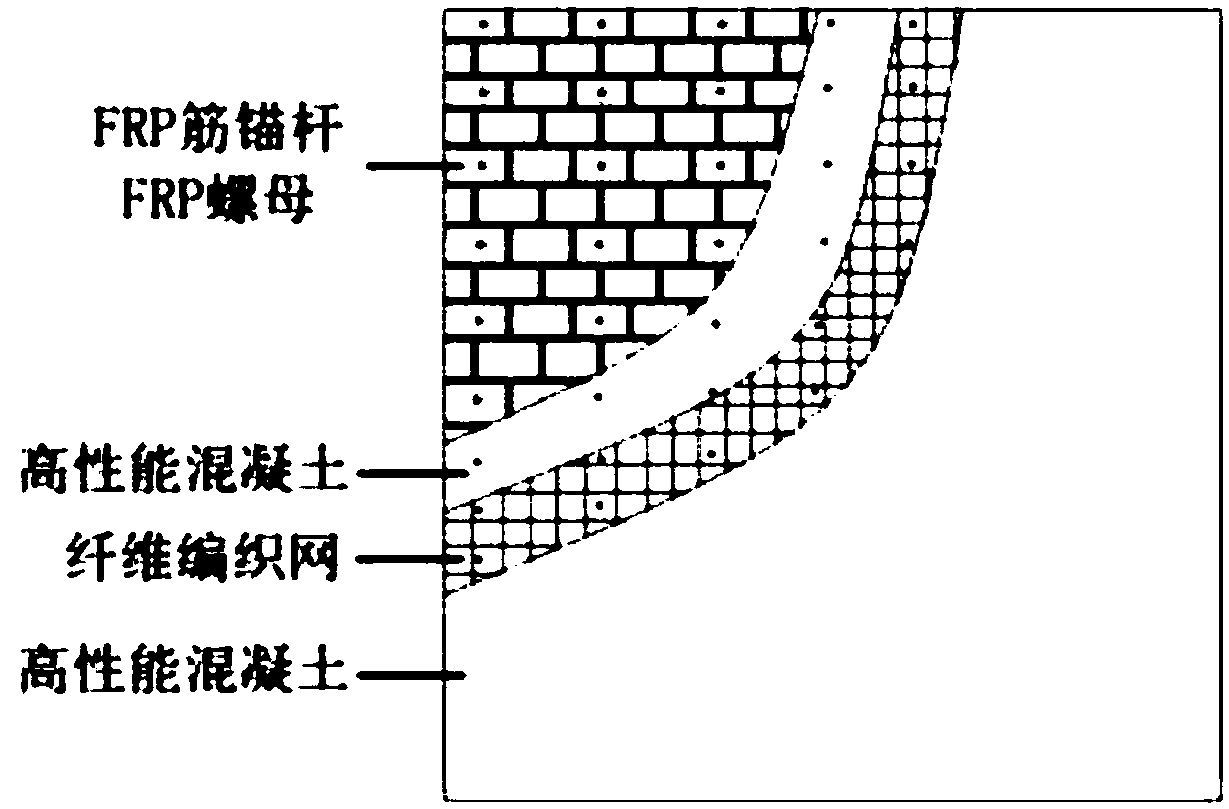

Reinforcement method of TRC for improving anti-seismic performance of multi-piece brick masonry wall

InactiveCN108532981AImprove seismic performanceImprove shear resistanceClimate change adaptationBuilding repairsFiberBrick masonry

The invention discloses a reinforcement method of TRC for improving an anti-seismic performance of multi-piece brick masonry wall, and belongs to the technical field of repair, reinforcement and construction of masonry walls. The reinforcement method comprises the steps that a plurality of penetrating circular holes are drilled in the wall to be reinforced, and fiber reinforced plastic (FRP) rib anchor rods are used for penetrating through the circular holes; the surface of the wall to be reinforced is coated with high-performance concrete, a fiber woven net is impregnated with epoxy resin, and the surface of the fiber woven net is coated with the high-performance concrete again; If one layer of fiber woven net can not meet the requirement of wall anti-seismic performance improvement, twoor more layers of fiber woven nets can be laid; and wet water curing is carried out until the high-performance concrete age is reached. According to the reinforcement method of TRC for improving the anti-seismic performance of the multi-piece brick masonry wall, in-plane shear resistance and out-of-plane bending resistance of the multi-piece brick masonry wall are improved, the risk of serious damage or even collapse of a masonry structure in earthquake is reduced, the inadaptability of a masonry material caused by the use of the epoxy resin in FRP reinforcement is avoided, deficiency of low reinforcement efficiency of engineered cementitious composite (ECC) reinforcement is effectively improved, and the integrity of multi-piece brick masonry wall is improved.

