Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

342 results about "Hexabromocyclododecane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

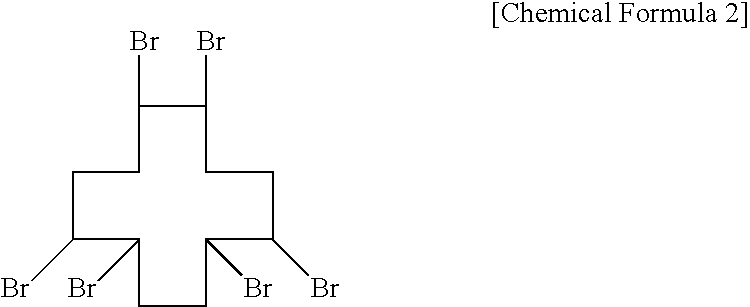

Inventor

Hexabromocyclododecane (HBCD or HBCDD) is a brominated flame retardant. It consists of twelve carbon, eighteen hydrogen, and six bromine atoms tied to the ring. Its primary application is in extruded (XPS) and expanded (EPS) polystyrene foam that is used as thermal insulation in the building industry. Other uses are upholstered furniture, automobile interior textiles, car cushions and insulation blocks in trucks, packaging material, video cassette recorder housing and electric and electronic equipment. According to UNEP, "HBCD is produced in China, Europe, Japan, and the USA. The known current annual production is approximately 28,000 tonnes per year. The main share of the market volume is used in Europe and China" (figures from 2009/2010). Due to its persistence, toxicity, and ecotoxicity, the Stockholm Convention on Persistent Organic Pollutants decided in May 2013 to list hexabromocyclododecane in Annex A to the Convention with specific exemptions for production and use in expanded polystyrene and extruded polystyrene in buildings. Because HBCD has 16 possible stereo-isomers with different biological activities, the substance poses a difficult problem for manufacture and regulation.

Reinforced toughening flame-proof polyolefin resin composition and its preparation method

The invention discloses a flame-proof polyolefin resin component and preparing method in the resin flame resistant modifying domain, which comprises the following parts: a. 9-20% bromine fire retardant with decabran diphenyl ethane or octabromobium ether and heat-stability hexabromide cyclododecane with weight rate at 2: 1-1: 2, b. 3-8% synergic fire retardant with antimony trioxide, c. 3-12% melt resistant melt drip agent with one or more of organic montmorillonite, kaolin and clay.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Burnthrough-resistant water-based fire retardant glue for spinning

The invention provides burnthrough-resistant water-based fire retardant glue for spinning. The burnthrough-resistant water-based fire retardant glue is prepared from the following components in parts by weight: 100 parts of a water-based adhesive, 10 to 100 parts of a halogen flame retardant, 3 to 100 parts of a synergistic flame retardant, 0 to 30 parts of an auxiliary and 0 to 100 parts of water, wherein the water-based adhesive is prepared from ethylene-vinyl acetate copolymer emulsion and an auxiliary adhesive; the solid content of the ethylene-vinyl acetate copolymer emulsion is 20 to 56 percent; the weight ratio of the water-based adhesive to the halogen flame retardant is (1 to 8) to 1; the halogen flame retardant is prepared from one or more of decabromodiphenyl ether, decabromodiphenyl ethane, tri(2,3-dibromo propyl) isocyanuric acid ester, tri(tribromophenyl) cyanurate, ethylene bis (tetrabromophthalimide), tetrabromo bisphenol A, hexabromocyclododecane, octo-bromo-ether, chlorine ester resin, ploy (vinylidene chloride) resin, brominated styrene, brominated epoxy resin, polyvinyl chloride, chlorinated paraffin and methyl chloride.

Owner:WUJIANG HONGYUAN SPRAY WEAVING CO LTD

Flame-proof polystyrene composition and its preparation method

The invention provides a fire-retardant polystyrene combination and its preparation method. involving flame-retardant resin modification field. The said combination contains (weight parts) polystyrene 100, halogen flame-retardant 8~25, and synergistic flame retardant 2~6. The halogen flame retardant is brominated polystyrene or a mixture of decabrominated dipheny ethane and hexabromocyclododecane with thermal decomposition temperature greater than or equal to 200degreeC, wherein the ratio of decabrominated dipheny ethane to hexabromocyclododecane is at 2 : 1 ~ 1 : 2. The synergistic flame retardant is antimony trioxide. The combination is prepared by mixing and melting the above materials with good fire-retardant properties, flame retardant level up to FV-0 level (GB / T4609-93) and the oxygen index up to 28, which can be applied to various adverse circumstances.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Novel anti-flaming anti-static electricity polypropylene dedicated material and preparation method thereof

InactiveCN101735516AImprove flame retardant performanceHigh mechanical strengthBromocyclohexaneAluminium hydroxide

The invention discloses a novel anti-flaming anti-static electricity polypropylene dedicated material and a preparation method thereof; the dedicated material is prepared by the following raw materials by mass percentage: 40-70 percent of polypropylene resin or polypropylene / nylon alloy or polypropylene / nylon / PP-g-MAH, 20-40 percent of formulated fire retardant, 4-10 percent of electric-conduction fillers, and 6-15 percent of inorganic fillers; the formulated fire retardant is formulated by several kinds of compound A, compound B, ammonium polyphosphate, tetramethylolmethane, magnesium hydroxide, aluminium hydroxide and tripolycyanamide, the compound A is bromocyclohexane or hexabromocyclododecane, the compound B is antimony trioxide or antimony pentoxide; the inorganic filler adopts montmorillonoid, hydrotalcite, talcum powder or attapulgite clay. The novel anti-flaming anti-static electricity polypropylene dedicated material prepared by the invention has good flame retardant property and good anti-static electricity performance, the mechanical intensity of the material is further improved after the alloy is prepared by adding the nylon, the used raw material has low cost and is environment-protection, and no melt body drops in the anti-flaming process.

Owner:ZHEJIANG UNIV OF TECH

Flame-retardant UV curing coating and preparation method thereof

InactiveCN103525272AGood chemical resistanceImprove low temperature resistanceFireproof paintsPolyester coatingsPolyesterSodium thiocyanate

A flame-retardant UV curing coating is prepared from the following raw materials in part by weight: 10-12 parts of trimethylol propane triacrylate, 50-55 parts of polyester acrylate, 3-5 parts of isopropanol, 5-8 parts of ethoxylated trimethylolpropane triacrylate, 1-2 parts of tetrabutylphosphonium chloride, 2-3 parts of sodium thiocyanate, 2-6 parts of hexabromocyclododecane, 3-4 parts of diethylene glycol butyl ether, -5 parts of benzil dimethyl ketal, 2-3 parts of 2-hydroxy-2-methyl-1-phenyl-1-acetone, 3-4 parts of dispersing auxiliary agent and 4-5 parts of dispersing auxiliary agent. The flame-retardant UV curing coating has excellent chemical resistance and low temperature resistance, and has strong adhesion to difficultly-adhered substrates, such as plastic; after addition of the dispersing auxiliary agents, the flame-retardant UV curing coating is good in leveling property, can form a uniform and thin coating layer, and is high in curing speed; and by adding tetrabutylphosphonium chloride and the hexabromocyclododecane, the flame-retardant UV curing coating has excellent flame retardance.

Owner:安徽蓝柯复合材料有限公司

Method for detecting content of tetrabromobisphenol A, decabromodiphenyl ether and hexabromocyclododecane brominated flame retardants in aquatic product

ActiveCN106124643AGuaranteed accuracyGuarantee stabilityComponent separationTetrabromobisphenol ADecabromodiphenyl ether

The invention provides a method for detecting the content of tetrabromobisphenol A, decabromodiphenyl ether and hexabromocyclododecane brominated flame retardants in an aquatic product. The method is characterized by comprising the following steps that the content of the tetrabromobisphenol A, decabromodiphenyl ether and hexabromocyclododecane brominated flame retardants in the aquatic product is measured by establishing accelerated solvent extraction-fast liquid chromatography-tandem mass spectrometry, an aquatic product sample needing to be detected is separated through a C18 chromatographic column, gradient elution is conducted by taking water and methyl alcohol as mobile phases, detection is conducted in a mass spectrum multi-reaction monitoring mode, the matrix standard is corrected, quantitative determination is conducted through an external standard method, and confirmation is conducted. The detection method has the advantages that operation is easy and convenient, and detection is fast and accurate; by establishing the method for simultaneously detecting the tetrabromobisphenol A, decabromodiphenyl ether and hexabromocyclododecane brominated flame retardants in the aquatic product, physical health and life safety of consumers are guaranteed, a great practical significance is achieved for promoting sustainable and healthy development of aquatic product processing industry, and a beneficial technical reserve is provided for a food industry supervision department and a detection mechanism.

