FRP reinforcement concrete component direct tensile test device and use method

A tensile test, concrete technology, applied in the direction of measuring device, using stable tension/compression to test material strength, analyzing material, etc., can solve the problem of not reaching consensus in analysis, underestimating the deflection of FRP reinforced concrete members, unable to strengthen the reinforcement Experimental Research on Tensile Stiffening Properties of Concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be described below in conjunction with specific embodiments.

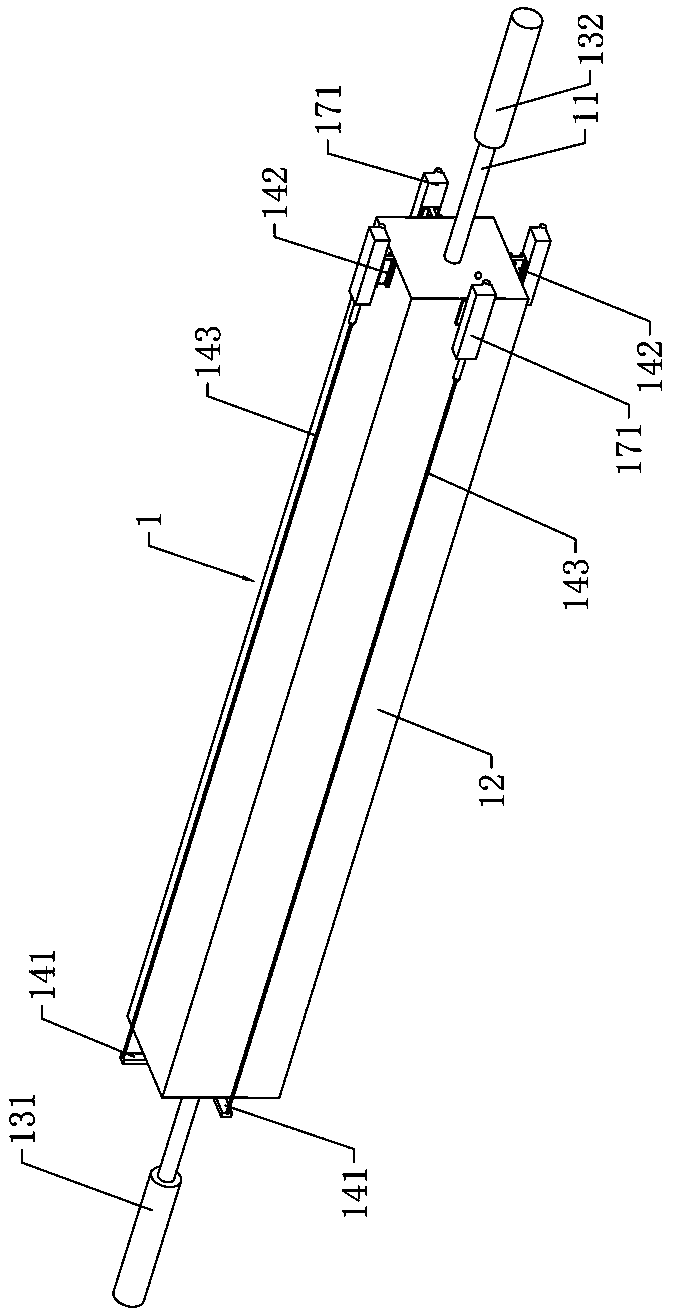

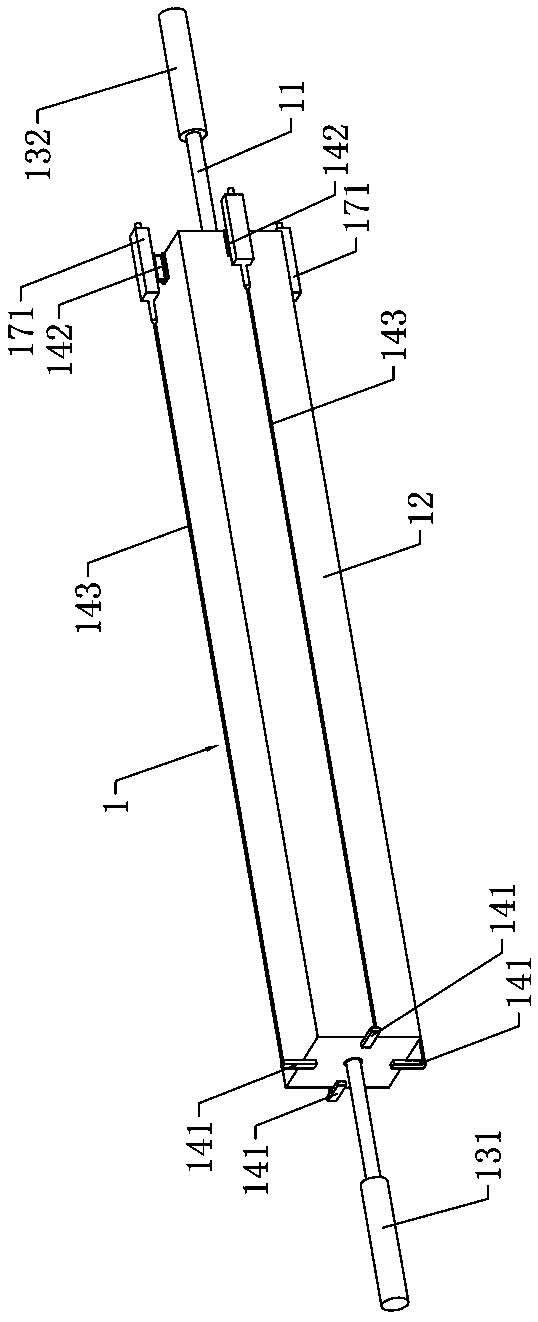

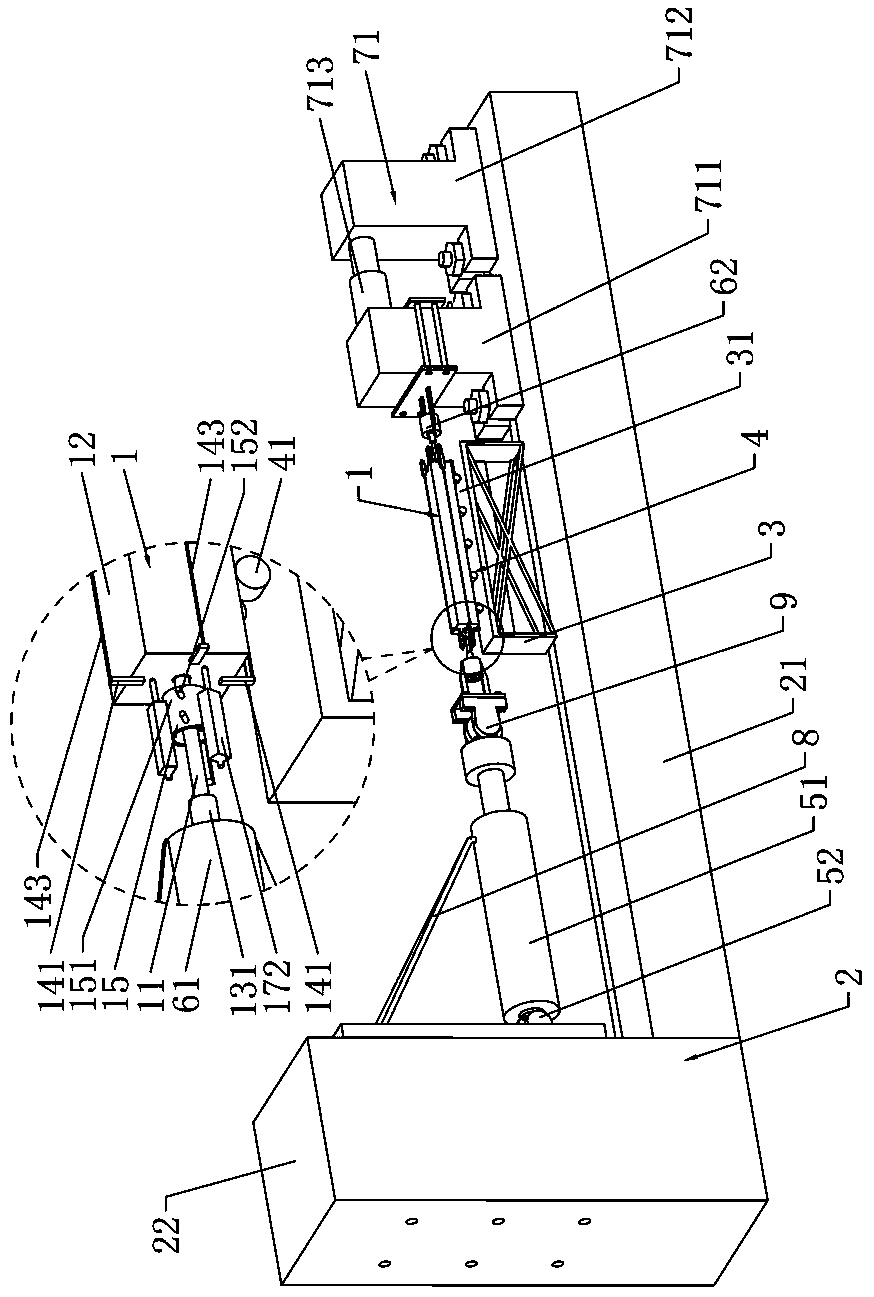

[0065] like Figure 1 to Figure 5 Shown, a kind of FRP reinforced concrete component direct tensile test device, it comprises FRP reinforced concrete component 1, and FRP reinforced concrete component 1 comprises FRP reinforced material 11, is poured in FRP reinforced material 11 periphery by concrete and with The FRP bar 11 forms a concrete part 12 of an integral structure, the FRP bar 11 is located at the core of the concrete part 12 and the FRP bar 11 extends along the length direction of the concrete part 12, and the front end of the FRP bar 11 extends forward to the concrete On the front end side of the front end of the part 12, the rear end of the FRP reinforcement 11 extends backward to the rear end of the rear end of the concrete part 12; the front end of the FRP reinforcement 11 is surrounded by a front steel pipe 131, and the inner wall of the front steel pipe 131 and An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com