Owner:CHINA UNIV OF MINING & TECH

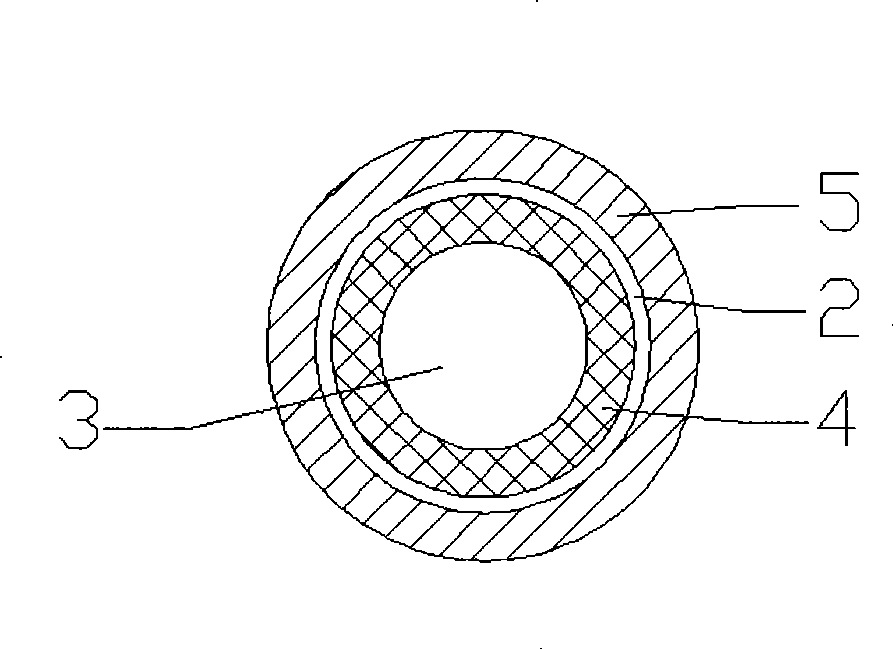

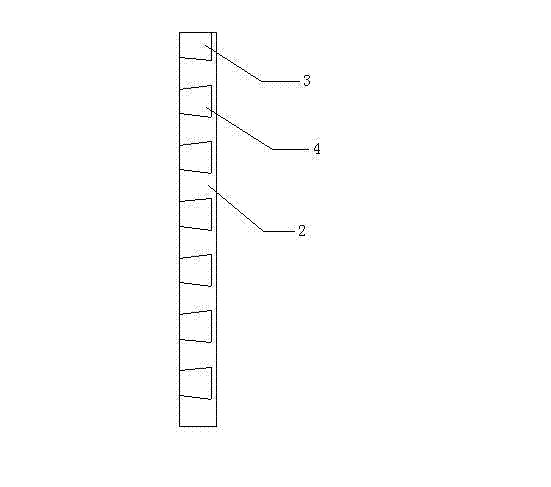

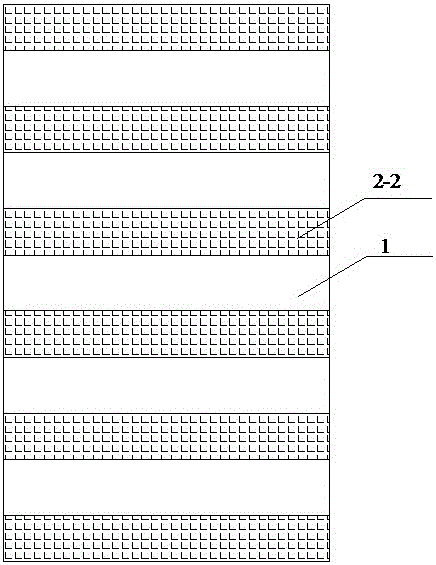

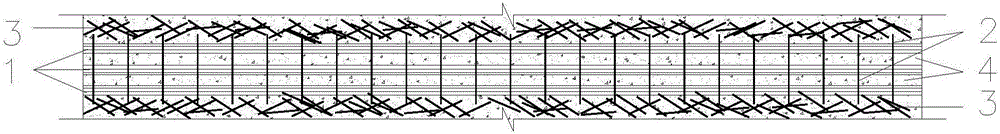

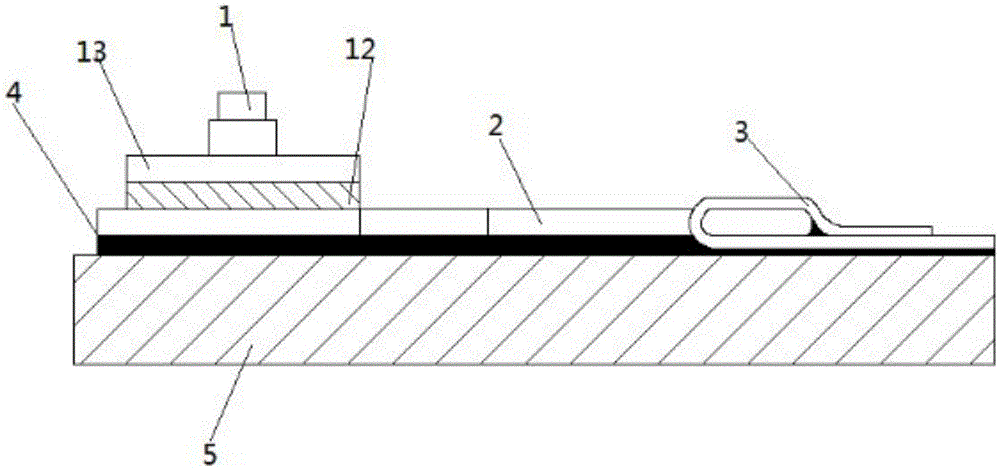

Textile reinforced cement matrix composite board for reinforcement of concrete flexural members and production method thereof

InactiveCN105781141AReduce crackingImprove ductilityBuilding repairsCeramic shaping apparatusFiberGlass fiber

The invention discloses a textile reinforced cement matrix composite board for reinforcement of concrete flexural members and a production method thereof. The textile reinforced cement matrix composite board comprises a prestressed textile (1), shearing chopped steel fibers (2), a steel fiber reinforced cement matrix (3) and an ordinary cement matrix (4), wherein the shearing chopped steel fibers (2) are vertically inserted into mesh holes of the prestressed textile (1), the steel fiber reinforced cement matrix (3) is poured on protective layers at the top and the bottom of the composite board, the ordinary cement matrix (4) is poured between layers of the prestressed textile (1), and the prestressed textile (1) is a carbon textile or glass textile. When the concrete flexural members are reinforced by the composite board, the problem that fiber materials are easy to peel off during reinforcement of external bonding of FRP is solved. The composite board has the advantages of slowing down cracks, improving ductility and giving full play to high-strength characteristics of fiber materials.

Owner:HUNAN UNIV

Quantification method for adhesive layer degeneration of FRP (Fiber Reinforce Plastic) reinforced steel structure based on antenna sensor

InactiveCN107085035ARealize self-aware intelligence featuresAchieve securityElectrical/magnetic solid deformation measurementMaterial magnetic variablesElastomerFiber

The invention relates to the field of FRP (Fiber Reinforce Plastic) reinforced steel structures and discloses a quantification method for adhesive layer degeneration of an FRP (Fiber Reinforce Plastic) reinforced steel structure based on an antenna sensor. The quantification method comprises the following steps: arranging a first rectangular micro-strip patch antenna sensor; sticking FRP into which a second rectangular micro-strip patch antenna sensor is embedded on a steel structure; calculating an initial strain ratio of two antenna sensors; obtaining strain at a middle point in a thickness direction according to a strain transferring equation when an adhesive layer is not degenerated; calculating a detection strain ratio of the two antenna sensors; calculating strain at the middle point in the thickness direction when the adhesive layer is degenerated; obtaining a function relation of damage variables according to a constitutive relation of an ideal adhesive layer elastomer; substituting the strain at the middle point in the thickness direction when the adhesive layer is degenerated into the damage variable function to calculate the damage variables. The device needed by the quantification method is simple, the construction is convenient, the cost is low, the practicability is high, and the method can be directly applied to practical engineering of the FRP reinforced steel structure.

