FRP reinforcement material end nut and manufacturing method and application thereof

A manufacturing method and nut technology, which is applied in the direction of building structure, structural elements, building components, etc., can solve the problems of no nut installation, no patent technology of FRP bar end elbow, etc., to achieve easy operation and reduce loss , Reduce the effect of the work site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0038] 1. The structure of FRP bar end nut 1

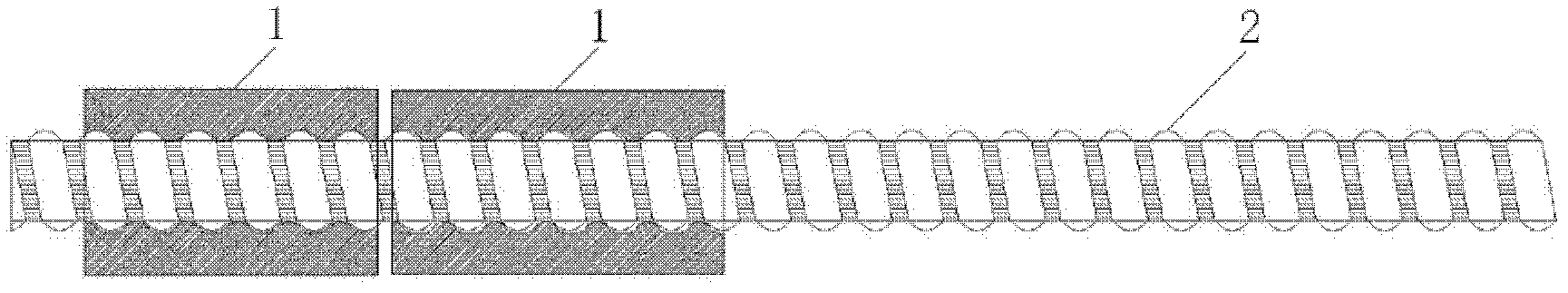

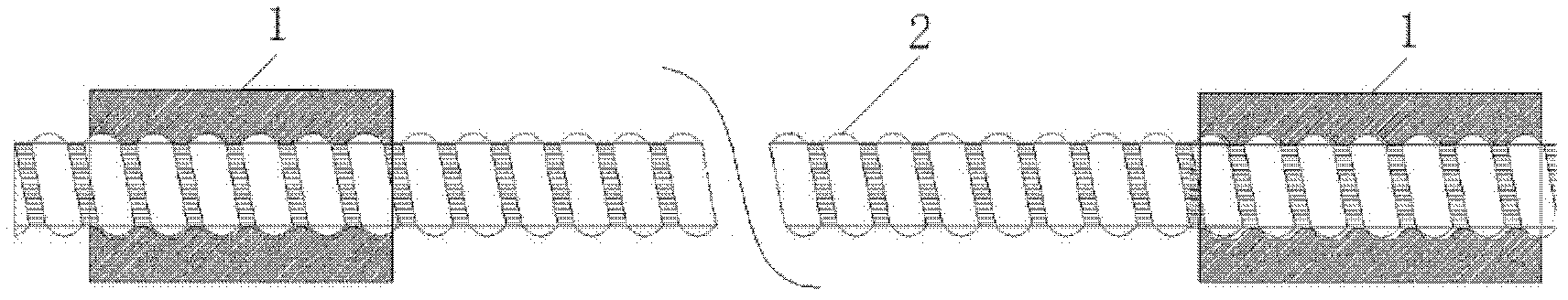

[0039] like figure 1 , the inner wall of the FRP bar end nut 1 is a structure adapted to the outer diameter of the FRP threaded bar 2;

[0040] The outer edge of the cross-section of the FRP bar end nut 1 is circular or polygonal, and the shape is a cylinder, a truncated cone, a prism or a truncated prism.

[0041] The outer edge of the cross section of the FRP bar end nut 1 is preferably a regular hexagon.

[0042] 2. Manufacturing method of FRP bar end nut

[0043] 1. In step ①

[0044] By weight percentage, the best is: chopped fiber 50%, resin glue 50%.

[0045] The chopped fibers are glass fibers, basalt fibers or carbon fibers, the length of which is 0.5-10mm, and the optimum value is 7mm;

[0046] The resin glue is a commonly used chemical product.

[0047] Specifically, the resin glue is a mixture of resin, curing agent, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com