Test piece end reinforcing method in test for FRP rib/anchor rod tensile property

A technology of tensile properties and anchor rods, which is applied in the direction of applying stable tension/pressure to test the strength of materials, and can solve problems such as difficult to measure the strength of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

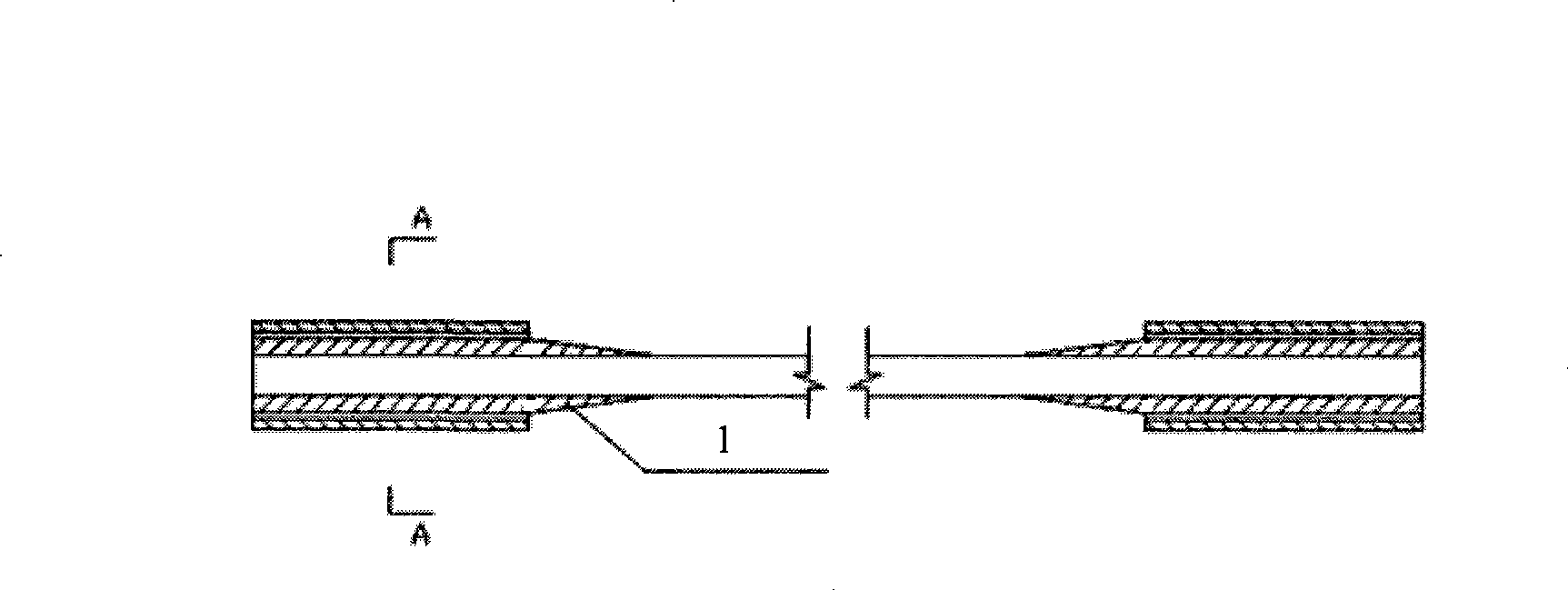

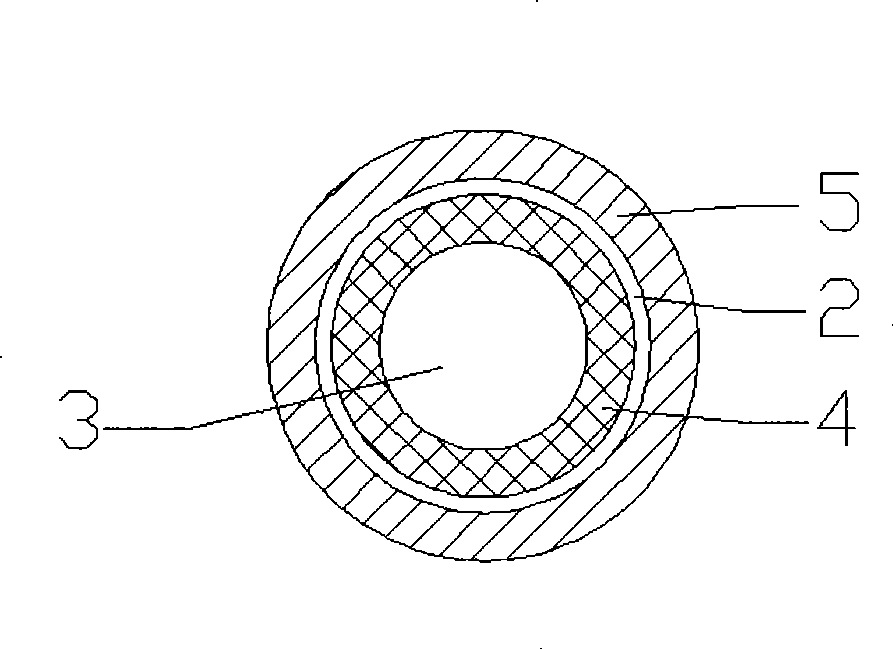

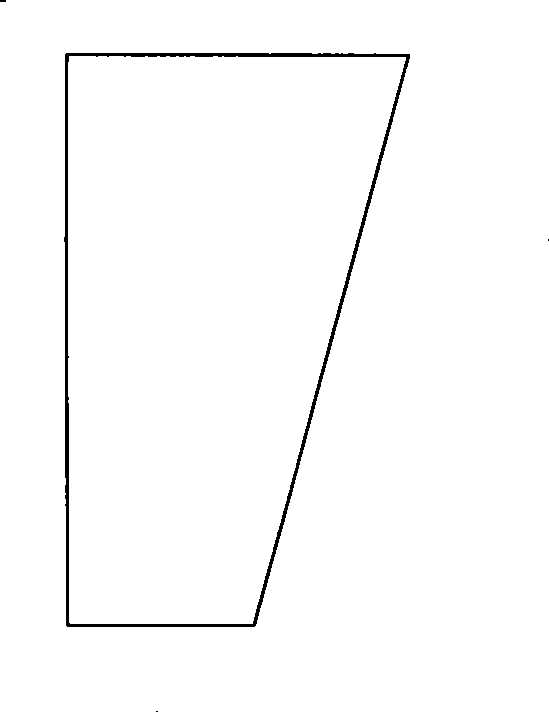

[0022] The method for strengthening the end of the test piece in the FRP tendon / bolt 3 tensile performance test of the present invention includes: (1) there is a section of gradient transition section 1 at the end reinforcement section of the test piece, avoiding the initial position of the reinforcement section Stress concentration caused by obvious cross-section changes; (2) Gradient transition section 1 is realized by: through the FRP tendon / bolt 3 specimen to be processed (the FRP tendon with sufficient length without end reinforcement material / bolt 3) the ends are wound with fiber cloth 4 (which can be glass fiber, carbon fiber, aramid fiber, basalt fiber cloth, etc.); (3) when the gradient transition section 1 is realized by winding fiber cloth 4, the / Nominal outer diameter of the anchor rod 3, inner diameter of the outer steel sleeve 5, determine the length of the transition section 1 and the size of the fiber cloth 4; (5) When winding the fiber cloth 4, it is recommend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com