Owner:ZHOUSHAN INST FOR FOOD & DRUG CONTROL

Flame retardant expanded polystyrene particle and preparation method thereof

The invention relates to a flame retardant expanded polystyrene particle and a preparation method thereof. The flame retardant expanded polystyrene particle of the invention uses styrene, desalted water, calcium phosphate, benzoyl peroxide, dicumyl peroxide, hexabromocyclododecane, structural modifier, infrared reflection agent, foaming agent and the like as raw materials. The preparation method comprises the following steps: mixing the raw materials, heating to react, and performing filtration and other steps. The flame retardant expanded polystyrene particle has higher burning class and good fireproof performance. The flame retardant expanded polystyrene particle is suitable for the external wall thermal insulations of all kinds of buildings.

Owner:常州诚达新材料科技有限公司

Formula of reinforcement and flame retardant polypropylene

The invention discloses a formula of reinforcement and flame retardant polypropylene, which comprises polypropylene, a flame retardant, an antistatic agent, a flexibilizer, a heat resistant agent and a wear resistant agent, wherein the flame retardant is magnesium hydroxide, antimony oxide and hexabromocyclododecane; the antistatic agent is sodium alkyl sulfate; the flexibilizer is a copolymer of ethylene and octylene; the wear resistant agent is glass fiber; and the wear resistant agent is graphite. The formula of reinforcement and flame retardant polypropylene enables the prepared reinforcement and flame retardant polypropylene to have efficacies of good flame retardance, high plasticity, electric static resistance, good flexibility, high temperature resistance, wear resistance and the like.

Owner:SUZHOU NEW DISTRICT HUASHIDA ENG PLASTICS

Antiflaming plastic for cable and preparation method of plastic

InactiveCN104086923AImprove flame retardant performanceImprove insulation performancePlastic/resin/waxes insulatorsPolyvinyl chloridePolycarbonate

The invention discloses antiflaming plastic for a cable and a preparation method of the plastic. The preparation method comprises the following steps: mixing polyvinyl chloride, polycarbonate, hexabromocyclododecane, zinc borate, chromic oxide, MBS resin, hydroxymethyl starch, organic montmorillonite, nano titanium dioxide, filler, a lubricant and a plasticizer, then carrying out extrusion molding to prepare the antiflaming plastic for the cable, wherein the antiflaming plastic comprises the components in parts by weight: 100 parts of polyvinyl chloride, 30-45 parts of polycarbonate, 30-45 parts of hexabromocyclododecane, 2.5-4 parts of zinc borate, 0.5-1.5 parts of chromic oxide, 7-12 parts of MBS resin, 3-5 parts of hydroxymethyl starch, 9-15 parts of organic montmorillonite, 0.3-0.8 part of nano titanium dioxide, 25-35 parts of filler, 1-4 parts of lubricant and 13-17 parts of plasticizer. The plastic has excellent flame retardance, insulation performance and mechanical property.

Owner:WUHU JUNHE ELECTRIC WIRE & CABLE

Rubber-modified styrene resin composition

InactiveUS20050020737A1Increase resistanceImprove stabilityOther chemical processesFilm/foil adhesivesEpoxyTetrabromobisphenol A

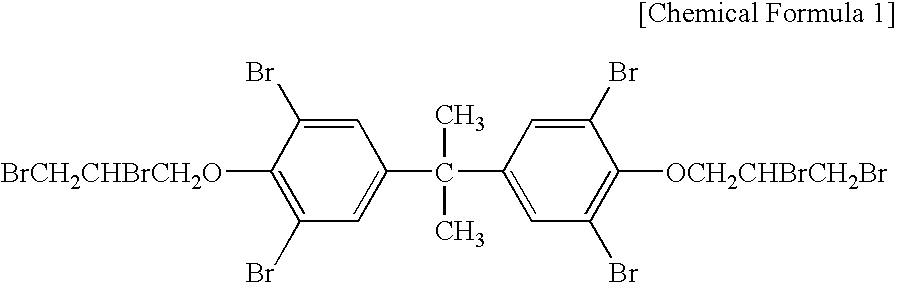

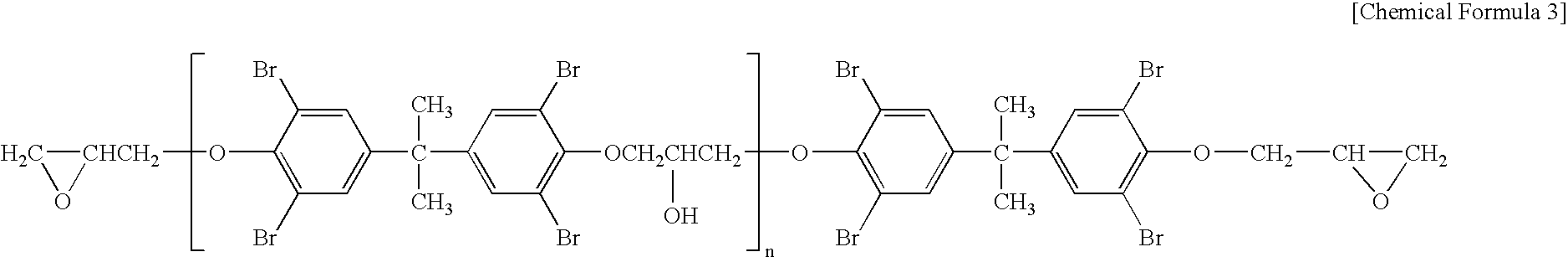

A rubber-modified flame resistant styrene resin composition, which has superior heat stability and weather resistance to prevent discoloration and deterioration due to heat or light and is processed under various molding condition, is provided. The rubber-modified flame resistant styrene resin composition includes a rubber-modified styrene resin, flame retardant comprising compounds selected from a group consisting of tetrabromobisphenol-A-bis(2,3-dibromopropylether), hexabromocyclododecane and a mixture thereof, and brominated epoxy oligomer, and calcium stearate as a lubricant.

Owner:LG CHEM LTD

Polyethene flame resistant material and preparation method thereof

InactiveCN104610629ASlow down decompositionAvoid conductionBulk chemical productionGas phaseAntimony trioxide

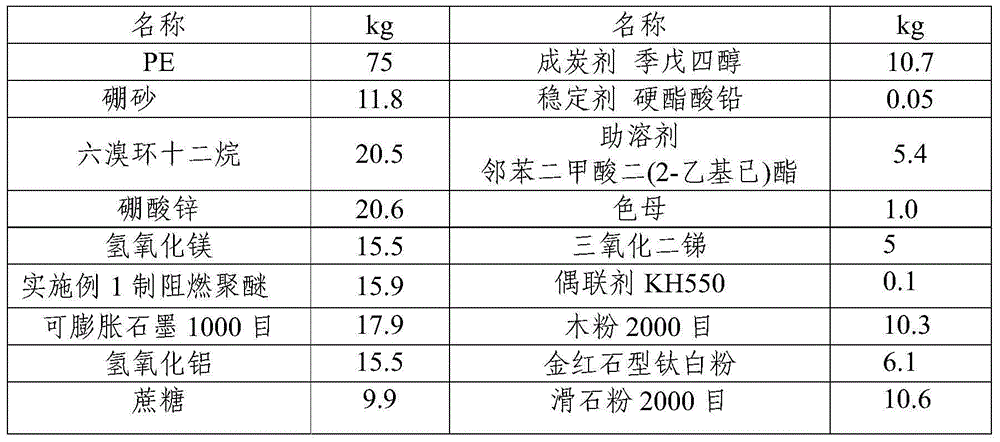

The invention provides a polyethene flame resistant material. The polyethene flame resistant material is prepared from the following components in parts by weight: 70-100 parts of polyethene, 10-15 parts of a char forming agent, 10-15 parts of sodium borate, 0.01-0.5 part of a stabilizing agent, 10-30 parts of hexabromocyclododecane, 8-12 parts of talcum powder, 4-10 parts of a solubilizer, 15-25 parts of zinc borate, 0.1-3 parts of color masterbatch, 20-40 parts of hydroxide, 1-10 parts of antimony trioxide, 15-20 parts of flame resistant polyether, 0.05-0.5 part of a coupling agent, 10-20 parts of inflatable graphite, 8-15 parts of wood powder, 5-10 parts of titanium dioxide, 5-10 parts of cane sugar, and 1-5 parts of molybdenum trioxide. According to the invention, an expansion method, a gas phase method, a physical phase method and a chemical method are combined to prepare flame resistant PE high polymer which achieves an A-class fire-proof material, the operation is simple, and the mechanical property and the fire-proof property of products are both excellent.

