Device and method for simultaneously testing constant-temperature stress corrosion of multiple FRP (Fiber Reinforced Polymer) reinforcements

A stress corrosion and test device technology, which is used in measurement devices, weather resistance/light resistance/corrosion resistance, and wear resistance testing. The lack of devices, etc., achieves the effect of outstanding technical effect, simple test process and simple stress application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

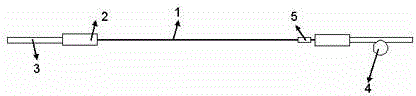

[0032] Such as Figures 1 to 4 As shown, a test device for simultaneous constant temperature stress corrosion of multiple FRP tendons, which includes a reaction force frame 9, is located in the reaction force frame 9, and is connected with a soaking box 8 of a temperature controller 14 and a stress test piece. The left and right side plates of the soaking box 8 are correspondingly provided with a number of piercing holes 10, and the left and right side plates of the soaking box 8 are vertically provided with a card slot above the piercing hole 10, and the card slot is sealed and connected with a card plate 17. The top surface of the soaking tank 8 is provided with a sliding door 15 that can move horizontally; the stress test piece includes a plurality of FRP tendons 1, bonded sleeve anchors 2 and worms 3, and the two ends of each FRP tendon 1 are respectively Connect a bonded sleeve anchorage 2 and a worm 3 in sequence, one of the worm 3 is connected with a worm gear 4, the FR...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com