Accelerated corrosion test device and method for FRP reinforcement sea water and sea sand concrete members

An accelerated corrosion test, concrete technology, applied in the direction of measuring device, weather resistance/light resistance/corrosion resistance, using stable tension/pressure test material strength, etc., can solve the problem of high price, limited test piece size, dry and wet cycle box Unable to accommodate and other problems, to achieve the effect of high integration and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

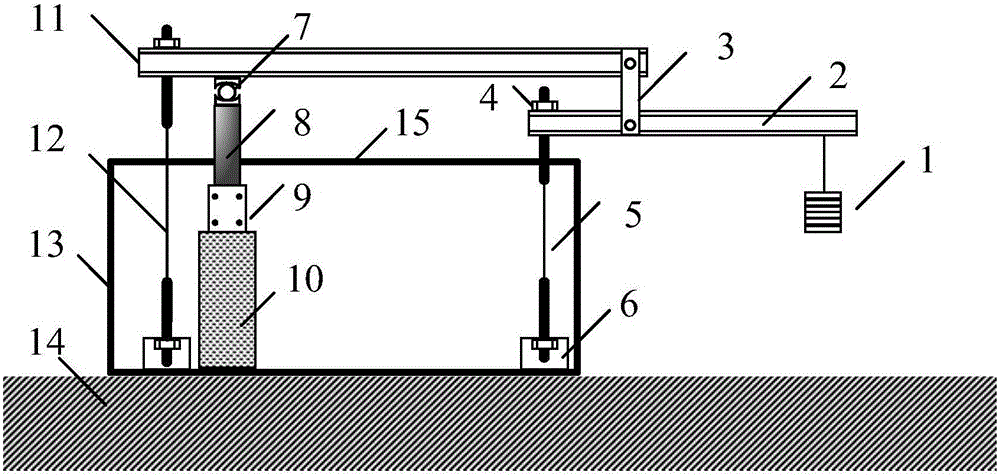

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

[0032] Such as figure 1 , figure 2 A kind of accelerated corrosion test device of FRP reinforced seawater sea sand concrete member shown, comprises tidal environment simulation system, loading system and FRP bar anchor mechanism; tidal environment simulation system includes two pools 13, and two pools 13 are arranged between Water pumps 26, 27, each water pump connects the water outlet 16 of one pool with the water inlet 17 of another pool respectively, heating rods 21, 23, wave-making pumps 22, 24 are also arranged in each pool 13; Heat preservation cover 15, heat preservation cover 15 is provided with fans 20,25 and air outlet 19, fans 20,25 are connected with time control switch, loading system includes a group of support columns 10 arranged in the pool, between the support columns 10 The frame is provided with FRP-reinforced sea-sand sea-sand concrete beams 9, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com