Owner:SHENDUN FIREPROOF TECH

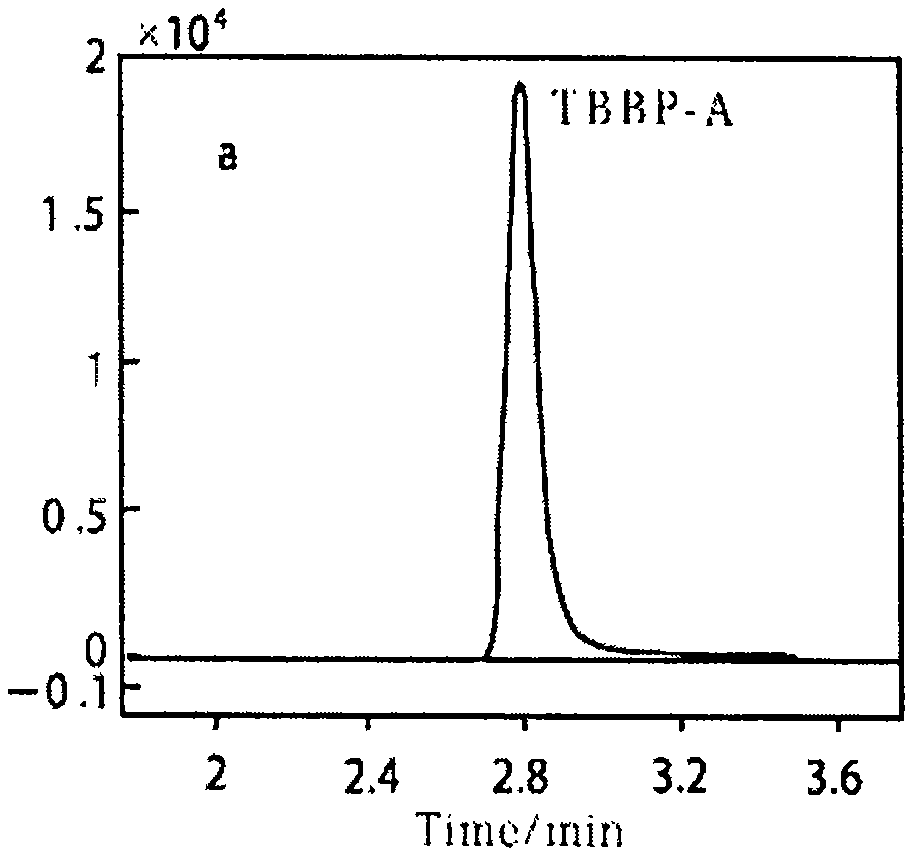

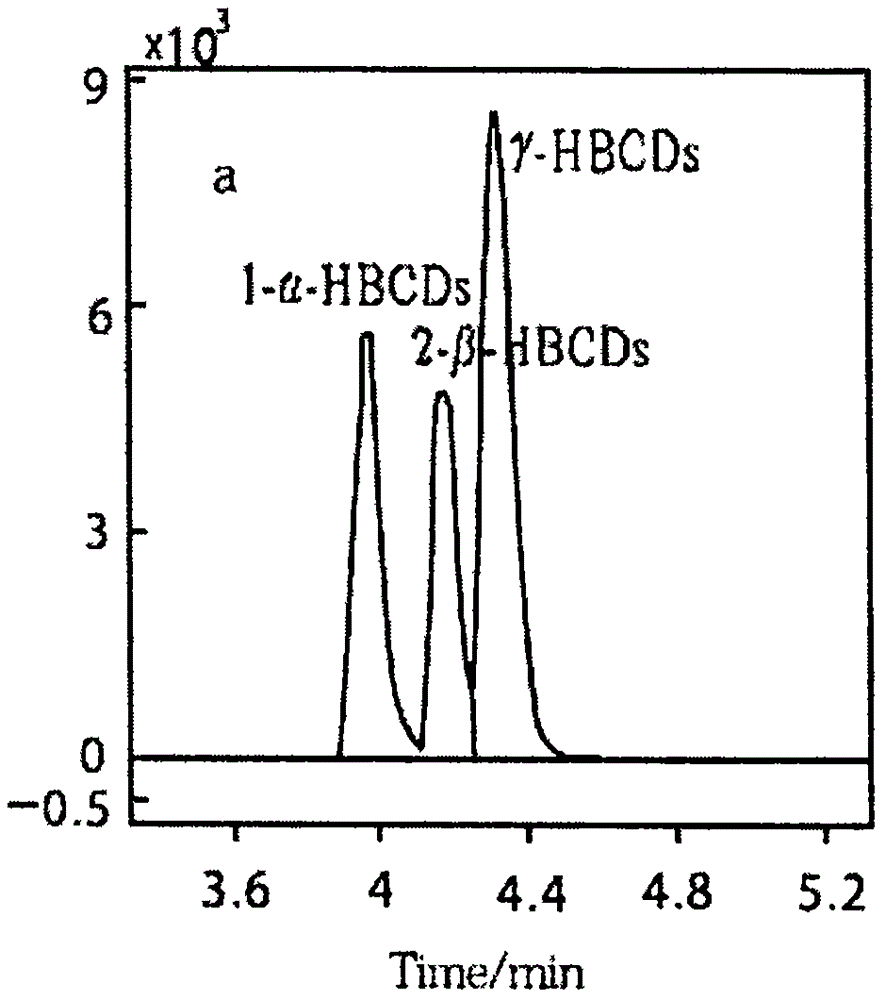

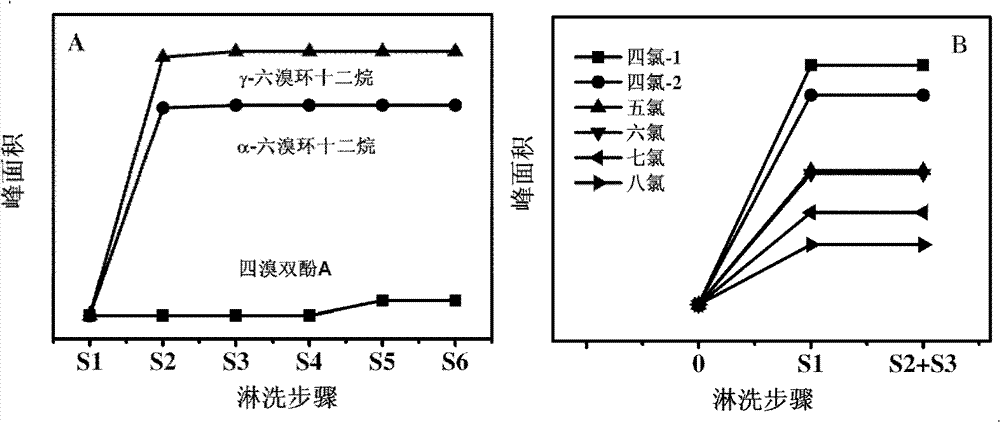

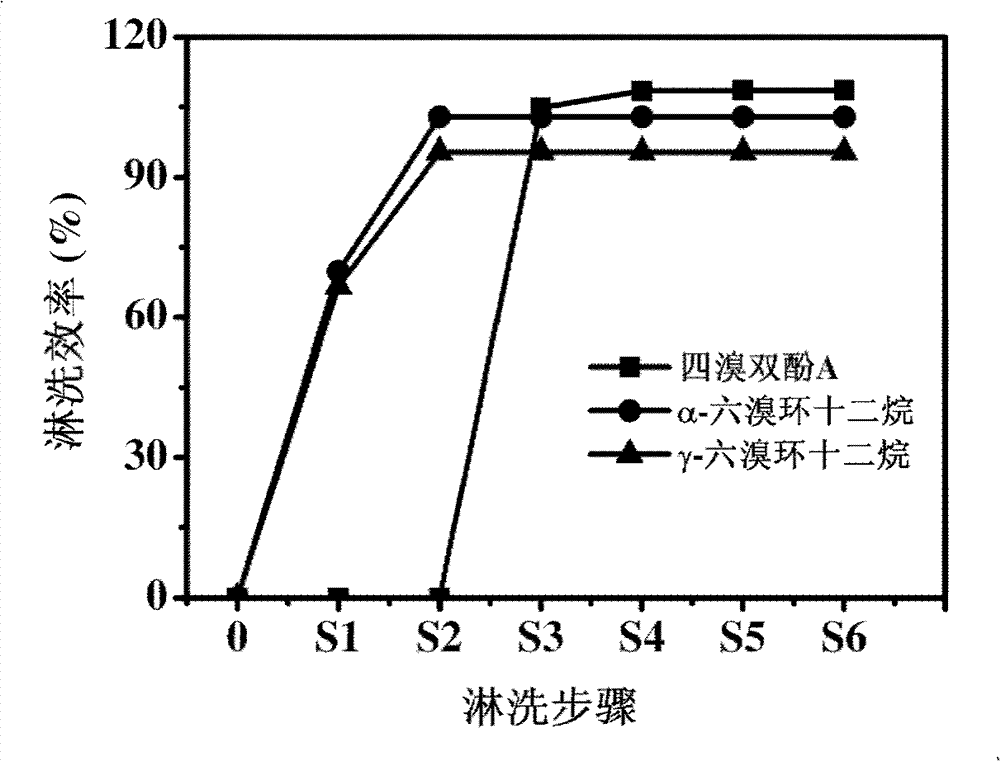

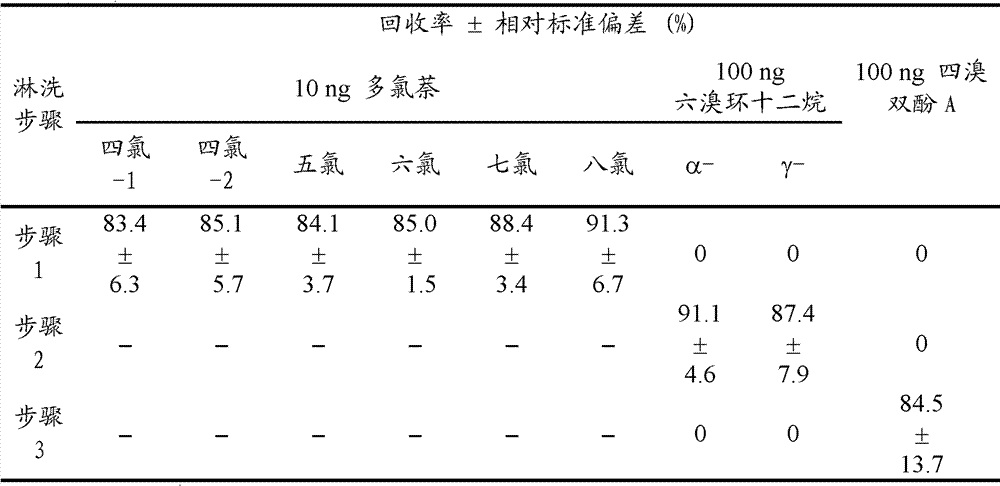

Selective separation of PCNs (polychlorinated naphthalenes congeners), HBCDss (hexabromocyclododecanes) and TBBPA (tetrabromobisphenol A) in complex samples

ActiveCN103364238AAchieve selective separationNo intersectionPreparing sample for investigationTetrabromobisphenol AOrganic solvent

The invention relates to utilization of a silica matrix as a sample pretreatment material, wherein a) PCNs (polychlorinated naphthalenes congeners), HBCDs (hexabromocyclododecanes) and TBBPA (tetrabromobisphenol A) in complex samples are extracted by a solvent extraction method and an extract containing target analytes is obtained; b) the silica matrix is selected as a chromatographic column filler; the filer is activated by using normal hexane at first and then the extract is loaded; c) the polychlorinated naphthalenes congeners, hexabromocyclododecanes and tetrabromobisphenol A are eluted orderly by using organic solvents (normal hexane, dichloromethane and the like) composed of different solvents, and then three eluates of different fractions are obtained; d) after solvents are volatilized from the eluates, the purified target analytes are obtained. According to the invention, selective separation of the polychlorinated naphthalenes congeners, hexabromocyclododecanes and tetrabromobisphenol A in the complex samples is realized by virtue of a simple chromatographic column; the method has the advantages of simplicity in operation, good selectivity and high efficiency.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High flame retardant grade expandable polystyrene product and production method

The invention discloses a high flame retardant grade expandable polystyrene product and a production method. The product is produced by components in part by weight as follows: 100 parts of styrene, 110-130 parts of process water, 0.3-0.5 part of BPO (Benzoyl Peroxide), 0.04-0.08 part of CP-02, 0.05-0.1 part of active calcium phosphate, 7-9 parts of pentane, 0.001-0.002 part of sodium dodecyl benzene sulfonate, 0.7-0.9 part of anhydrous sodium sulfate, 0.6-0.9 part of hexabromocyclododecane, 0.3-0.5 part of dicumyl peroxide, and 0.1-0.2 part of polyethylene wax. The product is produced by steps of feeding, low temperature reaction, high temperature reaction and cooling and discharging. Compared with the prior art, the high flame retardant grade expandable polystyrene product is high in foaming ratio and good in particle elasticity, the foam expansion reaches more than 120 times, and in particular, the flame retardant effect is good, and the oxygen index reaches above 32.

