Self-resetting limited-angle torque motor

A technology of limited rotation angle and torque motor, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problem that the limited rotation angle brushless DC torque motor cannot be reset normally, and achieve the effect of simple structure, convenient operation and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

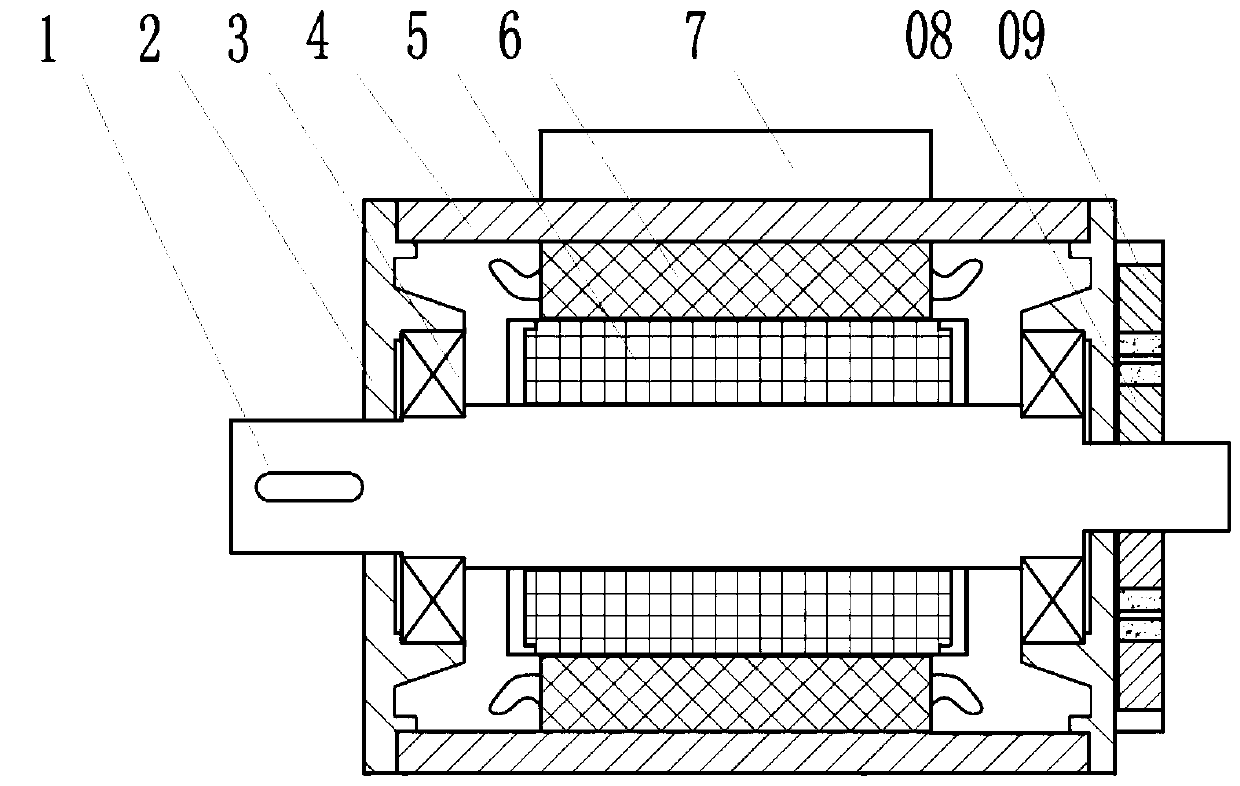

[0032] From image 3 It can be seen that the limited angle torque motor in this embodiment is composed of a motor shaft 1 , an end cover 2 , a bearing 3 , a casing 4 , a motor rotor 5 , a motor stator 6 , a motor controller 7 , a reset rotor 8 and a reset stator 9 . The end caps 2 are fastened on both ends of the casing 4 to form a closed casing. The two end covers 2 are provided with bearing holes at the center of the side walls inside the airtight housing, and the bearings 3 are fixed in the bearing holes. The motor shaft 1 passes through the center of the airtight casing, and its two ends inside the airtight casing are respectively supported by bearings 3 . Both the motor rotor 5 and the motor stator 6 are located inside the airtight casing, wherein the motor stator 6 is fixed on the casing 4, and the electronic rotor 5 is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com