Owner:WUHAN UNIV OF TECH

Single shear test device considering tensile bar bursting force

InactiveCN106840917AReduce experiment costMaterial strength using steady shearing forcesFiberConcrete beams

The invention discloses a single shear test device considering tensile bar bursting force. The single shear test device is characterized in that a fixed seat is arranged at one end of a bottom plate; a support screw rod is vertically connected with a fixing plate; the middle part of the top surface of the bottom plate is fixedly connected with a supporting seat; a support base plate is further arranged between the supporting seat and a test piece; the other end of the top surface of the bottom plate is provided with a fixture for clamping a test piece steel bar and an FRP (Fiber Reinforce Plastic) strip; the side face, which faces the test piece, of the fixture is provided with a first through hole through which the FRP strip passes; the upper part of the fixture is further provided with a clamping plate capable of clamping the FRP strip; a second through hole is formed below the first through hole; one end of a long screw rod passes through the second through hole; the other end of the long screw rod is connected with a jack, so that the fixture is under back pulling action force; a third through hole through which the steel bar passes is further formed below the second through hole; the side face, which faces away from the test piece, of the fixture is provided with a flange which is connected with the steel bar through the screw rod and covers the third through hole. By adopting the single shear test device, the bursting force of a tensile bar is considered, so that peeling at the plate end of an FRP reinforced steel bar concrete beam is simulated accurately. The single shear test device has the advantages of simple structure, reliability, convenience in use, low test cost and the like.

Owner:GUANGDONG UNIV OF TECH

Double-bar early warning device and ductility control method for prestressed FRP reinforcement structure

ActiveCN109235924ASimple structureThe construction process is clearBuilding repairsSelf lockingEngineering

The invention discloses a double-bar early warning device and ductility control method for a prestressed FRP reinforcement structure. The device comprises a fixing plate, an FRP strip, a self-lockingplate, an anchoring plate, a tensioning plate, tensioning screws, multiple nuts and expansion bolts. The two ends of the FRP strip are fixedly connected with the fixing plate and the self-locking plate respectively, the tensioning screws include the first tensioning screw and the second tensioning screw which are arranged in parallel, and large plastic deformation of the tensioning screws occurs when the structure is overloaded to achieve a safety early warning function of the structure; the tensioning screws penetrate through the self-locking plate, the anchoring plate and the tensioning plate, and the nuts are in threaded connection with the screws and are used for locking both sides of the self-locking plate, anchoring plate and tensioning plate separately; the expansion bolts are usedfor fixing the fixing plate, the self-locking plate and the anchoring plate to concrete, and long circular through holes in the self-locking plate are formed in parallel with the tensioning screws. Compared with the prior art, the device and the method have the advantages that not only are the ductility and rigidity of the components improved, but also the early warning function is achieved when the structure is overload, and the safety of the components is improved.

Owner:SHENZHEN UNIV

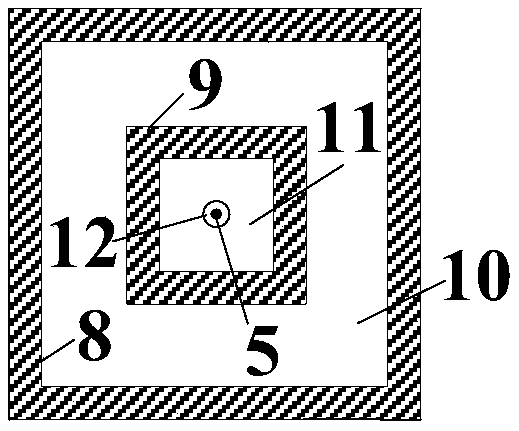

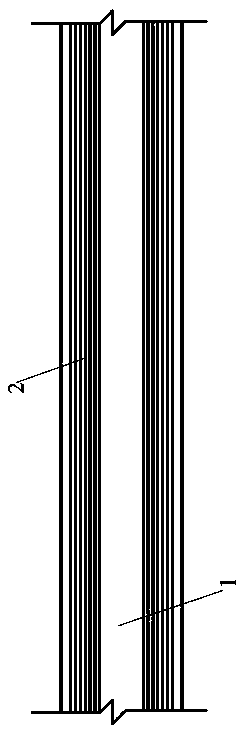

Fibre reinforced plastic (FRP) reinforcing rectangular column with corner reinforcement and construction method thereof

InactiveCN102777051AOvercoming the problem of reinforcement effect reductionTurn up Ultimate Deformation CapabilityStrutsBuilding repairsFiberFrp reinforcement

The invention discloses a fibre reinforced plastic (FRP) reinforcing rectangular column with corner reinforcement and a construction method of the FRP reinforcing rectangular column. The FRP reinforcing rectangular column is characterized in that an FRP reinforcing layer (2) of a rectangular column (1) is provided with a prefabricated chamfer (3) and corner reinforcement (4). The FRP reinforcing rectangular column has the advantages of small amount of FRP, high reinforcing efficiency, low reinforcing cost, high bearing capacity and ductility of the reinforcing column, high accuracy of FRP reinforcing construction, convenience in construction, etc.

Owner:HUNAN UNIV

Assembly type steel-wood buckling restrained brace with vertically embedded FRP reinforcement

InactiveCN104563320AOvercoming Tension DamageReduce energy consumptionShock proofingFiberBuckling-restrained brace

The invention discloses an assembly type steel-wood buckling restrained brace with vertically embedded FRP reinforcement, including a core material, a peripheral restraint, an unbonded material or an air layer, wherein the core material includes connecting sections, transition sections, a core work section, a stop clamp and a reinforcing plate, two ends of the core work section are connected with the connecting section by the transition sections, the stop clamp is arranged at the middle of the core work section, the transition sections are arc-shaped, connection bolt holes are formed in the connecting sections, the peripheral restraint includes two pieces of core material up-down laminated wood and two pieces of core material dual-side laminated wood, the two pieces of core material up-down laminated wood are transverse in wood grain direction and the two pieces of core material dual-side laminated wood are transverse in wood grain direction, and a vertically embedded carbon fiber plate is arranged between the core material up-down laminated wood and the core material dual-side laminated wood. The assembly type steel-wood buckling restrained brace with vertically embedded FRP reinforcement can be used in earthquake regions, and is convenient to repair after the earthquake and reduce earthquake damages. The assembly type steel-wood buckling restrained brace with vertically embedded FRP reinforcement has wide application prospect in middle-high wood structure buildings.