Owner:新疆蓝山屯河新材料有限公司

Polyvinyl chloride A-grade fire-retardant interior decoration material

The invention provides a polyvinyl chloride A-grade fire-retardant interior decoration material. The polyvinyl chloride A-grade fire-retardant interior decoration material is prepared from the following raw materials in parts by weight: 60-80 parts of polyvinyl chloride, 3-5 parts of melamine, 15-25 parts of wood powder, 1.1-2.2 parts of molybdenum trioxide, 8-11 parts of tetrabromo-bisphenol-A, 0.5-1.0 part of dicyclopentadienyl iron, 13-27 parts of hexabromocyclododecane, 2-5 parts of a plasticizer, 10-22 parts of zinc borate, 2-5 parts of a cosolvent, 20-40 parts of hydroxide, 0.6-1.8 parts of colour masterbatch, 10-15 parts of flame-retardant polyether, 30-60 parts of calcium carbonate, 5-10 parts of sodium carbonate, 5-9 parts of ammonium polyphosphate, 5-9 parts of brominated epoxy resin and 10-15 parts of expanded graphite. The polyvinyl chloride A-grade fire-retardant interior decoration material is environment-friendly and energy-saving, does not absorb water and is non-combustible and wear-resistant, the process is simple, the dimensional stability is good, and anti-compression creep property is good; meanwhile, the A-grade fire prevention standard in the national standard, Code for Fire Prevention in Design of Interior Decoration of Buildings, of the People's Republic of China GB 50222-95 can be met.

Owner:SHENDUN FIREPROOF TECH

Expandable granules of polystyrene and prepartion method

This invention discloses a method for preparing environmentally friendly flame-retardant expandable polystyrene granules. The expandable polystyrene granules can be used in colored steel construction plate, base pavement material for highway and heat-insulating material for outer wall. The method comprises: mixing styrene, desalted water, sodium sulfonate, calcium phosphate, benzoyl peroxide, dicumyl peroxide, hexabromocyclododecane, and pentane and structure regulator, stirring, reacting and filtering. The expandable polystyrene granules can reduce air pollution, reduce energy consumption, and increase production efficiency.

