Construction method for directly cutting guard post for tunnel end well by shield machine

A construction method and a technology for an end well, which are applied to the construction of directly cutting tunnel end well enclosure piles out of the tunnel end well, and the entry of shield machines into the field, can solve the problems of high construction difficulty, high cost, and long cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

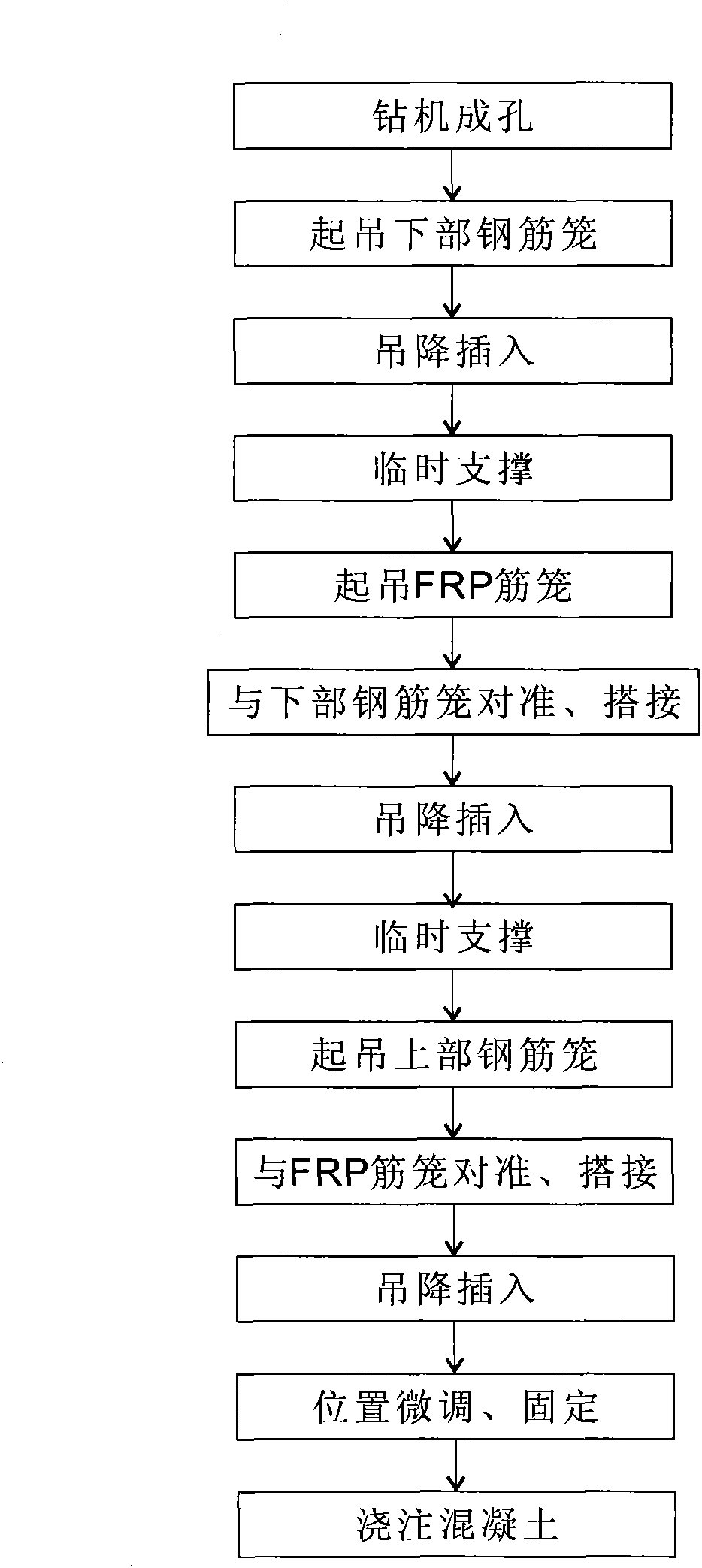

[0013] In the construction method of the present invention, the structure of the surrounding retaining pile at the end of the tunnel is different from the traditional structure. The reinforcing body of the traditional surrounding protecting pile is usually made of steel bars, while the reinforcing body in the present invention consists of an upper reinforcing cage, a lower reinforcing cage and The middle part is composed of FRP reinforcement cages. The position of the FRP reinforcement cages corresponds to the position of the shield machine entering and exiting the tunnel end well. Different reinforcement cages form a complete reinforcement body by overlapping. The construction steps are as follows: the lower reinforcement cage, After the middle FRP reinforcement cage and the upper reinforcement cage are hoisted, lapped, and bound, the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com