Owner:NANJING UNIV OF TECH

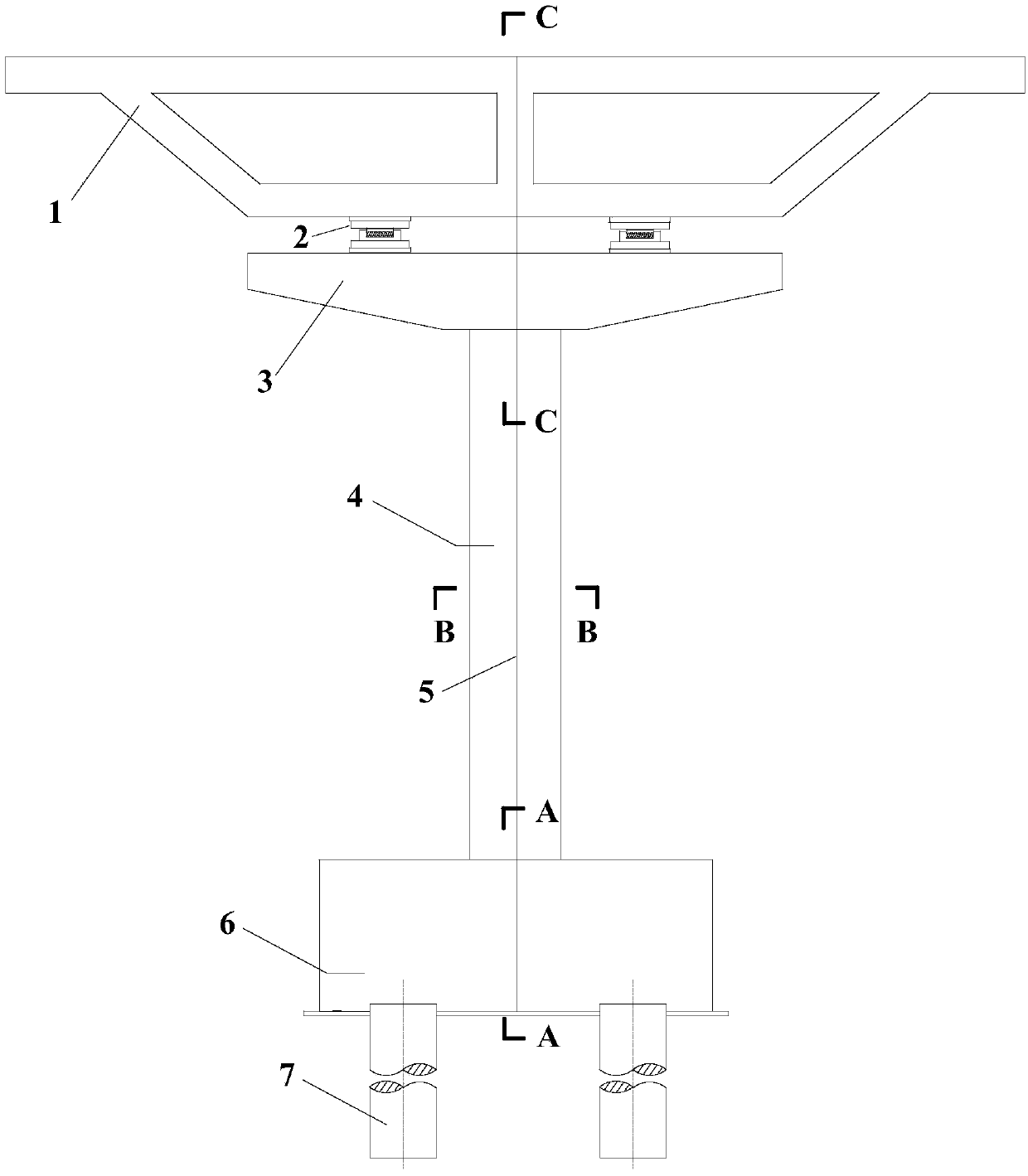

Energy-dissipation self-resetting double-layer rectangular hollow concrete-filled steel tube swing pier structure system

ActiveCN108677690ARemarkable effect of shock absorption and isolationPrevent premature yieldBridge structural detailsBridge materialsFiberBridge engineering

The invention discloses an energy-dissipation self-resetting double-layer rectangular hollow concrete-filled steel tube swing pier structure system, and belongs to the field of bridge engineering. Theswing pier structure system is mainly composed of main beams, supporting seats, a coping, a double-layer rectangular hollow concrete-filled steel tube pier, a bearing platform, a non-bonded prestressed fiber reinforced polymer (FRP) reinforcement with a self-resetting function and anti-buckling dog-bone-shaped metal dampers. The double-layer rectangular hollow concrete-filled steel tube pier andthe coping are cast in place to form a whole to be placed on the bearing platform, and are connected with the bearing platform through non-bonded prestressed FRP reinforcement and the anti-buckling dog-bone-shaped metal dampers so as to play the role of self-resetting and dissipate seismic energy. The designed swing pier structure system is clear in mechanical mechanism, on the premise of ensuringsufficient strength and stiffness of the structure system, the seismic action borne by the structure can be reduced by local lift-off of the pier on the bearing platform, the effective energy dissipation capacity and self-resetting capacity are provided, and the problems of serious damage and large residual deformation of a traditional cast-in-situ pier after an earthquake action can be solved.