Owner:无锡兴达泡塑新材料股份有限公司

Method for preparing flame retardant viscose fiber

ActiveCN102965750AHigh strengthImprove stiffnessArtificial filaments from viscoseCellulosePolymer science

The invention discloses a method for preparing flame retardant viscose fiber. The method comprising the following steps: A) mixing nano fiber having a flame retardant function, basic magnesium sulfate whisker, basic magnesium chloride whisker and magnesium salt whisker, then roasting the mixture in an oven of 400 DEG C, carrying out dispersion in absolute ethyl alcohol containing sodium hexametaphosphate, carrying out plasma treatment at normal pressure, carrying out ultrasonic dispersion and cleaning, filtering by a filter of 400 meshes and drying; B) uniformly mixing and drying the whisker and a titanate coupling reagent, adding and mixing antimonous oxide, hexabromocyclododecane, (HDPE+SEBS)-g-MAH and calcium stearate, and then adding cellulose spinning viscose to prepare flame retardant cellulose spinning viscose; and C) preparing the flame retardant viscose fiber by means of a wet or dry process spinning technology. The flame retardant viscose fiber is good in strength, stiffness, abrasive resistance and flame retardance.

Owner:嘉兴貂帅服饰有限公司

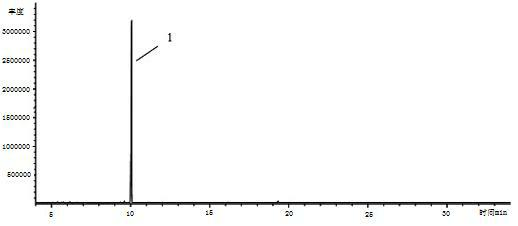

Electronic material hexabromocyclododecane content determination method

ActiveCN101216467AMeet studySatisfy productivityComponent separationGas chromatography–mass spectrometryConcentration gradient

The invention relates to a method for determining content of hexabromocyclododecane in electronic material by gas chromatography-mass spectrometry. The method comprises the following steps of: adding n-hexane and acetone with a ratio of 1:(0.5-2) in a sample to be detected, refluxing at 60 to 90 DEG C for 2 to 16 h to extract hexabromocyclododecane, filtering, and purifying to obtain the sample; weighting hexabromocyclododecane standard substance, dissolving with methanol, adding distilled water to fixed volume to obtain a stock solution, and further diluting with methanol to obtain standard solutions with concentration gradient; detecting the sample processed solution by gas chromatography-mass spectrometry; and calculating the result. The inventive method for determining content of hexabromocyclododecane in electronic material has high speed, high efficiency and less error rate not larger than 10%. Accordingly, the invention provides a reliable and easily-implemented method for determining hexabromocyclododecane in electronic material and can meet the requirement of study and production.

Owner:谱尼测试集团股份有限公司

Production technology of hexabromo cyclododecane

The present invention discloses a hexabromocyclododecane production process capable of effectively improving product quality. Said process includes the following procedures: bromization procedure, filter and centrifugal drying procedure, washing procedure, boiling procedure, drying procedure, powder-sieving procedure and solvent recovery procedure. It is characterized by that it adopts chloroform and isobutanol as medium, so that it can raise thermal stability of product. Said product is a good fire retarding agent, therefore it has extensive application.

Owner:HUALUN CHEM SUZHOU CITY

Filter paper doped with viscose-based activated carbon fiber for automobile filter and preparation method of filter paper

InactiveCN102912682AImprove adsorption capacityImprove filtering effectNon-macromolecular organic additionReinforcing agents additionPolymer scienceAcrylic resin

The invention discloses filter paper doped with viscose-based activated carbon fiber for an automobile filter and a preparation method of the filter paper. The filter paper comprises, by weight, 70-80 parts of wood pulp, 20-30 parts of bamboo pulp, 10-20 parts of mineral cotton fiber, 2-5 parts of the viscose-based activated carbon fiber, 1-3 parts of nano titanium dioxide, 2-4 parts of modified diatomite, 1-2 parts of activated aluminum oxide, 0.5-0.8 part of hexabromocyclododecane, 2-3 parts of water-soluble organic silicon resin emulsion, 1-2 parts of water-soluble acrylic resin emulsion, 0.5-1 part of tributyl citrate, 0.5-1 part of vinyl-tri (beta- methoxy ethyoxyl) silane, 0.4-0.8 part of sodium lauryl sulfate, and 2-5 parts of wet strength agent PAE (polyamide epichiorobydrin resin). The filter paper doped with the viscose-based activated carbon fiber for the automobile filter is good in water permeability, large in filtering area, small in maximum hole diameter, high in filtering precision, strong in bursting strength, high in temperature resistance and tensile strength and the like, has stable performance index under normal-temperature and high-temperature working conditions and is provided with good temperature resistance and filtering effects, filtering efficiency of the filter paper can reach 99.99%.

