FRP reinforcement tension test apparatus and test method

A tensile test and universal testing machine technology, applied in measuring devices, using stable tension/pressure testing materials, instruments, etc., can solve the problems of FRP tendon damage and complex production methods, and reduce pollution and leakage. Slurry phenomenon, the effect of convenient test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

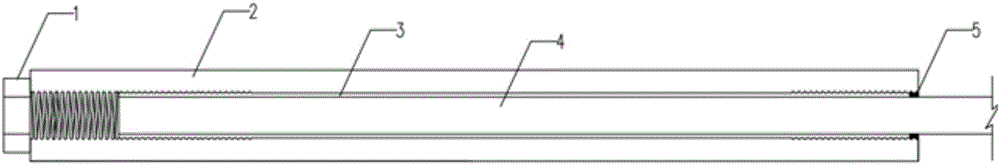

[0033] Such as figure 1 As shown, the FRP tendon tensile test device of the present invention includes FRP tendons 4, two identical anchors and two identical clamps 6, and the anchors include octagonal bolts 1, steel pipes 2, epoxy resin- Curing agent 3 and steel ring gasket 5.

[0034] Such as figure 2 As shown, the inner diameter of the steel pipe 2 is greater than the outer diameter of the FRP tendon 4, to ensure that the FRP tendon 4 can be placed in the steel pipe 2, and epoxy resin-curing agent 3 can be filled in the middle of the two. There are internal threads with equal lengths, the length of the internal threads is greater than the length of the octagonal bolt 1, and the design of the internal threads enables the epoxy resin-curing agent 3 and the FRP rib 4 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com