Owner:BEIJING UNIV OF TECH

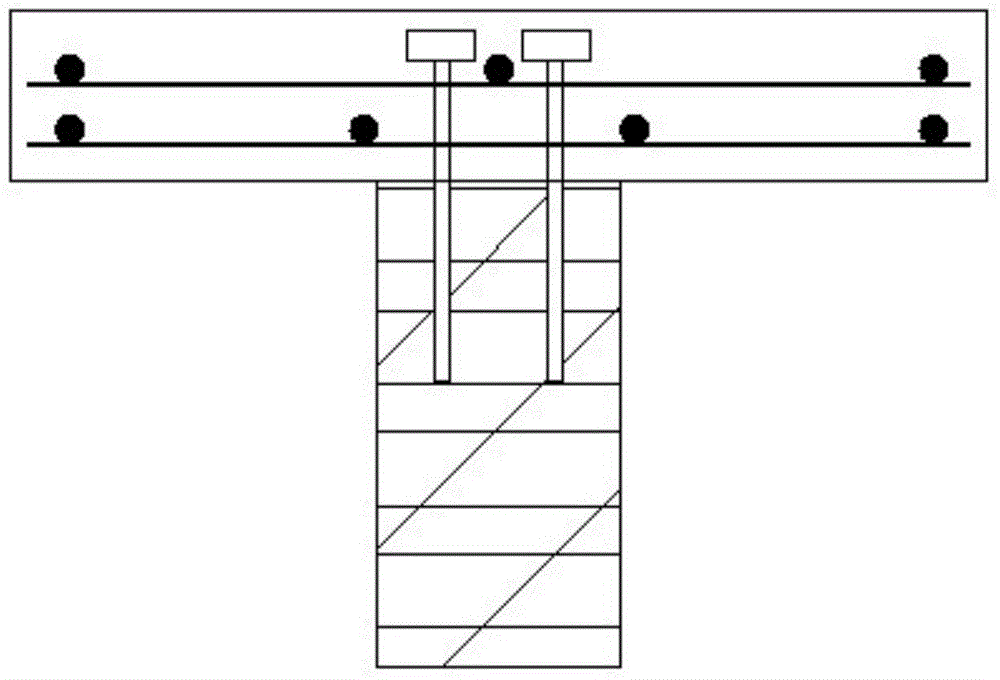

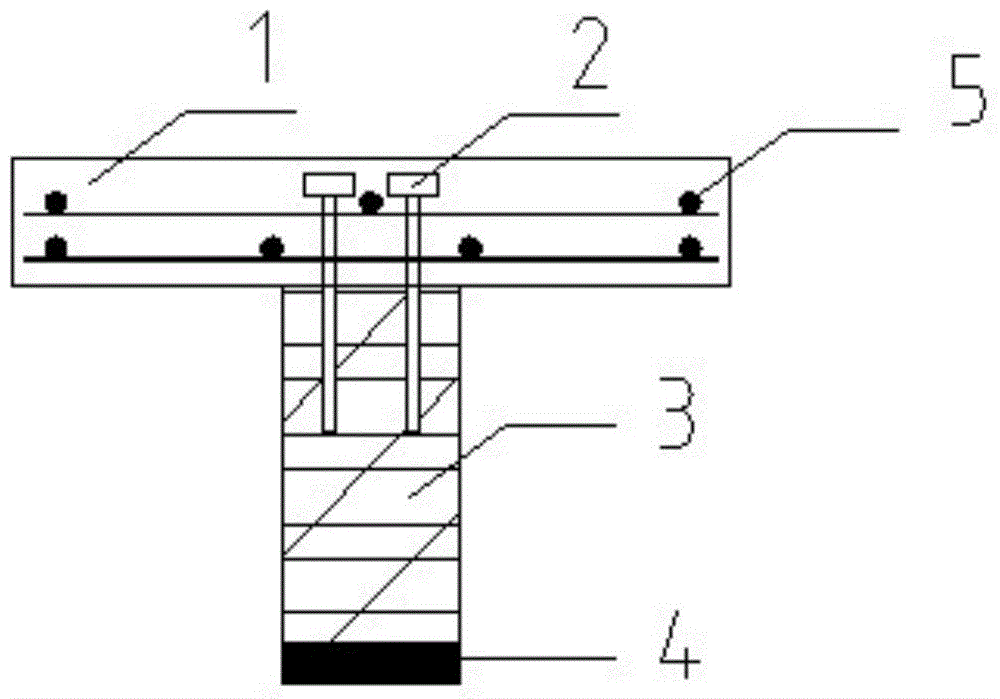

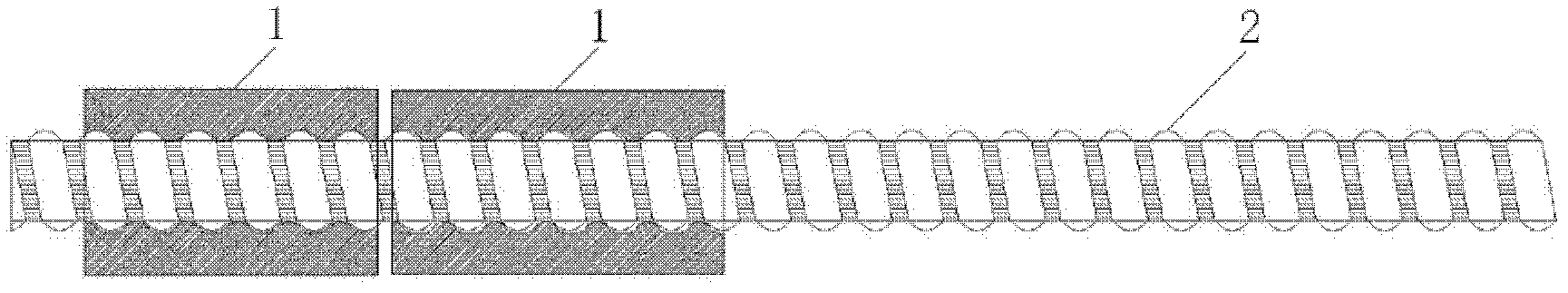

Cable tunnel shaft enclosure structure and shield machine cutting construction method thereof

InactiveCN101725354AImprove construction progressReduce wearTunnelsShaft liningRebarFrp reinforcement

The invention discloses a cable tunnel shaft enclosure structure, which is provided with a reinforcement structure formed by connecting an upper reinforcement cage, a middle FRP reinforcement cage and a lower reinforcement cage. At the same time, the invention discloses a shield machine cutting construction method for the cable tunnel shaft enclosure structure. The construction method comprises the following steps: lifting, lapping and binding the upper reinforcement cage, the middle FRP reinforcement cage and the lower reinforcement cage; casting concrete to form the cable tunnel shaft enclosure structure; and cutting the cable tunnel shaft enclosure structure when a shield machine advances to the FRP reinforcement cage and a cutter head of the shield machine is replaced by a hob, a toothed cutter or a scraper. By means of the enclosure structure and the construction method, the construction progress of a cable tunnel is sped up, and the abrasion on cutters of the shield machine is reduced to a certain extent, so the enclosure structure and the construction method are suitable to be popularized in enclosure structures at the inlet and the outlet of a cable tunnel shaft for the shield machine.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +3