Owner:ANHUI PHOENIX INT CO LTD

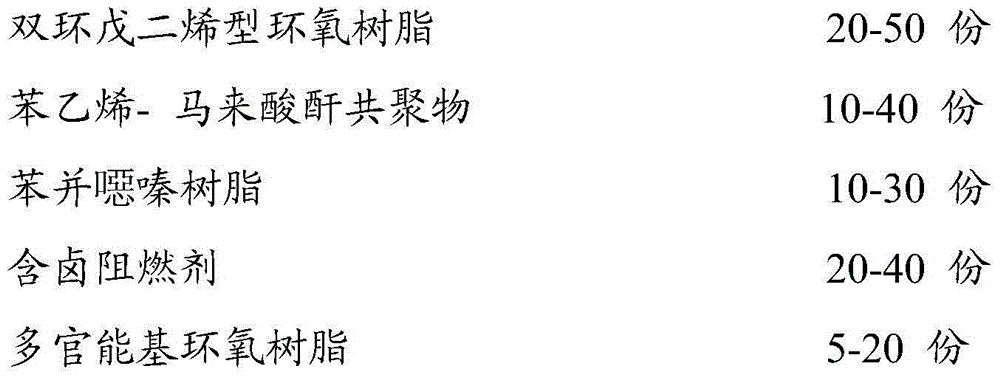

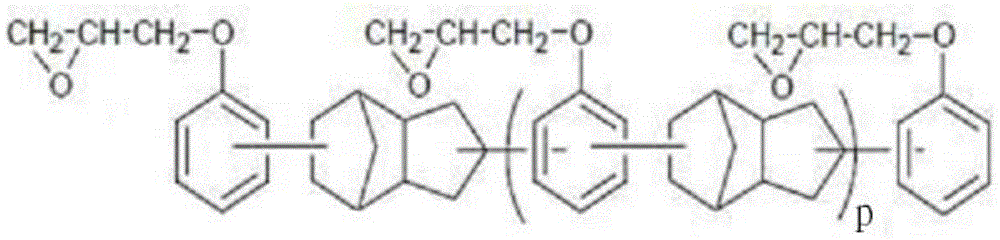

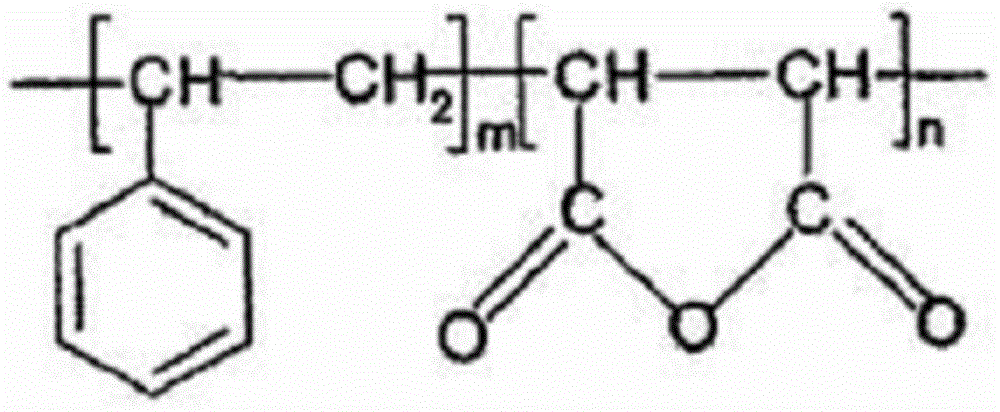

Halogen resin composition and application thereof

The invention relates to a halogen resin composition and an application thereof. The halogen resin composition is prepared from the following raw materials in parts by weight: 20-50 parts of dicyclopentadiene epoxy resin, 10-40 parts of styrene-maleic anhydride copolymer, 10-30 parts of benzoxazine resin, 20-40 parts of halogenous fire retardant, and 5-20 parts of multi-functional group epoxy resin, wherein the halogenous fire retardant is at least one of the decabrominated dipheny ethane, tri(tribromophenyl) triazine, brominated polyolefin, brominated polystyrene, ethyl-di(tetrabromobenzene o-dicarboximide), decabromodiphenyl ether, hexabromocyclododecane, eight bromo ether, tetrachlorophthalic anhydride, Hexachlorocyclopentadiene and perchlorinated cyclopentyl decane. A metal foil substrate made of the halogen resin composition has the advantages of low dielectric constant and dielectric loss, excellent heat resistance, good machinability and low swelling coefficient and can be well applied to a composite board.

Owner:GUANGZHOU GRACE ELECTRON CORP

Composite flame retardant in bromine series, preparation method and application

InactiveCN1958720AExcellent flame retardantGood resistance to drippingFireproof paintsPolymer sciencePolyolefin

This invention provides a method for preparing brominated composite flame retardant and its application. The brominated composite flame retardant comprises: brominated flame retardant 100 parts, synergistic flame retardant 30-45 parts, and anti-melting drop 30-60 parts. The brominated flame retardant is a mixture of decabromodiphenyl ethane or octabromo ether and heat-stable hexabromocyclododecane at a weight ratio of (2:1)-(1:2). The synergistic flame retardant is antimony trioxide. The anti-melting drop is one or more of organic montmorillonite, kaolin and clay. The method comprises: adequately mixing the above components according to the formula. The brominated composite flame retardant has a flame retardant grade up to V-0 without melting drop when used in flame retardant modification of polyolefin plastics. Besides, the brominated composite flame retardant has good mechanical properties, and can be used as packaging material for military products and electronic products.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

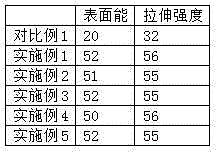

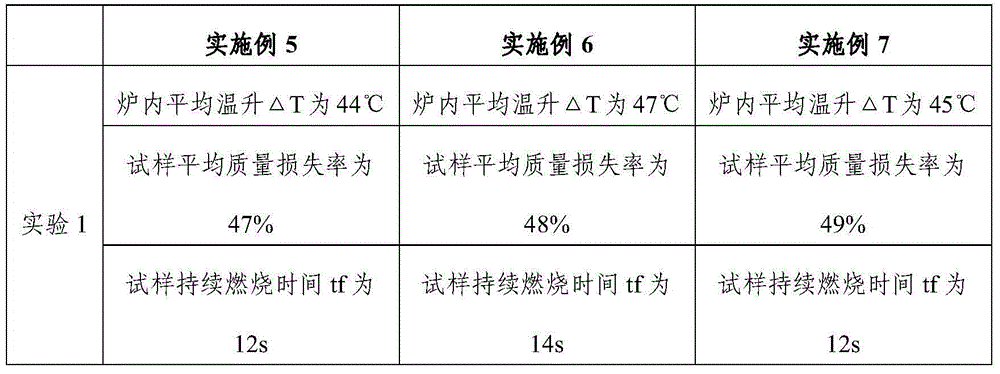

Solar battery backboard modified PET (polyethylene glycol terephthalate) base material and preparation method thereof

The invention discloses a solar battery backboard modified PET (polyethylene glycol terephthalate) base material and a preparation method thereof, and the modified PET base material comprises the following components by weight: 30-80 parts of n-butyl acetate, 40-80 parts of PET, 40-100 parts of hexabromocyclododecane, 30-150 parts of 3-methyl-2-butene-1-ol, 100-200 parts of methyl ethyl ketone, 40-80 parts of titanium dioxide, 20-50 parts of maleic anhydride grafted polypropylene, 40-120 parts of a stabilizer, 20-120 parts of carbonate and 30-40 parts of phthalic acid ester. The preparation method is as follows: mixing uniformly the n-butyl acetate, the PET, the hexabromocyclododecane, the 3-methyl-2-butene-1-ol, the titanium dioxide and the phthalic acid ester, heating to 800 to 950 DEG C, and slowly adding the remaining components, filling with an inert gas, reacting for 2-3H; drying, squeezing, cooling and casting into a sheet; stretching and forming. The n-butyl acetate significantly increases link force among PET macromolecules, so that the substrate surface energy and tensile strength are improved, and the mechanical property is stronger.

Owner:谭家湾遗址公园运营管理(桐乡乌镇)有限公司

Flame retarded extruded polystyrene foams

InactiveUS20140303294A1Improve mechanical propertiesImprove insulation performancePolymer sciencePolystyrene

The invention relates to flame retarded extruded polystyrene foams with a very low halogen content in the final product, i.e. containing a very low content of hexabromocyclododecane or preferably hexabromocyclododecane free, and a process for their preparation. The invention also relates to their use in construction, as building thermal insulating materials, or in transportation.

Owner:ITALMATCH KEMIKALS SPA

Polyvinyl chloride grade-A fireproof material and preparation method thereof

The invention relates to the field of materials, in particular to a polyvinyl chloride grade-A fireproof material. The polyvinyl chloride grade-A fireproof material is prepared from the following constituents in parts by weight: 70-85 parts of PVC, 15-20 parts of expansible graphite, 10-15 parts of borax, 35-50 parts of hexabromocyclododecane, 15-25 parts of zinc borate, 13-18 parts of magnesium hydroxide, 13-20 parts of fire-retardant polyether, 8-12 parts of a carbon forming agent, 0.01-0.10 part of a stabilizer, 4-10 parts of a plasticizer, 3-8 parts of antimonous oxide, 3-8 parts of a phase solvent, 0.05-0.30 part of a coupling agent, and 13-18 parts of aluminum hydroxide. The polyvinyl chloride fireproof material provided by the invention can be up to grade A, has dampproof and mildewproof functions when being processed and molded to form a plate, a sheet, a tube stock, a sectional material or a foam material, meanwhile has thermal insulation and sound insulation properties, is free of oil paint, non-combustible, not afraid of burning, convenient to process, environment-friendly, and non-pollution, and further has various processing characteristics of the wood.

