High-performance composite material for shells of notebook computers

A notebook computer and composite material technology, applied in the field of computer shell preparation, can solve the problems of unsatisfactory thickness and weight of the whole machine, unsatisfactory PC/ABS alloy performance, and difficulty in realizing ultra-light and thin design, etc. Conducive to popularization and application, low toxicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

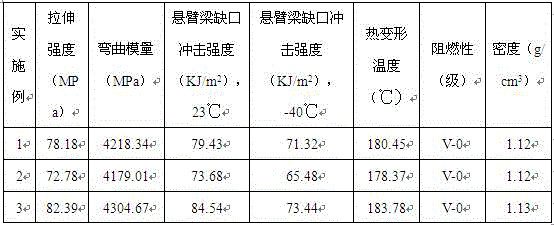

Examples

preparation example Construction

[0057] The preparation method of described high-performance notebook computer casing composite material, comprises the following steps:

[0058] S1: Mix PBT resin, PET resin, polycarbonate, acrylate zinc resin, benzene-free epoxy resin, and maleic anhydride grafted EPDM rubber at a temperature of 772-795°C and a speed of 200-400r / min Stir for 6-14min at lower temperature to obtain mixture I;

[0059] S2: Under nitrogen protection, add chloropropyl styrene, maleic anhydride grafted polypropylene, hexabromocyclododecane, 3-ethyl-2-butene-1- Alcohol, paraffin, sodium tartrate, sodium polyphosphate, sodium hydroxymethylcellulose, coupling agent, chain extender, compatibilizer, stabilizer, bridging agent, regulator, strengthening agent, coagulant, toughening agent , plasticizer, thickener, stirring for 3.2-5.7h at a microwave power of 216-318W, a temperature of 651-708°C, and a rotation speed of 200-400r / min, to obtain a mixture II;

[0060] S3: Add aluminum oxide, titanium oxide...

Embodiment 1

[0070] A high-performance notebook computer shell composite material, including the following raw materials in units of weight: 165 parts of PBT resin, 45 parts of PET resin, 35 parts of polycarbonate, 26 parts of zinc acrylic resin, 20 parts of benzene-free epoxy resin, horse Maleic anhydride grafted EPDM rubber 23 parts, chloropropyl styrene 18 parts, maleic anhydride grafted polypropylene 15 parts, hexabromocyclododecane 13 parts, 3-ethyl-2-butene-1 - 15 parts of alcohol, 8 parts of aluminum oxide, 7 parts of titanium oxide, 22 parts of paraffin, 16 parts of sodium tartrate, 12 parts of sodium polyphosphate, 15 parts of sodium hydroxymethyl cellulose, 4 parts of Kevlar fiber, polyethylene terephthalate 5 parts of butylene glycol formate fiber, 3 parts of basalt fiber, 10 parts of carbon black, 13 parts of silicon oxide, 1.6 parts of coupling agent, 0.9 parts of chain extender, 2.5 parts of compatibilizer, 1.2 parts of antioxidant, stabilizer 1.2 parts, 1 part of bridging ag...

Embodiment 2

[0101]A high-performance notebook computer casing composite material, including the following raw materials in units of weight: 129 parts of PBT resin, 40 parts of PET resin, 34 parts of polycarbonate, 24 parts of zinc acrylic resin, 17 parts of benzene-free epoxy resin, horse Maleic anhydride grafted EPDM rubber 19 parts, chloropropyl styrene 14 parts, maleic anhydride grafted polypropylene 12 parts, hexabromocyclododecane 10 parts, 3-ethyl-2-butene-1 - 12 parts of alcohol, 6 parts of aluminum oxide, 5 parts of titanium oxide, 18 parts of paraffin, 12 parts of sodium tartrate, 8 parts of sodium polyphosphate, 10 parts of sodium hydroxymethyl cellulose, 3 parts of Kevlar fiber, polyterephthalate 4 parts of butylene glycol formate fiber, 2 parts of basalt fiber, 8 parts of carbon black, 10 parts of silicon oxide, 1 part of coupling agent, 0.6 part of chain extender, 2 parts of compatibilizer, 0.9 part of antioxidant, stabilizer 0.8 parts, 0.3 parts of toughening agent, 0.4 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com