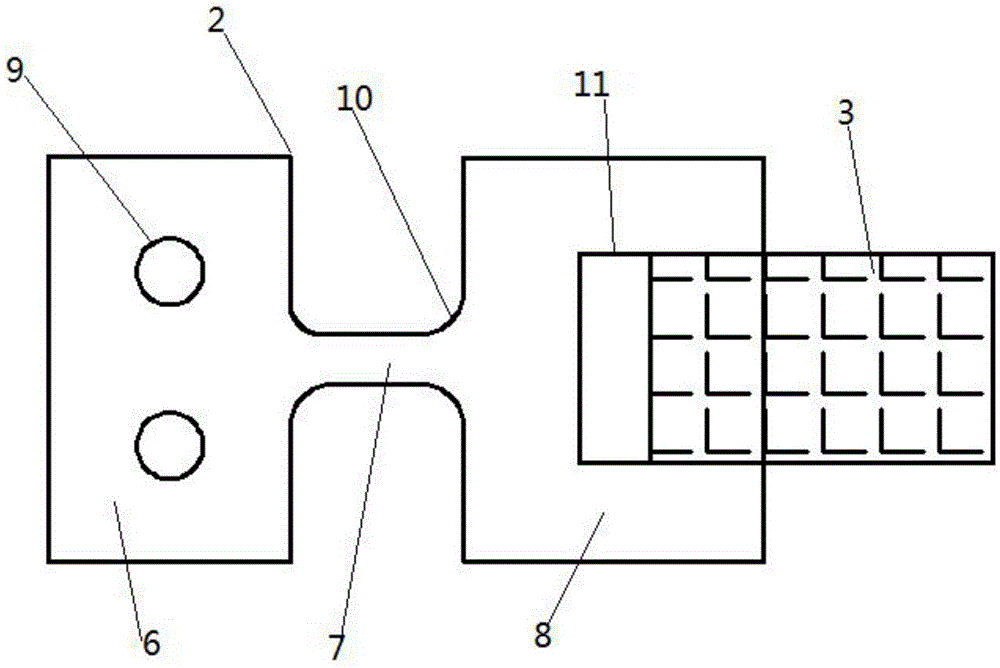

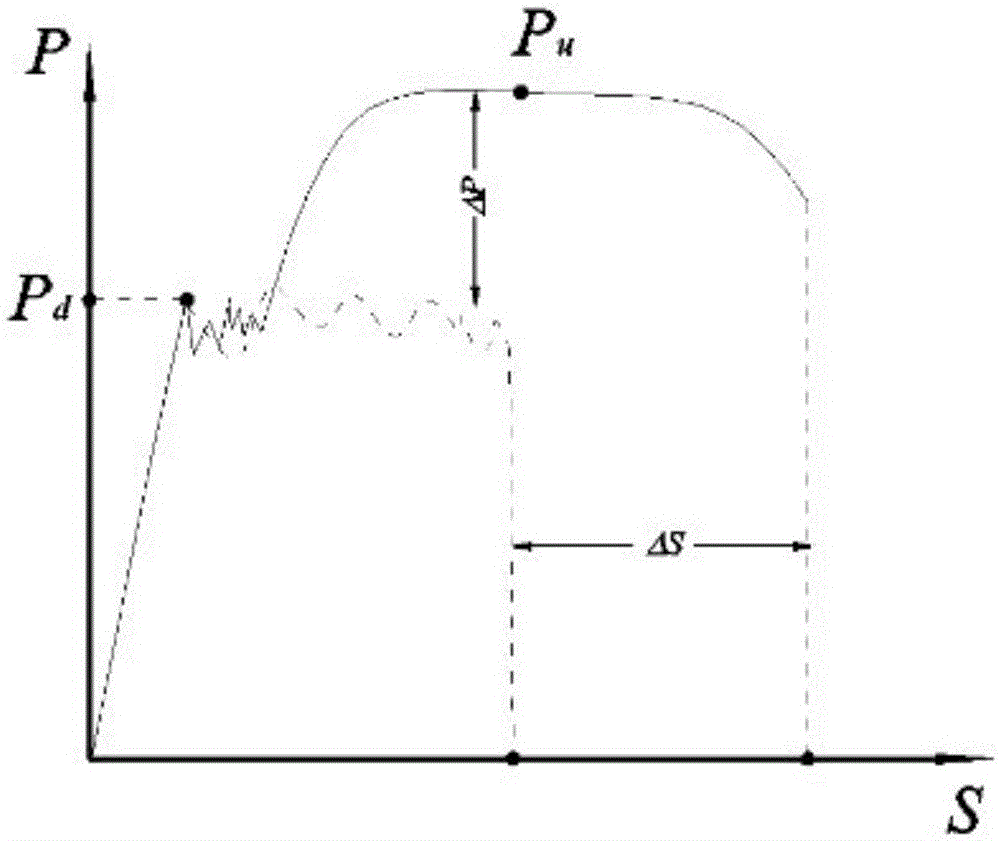

Method and device for improving ductility of FRP (fiber reinforced plastic) strengthened structure and increasing FRP utilization rate

ActiveCN105525767AIncrease profitPrevent peelingBuilding repairsBuilding reinforcementsFiberEngineering

The invention discloses a method and a device for improving the ductility of an FRP (fiber reinforced plastic) strengthened structure and increasing an FRP utilization rate. The device is characterized in that the FRP strengthened structure comprises end anchor devices, an FRP sheet, expansion bolts and a binder, wherein each end anchor device is processed from a low-carbon steel plate, an anchor section, a deformation section and a connection section are arranged on the end anchor device, the width of the deformation section is variable, and the ultimate strength of the deformation section is lower than that of the FRP sheet. The method comprises the following steps: two pre-punched holes are formed in a strengthening area of to-be-strengthened concrete; the binder is applied to the strengthening area of the to-be-strengthened concrete; the end anchor devices and the FRP sheet are adhered to the binder; the expansion bolts penetrate round holes in the end anchor devices and are pressed into the pre-punched holes. By means of the end anchor devices, the ductility of the FRP strengthened structure is improved, the FRP utilization rate is increased, and the conventional problem of brittle failures is solved.

Owner:SHENZHEN UNIV

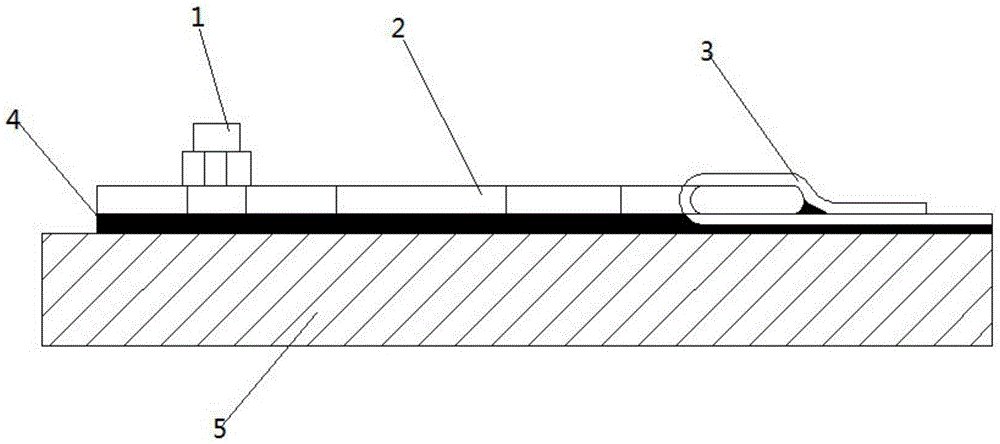

Single-bar early warning device and ductility control method for prestressed FRP reinforcement structure

ActiveCN109235923ASimple structureThe construction process is clearBuilding repairsSelf lockingEngineering

The invention discloses a single-bar early warning device and ductility control method for a prestressed FRP reinforcement structure. The device comprises a fixing plate, an FRP strip, a self-lockingplate, an anchoring plate, a tensioning screw with an early warning function, multiple nuts and expansion bolts. The fixing plate and the anchoring plate are located on both sides of the self-lockingplate, the two ends of the FRP strip are fixedly connected with the fixing plate and the self-locking plate respectively, the tensioning screw penetrates through the self-locking plate and the anchoring plate, and large plastic deformation of the tensioning screw occurs when the structure is overloaded to achieve a safety early warning function of the structure; the nuts are in threaded connectionwith the tensioning screw and are used for locking both sides of the self-locking plate and locking both sides of the anchoring plate, the expansion bolts are used for fixing the fixing plate, the self-locking plate and the anchoring plate to concrete, and long circular through holes in the self-locking plate are used for mounting the expansion bolts and formed in parallel with the tensioning screw. Compared with the prior art, the device and the method have the advantages that not only are the ductility and rigidity of the components improved, but also the early warning function is achievedwhen the structure is overload, and the safety of the components is improved.