Owner:SHENDUN FIREPROOF TECH

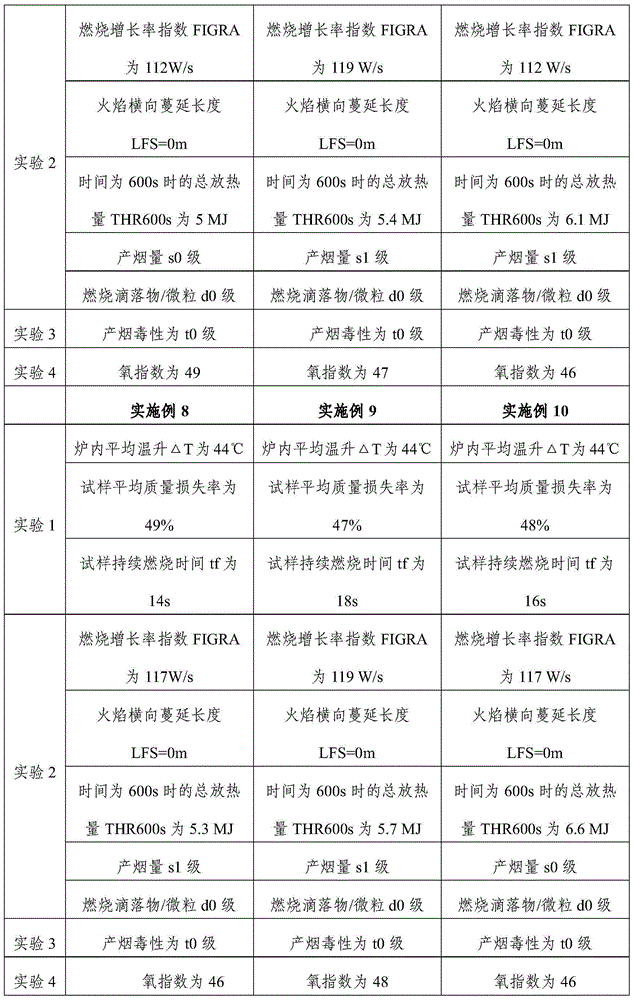

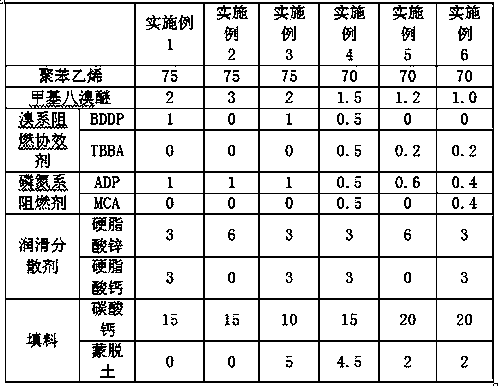

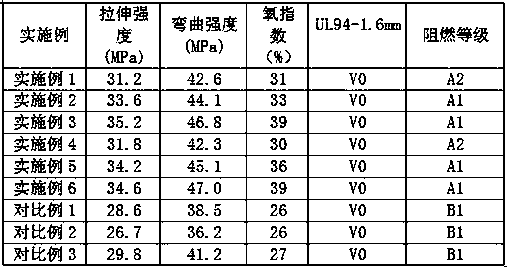

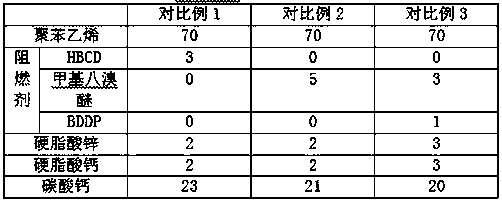

Methyl octabromo-ether flame-resistant polystyrene composite material, and preparation method thereof

The invention discloses a methyl octabromo-ether flame-resistant polystyrene composite material, and a preparation method thereof. The methyl octabromo-ether flame-resistant polystyrene composite material comprises, by weight, 70 to 90 parts of polystyrene, 1 to 10 parts of methyl octabromo ether, 0.2 to 5 parts of a bromine-series flame retardant synergist, 1 to 10 parts of phosphorus-nitrogen-series flame retardant, 1 to 10 parts of a lubricating dispersant, and 1 to 20 parts of a filler. The invention also discloses the preparation method of the methyl octabromo-ether flame-resistant polystyrene composite material. The preparation method comprises following steps: the components are uniformly stirred, and are introduced into an extruder for extrusion, wherein the temperature of the extruder is controlled to be 170 to 210 DEG C. According to the preparation method, methyl octabromo ether is adopted to replace the commonly used polystyrene flame retardant hexabromocyclododecane, and at the same time, the phosphorus-nitrogen-series flame retardant is added for synergistic effect, so that the prepared polystyrene composite material has excellent resistance and excellent mechanical properties at the same time, the tensile strength is 31.2-34.6MPa, the bending strength is 42.3 -47.0MPa, and limit oxygen index is 30-39%.

Owner:山东兄弟科技股份有限公司

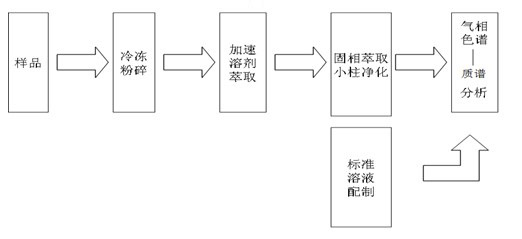

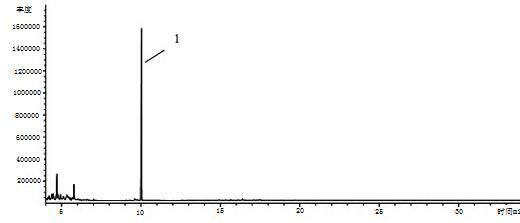

Detection method of hexabromocyclododecane content in rubber parts of electronic and electrical products

InactiveCN102279238AFully extractedAccurate measurementComponent separationOrganic solventPhysical chemistry

A method for detecting the content of hexabromocyclododecane in electrical and electronic rubber parts, comprising the following steps: (1) sample preparation; (2) extraction of hexabromocyclododecane: adding heavy metal powder to the pulverized sample, mixing Then put it into the accelerated solvent extraction pool and use the organic solvent to carry out accelerated solvent extraction on the sample to obtain the extract; (3) Purification of the extract: transfer the extract to the solid phase extraction column, and then use the mixed solvent for elution, collect the washed Deliquoring and concentrating to obtain purified extract; (4) Determination of hexabromocyclododecane: measure the purified extract and hexabromocyclododecane mixed standard solution with gas chromatography-mass spectrometer, After data processing and quantitative analysis, the content of trace HBCD in electronic and electrical rubber components was obtained. The method can effectively remove interfering impurities in the rubber, and the hexabromocyclododecane can be fully extracted, the purification degree is high, the detection sensitivity is high, and the sample testing cost is low.