Owner:SHENZHEN UNIV

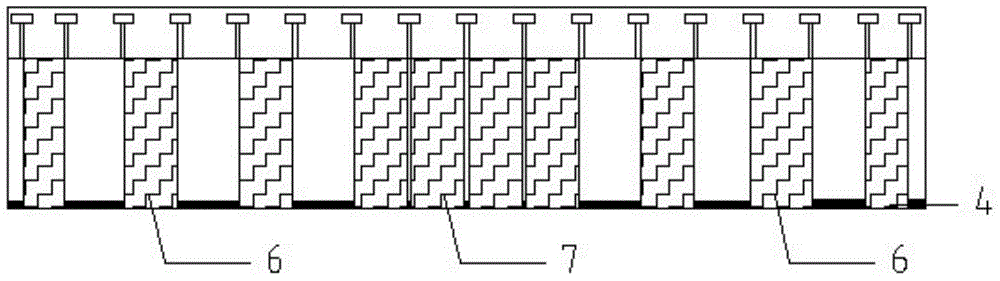

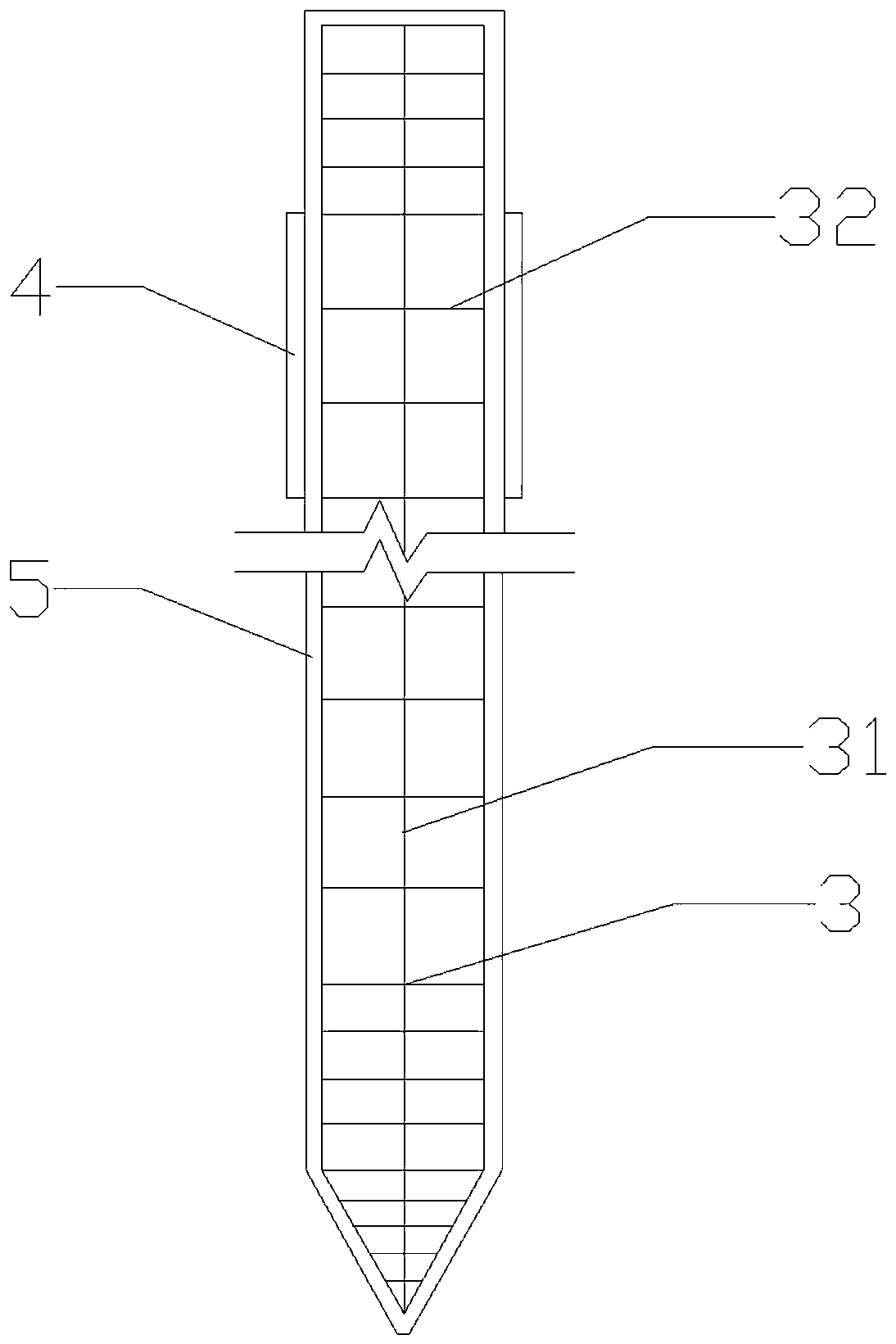

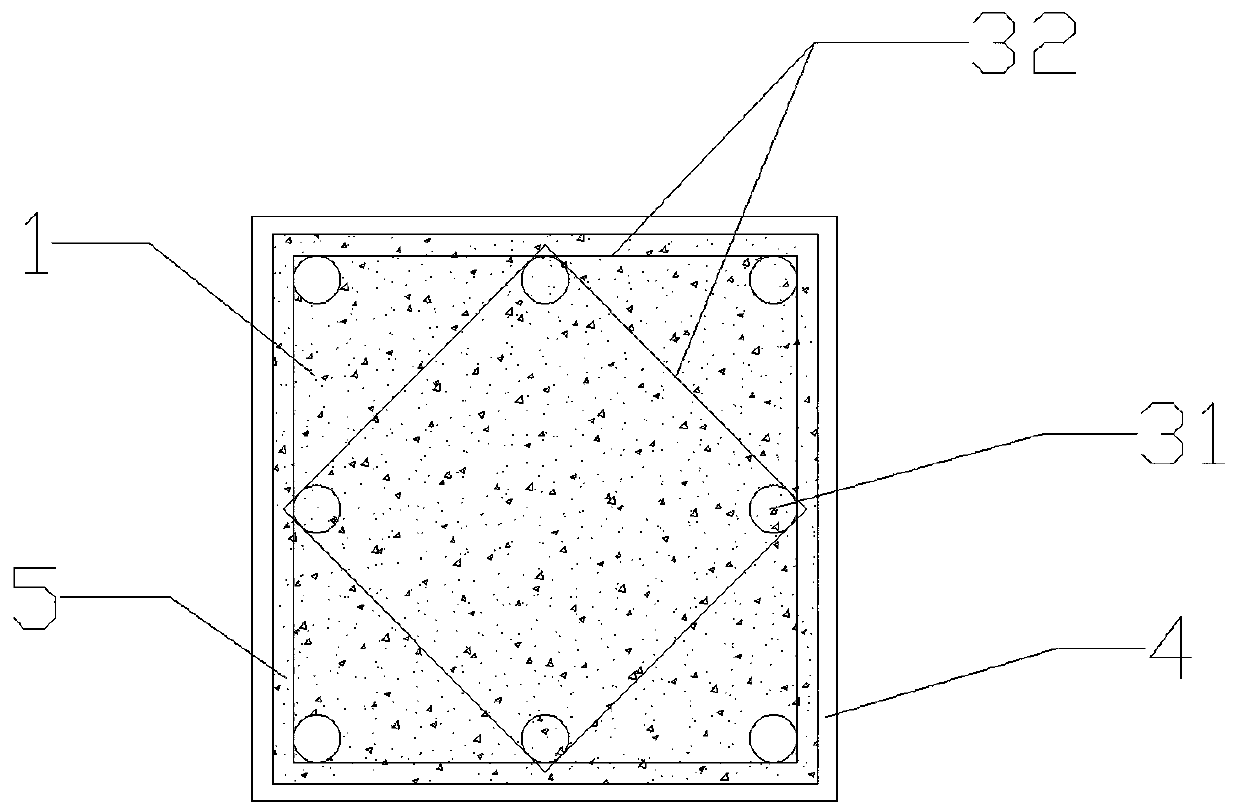

Fiber composite pile for marine environment and preparation method of fiber composite pile

PendingCN107905215AProtects against freeze-thaw cycle damageGood corrosion resistanceCeramic shaping apparatusBulkheads/pilesDuctilityEngineering

The invention relates to a pile foundation structure in oceanographic engineering, in particular to a fiber composite pile for the marine environment and a preparation method of the fiber composite pile. The composite pile comprises a pile body and a pile tip, and an FRP reinforcement cage is arranged in the composite pile and comprises a pile body FRP reinforcement cage and a pile tip FRP reinforcement cage. Two layers of FRP cloth are bonded on a flashing area, and the FRP cloth and the longitudinal axis of the pile body form an angle ranges from 0 degree to 90 degrees. The invention furtherprovides a fiber composite pile preparation method for the marine environment. The method comprises the steps that firstly, a fiber composite pile formwork is manufactured, and the FRP reinforcementcage is strapped; then concrete pouring and maintaining are carried out; the flashing area is ground and coated with bottom layer resin, leveling is carried out, and saturating resin smearing is carried out; and the FRP cloth is coated with bonding resin, and finally the FRP cloth is pasted. The fiber composite pile has the beneficial effects of being good in malleability, high in durable performance, low in self weight and the like, and can be applied to bridges and port engineering.

Owner:HENAN UNIVERSITY

FRP reinforcement concrete component direct tensile test device and use method

PendingCN110702516AEvenly spacedMaterial strength using tensile/compressive forcesArchitectural engineeringActuator

The invention discloses a FRP reinforcement concrete component direct tensile test device and use method. The test device comprises a FRP reinforcement concrete component and a fixed cabinet; the FRPreinforcement concrete component comprises a FRP reinforcement, a concrete part, a front-end steel tube, a rear-end steel tube, a patch, a light steel wire, a front-end clamp, a rear-end clamp, a first LVDT displacement sensor, a second LVDT displacement sensor, and a third LVDT displacement sensor; the fixed cabinet comprises a horizontal pedestal and a reaction wall; a test piece bearing bracketis arranged on an upper end part of the horizontal pedestal, and a roller module is arranged on a bracket placing surface of the test piece bearing bracket; an actuator is arranged at a front end side of the test piece bearing bracket, and a front-end clamping piece anchor is arranged at a rear-end hinge seat of a loading end of the actuator; and a rear-end clamping piece anchor is arranged at the reaction support seat of the rear-end side of the test piece bearing bracket. The test device disclosed by the invention can effectively perform direct tensile test on the FRP reinforcement concretecomponent. The test device disclosed by the invention can be effectively used in the use method.

Owner:DONGGUAN UNIV OF TECH

Method and device for controlling ductility of FRP reinforcing structure

The invention discloses a method and device for controlling the ductility of an FRP reinforcing structure. The FRP reinforcing structure comprises an end anchoring device, an FRP sheet, a friction piece, a rigid cover plate, an expansion bolt and an adhesion agent. The end anchoring device is formed by machining a low-carbon steel plate and provided with an anchoring segment, a deformation segment and a connecting segment. Two long round holes are formed in the anchoring segment. The rigid cover plate and the friction piece are both provided with two round holes. The round holes coincide with the first ends of the long round holes. The shortest distance from the round holes to the second ends of the long round holes is S. The width of the deformation segment is variable. The expansion bolt sequentially penetrates the two round holes of the rigid cover plate, the two round holes of the friction piece and the long round holes of the anchoring segment and is anchored into a structure to be reinforced; friction force is generated between the end anchoring device and the friction piece. Because the device is provided with a friction sliding segment S, and the ductility of the FRP reinforcing structure is controllable.

Owner:SHENZHEN UNIV

Shape memory alloy prestressed U-stirrup-FRP reinforced concrete beam and construction technology thereof

The invention relates to a shape memory alloy prestressed U-stirrup-FRP reinforced concrete beam and a construction technology thereof. The shape memory alloy prestressed U-stirrup-FRP reinforced concrete beam comprises to-be-reinforced concrete beam, externally bonded FRP, a shape memory alloy prestressed U-stirrup and externally applied sealing mortar. The to-be-reinforced concrete beam is a common concrete beam. The externally bonded FRP is cloth or a board and is fixed to the outer portion of the concrete beam by means of side adhesion or U-shaped adhesion, or the bottom of the externallybonded FRP adheres to the beam in the longitudinal direction of the beam. The mortar is polymer mortar and applied to the outside of the prestressed U-stirrup in a sealing manner. The invention also discloses the construction technology of the shape memory alloy prestressed U-stirrup-FRP reinforced concrete beam. Due to the annular tightening action of the shape memory alloy prestressed U-stirrupand reinforcement of the sealing mortar, fiber stripping during traditional FRP reinforcement is effectively avoided, the utilization ratio of the FRP is improved, and then the shear resistance and bending resistance of the beam are improved; and in this way, the bearing capacity of the beam is improved. The sealing applied mortar further can effectively prevent the shape memory alloy prestressedU-stirrup from being corroded.

Owner:YANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com