Owner:INSPECTION & QUARANTINE TECH CENT OF GUANGDONG ENTRY EXIT INSPECTION & QUARANTINE BUREAU

Polystyrene flame-retardant resin and preparation method thereof

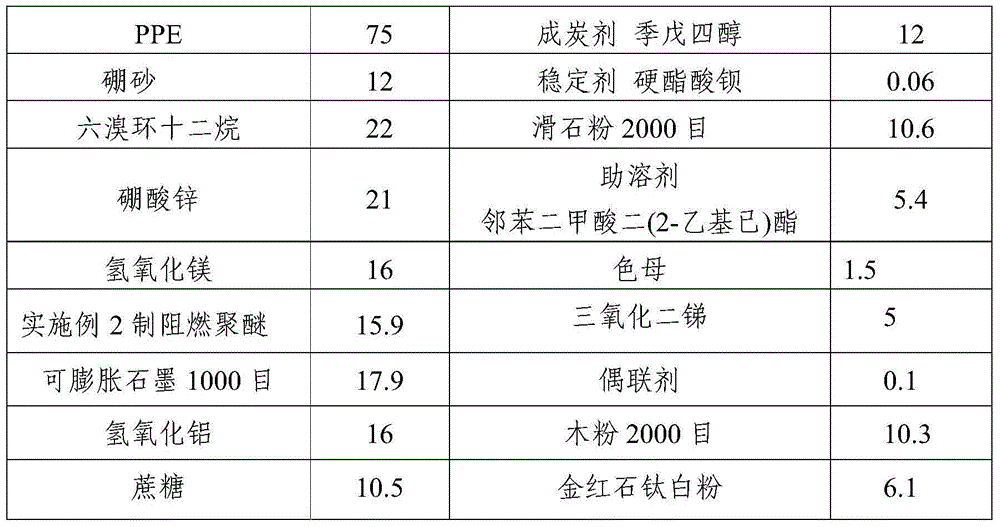

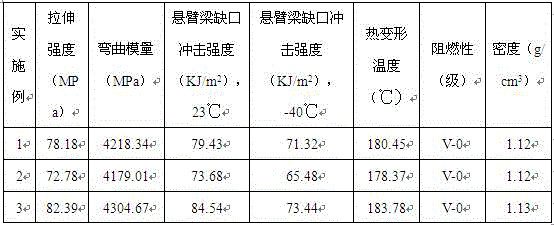

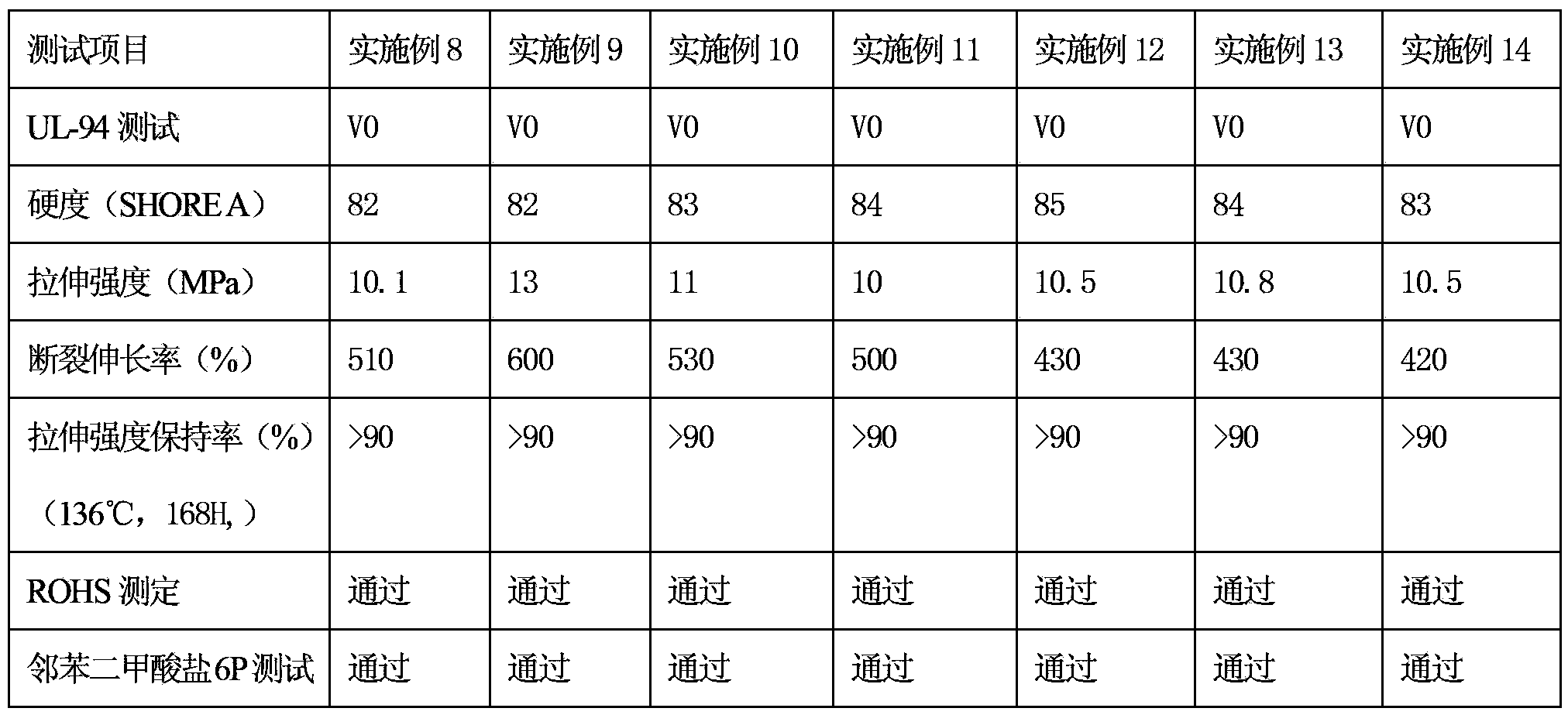

The invention provides a polystyrene flame-retardant resin which is prepared from the following components in parts by mass: 70-80 parts of polystyrene, 8-15 parts of char forming agent pentaerythritol, 10-15 parts of borax, 0.01-0.5 part of stabilizing agent, 20-30 parts of hexabromocyclododecane, 10.6 parts of French chalk, 18-25 parts of zinc borate, 4-8 parts of cosolvent, 20-40 parts of hydroxide, 0.6-1.8 parts of color master batch, 10-20 parts of flame-retardant polyether, 4-8 parts of antimony trioxide, 15-20 parts of expandable graphite, 0.1-0.5 part of coupling agent, 8-15 parts of wood meal, 8-12 parts of sucrose and 5-10 parts of rutile titanium white. The test result indicates that the polystyrene flame-retardant resin satisfies Grade A in Classification for Burning Behavior of Building Materials and Products GB 8624-2006 and Grade A in Chinese Code for Fire Prevention in Design of Interior Decoration of Building GB5022-95.

Owner:SHENDUN FIREPROOF TECH

High-performance composite material for shells of notebook computers

InactiveCN106479136AAdapt to performance requirementsAdapt to lightweight requirementsPolyethylene terephthalate glycolAntioxidant

The invention discloses a high-performance composite material for shells of notebook computers. The high-performance composite material comprises PBT (polybutylene terephthalate) resin, PET (polyethylene terephthalate) resin, polycarbonate, zinc acrylate resin, benzene-free epoxy resin, maleic-anhydride-grafted ethylene propylene diene monomer rubber, chloropropyl-based styrene, maleic-anhydride-grafted polypropylene, hexabromocyclododecane, 3-ethyl-2-butene-1-alcohol, aluminum oxide, titanium oxide, paraffin, sodium tartrate, sodium polyphosphate, sodium carboxymethyl celluloses, aromatic polyamide fibers, polybutylene terephthalate fibers, basalt fibers, carbon black, silicon oxide, coupling agents, chain extenders, compatilizers, antioxidants, stabilizing agents, bridging agents, regulators, reinforcing agents, flocculating agents, toughening agents, plasticizers, thickening agents, stabilizers, flame retardants, smoke inhibitors, ultraviolet absorbents and terminators. The high-performance composite material has the advantages of excellent comprehensive performance, low density and high specific strength.

Owner:蒙宇

Impact-resistant and high-strength plastic plate and preparation method thereof

The invention discloses an impact-resistant and high-strength plastic plate. The impact-resistant and high-strength plastic plate comprises raw materials in parts by weight as follows: 0.2-0.4 parts of hexabromocyclododecane, 4-6 parts of polyisoprene, 100-140 parts of polyvinyl chloride, 0.6-1 part of lauroyl diethanolamide, 0.7-1 part of p-toluenesulfonic acid, 10-14 parts of polyethylene fibers, 0.7-1 part of potassium dichromate, 50-60 parts of 96%-98% sulfuric acid, 0.4-1 part of caprylic capric triglyceride, 5-7 parts of tributyl citrate, 2-3 parts of zinc dihydrogen phosphate, 10-14 parts of clay, 0.6-1 part of dialkyl p-diphenol, 2-3 parts of calcium fluoride, 0.2-0.3 parts of N,N-diethyl aniline, 1-2 parts of aluminum tripolyphosphate, 3-5 parts of polyvinyl alcohol and 2-3 parts of fine silica aerogel. Polyisoprene, fine silica aerogel and the like are added, so that the impact-resistance strength of a finished plate is effectively improved.

Owner:宁波远欣石化有限公司

Weather-proof environment-friendly flame-retardant polymer material for flexible cable and preparation method thereof

InactiveCN104059321AWon't releaseEasy to processInsulated cablesInsulated conductorsTetrabromobisphenol AAntimony trioxide

The invention discloses a weather-proof environment-friendly flame-retardant polymer material for a flexible cable and a preparation method thereof. The polymer material comprises the following components by weight: 100 parts of a component A, 20 to 200 parts of a component B and 50 to 130 parts of a component C, wherein the component A is TPE, the component B is TPV, the component C is a fire retardant and comprises C1 and C2, C1 is one selected from the group consisting of decabromodiphenylethane, 1,2-bis(tribromophenoxy)ethane, tetrabromobisphenol A, tetrabromo-benzene anhydride, octabromo-ether, bis(tetrabromo-o-benzene-dimethyl ether imide)ethane and hexabromocyclododecane and has a particle size in a range of 10 to 30 mu m, and C2 is one selected from the group consisting of antimony trioxide, zinc borate and zinc oxide. The polymer material provided by the invention has improved processing performance and tensile strength, high usage temperature and excellent weatherability, environmental protection performance and flame resistance and is especially applicable to outdoor usage in a severe environment.

Owner:SINOTEX INVESTMENT & DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com